Leaderboard

Popular Content

Showing content with the highest reputation on 10/19/22 in all areas

-

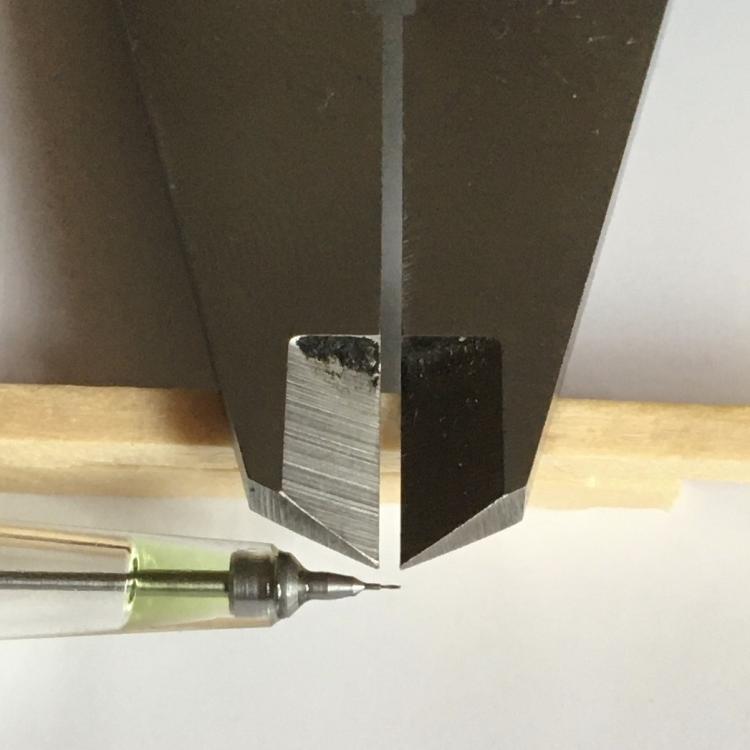

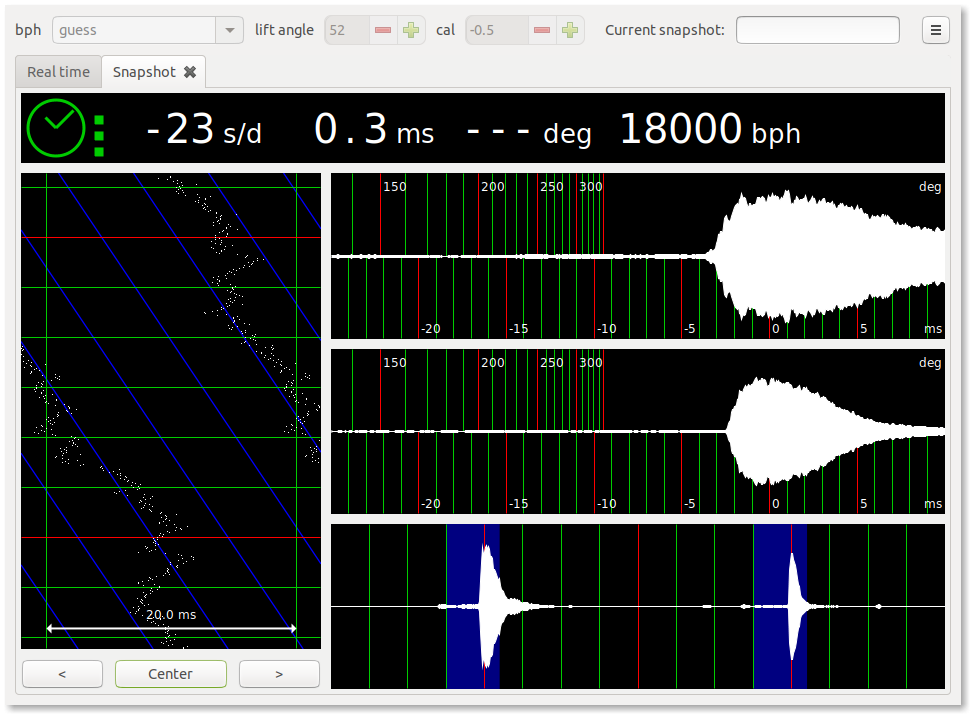

Hello everyone, I would like to present to you my latest project, a Vulcain Cricket (yes, another Cricket), model S2315A. I always wanted a Cricket, and it looks to me that Vulcain has made a lot of different variations of dials, watches etc. Cannot really find much info on the one I have. Initial condition overall: is running, but definitely needs servicing. It has a lot of DNA allover the place. Also, the watch came with its original bracelet (I wonder how that will turn out). Movement: looks to be a cal.120. Not 100% sure as googling for this caliber brings different results. What do you think? Also had tested it on the timegrapher, results on the picture. Crystal: needs a new one, as the original is cracked and has oxidation on the tension ring. Dial: looks pretty clean. Case: gold plating has some ware. Honestly not sure what to do as I have no setup of my own yet. Is it worth sending for replating? I am a newbie in the trade so any thoughts or suggestions are super welcome! Thank you!1 point

