Leaderboard

Popular Content

Showing content with the highest reputation on 07/23/24 in all areas

-

4 points

-

That looks very much worth reading; just trying to find it and discovered that the third edition is available to "borrow" & read online from the internet archive: https://archive.org/details/modernwatchrepai0000unse3 points

-

2 points

-

Definitely full marks for experimentation. Another factor is is wear on the barrel wall without lubrication. Steel constantly rubbing on brass/ aluminium, I can't see it surviving for long.2 points

-

An interesting test indeed. However with at least one dangerous assumption, and one omission. The assumption being that "fresh from the factory" equates to appropriately lubricated with a braking grease. Had this been of Swiss or Japanese origin then the assumption may not have been as problematic, however my understanding (and I will confess this is from reading not direct experience) is that one of the problems with the Chinese movements is the lack of appropriate, or even any, lubrication. The omission being to repeat the test with a known braking grease applied, which would have negated the assumption and given a known and verifiable result for braking grease. 10 out of 10 though for experimenting.2 points

-

Renata 2 should be a 392 but if you're ever not sure then just measure it. https://www.watchbattery.co.uk/Watch_Battery_Cross_Reference_Table.php?Info=&Sort=Renata2 points

-

We did discuss this sometime ago. While non-magnetic nickle alloy hairsprings do not become magnetic themselves they can be drawn to something that is magnetic. If i remember correctly they have paramagnetic behaviour .2 points

-

2 points

-

It looks to me as if the cap jewel for the balance is also missing within the setting. I found one photo a complete movement as it should be: Also note that there seem to be different versions of the Rolex cal 710. Some with shock protection systems for the balance. This one is without. And for the escape wheel jewel setting, some 710's have a screwed-in settings with two screws on top of the train bridge (whereas this one seems to have a single screw from the bottom of the bridge). So one has to be extremely careful when looking for a replacement/donor movement. But these jewels must be replaced. Otherwise the watch will not run properly. Sourcing these parts at reasonable cost won't be easy. If you get the right parts, the repair itself shouldn't be too hard. Swapping out the whole movement is a lazy approach. That being said, it may be necessary to obtain a whole movement to get all the necessary parts (buying them individually may be hard). I would strongly suggest that you find an experienced watchmaker for this project (who's good at sourcing parts). Maybe others can suggest one in your region.2 points

-

It is a caliper and should have a scale attached somehow: https://www.datamp.org/patents/displayPatent.php?pn=1295327&id=149872 points

-

You guys are right there was a piece of the old pivot stick inside the hole, it took me like 45 minutes to take it out and now the stem I have fits nicely. Now I need to find a new split stem or use another case which I do have but I kind of like this one. (that XX rated movies joke cracked me up) Thank you very much guys.2 points

