Leaderboard

Popular Content

Showing content with the highest reputation on 03/24/15 in all areas

-

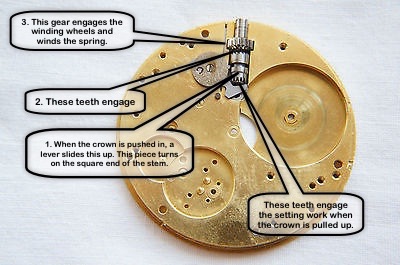

Repair and restoration of a Tissot pocket watch The watch arrived with a number of problems, the crown wheel was missing and so was the barrel arbor. The barrel arbor is a difficult part to make, because it has so many things all contained in a very small space, so I think my first task is to make a new one. Here are some of the critical parts of a barrel arbor: square boss has to have a hole drilled and tapped to accept the winding wheel screw a hook needs to be made on the arbor to fit and hold the inner part of the mainspring allowing the spring to be positively secured and the required clearance to the coil so it doesn't touch the hook there are numerous pivot surfaces, 2 to fit into the mainplate and barrel bridge, 2 to fit into the barrel the dimensions of all the pivots and spacing is critical if the arbor is going to fit and work properly the arbor needs to be hardened and tempered for strength and durability, and it's friction surfaces need a high polish and burnishing to reduce friction to the minimum Whenever you are making a part from raw stock, you have to have a plan and logical approach. My first task was to drill and tap the hole for the screw. Once that was done, the next step was cutting the 4 faces that would secure the arbor to the winding wheel and allow the movement to be wound up. I made these with a very slight taper, so that as you tightened the screw the wheel would be held more securely. Here is a view of the winding wheel being test fitted to the arbor. The next step was to fabricate all the various pivot surfaces and make sure that the heights were correct so that it fit into the barrel as well as between the mainplate and the barrel bridge. Here's the arbor ready to be parted off and the bottom pivot finished. Once the bottom pivot was finished, the arbor needs to be hardened, it is coated in boric acid to keep the oxygene away during heating, heated to a red heat and then quenched in water. Here it is after quenching. Next it gets a polish so that I can see the colour change as I temper it to a blue hue. Now it needs another polish of all surfaces, and I burnished the pivot surfaces for durability. [/url] Now the big test, fittin it into the barrel and the mainspring, it fits perfectly. And next is the installation of the cover, which also is a perfect fit. Moving along the whole assembly gets installed into the movement, end and side shakes are checked and corrected if needed. And finally I am able to re-install the winding wheel and it fits perfect with the required clearance to the barrel bridge and no end play. With that out of the way, my next task is the making of a new crown gear.3 points

