Leaderboard

Popular Content

Showing content with the highest reputation on 04/15/23 in all areas

-

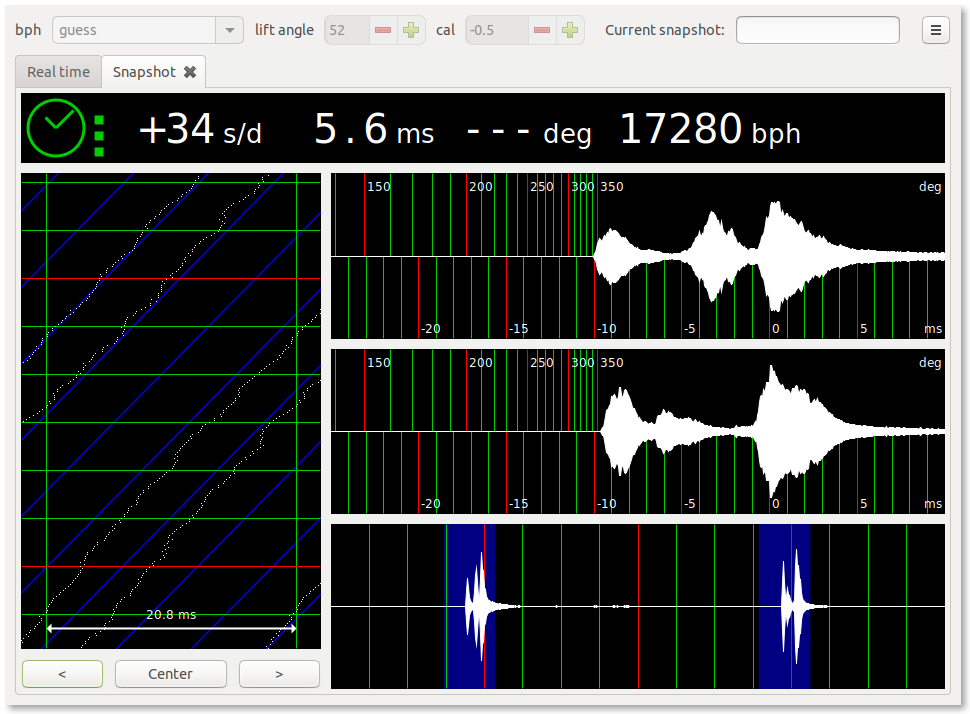

@Waggy I thought I had a Newmark in the collection, so I tool a look and sure enough, not only is it a Newmark, but it is also an Aviation. I even posted about it back in 2019 These are pretty thick watches, and I must admit it does tick pretty loudly, but lets call that "wrist presence" and assume it is a good thing. Its certainly not as big or obtrusive as one of these newfangled "smart" watch gadgets. Your post finally stirred me into action and I replaced the crystal on mine today. I must say it has made a huge difference to its appearance. The period correct strap also got a bit of TLC, and I gave it another polish for good measure. Bizarrely it appears to run at 17280 bph, which makes it a bit of an odd ball to say the least. Assuming this is correct, (and five minutes of "research" on Google suggests that it is correct) that may be why your time grapher was not sure what to make of it. Some more info about Newmark can be found here -> https://chronopedia.club/Newmark3 points

-

Very much new to this, but I am dedicated. Have spent some money on tooling to include grabbing up vintage tools when I can. Have a vintage K&D staking set, two vintage screw polishers, and an older undercutter. Other tools are new to include mixing in Bergeon and Horotec as well as generic when it makes sense. I have a fairly good size collection of around 50 (cased and straped) watches so far, and somewhere around 30 movements in various states (cased, no case, working, few not working). I have been practicing some acrylic polishing as well as cleaning case parts in an ultrasonic. My test run on working a scratched acrylic on a Benrus that is running very very well attached. A few deeper scratches to attach but considering I did this in about 20 minutes running from 800 to 10,000 grit pads (hand) not bad. The 3L Vevo ultrasonic came in today along with the L&R ultrasonic cleaning solution, so I put in a gross case and stem from a Bradley watch (EB 8800). I am using the jar method, where I put distilled water in the tank and the cleaning solutions in jars with the parts. That way I don't have to dump out the solution constantly; I can seal up the jar and wait for the next run and of course do concurrent clean/rinse if I get staggered. The L&R rinsing solution is a day or two out still, so I just rinsed with water for now - this was a test run on a watch I will service and then flip. I will catalog my journey here, get tips and tricks from you experts. I have the oils, oilers, tools and gumption to start taking down some movements, so game on!2 points

