Leaderboard

Popular Content

Showing content with the highest reputation on 01/01/23 in all areas

-

6 points

-

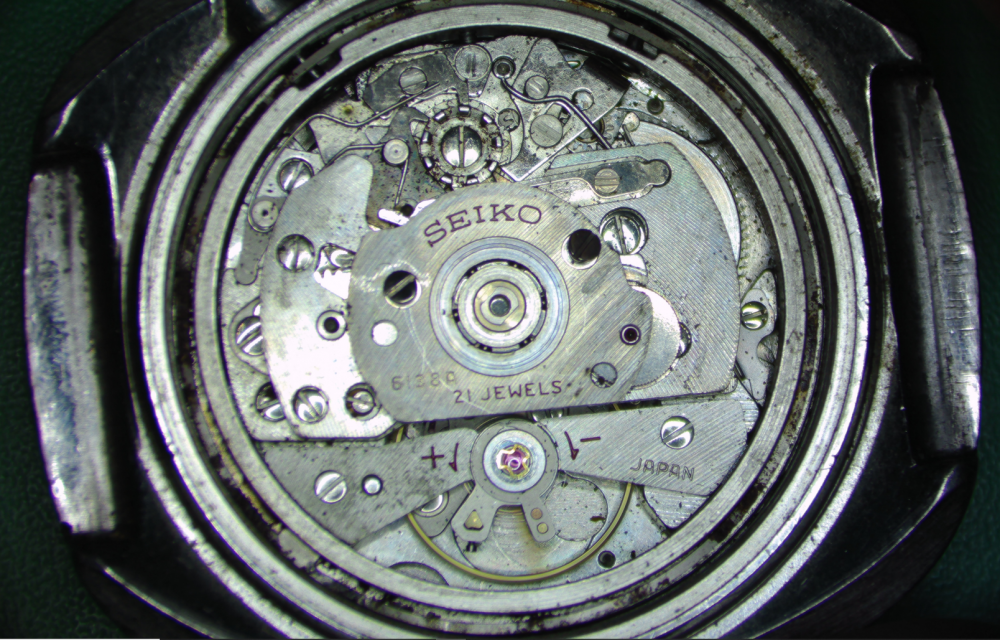

Tonight I was finally able to spend some time at my bench and put my 6138A Seiko dual register chronograph back together. This is from a 6138-0010 (UFO) that I picked up a few months ago. The movement was originally covered in oil, spots of rust, and looked terrible. It cleaned up pretty well. I replaced the mainspring, replaced the upper barrel arbor bushing with a jewel, and replaced a broken hour fly-back lever. This was my most ambitious attempt yet, and I'm really glad the nights of watching videos, and studying the service manual cover to cover about 5 times paid off. This movement went back together really well and is now running in for the next 24 hours before making any further adjustments. Before: After:5 points

-

First of all on this New Year's eve 2022/2023: Happy New Year! I just finished this book. Frankly, I am a little surprised that I finished it because it was not delivering as expected...was hoping for more clocks and less philosophy. (This is not a book review.) I found on page 167 a sort of synopsis of the tenor of the book: "The standardization of time and space is all about maintaining order, controlling people's behavior, making money, securing political power, building empires and waging war." A bit of pathos, no? Yeah, the book is about how time pieces are instruments of oppression. Well, like I said...I was not hopeful about finishing it, but I stayed the course hoping for redemption. Should you read it? Dunno. There is some interesting clock history (Gog and Magog, e.g.) and as a result of this read, I appreciate that time-keeping contraptions have been around for quite awhile (not referring to sun dials and such...the mechanical ones). I think that I need time for this book to sink in before I get its full impact. My mom would have enjoyed it...she was obsessed with time. She has now gone after living 98 years on this good earth (2016). Attached is one of her poems "Damn Time"4 points