-

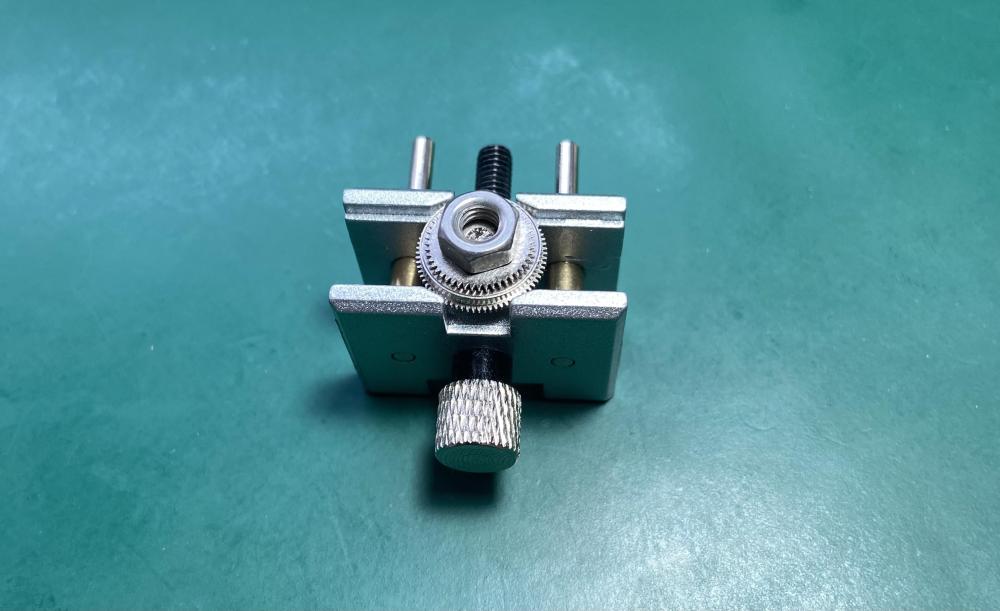

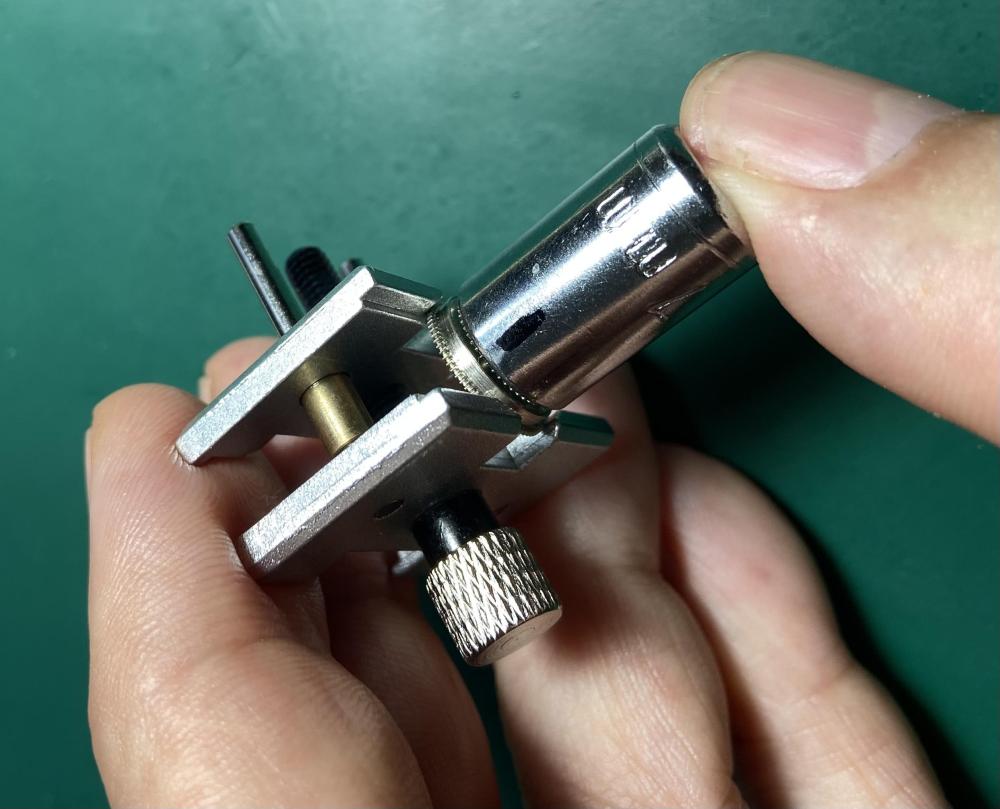

For me, a braking grease is essential for the proper lubrication of the highly loaded contact area between the mainspring bridle (steel) and the barrel wall (brass or aluminum). Both in combination serve as a slipping clutch or „brake“ in an automatic watch. I always doubted the idea that braking grease can be used to prevent the bridle from premature slipping. After searching this forum and the net for some side-by-side testing of bridle/wall lubricants with no success, I decided to do the following test: 1.) take a brand new barrel with mainspring of an automatic watch and find the power reserve 2.) remove all lubricants inside the barrel and test the dry (unlubed) barrel again 3.) oil the inside with D5 and test again What would you expect? Here is the barrel of a brand new (Chinese) skeleton watch I used. The opening allows cleaning and lubricating the inside without removing the mainspring and risking a bent spring or bridle. I counted the turns of the barrel arbor before slipping. To be able to wind the spring I glued a nut on top of the ratchet wheel. The nut was turned with a socket. A mark on the socket helped counting. Here are the results of my simple testing after 10 repetitions with each setup. - barrel factory lubed => 7 turns +/- 10° - barrel dry w/o lubrication => 7 turns +/- 60° - barrel oiled with Moebius D5 => 7 turns +/- 10° My expectation before testing was a slightly lower power reserve of the oiled barrel and a significantly higher reserve of the dry barrel. So the result surprised me a lot! On the other hand the result supports my assumption that a braking grease should not increase the power reserve. Knowing that my testing does not comply with scientific standards, I am sure we will get at least some interesting discussions.1 point

