Leaderboard

Popular Content

Showing content with the highest reputation on 01/02/16 in all areas

-

Hello from a watchrepairtalk noob. I am in the process of having serviced a handful of vintage mechanical watches that I inherited from my father. See my post re: Longines mainspring on another forum. I am a mechanical engineer by profession, but the machines I work with are much larger (hydroelectric turbines). In any case, I am discovering perhaps like many of you that replacement parts for vintage watches can be difficult to locate, and that servicing older mechanical watches is not an inexpensive proposition. I'm attaching a photo of two of my watches. Looking forward to learning a lot here.4 points

-

Thank you, gentlemen. Welcome :-) My name Leszek. I live in Poland. I'm 50. I am a novice enamellist. It's my hobby. I love the dials of the Master Donz Cadrans of Vacheron C. My favorite company is Patek and Ulysse Nardin. And Especially I love the vintage-style wheels cloisonne enamel. I like cloisonne enamel and guilloche I use different materials: copper, silver, gold. I do not know the language writing by the translator. Thank you for your interest. Shield on the backing of copper: Przygotowanie do trawienia w kwasie wytrawiony podkład wypalanie podkładu nakładanie drutów pierwsza warstwa emalii wypalanie 2 wypalanie 3 moje studio test kolorów : kolorowanie tarczy wypalanie 4,5,6,7 szlifowanie przymiarka do koperty I hope you like :-) Pozdrawiam Leszek3 points

-

A quick shot of two of my vintage watches. On the left is a jump hour digital Sindaco watch from the the 1970's. It is running but needs hairspring manipulation to put it in beat and separate the coils. I may have a go as although the movement in these watches is basic in the extreme, it is in very good condition with its original plastic strap. The other watch has great sentimental value to me as it was a gift from a relative when I achieved a place in grammar school way back in the 1960's. I was taken to an upmarket jewellers and told to pick a watch from a selection, none of which were cheap by the standards of the day. It is a Roamer Vanguard with a beautiful 17 jewel movement and I wore it every day from the day I received it up until a few years ago when it ran out of ticks. The only repair needed has been a new crystal after I broke the original when my motorcycle and I involuntarily parted company. That also accounts for the tiny scratch on the face. Anyway it is now running perfectly again having been serviced and is now worn regularly again.1 point

-

I'll show how to make a shield with enamel. Today, copper shield. I invite :-) Będę pisał po Polsku - gdyby interesowało proszę używać translatora. 1. Cięcie miedzi. 2. Wycinanie krążka 3. Czyszczenie w kwasie 4. Wypalanie 1 5. Wypalanie 2 6. Gotowe podkłady 7 Efekt końcowy 8. Bezel 9. Gotowy podkład do cloisonne 10. Nałożenie drutów 11. Wypełnienie emalią 12. Wypalanie 760 C ok 8-20 razy Finał Tarcza powstaje ok 40 godzin. Pozdrawiam serdecznie Leszek Kralka1 point