-

Typically with self-contained timing machines they do a pretty good job. The variety of apps for whatever tend to not do a good job. The key to all of this is getting a good clean signal into the timing machine. For instance the Seiko mentioned above was that in its case? Getting a signals out of a watch case can be problematic at times. Seiko a lot of times has plastic movement ring is they don't transmit the sound well. Which is why you're supposed to place the crown against the where the sensor is on the timing machine. But not just Seiko cases I see a really heavy Rolex and other type watch cases they just don't transmit the sound well. We had a Seiko come in they get a regulation on it it looked horrible in the case out of the case it looked wonderful. That's what happens we can't get a good clean signal in a classically the numeric display, the graphical display and your visual eyes of whatever your observing all should look similar. Then the timing machine is probably right. Typically was super low amplitude the timing machine looks at the wrong part of the waveform and gives you a really nice happy amplitude because reading the wrong part of the waveform. This actually comes up well for me quite often on the witschi at work because I'm doing vintage. Fortunately the witschi at work has in our oscilloscope mode and it shows where it's triggering from. So I can see whether it thinks it's triggering in the right place are not. Unfortunately with cheaper witschi machines or Chinese machines is no oscilloscope and we have no idea what the machine thinks it's triggering off of. So the most important thing is is to get a good clean signal into your timing device.4 points

-

It started snowing.. ... Heavily... ... Really heavily ... ...so we decided to drive down to Stirling anyway to see the fireworks. My friends in the Canada office fully understood. It was well worth the effort. I'm not sure about the whole human race becoming more civilised as time passes, but maybe some of us are. Particularly round here, I would suggest. I guess it depends on your definition of "civilised". Happy 2023 everyone. Oh.. and "the algorithm" suggested a few hours back that I should read this. https://www.npr.org/2022/12/16/1139780043/what-is-time-physics-atomic-clocks-society3 points

-

On the 6138 the lower arbor is already jeweled. The upper arbor port in the barrel bridge is just a bushing that can be pushed out and directly replaced with a jewel without reaming. On the 6139, both upper and lower’ arbor ports are bushings. The lower would have to be reamed, but if you have a 6 mm OD stump, that is the perfect size to sit in the recess on the main plate so that it doesn’t move while you are reaming it out. I actually have one of those on the way from VTA for a 6139-6005 Pogue that will be serviced soon.2 points

