Leaderboard

Popular Content

Showing content with the highest reputation on 05/10/23 in Posts

-

I'm trying to learn the polishing of screw-heads, bluing of screws and bluing of hands. Stumbled over this 48mm brand-less, key-wound, silver cased, Swiss anchor, Breguet hairspring, porcelain dial pocket-watch which seems to me a nice candidate for the time-consuming operation. The allegedly running movement doesn't seem to be tinkered to death and judging the winding-keyhole, not used "forever". The hands are nicely delicate for bluing, so what possibly can go wrong? And it has, for a change, a doggy on the case-back If anybody recognizes the movement (with such a long regulator-pin) or can put a date on the watch or its origin, I would love to hear ....5 points

-

3 points

-

Watching Leo Vidals video about how to blue hands, at one stage he uses copper / brass shavings to distribute the heat equally to the hands. Most of the materials, or kinda equivalents thereof, used in this video I already have. Missing were fine copper / brass shavings. I guess for the most of us, not too expensive to get. But if you live in one of the Nordic countries, where the national sport seems to be to make everything as expensive as possible, a small 500gr bag of mixed sizes copper / brass shavings on eBay, including postage, sits around $20, of which the postage takes the biggest part. As mentioned in the video, one has to take care of the possible impurities in those shavings and the finer shavings are better. Thinking about how to get copper / brass shavings cheaper, the idea came to me to chop up the fine copper-strands inside an electrical lead. You can cut them as fine/short as you like, as many as you like and they are clean, no factory sweep One meter yields more than needed; I do assume that these will work just as well and that they can be re-used .......2 points

-

Then again, I've done 8 years without a microscope. For sure, I could not have done 8 years without a decent timegrapher ......... Decisions, decisions, decisions ..........2 points

-

2 points

-

They are alright to practice with such as getting use to using your watchmakers screwdrivers, handling fiddle parts with your tweezers, using you eye glass (you will need a few of those with different strengths) taking notice of the wheel train and the keyless workings.2 points

-

You'd be better off starting with the ST36/6497 clone for the reasons that @ManSkirtBrew mentions. Also, the ST36/6497 clone (or the original ETA/Unitas 6497) has Incabloc shock settings which are easier to disassemble, clean, and reassemble when you're new. If you want something truly affordable, fun, and with plenty of inexpensive spares, however more fiddly to work on, then I'd say Vostok calibre 2409.2 points

-

Hey there Alex! I'm up in Hackettstown, northwest NJ. Whereabouts are you? I started with a bunch of Elgin 345 movements. They're great practice for all your fundamentals, but one thing I did learn is that parts are seldom interchangeable, even among the same year/movement. So if you need to replace something, it becomes a lot more complicated and difficult. When I later started doing Mark's course, I bought one of the ST36/6497 clone movements available on eBay. It gives you a known working movement, that way when you take it apart and reassemble, you know it should be working when you're done. They're also relatively inexpensive to get started. Edit: in fact, I'd be happy to send you mine to play with. It's just sitting in a drawer.2 points

-

Some people learned their skills under a stereo microscope with a swing-arm. Obviously a lot more expensive than what you are considering now. It also depends on what your aims are with this hobby? If your aim is to go "full-in", eventually you will end up with a microscope. You can try one of these Head Mount Magnifiers. I started with one, but quickly found out that the magnification quality was (severely) lacking for my needs. Decent lighting on your desk is a must, the brighter the better. Next to my microscope, I've been using (and still do) high quality (Steinkreuz) eye loups (2x, 3.3x, 5x & 10x), but I don't wear glasses. Perhaps somebody who does wears glasses has some other / better tips and/or experiences with eyeglass loups Often, not always, you get what you pay for .... In this hobby decent high quality screwdrivers, tweezers, magnification and lighting are a must. There is a Dutch saying: "Goed gereedschap is het halve werk", which translates to something like: " Good tools are half the battle"2 points