-

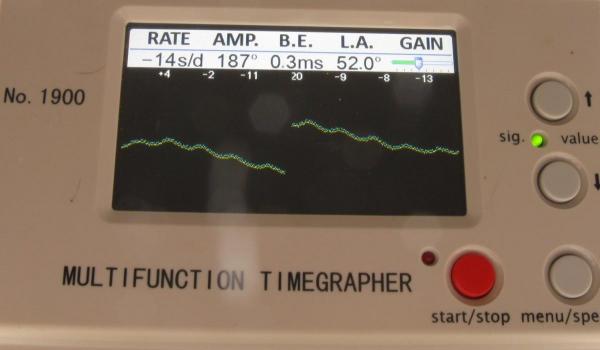

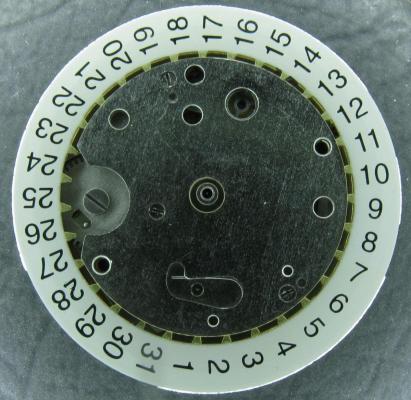

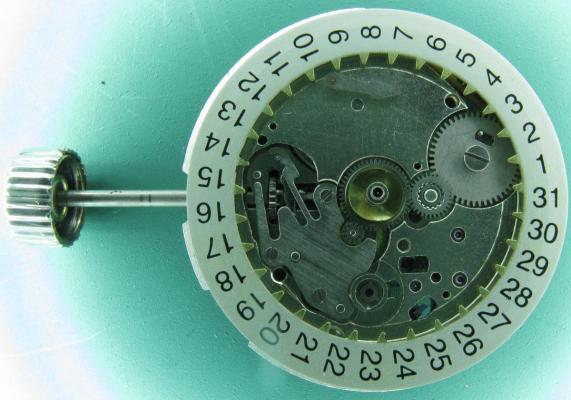

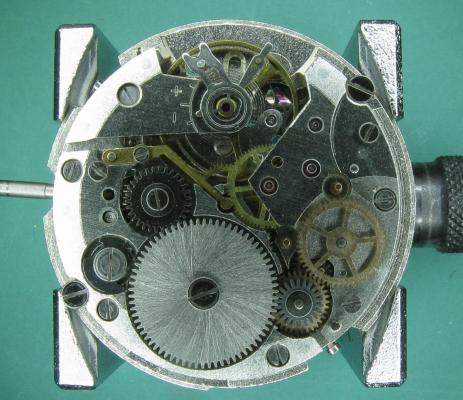

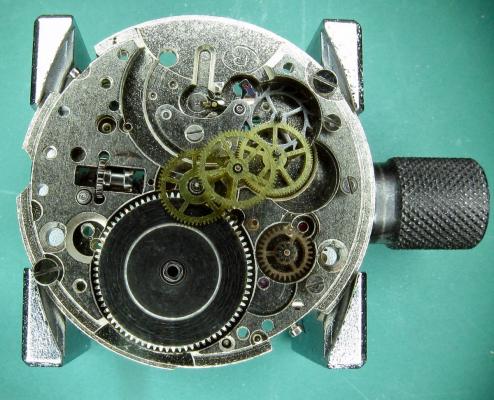

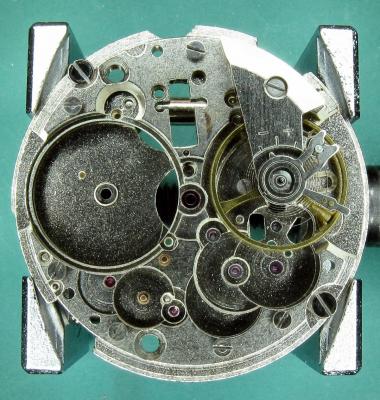

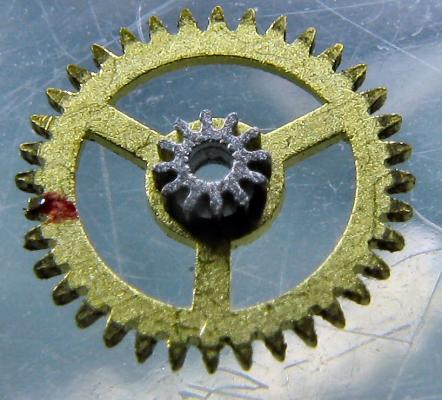

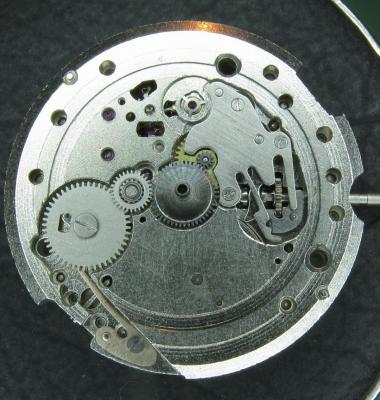

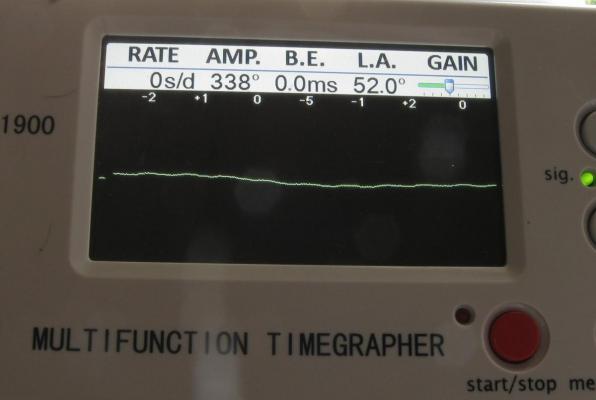

This is a bit of a departure for me as I usually like to play with stuff a little more vintage and a little more Swiss. That being said I have done a few vintage Russians in the past and this is a watch that I had been curious about for some time. I picked this one up at a car boot sale last summer for just £3 in a less than wonderful state. As you can see, the seconds hand was off and it was described a not running. It turned out that it did run, just not too well and the hour and minute hands didn't move. Canon pinion anyone? First impression with the back off is pretty encouraging. Still looking good with the rotor off. This is a 31 jewel movement, 10 of the jewels are inside those reverser wheels. Somewhat minimalist under the dial. With the calendar wheel retaining plate off you can access the motion works, the calendar works, and the keyless works. Flipped back over and with the auto-wind bridge out of the way. This is an indirect driven centre seconds hand which has a tension spring to hold the seconds hand pinion in place. This has to be supported when installing the seconds hand otherwise the hand simply pushes the pinion against the spring and won't install. Balance cock removed with the shim that the soviets are so fond of for adjusting end shake. Hair spring is in good shape. With the train and barrel bridges out of the way the going train is revealed in all its glory. Flipped over again to strip out the bottom plate and a problem comes to light. There is some damage to the minute wheel (marked in red ink). Maybe the canon pinion isn't the problem after all? In close up you can see the damaged minute wheel tooth. This I didn't think would be a problem, just replace it..... I thought. Not so easy as it turned out as I couldn't find anyone that could supply a new wheel, and a donor movement proved elusive unless I wanted to spend a fortune on a complete, working watch, which I didn't, so