-

Oldhippy suggested I make a video how I strip, clean & polish the brass parts of a torsion ( Anniversary) clock ready for lacquering, it’s not the only way but it’s the way I do it. Dell1 point

-

Hello All, Im Rick and i live in the Netherlands. Total beginner here. Always was into watches and recently decided to pickup watchmaking has a hobby. For now i am here to learn about watchmaking, tools, movements etc.1 point

-

I see, it now. I read it now refers to the V252A manual, which I linked now. Looking at it. I am not sure how to press it to reset the movement? Edit: I found that the black pin is the reset, and now the movement works. HATTORY-PULSAR-V252A.pdf Thanks everyone.1 point

-

Re purposing the old hands usually means adapting them to fit. Ie broaching /closing and I have found the easiest way is to use new hands. As far as I know all you get from Cousins is the movement and new stem attached. If you know the hand sizes and style you may be able to order them from cousins also. The attached might be useful either now or I; the future hand_hole_size_booklet.pdf1 point

-

Did you carry out the same test with braking grease applied to the barrel? Another factor to consider is the amount of slippage that occurs, i.e. the number of turns left to power down to zero. I have always wondered if "damping grease", the stuff used for audio potentiometer shafts and camera lenses, would work better as a braking grease. That stuff is so much cheaper than anything with the name Moebius on it. Maybe I'll test it out, as I have a whole jar of it.1 point

-

The parts list for the movement includes a "Reset pin" - which implies it may need a reset after a battery change? Quite a few quartz movements have (or or had) a reset or clear point than needed shorting to the battery after a battery replacement. You could also just try sharply tapping the side of the movement a few times & see if a bit of vibration kicks it back in to life? That could either unstick a slightly sticky movement, or start the crystal oscillator if the IC gain is a bit on the low side.1 point

-

Yes they're 0.65/1.10/0.20mm 3rd column is function which in your case is Small Second Hand and 7.0mm from centre Last column is equivalents. Yes a Y121 or a Y120 without seconds would fit as they're the same depth as the V2531 point

-

Not exactly the same thing, but - have you ever noticed that the volume controls on good quality audio equipment "ooze" round rather than turning freely? That's purely due to the spindle being lubricated with a purpose made grease, "Kilopoise" or similar: https://www.farnell.com/datasheets/494932.pdf Purpose made braking greases could have equally strange properties, partly gelled or something like that?1 point

-

Not at all. What I am saying is that the effect of magnetism in a scenario where the coils do not stick together is significantly less the impact that sticking coils has. I'm certainly not trying to suggest that magnetism has no discernible effect. It's interesting to note the differences between Alex's magnetised trace in his video, which I would (rightly or wrongly, I'm happy to learn) attribute to a shortened effective hair spring length and the wavy traces you presented above which might be explained by magnetised wheels with poles whose orientations change relative to each other periodically as the wheels turn relative to each other. @praezis there's nothing like a bit of experimentation, and while you were posting your link (worth a read) I was torturing an old Nivarox hair spring from an ETA 2879 with the neodymium magnet out of an old hard drive to see if I could get the coils to stick together, and I couldn't. The spring was deflected by the magnetic field but nothing stuck. I had no means of measuring the degree to which the H/S was actually magnetised though so not very scientific, and it may not have become magnetised at all.1 point