-

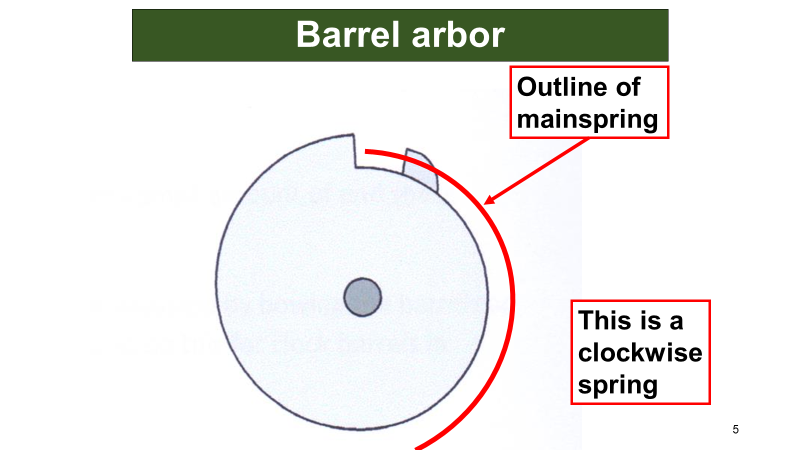

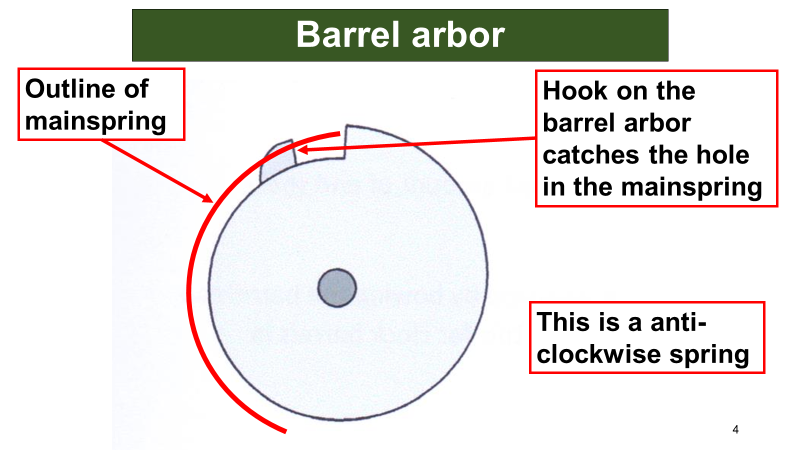

Yes, flip it upside down. To be honest, calling mainspring left handed and right handed is really confusing. 90% of mainspring are 'clockwise' mainsprings with the colour of the new mainspring holder facing towards you (UP). Pretty much all Russian watches are anti-clockwise mainsprings. Here's a pic of a clockwise spring. As the mainspring comes away from the arbor towards the barrel wall it moves in a clockwise direction. These mainspring are the most common. If you were to buy Bergeon anti-clockwise mainspring winders they would be marked with a blue mark on them. Clockwise mainspring winders, which are far more common have a red dot on them. When this mainspring which is hooked to the barrel arbor moves away from the arbor towards the barrel wall it is an anti-clockwise direction. All mainspring winders from Bergeon will be bought as clockwise or (counter)anti-clockwise, so calling them left handed or right handed can cause confusion in my opinion, but maybe it's a cultural difference and in the states you do refer to them as left handed and right handed. I'm assuming a left handed mainspring is a clockwise mainspring, because it comes away from the barrel arbor in a left handed way? It's not that, although I sometimes wonder! They have a deal with Bergeon, that if anything in the Bergeon range is defective there is no quibble about replacing it. I had the same with a Bergeon tool that broke and they replaced it without even wanting the old one back. Pretty cool. You can count on Bergeon. Don't count on Cousins though!.. lol The one place we have left in London is Gleave and Co (https://gleave.london/). which is one of the only places you can go and get good advise from Graham and Luke (Father and Son). It has a counter service and online sales. There is H S Walsh which has a shop in Hatton Garden, London, but they know very little when it is specific watch related stuff, because their staff are more jewellery related, I find. Gleave are the absolute business in my opinion. Nowhere left like it in the UK, which is a sad thing!2 points

-

Hi folks, hope you are all well. I'm going to guess that I am a common occurrence here in that I found watch repair videos on YouTube fascinating and such a relaxing way to pass an hour or so that I started to think about taking it up as a hobby. It doesn't look like the kind of thing you jump into without backup and expert advice, so after much looking around, here I am. I have a military aircraft engineering background (23yrs) and have good basic skills and engineering principles, which I hope will help me understand the mechanics etc. I have some basic, good quality tools for now and am looking for the best way to start. My aim is to eventually (one day) have the skills to renovate my grandfather's Timor (issued to him after he fought with the 8th Army in N Africa, he received the watch in 45 or 46, I'm not sure which). I wore the watch through the Falklands, Gulf War1 and in Bosnia - where it stopped working. It is dear to me so I have much to learn. Anyway, thanks for letting me join and I look forward learning from you as I go.1 point