I had to wait for eBay to come up with a spares or repair victim at the right price, which it eventually did. The stripped out main plate with the balance and cock, minus jewels, ready for the cleaning machine. The bottom plate back together again after a good wash cycle in the Elma. At this point I did check the canon pinion anyway and it was as well that I did. There was virtually no transfer of power through to the hands at all so a suitable adjustment was made and a tighter fit achieved. Back in the case and ticking like a champ. The rotor and massive case back gasket back in place. And a much improved trace on the timer. This is with the original mainspring which turned out to be in very good shape requiring just a clean and relube. The trace isn't perfect by any means, but compared with other Russian watches that I have played with (and with it's starting trace), it's pretty good. There is still a hint of a periodic variation that I may investigate at some point but for now I shall just wear it and enjoy it. And here it is on the wrist after a bit of a cosmetic brush up. These are available with many different dial designs, apparently this one is referred to as a "SCUBA Dude". I have worn it for two days now and it has gained about 5 seconds a day so there is a little fine tuning to do to get it right "on the wrist". All in all I'm very pleased with this one. I had been curious about the Amphibia for some time having read a couple of articles detailing its history and design. It also has quite a large following of avid enthusiasts who rate it for both value and robustness. On the value front I can't complain with this one as the total cost to me was just £11 (including the donor). As for ruggedness only time will tell, but the performance so far is very impressive.2 points

-

Just finished refurbing a tired Smiths TY believed to be from 1965: Before: After: Case, dial & hands cleaned. Crystal polished. Movement serviced & broken click spring replaced (thanks to John at Obsolete Clock & Watch Parts). New strap. The timegrapher readings were a little variable, however it kept good time all weekend. I am getting a bit of a thing for Smiths (the watches, not the designer-misery band from the 1980's) and have got myself a 1960 Astral to do after the next Seiko.2 points