-

1 point

-

1 point

-

1 point

-

I don't buy Alex's line of reasoning here. He states that the magnetised hair spring is showing no sign of sticky coils yet the rate and amplitude have been severely impacted. He shows us a video of the breathing hair spring in which sticking coils cannot be observed, and a view of the hair spring from underneath with all the coils separate. This, he claims is proof that the increased rate and decreased amplitude are not due to sticking coils and therefore must be down to something else, so he attributes it to "magnetic friction". I believe that he is completely missing an important mechanism here which dramatically diminishes his argument for magnetic friction, ie. that of momentary sticking. This is where the magnetism isn't quite strong enough to cause the coils to stick with the inter-coil spacing of the spring at rest, but is strong enough to cause them to momentarily stick as the inter-coil spacing is reduced when the spring breaths in, but release again as the spring breaths out and the inter-coil spacing widens enough to overcome the magnetism. When this happens the effective hair spring length is reduced (and therefore rate increased and amplitude decreased) for that period during which the coils are close enough together for the magnetic attraction to cause them to stick, which is also when the hairspring diameter is smallest and so the whole spring is hidden by the balance cock. However as the balance spins the other way and the hairspring expands the breathing action of the spring overcomes the magnetic attraction and the coils separate again. In Alex's video the hairspring diameter only shows us between 2 and 3 coils (excluding terminal curve) at max diameter, and no coils at all over half of the circumference at a smaller than at rest diameter. Whats more the part of the spring where the inter-coil spacing changes the most (opposite the regulator) and is therefore the part of the spring where the coils are closest at minimum diameter and most likely to stick, is completely hidden under the cock the whole time. As this is the part of the spring where coils are most likely to become momentarily stuck it is not surprising that we can't see sticking coils, even when the balance is stopped or removed and viewed from below with the balance at rest. However that does not mean that we can't see evidence of a sticking hairspring. One of the things that I look out for is trembling coils. By this I mean coils that vibrate as the coil expands. A spring that has no sticking coils at all breaths in and out smoothly as the balance oscillates. On the other hand if two coils momentarily stick and then suddenly release, the spring will vibrate like a plucked guitar string, and this can be seen even when no actual stuck together coils are in evidence. This is easier to observe in lower beat movements, but can be seen in 28000bph movements as well. I don't think that Alex's video is clear enough to be sure but I think I can see it there. I don't know enough about electromagnetic induction to be able to comment on the magnetic friction theory other than to say that my gut feeling is skeptical.1 point

-

1 point

-

I used those pictures to determine which parts were missing and to cross-check some eBay listings that were in Italian.1 point

-

If you need to find a mainspring by number of turns in the barrel you can use the mainspring calculation spreadsheet from this page: https://www.vintagewatchstraps.com/mainsprings.php Among other things it allows to calculate number of turns based on barrel/arbor size1 point

-

1 point

-

1 point

-

It's great to hear you're enjoying the Borer book! The straightforward, no-fluff style really does make it a valuable read. I'm glad you're finding it informative and that it's expanding your understanding. Thanks for the feedback!1 point

-

Ok, I'm curious what results would I get if I search "pivot in hole" on those sites, this conversation is gonna get us both blocked from the forum1 point

-

This tool is really just for use to adjust the beat of a watch- correcting the beat error when there is no adjustment arm that changes the position of the hairspring stud. Accomplished by safely separating the balance cock from the balance wheel but by still having the hairspring attached. Once seperated and firmly held a screwdriver can then be passed between the hairspring coils to reach and turn the staff collet which has the same effect as moving stud holding arm. You could I suppose use it to adjust a hairspring's shape but its better to do that when the balance and cock are fitted to the watch or flat on a bench either fitted or not to the balance depending on what adjustments need to be made. What you're describing as out of flat Ross is usually an adjustment to be made directly at the pinning point to the stud. Often just a twist to one side or the other, which can be done while the balance and cock are installed in the movement. Just get some practice in Ross and you'll soon see how easy it can be.1 point

-

Mystery solved, "onwards and upwards" Ammar - another porn reference for ya matey1 point

-

sorry late, if you have a staking set and the proper stump to hold the regulator, I think a small pin mounted in a punch could push the hairspring stud out of the center of the hairspring adjustment screw, you see the hole in the center and I think the stud is pressed into it....just a thought, some bench blocks have a V and straight notches that could carefully be used also, it wouldn't hurt to see......1 point

-

I very much doubt he's even a watch repairer to leave the barrel screw out when he's returned it to you. As @RichardHarris123 said, the first thing would be to replace the screw in the barrel and try and wind it. If this doesn't work then the only part of the report I'd believe would be that it needed a new mainspring. There are varying details shown across the web as to what size the mainspring should be but measurements could be taken from the old one even if broken. Edit Looking at the photos closer and the comment about damage to the main bridge could mean what looks like a jewel missing from the train bridge.1 point