-

evaporates or abducted by aliens? I once had a Rolex watch that I hadn't service for 25 years. I knew exactly how I had oil that before it was 9020 for the entire gear train and 9010 for the balance and probably the escapement. I really wasn't worried about it because I only ward a couple of times a year. Then 25 years later it's time to service it again. This is because I have a fancy new witschi timing machine like it do a before and after and this was at a time when the cheap Chinese machines didn't exist. So when I went the service my watch I notice that the 9020 a synthetic oil was still visibly there I assume it was still functional. The 9010 was long since missing. Under the dial the PML stem grease that I used at that time if I didn't know better I would've thought I was assembling the watch because everything looked perfect degrees was exactly were supposed to be it looks very functional. Then as far as the 90 10th of that operating the indication is that it spreads with time. All lubricants at some point in time will spread it just how fast. This is why if you look at anything today it talks about 9010 they've epilam the balance staff the jewel assemblies whatever to keep it from spreading. Then if you work on vintage watches like I do you will see the effect of organic oils they typically just harden up with time the watch doesn't run. This is why classically at least up until now cleaning a watch would fix the problem is because the oil was just bad and it just needed cleaning. But now with modern synthetic oils were they don't go bad or they get abducted by aliens and no longer do their job you can literally run your watch right into the ground until it disintegrates and you won't notice until it stops. Considerably more common on automatic watches especially early ones with a lot of metal on metal bearings.2 points

-

Any style of bespoke furniture doesn't come cheap. A lot of the cost will come from the quality and type of timber used. But if you want something really nice to your own specifications you will need a reputable joinery company with a well kitted out workshop. Or as a minimum a highly skilled bench joiner with a good home set up. There is a lot of time involved in the final planning of the design and preparing a cutting list before a single tool is lifted. Certainly not your average joiners task unless you want something basic and rustic.2 points

-

No matter how wonderful a work bench may look, you have to make sure it is the correct height for you it is very important that your posture is correct otherwise you could end up hunched backed, make sure your seat is adjustable. No matter how big your bench will be I can tell you it will never be big enough. Go to at least 3 carpenters and get estimates then pick the middle one.2 points

-

For fine detail work such as watch cases, 3D resin printers may be a better option. A bit more faff and there can be a bit of a smell from the resin, but the end results from 3D resin look superb. Small resin printers are not that expensive.2 points

-

As it appears in the DeCarle image ia correct. Yours is still out too far.1 point

-

I do not believe there is one answer for this, a lot depends on what you work on. I have come to believe, possibly, that modern watches use m-fine screws. However if you are doing vintage it can be all over the place, between manufacturers and even within ranges they had their own specific threads. I have seen a post by @nickelsilverthat he knows a clockmaker with 500+ different screw making plates. i think this maybe why you are not getting answers on this topic. Tom1 point

-

1 point

-

There are three aspects to making a microscope-camera connection. The first is the one that is basically a plumbing problem where you need to fit up the proper diameter and threads with one or more adapters to make a physical connection. The other is the magnification factor, which is generally noted on the adapter. The final piece to the puzzle is the resulting focal length of whatever lenses ended up being in the light path, and whether or not they can be adjusted to focus properly on the camera sensor array. It's possible to solve one or two of these problems but still end up with the third being unacceptable if the choices aren't compatible. Some connectors have no integral optics, so it's just the lenses in the microscope and trinocular mount that are sending light through to the camera sensor. Others may have their own internal lenses, like the 0.35X connector mentioned above, which will establish a new focal length/image plane. Finally, some adapters don't have integral lenses but are meant to fit over an eyepiece lens and then it is the magnification and focal length of the eyepiece that will have to be matched by the camera placement. The top diagram in the drawing appears to be an example of an eyepiece adapter, so it will have a much longer physical dimension than the direct coupling adapters. There are a lot of variables, so the easiest path is to match a particular camera/scope/adapter combination that has been documented to work together to avoid reinventing the wheel. Also - this might have a more noticeable effect on a high-mag microscope than it would on a dissecting-type scope, but adjustable eyepieces can play a role in getting the camera parfocal. If only one of your eyepiece lenses is adjustable, then you can really only use it to match one eye to the other. However, if both are adjustable, then in combination they both can be adjusted in tandem to one end of their adjustment or the other, which can help you get to that final sweet spot where everything is in focus. Worth playing around with in any case.1 point