-

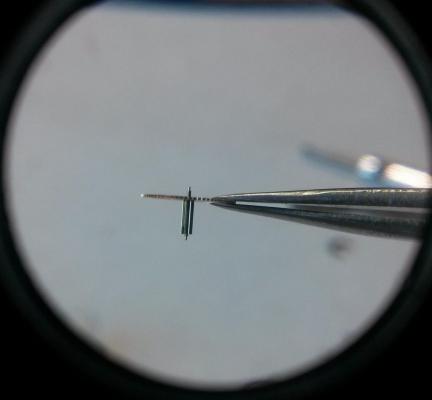

The Patek Philippe pocket watch arrived with a number of problems. The most serious was that the escape wheel arbour was snapped off. General view of the movement The broken escape wheel arbor The biggest problem was that the arbour had broken off flush with the escape wheel pinion, a worse case scenario, leaving me no arbor stub to use as a alignment guide for drilling. So in order to install a new arbor I had to drill freehand with no guide. Here's the escape wheel mounted in the lathe, where I used a grave to cut a center v-notch to guide the drill. Next up was the drilling, the drill measures 0.25mm in diameter and standard practices is that the hole is 3X the diameter, so I drilled down 0.75mm deep. Holding onto and drilling a hole with a 1/4 of a mm drill is a big challenge, it's only 4 times thicker than a hair, so not much pressure is needed to snap it in two. Here's a better view of the 0.25mm hole I drilled. Next up was fabricating a new replacement arbor, I did this using silver steel, and made it oversize so that I could adjust it for a perfect fit. The diameter of the arbor is 0.35mm and the pivot is 0.11mm. Checking the pivot diameter. Replacement arbor on top, old broken one on bottom. A small dab of Loctite was applied to the part of the arbor that would be press fitted into the escape wheel, then the new arbour was carefully tapped in place and seated and aligned. With that taken care of, the escape wheel was installed in the movement and I measured how much of the tip of the pivot I needed to remove for a perfect fit with the required end shake. Here's the pivot sticking out of the jewel with the cap jewel removed. And here's the view with the pivot trimmed in length and sitting just below the jewel. There were a number of other issues with the movement, but I always start with the most challenging. With the new arbor in place and the escape wheel fixed, I went on to the other defects, which will have to wait till another day.2 points

-

2 points

-

Finally came around to getting a donor for my Helbros Invincible "Lorsa P72" movement off ebay for $5 free shipping. The donor is a P75 movement and I went straight to work, cleaning and lubricating all the pivots and jewels. Bobm12, you are right I do feel proud of the accomplishment...best feeling ever! Thanks guys for all the encouragement you have given me. Geo, your acetone method worked like a charm....thanks! 2nd project complete.2 points

-

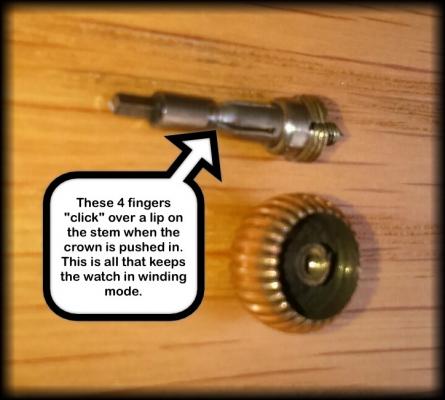

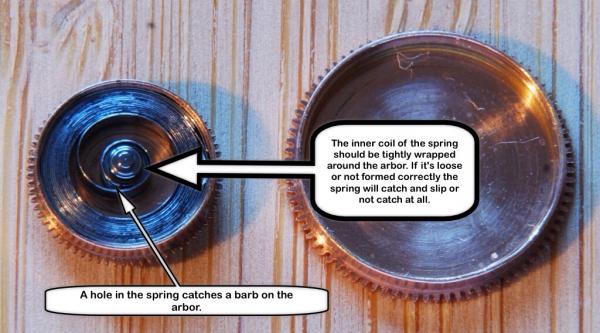

That description clears it up. My best guess is there are two separate problems that need to be addressed. And both may be very easy fixes. 1. The main spring barrel needs to be opened and you need to see if the spring is broken or if it's not catching the center arbor. Sometimes when they slip a few times the force of the spring slipping opens the inner coil of the spring even further which makes the slipping worse...until it won't catch at all. This can be repair by gently closing the inner coil with some pliers so that its tighter around the arbor. 2. If the stem isn't "clicking" firmly in place that will cause all sorts of problems when winding. These fingers can often be bent slightly inwards so they engage the stem more tightly. Pull the stem out of the sleeve by pulling on the square end. Squeeze the fingers slightly inward. Reinsert the stem and see if it "clicks"2 points