-

Got this wonderful 1971 $8 eBay find running. Other than a broken mainspring and a crack in the crystal, it just needed a good clean up. It did have a beat error problem, but I got it adjusted to a 0.6ms BE, a 260° and positional error of +/-30s. Not bad for essentially a novelty watch probably not expected to make it much past the '70s. I think the hardest part was fitting the pallet fork without jewels. Those holes are TINY! That brass plating was 10 kinds of awful so I just polished it off for now. I might nickel plate it. Or 24k rose gold, for such an elegant timepiece.1 point

-

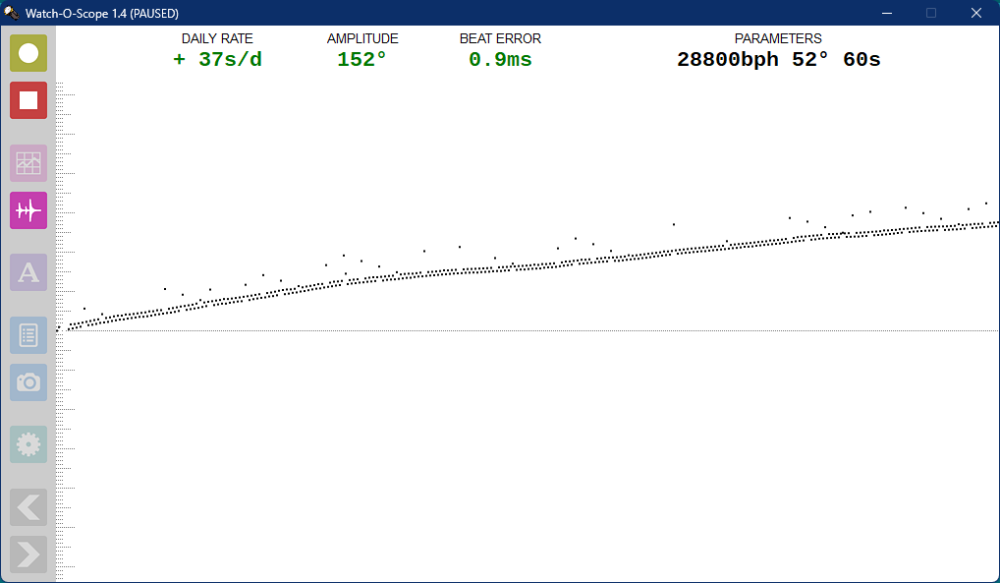

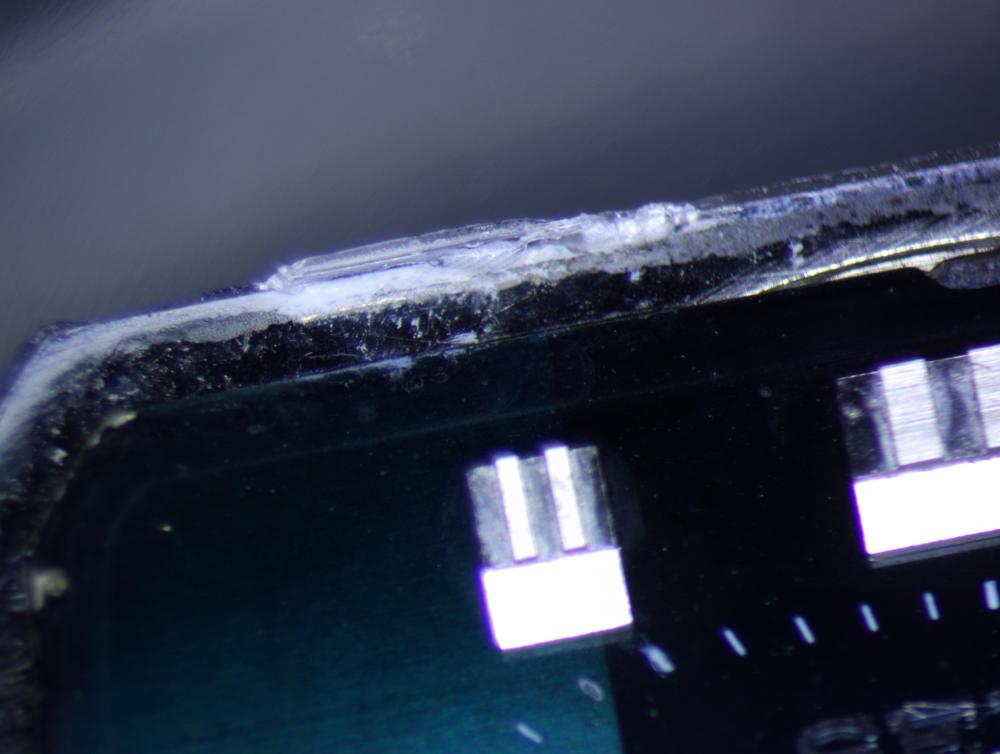

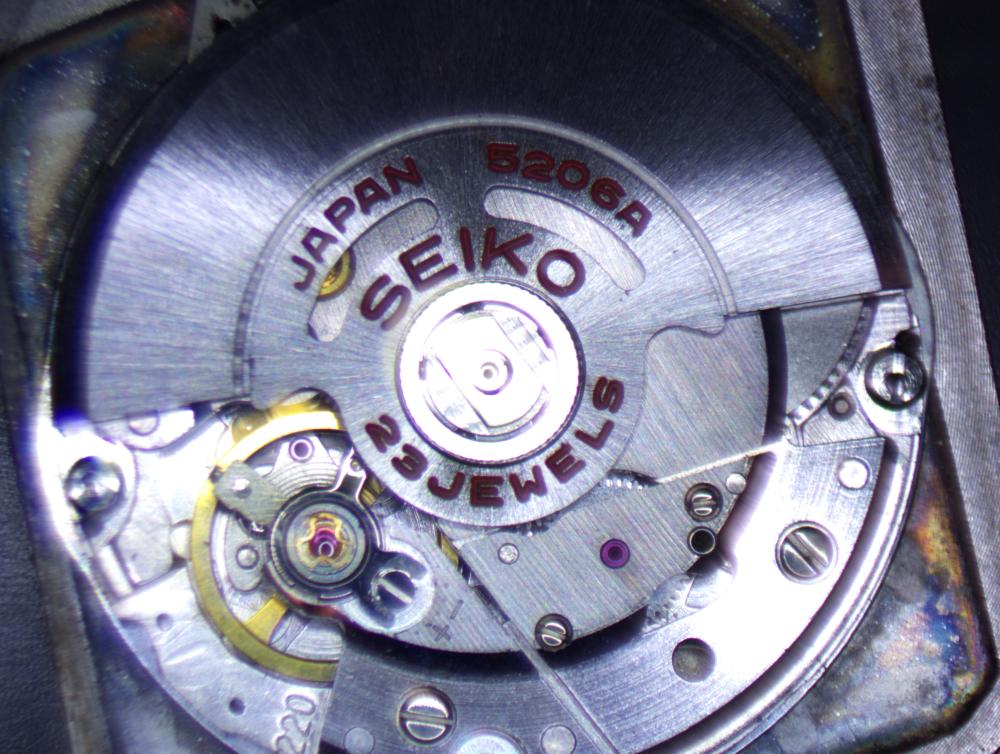

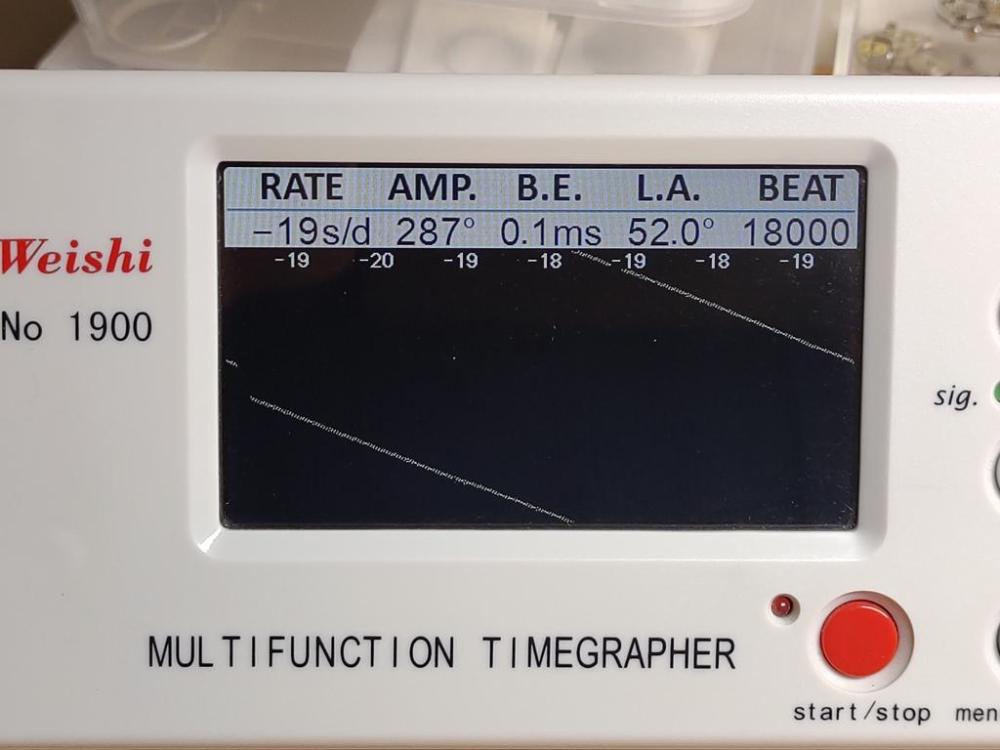

From the "which watch have you got coming" thread, this is a watch I bought off eBay from Japan. There were no pictures of the movement, so it was a bit of a gamble. Initial timegrapher reading looks decent, other than the low amplitude. The case was difficult to separate, but I got it apart. The dial shows a bit of wear, but I think it'll clean up pretty well. Super interesting that instead of a split stem, you get