-

I know exactly what you mean Andy " oh whats this i dont remember seeing this in the seller's photos and i quite like ".1 point

-

1 point

-

1 point

-

That spring is tough to find and seem to be easy to break. When servicing: the spring, setting lever, and the unlocking wheel should not be disassembled...just keep together as a unit. That is my humble view. You can do gold electroplating yourself, but it is a pretty thin coat...costs under $100. I have plated a few things. Frankly, I would not try to re-plate yours. Your dial looks fine--leave it alone. I have replaced several Cricket crystals but it has been a year. I cannot recall if I used a Sternkreuz, GS Flexo, or some generic. Do not use a low-dome crystal. I seem to remember having an issue with the sweep second hitting the crystal. Here is a side view of the Cricket I am wearing...OH NO...looks like there is a crack! I know that I have accidentally whacked this thing a few times--I wear it constantly.1 point

-

1 point

-

Hello! Im a new member on this forum. I am a hobbyist watchmaker. I have a few great projects lined up for myself, however I will be conservative with my skill. I will of course take advantage of the knowledge on this forum and also am willing to share the little experience and knowledge that I have.1 point

-

Hm. I'd think the best way would be with a stiff sanding stick (or just rigid sandpaper) by hand, and methodically following the existing grain lines.1 point

-

I like the suction cup idea. I found one from my aquarium which was just the right size. Push fitted an electrical connector in to the hole, then mounted in the cordless drill. Spinning at low speed, and using 400 grit wet and dry. It only takes a little pressure, so you don't need a strong fixture. And it works !1 point

-

A glue gun ?, they have two adhesives to try and allow a little time. You could also apply heat from underneath to reposition it if its not centered as accurate as you need. Haha thats spooky that was my next one I actually have some of that in my shed . Also have a 2" velco sanding disk that fits in a drill the velcro tape would stick onto the inside of the caseback after a little padding out. Great minds think alike eh1 point

-

That's probably the watch Douglas Adams wrote about at the beginning of the first Hitchhiker book.1 point

-

1 point

-

Here is a bunch of pictures of one of my recent "ebay barrel scraping" purchases. A Swiss/German "Gallone" style cylinder escapement 80% silver cased pocket watch. At a purchase price of a fiver, it doesn't quite make it in to the 404 club, but maybe we can give it honorary membership. The lack of other bidders was presumably due to the poor condition of the watch, and the fact that it didn't run. The case has a small crack in it, which I may fix at some stage with low temp silver solder and a small patch, however someone has attempted a repair with what appears to be lead based solder, so that may complicate things slightly. The "Gallone" style as far as I understand it refers to the rose gold plating over silver that would originally have adorned the front bezel of the case, some of which is still visible. Inside, while there is no obvious makers mark, there is in addition to the "Gallone" stamp, a German "Moon and Crown" silver designation and a more typical Swiss "0,800 Silber" hallmark. The watch may therefore have originally been sold in Germany, although the stamp also appears on watches exported to other places. The main reason that it refused to run or wind was that the movement retaining screw had fallen out, and jammed itself into the gap around the mainspring barrel, wedging everything solid. Once that was removed and re-fitted things started to tick, all be it somewhat sluggishly, so a quick clean and rebuild was all that was required to get it running within +/- 30 seconds a day or thereabouts.1 point

-

Welcome to the forum. @RustinboxVinyl as in records or vinyl as in the awful coloured stuff that they used to put on car seats?1 point

-

Just some thoughts about the amplitude in the 28XX series. To get maximal amplitude before regulating these beauties I use to let it take some time. If one follow the oiling scheme in the tech notes one should get a quite good amplitude. The important step in the process is to let the movement run for at least a day or two before starting regulating the movement with a time graph. If you measure the amplitude just after servicing you will get a lower reading which is natural. To get maximum lubrication one have to let it get worked in and spread out on the surfaces. To gain maximum amplitude on these ETA Movements or any one else I guess it is of most importance to learn how to oil/grease the jewels on the pallet fork with for example Moeibus 9415. In my experience this boosts the amplitude significant. To get an amplitude of 300 one have to do the complete service including main spring change. When I get the amplitude to 280 or higher i begin the regulating work. Hope these observations can help you in some way.1 point

.thumb.jpeg.cd6d20f3fd1f21747a43456b96dd785d.jpeg)