-

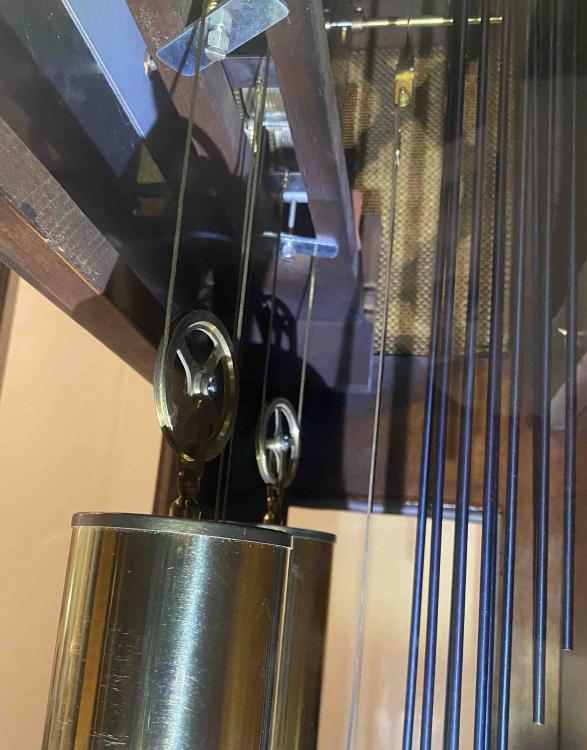

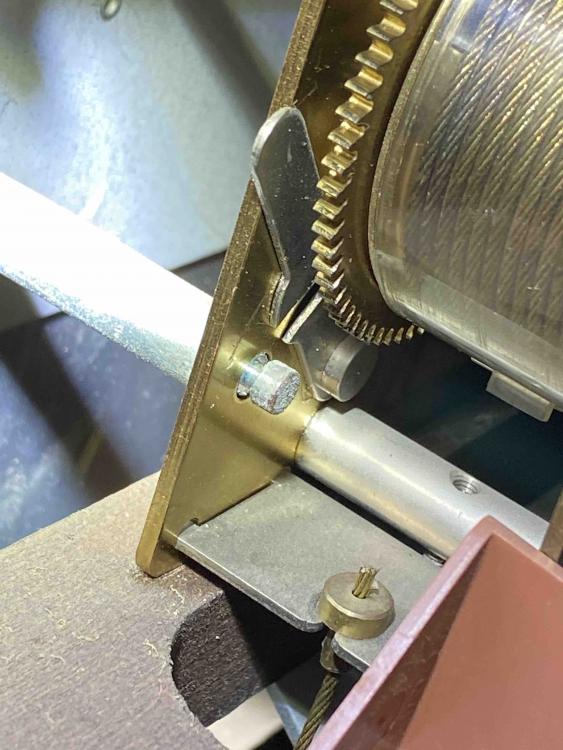

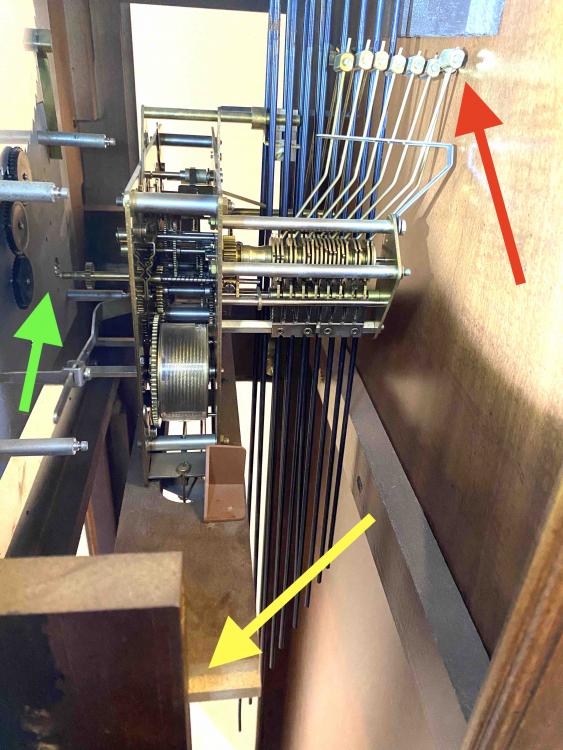

I have a grandfather clock that stopped that I needed to take the movement out to service it. I could not find instructions anywhere for this type of clock case so thought I would post how to remove the movement. The back of the clock does not have a rear service panel (even though the user manual that came with the clock says it does!), and the hood of the clock does not slide off the front as in older clocks. It was not obvious how to remove the movement on initial inspection. The movement is an 8 day cable driven westminster+ chime, and was distributed in 1980 by Pearl Clocks from Memphis TN. The markings were #84, with the number 1161-853A, which led me to understand that it was a Hermle movement. I have the Hermle Service manual but it is vague about removing movements because each clock distributer will have different ways to install the movements. Some through the side, back or even front. For this movement which has striking arms on either side of a set of chimes that runs between them, it did not appear that I could remove it from either side. The back of the clock case is solid (no access panel, so I had to figure out how to remove the moon face plate. Step 1, removed the weights. The 10.5 inch pendulum bob meant there will be two 7.7 pound weights and one 9.9 pound weight, that must be replaced in the same positions you removed them from. They are hooked to the wheels right above them and simply need to be lifted off. I used gloves, labelled each weight with a piece of tape on the bottom of each, and placed the weights in socks to protect them. I put them in the bottom of the case. I gently disconnected the pendulum from the hanger by lifting up so I could clear the post the pendulum hangs on and put it in the bottom of the case as well. Step 2, removed the hands. I set the time to midnight, just as general practice. (in case I don't have to fully disassemble the movement). Finger tight nut over the minute hand was removed, and although I could have pulled the hour hand off, I used a clock hand puller to not put stress on the center wheel. Step 3, removed the panels on either side of the clock. You need to grasp the panel and push it up to get the panel out of the bottom slot it sits in, the pull it down to clear the top slot. Finally twist it and take the panel right out. Note: panels on cases will vary, but that is how the pearl case from 1984 worked. Step 4, unlocked the face from the movement. Four sliding levers connect to pillar posts protruding from the dial. (sometimes there are pins that have to be removed from the posts instead of a sliding lever). The first picture shows the lock in place, the second is with the piller post unlocked. Step 5, removed the screws attaching the seatboard from the case (the wooden piece the clock movement sits on). Step 6, pushed the seatboard with the movement back a bit in the case so the center wheel was inside the dial face. This allowed me to next remove the dial face once the center wheel shaft was clear. I could only move the seatboard back so far before the striking hammers were pressed against the back of the case. The yellow arrow shows that only have moved half of the seat board slot out from the case. The red arrow shows the reason I could not move back any further because the striking arms are pushed up against the back. The green arrow shows the center wheel arbor clear of the dial now. Step 7, removed the dial (and moon dial) assembly. Four twisting plastic lever hold the dial pressed against the front of the case. I twisted the top two and was able to push the dial in and push the dial up to clear the slot it sat in. Then twisted the dial to remove it out the front opening. Step 8, loosened the two bolts that hold the movement in place on the seatboard. Ended up removing them completely so I could easily remove the movement without hassles otherwise. Note: Before I loosed and removed the bolts, I marked on the seat board where the movement sat so I could replace it in exactly the same place as before. Then simply leaned the movement forward making sure not to mangle any of the bits that were hanging off the clock. With the movement out I could now actually read the movement number that was not readily visible and service the clock properly. Hope this is helpful.1 point