-

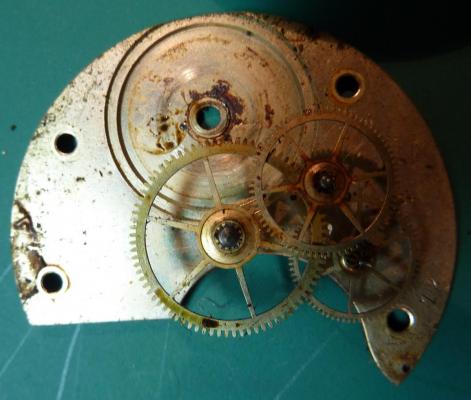

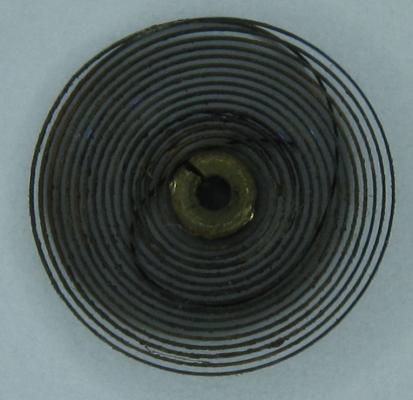

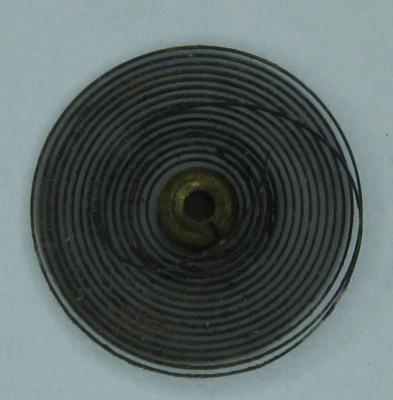

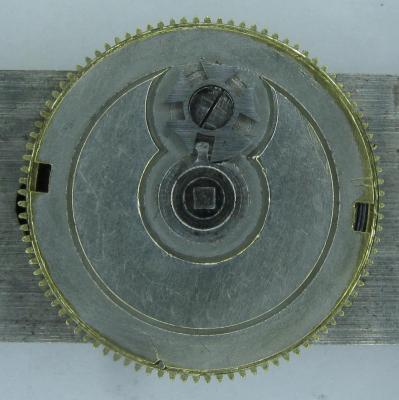

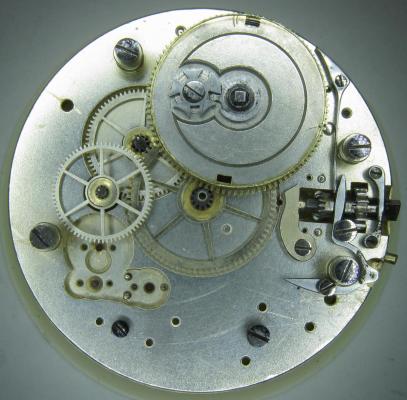

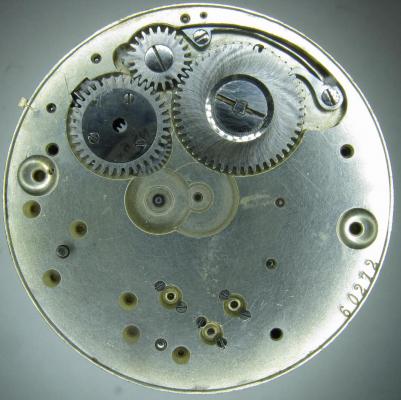

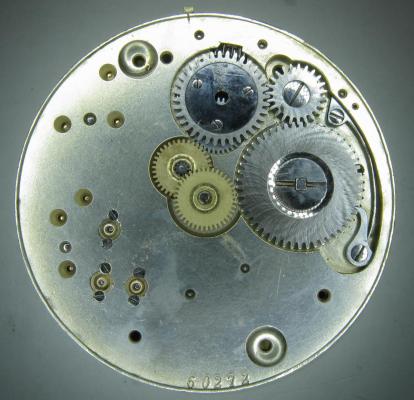

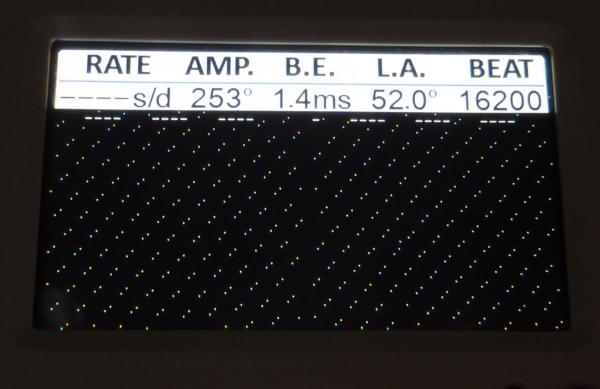

OK, so me and Mrs H did Christmas day with the family, and then we did Boxing day with the family, and then we were granted a day off so got to relax, and for me that meant I had the chance to tackle a little project that I had acquired as part of a job lot from a long retired watchmaker that had been sitting around in a shed for about 35 years (the job lot, not the watchmaker). Pocket watches are not usually my thing although I do own and use a couple. Orphaned pocket watch movements are even less my thing; but this little baby was in such a state that I couldn't resist the challenge. I don't think I have ever attempted to resurrect anything in quite such a sorry state as this before but it wasn't all bad. The balance was free and with sufficiently little end shake to hint that the pivots were not broken. However, the accumulation of dirt and dried grease obscured just about everything else. The inner coils of the hair spring also looked to be completely filled in with rust/gunk. With the balance cock and balance removed things got a little more interesting. Underneath the grime is a rather nice English Lever escapement with cap jewels on both the pallet and escape wheel pivots. A good sign, but I need to let down any power in the mainspring before I go any further, which means flipping it over and removing the dial as the keyless works are dial side. Not quite so bad under here as the dial has kept the worst of the dirt away. You can see too that both ends of the pallet and escape wheel pivots are capped, and the click spring is a proper cut steel affair, not wire. There is worrying evidence of rust on the steel work though. With the power let down the pallet and escape wheel cock is removed and you can now see the English Lever escapement in all its (rather grubby) glory. What a mess, but through the gunge there are just little hints of quality watchmaking peeping through; the thickness of the 3/4 top plate, and the cut and form of the teeth on the wheels. The top plate comes off taking the entire train and barrel with it as the pivots are seized in their bearings. The main plate is a mess. The under side of the top plate with the train still in place. The barrel has vacated its bearing revealing rust. Not a good sign but it could be worse. The train now removed from the top plate and dropped back into the main plate for a reference shot. The set lever and stem retaining bridge do not look healthy. Again though the set lever spring is cut steel, not wire. Oh yuk!!! The main plate now stripped. The barrel lid, with another nice touch; Geneva stop work, designed to only allow the central portion of the springs torque curve to be utilised thus reducing isochronism. Main plate, top plate, and escapement cock ready for cleaning. Ok, so whilst I was stripping all of this down, the hair spring, removed from the balance has been sitting in some Cola. The result is that the rust has softened and with a little careful tweezer work with a pair of Dumont #5's, most of it has been dislodged. The terminal curve of the Breguet over coil is badly out of shape due to a mishap when trying to unpin it from the rusted steel stud. I'll sort that out later. For now it's back into the pop to see if I can get those coils a little cleaner. Everything cleaned and ready for reassembly. I