-

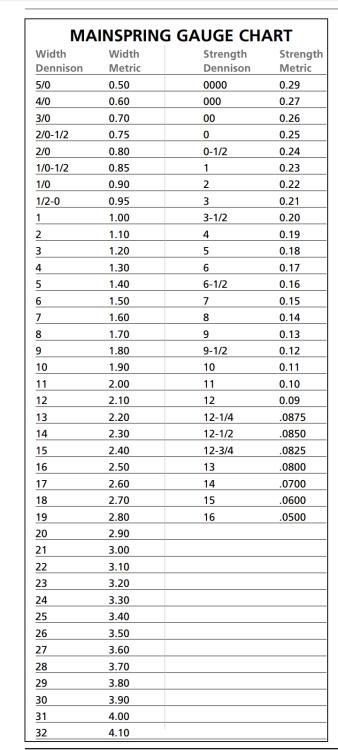

automatic means a watch with self winding and your watch is not a self winding watch so a normal bridal would work and that's what they would be indicating. Another thing I like to do for stuff like this is the look in the mainspring catalog and see what they recommend. sometimes I even like the look and a second reference all of the problem with the second reference is the listing is in Denison and I'm too lazy to go look up the Denison chart but it does tell us the same thing I believe then once you get the mainspring part number you go back to cousins and there is your mainspring it even says it's for your watch plus it's in stock http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Cyma_7751 point

-

I stumbled across a new channel that is just a few weeks old, it is run by Cameron Wies a young American watchmaker. Tom1 point

-

Hi guys and gals, just registered and saying hello, I've been an avid reader on the forum and found it very helpful, lots of people with tons of knowledge, I only got to the watch repair scene recently after finding my old seiko from the eighties and fixing it up, since then it's gone crazy, bought loads of tools and watches and enjoying every minute, wish I'd done it years ago before the dodgy eyes set in, luckily I haven't got the shakes so that's a bonus, I've stripped and rebuilt half a dozen autos already and very chuffed with the results, not bad for 6 months in, look forward to future posting, cheers1 point

-

Addictive it is. Great fun. No problem with my eyes. No eye-strain at all. I use a head magnifying head set with LED. Never look at the watches without it on. I use reading glasses 1.5 which I keep on. Then I use the double lenses, 2.5 and 3.5 for normal work, and the loupe for checking pivots and jewels. LED is a boon. https://www.ebay.co.uk/itm/404167874198?hash=item5e1a485696:g:z-YAAOSwv-5j7z1i&amdata=enc%3AAQAIAAAA8IlOhxI4B%2F26Yd0W8vnK2aD3GEdV%2BiCMWZPHKqmkctk%2Bt72pJFk54kEWB8pzOlQaElcpEK%2BilKp%2BvAufAL5hTNHm4xfLb2wlc%2BnD8IRPbkCZarYKMP7wt1y9X2ZTtdzX9JXIdnWdCQH9NOUPCpIEigCt9yQAbXMjU485159Pck8OZB0iZ9PaWKH97T%2Bf1NOZy%2FV9MWZly9KhT%2B9jxK9nBuKNhI%2BGb8hJkUJS0HUbanSVgUJVEoZtH0QvXhuW6N6qIhNBnc0lZXkqiFGzztMiCQEIBBo6qSOPbUxt6mBOFlUkvk007AxTrEOVEUx6xGyu2w%3D%3D|tkp%3ABk9SR9rDodTwYQ1 point

-

an example of this was my sisters 21st birthday watch that she gave me to look at that stopped working many years ago. She is now 65, the watch was a tiny Everite that had a large beat error that wouldnt allow it to start up on its own, so an easy fix. It had never been serviced and the oil was still fluid sat in the jewel wells over 40 years after it was manufactured.1 point

-

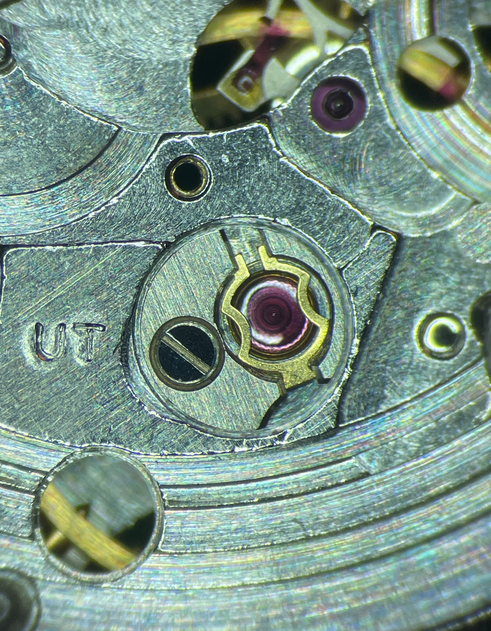

Oh no, that would be way outside my comfort zone! I simply unscrewed the disk that holds the cap jewel assembly and shimmed it with a couple pieces of thin foil. Shimming the balance cock would probably have worked as well, but I believe it would have been more difficult due to its geometry. Side-note: Do you know why the lower assembly is held in place by a disk such as this? The leading theory is that the balance was replaced at some point, and that the new balance staff was slightly longer than the original one, but it's hard to be sure. Anyway the movement runs with ridiculous amplitude now - well in excess of 330 degrees DU/DD, and it does knock a bit at full wind when I move my arm too much. Maybe someone replaced its spring with a slightly stronger one to combat the binding balance? I should inspect the mainspring again... one day! There are too many projects on my bench.1 point