access to the setting lever release through the dial. I like that. It seems like it hacks when it's out of the case. I didn't take it apart yet, but I'm super interested to see how that works. Then I noticed something that looks suspiciously like super glue. And sure enough, I discovered one of the springs that holds the case halves together is missing and was glued together. That explains why I didn't get any movement photos!1 point

-

Looks like my gamble paid off again. I haven't opened the caseback yet (still at work) but it arrived ticking at a ridiculous rate, the second hand sweeps, the day, date, and time all set. There's a little ding in the dial, but I was expecting that. The back is slightly dented in, but we can fix that too. For the price I paid, I am extremely happy. I took a video to try capturing how the dial shimmers. It's like a butterfly's wing.1 point

-

As @RichardHarris123 wrote, this hairspring does not look right. Another photo please?1 point

-

I would look at the hairspring first, make sure it is free, check for dirt a tiny hair could be the problem, Make sure the whole movement is demagnetized including the tools you use. I would certainly clean the balance again and re-oil. It is good practise to demagnetize first the movement you are going to work on and the tools you are going to use.1 point

-

I believe Neven was referring to the impulse jewel when he said that they are typically press fit in contemporary watches instead of being held with shellac. He also suggested that the hairspring being glued to the collet was a sign that the movement was contemporary, it wasn't something unusual. It looks to me like the glue has been there from the factory. You can just make out in my previous photo that the end of the hairspring passes through the middle of the stud being held in the collet. The top of the stud is open, and this is where some kind of glue has been used to fill the space and lock the hairspring in place. It doesn't look like someone has done this as a quick repair (although correct me if I'm wrong...). There wasn't any snow on the timegrapher, it was actually pretty good to start with (perhaps all it needed was regulation but the movement and overall watch were really dirty). This was Dial Up before disassembly: I'll post an update once I've got it all back together. Cheers.1 point