-

1 point

-

...are you bored of my Crickets yet? One more today. This one was in rough shape with many missing parts. I bought a donor and debated about which watch should be the runner but here it is. Maybe not my best work but when I snapped it closed the beat was less than 1.5, a few seconds fast DU/DD and for an unadjusted cal 120 the positions were all pretty close though the nine o'clock is a bit heavy. It just didn't seem worthwhile to wrestle with it. I also discovered the alarm is much louder than usual. Perhaps something to do with the friction fit membrane gong plate instead of the typical case screw/gong plate set up. Haven't seen that before...1 point

-

It was my grandfather's, he was in N Africa and when he came home after the war he served another year or so and was issued with it in 45 or 46. He passed it on to me when I joined up, and I wore it through the Falklands, Gulf War 1 and Bosnia. It's more than earned it's keep!1 point

-

Having seen the video I have a few suggestions. Add a bit of thin oil (like 9010) to the pivot and pivot bed before burnishing. Do not place the burnisher on its edge (as seen in the video) as it will increase the risk of sliding up on and damaging the arbor of the wheel (I believe that happens in the video). Use long and not overly fast strokes with the burnisher rather than short and fast (as seen in the video). Inspect the pivot shoulder before and after burnishing. It should be perfectly flat and be polished black. That is, all light from the pivot shoulder should reflect in the same direction making it look black under a stereo microscope. When looked at from above a slight vortex pattern can be seen on the pivot shoulder but that, I've learned, is natural. It is extremely important to clean the pivot and shoulder before inspecting it. If you forget you can't draw any conclusions. I also found out that it helps to look at the Jacot tool from above while burnishing rather than look at it from the side. A few years ago I did summarize my conclusions about using a Jacot tool and asked @nickelsilver what he thought of it. Hopefully, it will add to the subject!1 point