have a couple of spare jars for my cleaning machine and when I renew the cleaning solutions, the old stuff is kept in the spare jars. Any really heavily soiled movements get a "pre-wash" in the old chemistry so as to prolong the life of the new. With this watch everything was washed in the old gear and then very carefully gone over with peg wood, a G/F scratch brush, and tooth paste on a cotton bud in order to remove all of the staining that the bath didn't touch. All the jewels, bearings, and pinion leaves were also pegged out. Then it all went for another cycle through the old stuff before going through a normal cycle through the fresh chemistry. Main plate dial side prior to reassembly. And train side. Scrubbed up quite well I think. Stem, winding pinion, clutch, and stem retaining bridge reinstalled. Set lever and spring back in place. I haven't removed all of the rust pitting from the stem bridge and the set lever as it was too deep and to take it out would alter the shape too much, but it has been stabilised. The reassembled barrel and Geneva Stop work. I have reused the old main spring for now but made a note of its dimensions in case I choose to replace it. Another (gratuitous) shot of the Stop work as I just love it :-) Barrel and train back in place and things are starting to look fairly healthy. The top plate goes on. Quite a difference compared to the strip down shot from the same angle. The keyless works back in place dial side. And the balance, with reshaped and re-pinned hair spring goes back into place. After about half a dozen attempts to adjust the beat, removing the balance from the cock and turning the hair spring collet each time, and she comes to life!! Everything back in place dial side. And the cleaned up dial goes back on, complete with (broken) hands. And if you ignore the rate error for now (I need to re-pin the hair spring a little shorter), it's actually not a bad performance. As I said at the outset this was a challenge for challenge sake. I really enjoyed doing it and have learned a little bit about quality English watchmaking from the days when we were really rather good at it. I have absolutely no idea what to do with it now though although I want to try and find a bit more about it. Here is what I know; The name on the dial is T Donkin. There was a T Donkin watchmaker in Scarborough but I have no dates (yet) I'm guessing somewhere between about 1890 and 1910. It is a 19 ligne, 19 jewel English Lever escapement movement with capped balance, pallet, and escape wheel pivots (diamond on at least the balance top pivot). It has a screwed, split bi-metalic compensating balance, Breguet over coil hair spring, and Geneva Stop work on the barrel, and a 16200 train. A technical spec that suggests that it was of a reasonably high grade for its day. I still have a couple of issues to address though, the most problematic of which is that it has a slightly bent balance staff pivot. I decided not to tackle this on this occasion as the risk of breaking it whilst trying to straighten it was too great and I desperately wanted to see it running, but I may have a go in the future. I will re-pin the hair spring at the same time to get the rate up to where I can regulate it properly; it is currently about 25 minutes a day slow which is way beyond the range of the regulator. I also need to re-attach one of the dial feet and source some new hands. Then of course there is the question of recasing it. If you have made it this far then thank you for indulging me :-) I hope you have enjoyed it. If anyone can shed any more light on this little old lady I would be very grateful.1 point

