Leaderboard

Popular Content

Showing content with the highest reputation on 11/02/15 in all areas

-

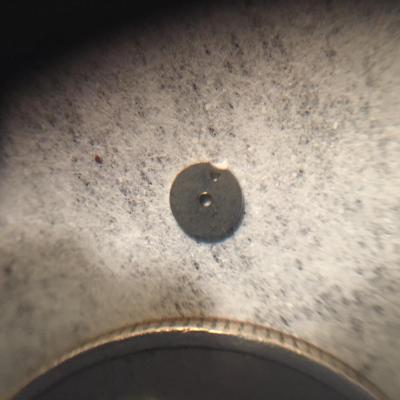

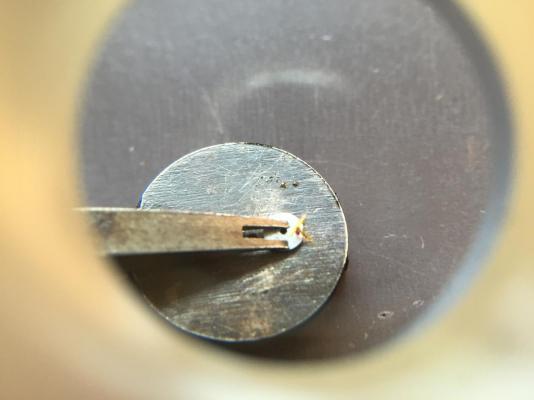

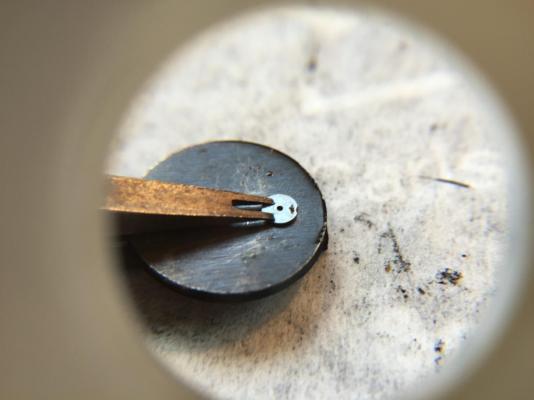

An encouragement to newbies, and perhaps a useful trick for veteran watchmakers Last week I replaced an impulse jewel in a roller table for the first time. Hurray!! I feel I'm growing as a watchmaker, although still largely through making mistakes and then saying, "Well, I'm not going to try THAT technique again!" So I want to encourage my fellow newbies that one really can learn how to do these challenging maneuvers. I puzzled for a long time over the techniques by which I would pick up a slick tiny impulse jewel measuring 0.38 mm in diameter, and place it, facing the right direction, precisely at a 90 degree angle into its tiny hole on the roller table. And how would I keep the jewel in place as I added a tiny thread of shellac to the roller table and as I heated it? I figured I had to put the roller table securely in place on top of the heat-transfer device—what is the name of that thing?—and do all subsequent operations on that platform. I'd never be able to transfer the roller table and unsecured jewel from the workbench to the heat-transfer device without the jewel falling out and disappearing. The bigger problem was picking up and moving the jewel. I couldn't get a good grip on it with tweezers. One of the techniques I had read in a standard textbook described getting the flat top of the jewel to adhere to the inner face of the tweezer tip, and then pinch the jewel down into the hole as the other tweezer tip is pushing up from the opposite side of the metal heating table. But that dog wouldn't hunt. The clamps holding the roller table onto the heating table prevented my having maneuvering room to do that. Besides, I couldn't hold the heating table off the work bench, maneuver two tines of the tweezers without dropping the jewel, and still get my loupe close enough to the jewel to see if it was facing the right direction. I considered wetting the outside of the (held together) tweeter tip with water to use water's surface tension—or as my son the chemist corrects me, its dipole moment—to have the jewel adhere to the outer surface of the tweeter tip. But that presented two potential problems. One, the water would likely heap up into too large a droplet on the tweezer, and two, once the jewel had been picked up by the droplet on the outside of the tweezer, it might not easily be released from the wet tip. So...instead of using water, I dipped the tweezer tip in acetone—nail polish remover. My idea was that the acetone would have less dipole moment than water, reducing its tendency to bead up, but still enough dipole moment to pick up the jewel. Also, acetone evaporates fairly quickly, especially when, as in this case, the ratio of surface area to volume is so high. So the adhesion of jewel to tweezer should be declining when—if!—I maneuver the jewel into place and want to separate it from the tweezer tip. This technique didn't make the procedure EASY, but it made it DOABLE for me. The jewel is now securely and properly affixed to the roller table. (The watch still doesn't run, but that's another and sadder story.). I'll upload some before and after photos. Then I began to wonder. Had I merely stumbled across a technique that is already well known and widely used? Or is this a new idea? Also, since I didn't actually run a controlled study, I don't really KNOW if acetone is superior to water for this arcane purpose. So I invite the veteran watchmakers here to share their reflection on this technique, and to report the results of any experiment they are inspired to perform.3 points