-

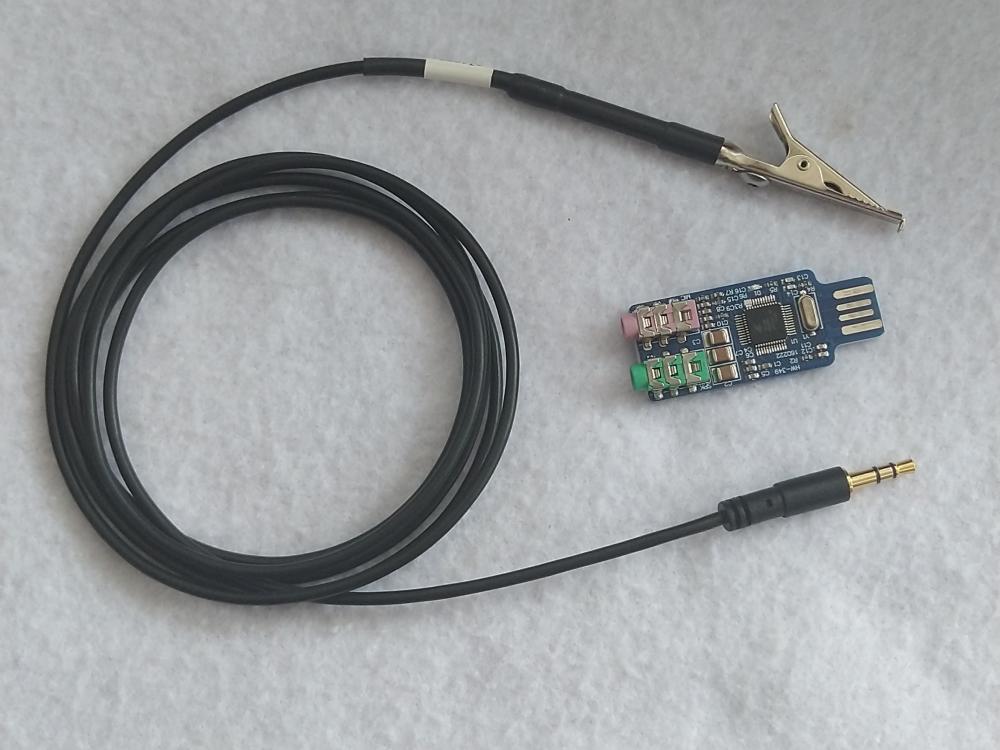

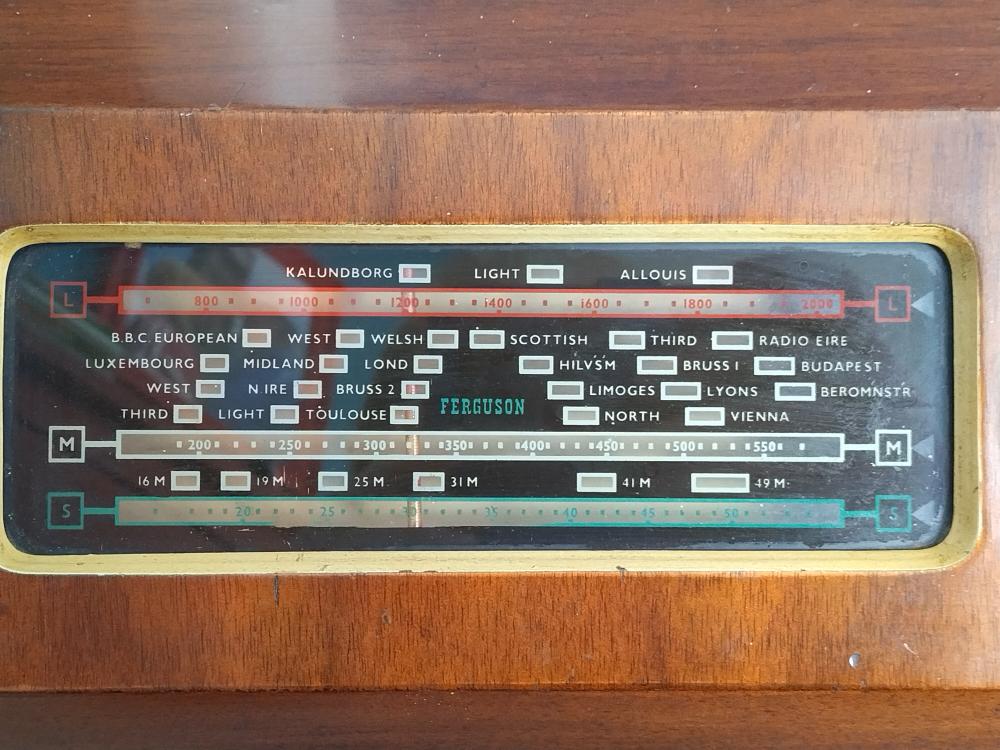

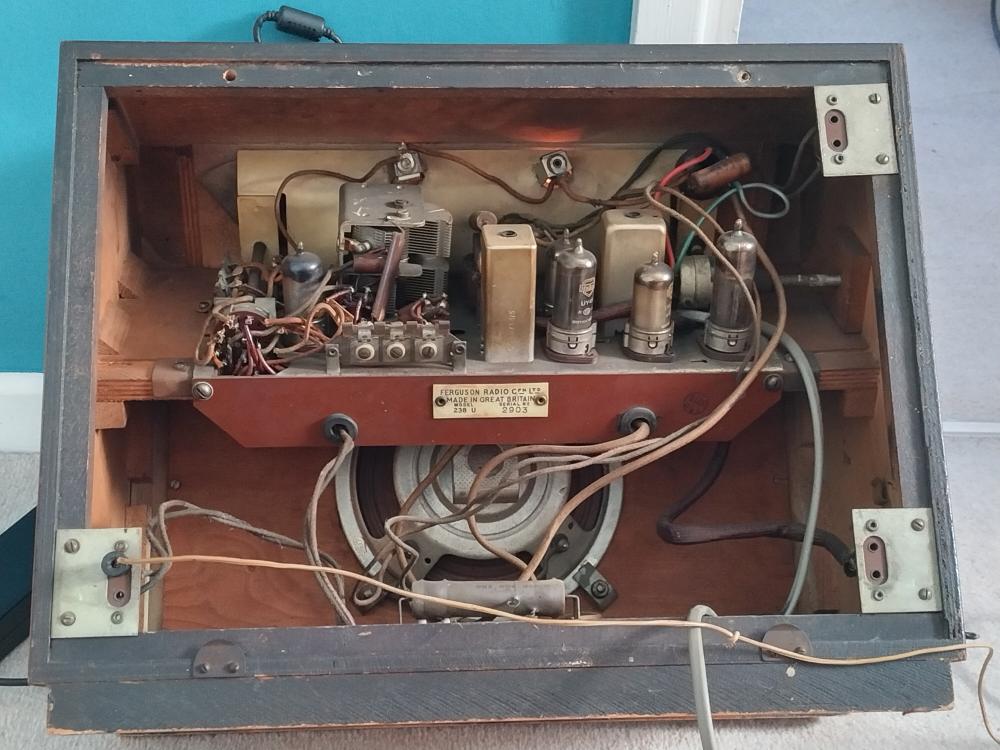

"The essentials for success are scrupulous cleanliness, a clear bench and good light. A clear bench is contrary, perhaps, to the ideas of the majority of watch repairers, who seem to accumulate on the bench many tools, some in use, and others of no immediate use, together with a confused collection of litter consisting of old material, work in hand, oil pots and a host of other things. The result is that tools get damaged or lost, and the time taken in rectification and search mounts up to many costly hours in the course of the year." Donald de Carle Watchmaking is only a hobby to me so here we dont talk about a commercial workshop environment, but having a chaotic desk just upsets me, and I cannot be in a mental state where I actually could work on a watch, especially if it is not mine. Almost an entire year spent with a chaotic desk and room full with watchmaker related books, parts, tools, movements, clocks, boxes, litter, dust, etc... i barely worked on watches.. sorry Stephen... However while I sailed other parts of the adventurous see of watchmaking I made my own attempt to convert an old timing machine microphone to work with my PC and the different timing software installed on it. It has a one stage amplification built into it and it sort of works, but not sensitive enough so does not really work with all of the watches only above a certain noise level. I have a number of these mics and while I was thinking what to do with them i contacted Steve Lunn from https://www.etimer.net/ . It turned out that he is another internet fairy I met on the world wide web and with his help now I possess one of the best timing software you could possibly have. The same one our common mentor @Mark has. The mic I prepared: The reading: The clip and USB sound adapter I received from Steve: The reading: All together: Contact and the USB sound adapter: 3.5 mm plugs: EB8420 Note the difference that I had to boost my mic with 42dB, the max i could set to make it work while it is on 0dB using the clip. Also note that the the clip has a different 3.5mm jack plug compared it to my own, therefore the clip has to be used