-

Another piece of (translated) horological poetry, berating time and its measurement. This one from Plautus in Roman times. Source - https://en.wikipedia.org/wiki/History_of_timekeeping_devices1 point

-

In a movement holder, resting on its plastic spacer ring. I placed the stem against the adjustable metal bracket . I have yet to remove a movement from an actual case even though I’m 5 months into the hobby. Practicing on old movements rather than watches for now. On my 4th movement, an 1104A, after two 7S26As and a 6497 Chinese clone. The 1104a is working after preliminary cleaning and reassembly so I will service it. I took another 1104A apart (I’ve got three dozen of them) to (successfully) replace the balance staff, repin the hairspring stud etc, and am currently mangling its hairspring as I attempt basic bend manipulation. Have a Chinese Horia clone so will practice adjusting and replacing jewels as well as more balance staff work. Also got a size 1 right handed Bergeon winder so will learn to rewind mainsprings as well. Slowly developing my skillset before tackling my intended project watches.1 point

-

I saw the title and had to click on it. And, wow, that is pretty cool! I may have to see if I can find one myself.1 point

-

1 point

-

1 point

-

I came across the video above where circuit stripboard and a soldering iron is used as a pallet warmer. The adjacent strip serves to heat sink the other jewel and the holes accommodate the pivots. I now have a few dozen scrap 1104a movements so plan to try this on some forks once I obtain shellac from Cousins.1 point

-

I saw the same thing with my newly acquired 1900 TM and the 7S26A I serviced. Ended up using a gain setting that agreed with the watchtuner phone app and keeping the same position of the stem against the microphone bracket to have the same before and after conditions.1 point

-

I've just been through a pallet-jewels change-out exercise, a total improvisation as the original 120 years old jewels just happened to be "out-of-stock". With the Omega 861, I'm just like you, the knowledge that the jewels sit as they should before the total re-assembly. I just need to order a few bottles of adrenaline I wish I could say the same after I'm done Well done !1 point

-

I had a similar problem with as As 1701- everything looked good and I couldn't get amplitude above 230°. (Like prasezis and JohnR725 I'm not fanatical about amplitude and beat error, but I like to see at least 240° when everything is looking good). Like yours, the lock of one pallet jewel was too deep. At Nickelsilvers' suggestion, I pushed it in a bit (easy to do) - and I gained 45° amplitude to 275°. https://www.watchrepairtalk.com/topic/24872-as-1701-this-may-have-me-beaten-what-can-i-do-next/1 point

-

1 point

-

Objection, John! Imo amplitude is just 2nd place, after the main topic: beat error. Frank1 point

-

That clasp is held to the bracelet by friction. In the centre of the clasp you can see a part with a rectangular hole in it, this levers up to allow the bracelet to be fitted through the clasp. Once in place and sized to the wrist this part should be firmly closed which will hold the clasp to the bracelet. Tom1 point

-

Definitely need pictures and some idea of what you're trying to make. Making parts in general is pretty advanced, making repeater parts is really advanced. If a rack or snail is missing that's a very big job, if it's the minute wheel or hour star not so big (but still).1 point

-

1 point