-

2 points

-

Do'nt do it - you will end up making new tools for/with you lathe all the time! ;) Thank you! I must admitt that I usually end up using my small mill when refinishing cases - easy to adjust the angle of the disc, the hight e.t.c. e.t.c. and standard collets makes life easy! :) A badly beat up Speedy MKII case lapped in the machine above using a 305mm disk with 240 grit paper.2 points

-

As everyone know, some tools can be somewhat overpriced for what they are, take the Bergeon dial working platform for example. Bergeon_7053_ by Micky Aldridge, on Flickr BERGEON do sell some great tools of high quality, but the prices are crazy at times, the above dial platform retails at €189 euros. I decided there is no way I would pay that much, and then started looking at how I could make my own, it couldn't be too difficult, right? Here's what I came up with, not pretty, but it works, its a hockey puck, and I drilled lots of small diameter holes in the one side. Hockey puck costs €3 euros delivered. Started life like this. Hockey Puck by Micky Aldridge, on Flickr My Bergeon Alternative watch dial platform project by Micky Aldridge, on Flickr After some drilling.. Untitled by Micky Aldridge, on Flickr And here's another tool I made for a special case back screw design. Untitled by Micky Aldridge, on Flickr Other thing I use, instead of Bergeon dial protectors when removing hands, I use a clean ziplock bag.. Oh, and a bonus item I made is this microphone dust cover. Untitled by Micky Aldridge, on Flickr Lets see what tools you have made to make your watchmaking more enjoyable without breaking the bank. :)1 point

-

I have 2 of those too! Sometimes it is not enough to have just one otherwise what other excuse would I have to provoke an argument with the wife! :)1 point

-

1 point

-

1 point

-

Look like you can have small boxes two . But can't see any in the picture . It's a very large machine .1 point

-

1 point

-

The link below might be of some help. In my opinion if you wish to repair/service watches & clocks you will need more than online courses. You will need tools, a dedicated workspace & a lot of hands-on experience. http://www.clockmakers.org/horology/horological-training/1 point

-

What am I like! Re-read your post and realised there was no 4205 "after" photo anyway. I can only blame it on the paint fumes from the redecorating that I am lumbered with :biggrin: I do look forward to seeing them when you're finished. PS I have just received another 3 4205's from Ramon myself. Once I get everything done here decorating-wise I can get on with something more worthwhile.1 point

-

If you do buy from Ramon (thewatchcollector) and find you need/want to replace dials/hands...... Aftermarket but superb quality. http://www.dagazwatch.com/apps/webstore http://www.yobokies.com/ If you want new/used OEM parts....... http://www.speedtimerspares.co.uk/ http://www.speedtimerkollektion.com/ Also Stefan AKA schillachi61 on eBay. Bought bits from all of them. Well respected sellers on the Japanese watch forums. [emoji106]1 point

-

Here are some of my "tools" Small tiltable table for one of my lathes larger tiltable table for lapping Lappingmachine for cases Simple chuck "Adapters" for case opener 5700 to open Speedmaster MKII cases, Heuers etc Stand for oilers, anodized aluminium Demagitizer ....and much more - I almost like making tools/machines more than refinishing watches! :D1 point

-

My recommendation is to carefully observe whether the hour and minute hand are always off concordantly. That is, if the minute hand is fast by thirty minutes, has the hour hand advanced halfway between the number markers too? If so, that is a concordant error, likely due to a loose cannon pinion, a Geo suggests. However, discordant errors may be due to both minute and hour hands being loose on their respective pipes. The required intervention between the two is quite different. Sent from my iPhone using Tapatalk1 point

-

1 point

-

1 point

-

I use a ribbed mat for my tweezers, hand levers, and hand fitting tools. Untitled by Micky Aldridge, on Flickr1 point

-

1 point