-

1 point

-

Many thanks. I found a parts list for the 2450 series of movements and spotted the centre seconds pipe, which is actually detachable and friction fit. I think the similar arrangement on some old Seiko movements are riveted in. I managed to get the old one out with a pin vice and the new one in with a jewelling tool. So far everything is running well again.1 point

-

Same here. It took me a bit of trial and error of trying different things, but I can just barely get the full movement in frame, in full focus using the 0.35X, adapter, and 0.5 Barlow.1 point

-

Like thor447, I also have the same adapter and it is a 0.35X (not the 0.5X that you have) and can adjust focus on the adapter. I can get perfect focus on my microscope with the 0.5X Barlow attached.1 point

-

For the majority of its lifespan, the Benrus company used primarily ETA movements in its bread-and-butter mens watches, up through the era of the 2750 family. Their second-tier Belforte line made the jump to Japanese movements (Seiko-made but branded as Qualco) first but then the main project lines went over as well, right before the quartz crisis finally took down their sale of any manual movements. If your dial is original and the watch is legit, it must have been one of the last gasp products that used the Benrus name but really had little or nothing to do with what went before - I think of these as "Benroids." There are also a lot of outright fakes with Benrus on the dial but nowhere else on the movement or case that are fitted-up with generic ST96-type movements. So depending on what bare Benrus movements you have, the ability to fit them up in a case like this would vary.1 point

-

I had the exact same problem. I ended up purchasing this adapter to manually adjust the focus on my microscope camera: https://www.amazon.com/gp/product/B088C19QV6/ref=ppx_yo_dt_b_asin_title_o04_s05?ie=UTF8&psc=1 Unfortunately it did not have the correct thread to mount to my camera, so this little $6 "C-CS" 5mm adapter did the trick: https://www.amazon.com/gp/product/B096FG8X78/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&th=1 Both pieces combined allows for easy manual adjustment on my AmScope SM-4NTP with a cheap Amazon Hayear camera: https://www.amazon.com/gp/product/B07NSNQSGK/ref=ppx_yo_dt_b_asin_title_o04_s05?ie=UTF8&psc=1 The same setup will probably work for you, you'll just need to confirm the mounting/thread type for your camera.1 point

-

I’m keen to see what can be produced by these processes. I’ve never done any 3D printing design and don’t have a 3D printer though, so this may be a long term ambition. As @RichardHarris123 highlights re: the number of movements without a case, this could be a cost friendly method with significant scope for designing the desired mould. @praezis is spot on with the shrinkage of casted metals but i wonder what can be achieved by figuring that 2-5% into the mould. I’m working on some jewellery that will be casted in the next few months and will see what my caster thinks about it. There’s an compelling thread on 3D printed mainspring winders, I’d be interested to see any pics of attempts to use 3D printing for cases as well.1 point

-

If the end-shake of the 4th wheel isn't too bad you could possibly instead move the 3rd wheel a bit away from the fourth wheel. If the end-shake of the 3rd wheel is already good you would have to adjust both jewels equally. As a rule of thumb, the end-shake for small pivots should be approximately half the diameter of the pivot and about 1/3 of the diameter for large pivots .1 point

-

That is cool! I wonder, if when it was made did it have a thin piece of wood where the plastic is now? Maybe that was just added later when the wood door broke. It sort of reminds me of the little things they had for the telegraph operators that allowed the sound to be concentrated a little more to ease them hearing it (telegraph sounder box). Although, I think the way those telegraph sounder box was also to direct the sound more to the person working the telegraph and to be less distracting when there were multiple telegraph machines in a room.1 point

-

He is a funny guy, when I brought him my first watch for service (it was an old Seiko 5 with 7009 movement) he disassembled it in a matter of seconds. He just unscrewed every screw he could, turned the watch case over some bowl, and patted the case. The whole watch fell apart in the bowl. I was horrified. But the next morning when I came to pick up my watch it was working perfectly, and it continued to do so for years. Nobody ever complained about him, except my father. My father said that he stole the Omega logo from the dial of his old Omega pocket watch 30 years ago, and my father likes to remind him of that every time they see each other Watch service in my part of the world costs approximately 30$ Thanks, I'm trying my best1 point