-

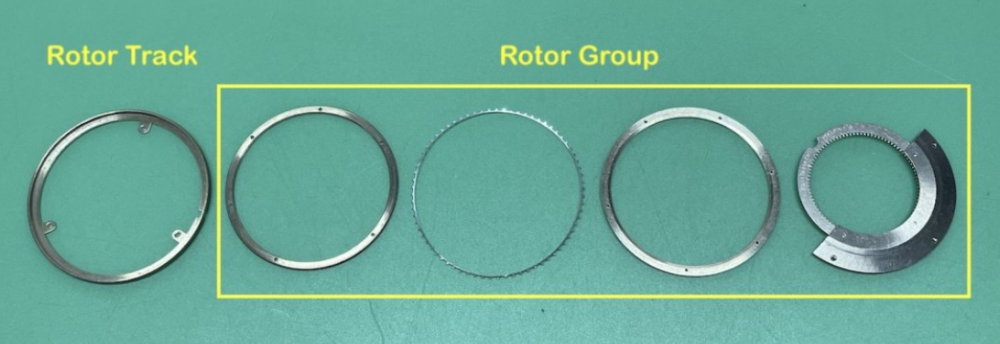

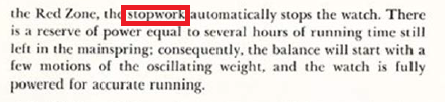

I believe this is a device that stops the movement when power indicator gets to 0. If the real power reserve is 50 hours, thus the power indicator by the hepl of this stopwork will limit the power reserve to 40 hours by stopping the movement. This works the same like maltian cross barrel arbor limiter on old quality movements Thus, when You start winding, You will imediately have good torque in the train for reaching good amplitude.1 point

-

It looks like what I need. I have 4 balance hairsprings knackered early on in my self imposed apprenticeship. They are all bent off level. When you look at them, one side is higher and touches the bottom of the balance cock. It looks like it could be used to bend the hairspring down at a certain point to allow the hairspring to become level again. I'm at the stage, where I am beginning to get enough skill and confidence to be able to work on hairsprings. Have done one. Got it level but it is at the top, just below the cock. Too close. Will need to try again. Might use the method shown.1 point

-

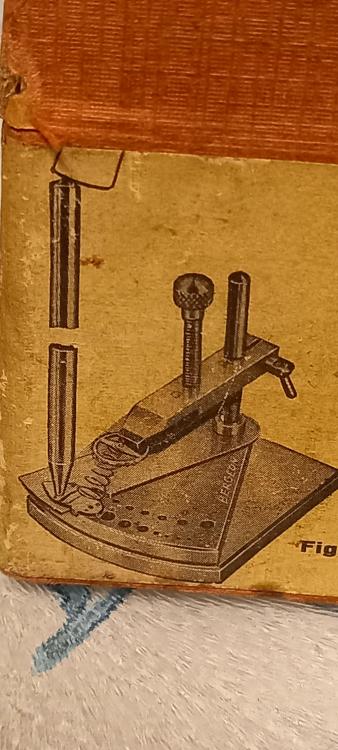

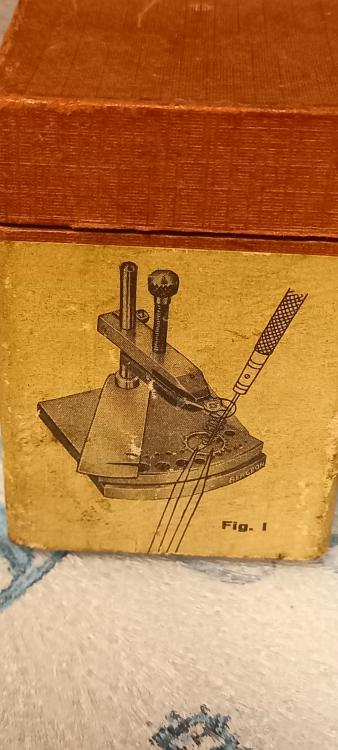

Ah-ha, Jon that is only half of the answer, it does have another use although one that is a little bewildering to me. It is shown in picture on its original box i have with it, i searched for an explanation as well but it sounded dodgy to me, but the box does also confirm it in writing and yes its dodgy .Anyway its a Bergeon 2325 I was trying to figure out from the picture whats happening to the balance cock. Apparently its called a "grenadier"1 point

-

Glad I could help and maybe you do need a professional but we are really helpful on here.1 point

-

Thanks @AndyGSi, I appreciate you having taken a look, Rotating counter clock wise (to open) @RichardHarris123 Thanks! actually that did the trick, unfortunately I ended up bending a bit the cover, but it did close which is good. I will need to take it to a Pro for sure Thanks for the help guys!1 point

-

Hello and welcome Feli. Not sure from the photo but it looks cross threaded, the right of the photo looks lower than the left. Try putting something like peg wood under the right side and gently push up, whilst rotating.1 point

-

Can you confirm which way you were rotating it when this happened? I'd say you've applied too much pressure while trying to unscrew it and crossed the threads. To be honest I don't know of any safe way to open this where you'll keep the threads intact but other may be able to help.1 point

.thumb.jpg.f10e4a6d92fb0d228b8aa21a2b0ad450.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)