-

Hi All! I have just finished disassembly and reassembly of an old Marvin watch I purchased. Now ticking and running with a quick quarter wind. However, it seems the hour hand may be a bit wobbly and at some time contact the hour hand causing an issue. Am I correct this may need tightening? Fault finding is on going learning for me. Thanks, Gary1 point

-

Fantastic video! It's really cool to see the inside of a working shop. I've been working up my nerve to approach a local watchmaker and beg for a tour. This is the next best thing. All those tools...why isn't there a "drool" emoticon? And there's that Cousin's LED lamp again. Thanks for posting!1 point

-

Cracking workshop Mark. You have created a really functional work area. Have you ever calculated how much you have spent on your equipment. At a guess I would say you have at least 20k.1 point

-

What a cracking job you have done Mark, working should be a pleasure. I would also thank you on behalf of the members for your kind words regarding their input to the forum. :)1 point

-

1 point

-

Anil, I am inclined to agree. I would imagine that the loose canon pinion caused the watch to indicate poor time keeping, prompting the owner (who may not have had too much experience of this sort of work) to try and sort it out himself. I reckon he got as far as taking off the hands and dial, and stripping out the motion works before he gave up and put it back together again which is when the damage to the minute wheel could have been caused. I also think that the seconds hand was off because he couldn't get it back on again; like I said, you have to support the other end of the pinion otherwise the hand simply won't install. (I used a staking tool with my smallest stump for this in the absence of a dedicated movement holder with the support built in). You're right about the rest of the movement too. Apart from being a little dry it was absolutely pristine with nothing to indicate that I wasn't the first person in there. To be honest I was quite impressed as the quality and finish were rather better than I have come to expect from older Russian watches.1 point

-

John, I am really liking it as well. It's just simple and elegant and so comfortable on the wrist. I have it torn apart at the moment. I haven't found anything broken, but boy what a sticky dirty mess inside. Stay tuned for a full service walkthrough.1 point

-

1 point

-

Hi guys, My newly restored skx something or other (7S26-0030) mid size diver from Seiko, "vintage": By the way, if any one know the equivalence between the SKX (or whatever model number) and the 7SXX-XXXX correspondence/equivalence, please post a table. It would be very much appreciated (and useful). Thank you in advance, Cheers, Bob PS. I retrofitted this watch with the new NH36 (or maybe the NH35 from cousinsUK with day disc added, will have to open again to look. Same thing basically) movement so it now hacks and hand winds (The original movement is complete, working and serviced in a little box in case I want to make it the real thing). The aftermarket dial window is not exactly where it should be cut - a little too low, fixed by repositioning dial feet which I preferred not to do/not worth it -- but at US$6 including shipping I'm not complaining! :) New Movement:1 point

-

Can't go wrong with a seiko that is a smashing looking watch agree with all the chat re the hands My Japanese 007 says hi1 point

-

Love Seikos! They are so under-rated as a brand. As I've posted before ... if anyone asked me what brands they should be looking at for their next purchase: the first company I mention is Seiko. Whether the budget is $300 or several thousand (a Grand Seiko), my answer is still the same.1 point

-

Reminds me of some Dagaz hands and they are awesome! Nice Seiko, only need a padlock so it is safe on the wrist! :) Cheers, Bob1 point

-

That's a nice watch Nigel. I particularly like the hands, the minute reminds me of a Roman gladius. and the hour is like a hunting arrow head, they're brilliant! :)1 point

-

1 point

-

1 point