with the USB sound adapter. Make it sure that you have it in your basket if you order the clip from eTimer. The watch has an EB8420 movement, ignore the hands found them in a bag only contained parts marked as scrap and I only have these, also ignore the beat error, I made an experiment with interchangeable parts and the complete balance comes from a different EB movement. The complete balance is nice because it has the option to set the beat error easily, I could not bring this down to 0 just using this option without further adjustment though. Maybe I just put the original back into its place. In summary: I am very happy, the clip is incredibly sensitive with very good amplification. I also can listen to the noise of the watch using my headphones or the built in internal speakers however i was advised not to use the speakers so they would not interfere with the sensitive clip. I am at the beginning of my experiment with the software though, received the pack many months ago, but tried it with a watch last night at the first time only. I only tried a few features it has, looks very promising, I probably try the long run diagnosis next. Well this was one of the many other reasons why my watchmaker carrier was not progressing enough: Found a manual with circuit diagram for it but I only needed to replace its electric plug and to gently blow out the dust with my compressor.1 point

-

Once again, thank you all. Sorry for the rushed post above but I appreciate the fast responses! I had added those Elgins to my eBay watch list before I joined here. The alert popped up this morning that they were closing and they were still very cheap. I actually went for them but lost by a dollar. I'm assuming some sniping software beat me. No big deal. I will definitely start with the ST36/6497 as has been suggested. @ManSkirtBrewThank you so much for the offer. It's very kind. I will send you a message. This is something I love about most forum communities is people are always quick to help! I'm currently in Hamilton, NJ (just updated my profile) but I grew up in Vernon so I'm very familiar with your neck of the woods. I actually just got home from a meetup with another watch collector from my other forum. Lots of fun and talking watches!1 point