-

1 point

-

Hello John :-) I am an amateur :-(. We deal with enamel 12 months. I learned from the movies on you tube. I like enamel guilloche Faberge Peter. I built the machine straight line and actually build a rose engine. 3 weeks I'm trying to "guilloche". The first discs brass. Pozdrawiam serdecznie Leszek :-) .1 point

-

Hi Finchy, welcome aboard! I have this small but repetitive fault with my hydroelectric turbine so maybe you're the guy........ Your dad obviously had good taste in watches. Envious! You're in the best place for any advice you may need to get your head around any aspect of watch repair, with a good selection of videos and picture walkthroughs. Fill yer boots! John1 point

-

Hello! Since you're into watches I am confident in assuming that you're a Springer Spandrel! :lol: I'll get me coat!1 point

-

Hi Leszek, Welcome. For a short time, when I was about 20, I had a job as an enameller, though nothing as elaborate as your work. Beautiful! I also find guilloche dials irresistible! John1 point

-

1 point

-

Nice job Leszek! My Polish is not so good - has Google got this translation right? 1. Cut copper. 2. Cutting disc 3. Cleaning acid 4. Burn 1 5. Burn 2 6. Ready sleepers 7 The end 8. Bezel 9. Ready primer for cloisonné 10. Imposition of wires 11. Fill enamel 12. Firing 760 C approx 8-20 times Final Shield formed about 40 hours. Yours sincerely Leszek Kralka Rgds S1 point

-

Amazing work, Leszek! Thank you for the walkthrough!...and welcome to the forum, this is a great new year start! Cheers, Bob1 point

-

Agree with Marc. The correct spring for the Longines 280 is GR2673-T 1.10 Height 0.13 Thickness 380 Length Dia. 12 The T is special Bridle type or T end. https://www.cousinsuk.com/search?SearchTerm=GR2673-T1 point

-

I think you'll find that the 12 is the barrel diameter on mm. According to CousinsUK the spring is a GR2673T which is 1.1 x 0.13 x 380 x 12 T end, so 380mm in length. If the spring that came out didn't have a T end then it looks like someone put the wrong spring in in the past. If it were mine then I wouldn't use it with a spring that could slip as the barrel is not designed for this to happen. I would be concerned that each time it slipped the spring would be shaving the barrel inner wall, damaging it and creating swarf that could further damage the watch. Cousins list the correct part as in stock for £11.95 so replacement with the correct part shouldn't be a problem. By the way, welcome to WRT. Nice Longings.1 point

-

For setting watch hands, I have a personal rule: nothing made of metal touches dials or hands. Ever. Rodico, boxwood, Jewel-picker-uppers etc...1 point

-

Whilst trawling for some movement info, I found this site. Has loads of movement data and all in one place. Others may find it useful. http://tech.gleaveandco.com/tech-sheets1 point

-

1 point

-

1 point

-

Happy new year Geo, and everyone in this little community. May all your 2016 horological endeavours keep time.1 point

-

Ok, actually I found that it is pretty hard to find clear information about the technique of creating sunburst effect on dials. There are some articles (and forum publications) that explain more or less the process. The common information that can be found is that the sunburst effect on the dial is done not with paint but with polishing the brass in certain way, namely from the center to the edge, of the dial, using discs with plastic brushes, pad or very fine grinding tools. Diamond paste is a must. Here you can see a video from a Breitling factory where at 2:45 min for very short period you can see the process. https://www.youtube.com/watch?v=4wFHVdxWNDc The dial is mounted on spindle that is rotating slowly, while the disc with brushes has higher speed. Here below there is a picture of the machine. For the enthusiast I will say that it doesn’t looks like so difficult to build such a machine. Later I will publish other articles that I’m finding for interesting related with the topic for the dials. Best regards, Martin,1 point

-

1 point