-

I agree with @GuyMontag, a stereo microscope is a game changer. Once you've used one there's no going back.1 point

-

1 point

-

That's quite ambitious to do a 4006 as your first watch, lots of levers and springs. As it sounds like a cherished watch, and it's your first service, I would personally get experience servicing simpler movements before having a go at this one. I waited until I'd serviced quite a lot until I moved on to alarm watches. Here's the service guide (the notes in yellow are mine) 4006A.pdf The Seiko part number for the alarm spring is 416805. If you can't find one, the best (and cheapest) option is the measure the existing one. You only need the height and thickness accurately. The length doesn't need to be exact - just your best estimate will do. Anything sold "Barrel Complete" should have the mainspring installed. Finding parts is usually not difficult, once you figure out where, and how, to look - You found Cousins, but I find the Jules Borel database very useful - it tells you which parts are common to other movements : http://cgi.julesborel.com/?_ga=2.99547678.1292671413.1673701735-126716363.1672876102 For general reference on movements Ranfft is useful http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Seiko_4006A Also you can find technical manuals on Cousins, and places like https://watchguy.co.uk/cgi-bin/files Some of the fiddly bits :1 point

-

1 point

-

Hey I just acquired a Paulson without a tailstock. Got it cheap. Don't need it but I have an addiction. Anyway, I was gonna search for a tailstock. Based on your comment from 2018, any Paulson or Leinen tailstock should line up. Correct??1 point

-

I wear glasses but they aren't needed when using magnification. I remove my glasses and then wear magnification glasses like these from CousinsUK. I bought two sets and then combine 3.5X magnifier glasses. You can see the setup in this post on WUS (written almost six years ago). The magnifiers you link to I would expect to be too heavy and clunky, and get in the way if you get close enough to the movement.1 point

-

I’ve been watching YouTube videos on watch repairing and restoring and have decided to give it a try. As if I needed another expensive hobby, lol. Anyway, pleased to meet y’all.1 point

-

1 point

-

For those considering the cheaper Chinese-made mainspring winders—Chinese-made handle is compatible with Bergeon's winders. You can see from the picture the dimensions between the Bergeon's handle (Left) and Chinese-made (right) is almost identical. While Bergeon's handle is thicker, the Chinese-made works just as well (perhaps don't last as long, depending on your usage). Also, the Chinese-made handle comes with both right-hand and left-hand slots in one handle.1 point

-

Agree completely with the above I started with a loupe, then discovered that stereo optics made life much easier as they offered depth perception so I graduated to a head visor type of optics which I still use today for 80% of my work. I do wear reading glasses and find that I can use the visor with or without my glasses, so most times I use without. I do have a boom type stereo microscope which I use for any fine work like making sure the pivots are in the jewel holes and installing the pallet fork etc., which was a game changer. I tried one of those desk magnifying glasses with the built in light which quite a few people use, however, I have difficulty with it as my eyes have to sit too far away (maybe I need longer arms?) but the thing I am looking at is too close to the lens and I keep crashing into it with my tweezers. I am sure that I am the problem and just haven't taken the time I should have to get used to it... maybe one day?1 point

-

1 point

-

It doesn't always happen but Its nice when there is a simple fix. I Hope this is for you its a decent movement shame the dial was a bit battered.1 point

-

I asked myself that question many times until I saw Kalle Slaap from Chronoglide show an amazingly simple and effective way to determine if the side shake is correct.1 point

-

The stuff he knows and is experienced with looks immaculate, but there's a video where he slaughters and then pings a clip for the day wheel with a pair of hand levers. That's more than perfectly fine with me. I appreciate that he includes it so that I don't have to make the same sorry mistake.1 point

-

@Waggyit might be worth checking Vintage Time Australia, they have had seiko date corrector wheels made for various movements I believe. Metal, not plastic. Tom1 point

-

I use water-based solution and IPA, the drying temperature can uphold around 70 celecious, most of time it take really fast to dry up parts (20 secs).1 point

-

For your date change issue the first place to look is the little day/date corrector star wheel. This is a common problem with 5606's and arises because on some movements the star wheel is made out of plastic, which over time degrades and becomes brittle. It then splits and the quick set stops working. On some some movements the wheel is actually made out of metal (thankfully on both of my 5606's they are metal) but whether this applies to the earlier movements and they were later changed to plastic to save money, or they started off as plastic and then changed to metal because the plastic wasn't resilient enough who knows? I suspect the former rather than the latter. The issue is documented here, and a solution is documented here.1 point

-

Lost of bad experiences with Cousins in this thread, so I though I'd share my positive experience with their customer support team! I purchased a set of Bergeon screwdrivers with the rotating base, and noticed that the base was very "crunchy" and didn't rotate properly. Sounds like the bearing had taken a good beating. I told them this and they sent a new one. They didn't even want the old one back. Maybe it depends on whether the support rep is having a bad day or not?1 point

-

Here is my watch of today - I made it myself from all new parts, I think I may switch out the hands to ones with white lume as the plain silver doesn't show up very well at night (see below and tell me what you think), ie the black polish on the hands is black most of the time (see minute hand below) unless it catches the light and turns white (see hour hand in picture below) which is the only time you can see it on the busy backdrop of the dark skeleton movement. It's a Seiko NH72A skeleton movement and an 'Ali Express special' strap/case, here are the hands I am thinking of switching to with white lume and red seconds hand.....opinions:1 point

-

1 point

-

Just bought myself an early birthday present. I've been eyeing Seiko 6139 series chronographs for a while, and finally enrolled in Mark's level 5 chronograph course. Been keeping an eye on eBay and the plan was to piece one together from various watches and parts, but then this 1972 6139-6012 came up in nice shape, with the railroad bracelet, and as far as I can tell a reasonable price. It'll be my first chronograph, so I'm looking forward to it!1 point

-

1 point

-

Not a watch, but a screw-head polishing tool. Offered on eBay as an auction, but the seemingly incomplete Lorch & Schmidt polishing set with a below mid-starting price got no bids, apart from my one in the last 5 seconds. However, only when enlarging the other sellers pictures, it seemed as if there were more collets hiding underneath the polishing disks and the polishing tool. This turned out to be the case. After quite some TLC of the parts and the wooden box, the set turned out to be like this; Less than 1/2 price than what these (be it fully complete) set are currently going for on eBay Three parts, for polishing screw-thread-ends, are missing ...... I can easily live with that1 point

-

A slightly scruffy "La National" French cylinder pocket watch, with a nicely decorated main plate, is on its way. Its missing its crown, stem and bow, but otherwise looks complete. Hopefully with a little care and a clean and service, it should run. I probably have something suitable to replace the missing parts with. It came in 14 pence over the 404 club budget, but with inflation the way it is today, I think we may bend the rules and allow it in to the club.1 point

-

1 point

-

The only one I follow is Chronoglide Watchmakers.1 point

-

1 point

-

I have recently used a jacot tool to successfully re-polish a badly worn pivot in a pocket watch the first time in my life. I have watched Richard's videos about it and I also went to a book printed in the same year I was born in 1976. This book is written in Hungarian and was one of the book used by the state sponsored and only one watchmaker school as far as I understand. (To my knowledge you cannot learn watchmaking any longer in Hungary as of now.) I scanned the corresponding pages as how to re-finish a pivot including the usage of a jacot tool. It was a great help to me so I thought I share these pages with you. After scanning the pages i sent the pdf through a pdf to txt engine then sentence by sentence I translated the Hungarian text to English. I learnt watchmaking in English and it might sound strange but the Hungarian name of the parts and methods were unknown to me. This added some more difficulty on top of the fact that my English is far from perfect. I am writing this because I am not sure how good the end result is. If anyone feels that could correct the text so it would be more readable or would make better sense please do so. Enjoy if you can. jacot_tool.pdf jacot_tool_Kopasok_javitasa_magyar.txt jacot_tool_repairing_wear.txt1 point

-

The tailstock in the OP is a Paulson. All the Paulsons had the curvy phenolic knob, all the Leinens had brass. Doesn't really matter, as they are all Leinen regardless of name, and the tailstocks will line up on any Leinen WW lathe (one of the very nice things about Leinen)- as long as they have the straight black locking levers. Earlier Leinens had a very slightly different bed profile, these are spotted by more ornate non-black locking levers.1 point