Leaderboard

Popular Content

Showing content with the highest reputation on 10/08/22 in all areas

-

If you do scare up a donor movement, I'd inspect the setting train from crown to cannon pinion. If every piece looks better than yours, I'd swap them all out. The force that was applied from turning the crown has traveled throughout the setting train. If JohnR725 is correct, the teeth only got nipped off because of someone snapping the cannon pinion down onto the minute wheel teeth. But looking at the cannon pinion too, I kind of wonder what else has been going on here. Looking at how the faces of the teeth of the minute wheel were mushed down by force, I think the whole train was stressed. If it were me, I'd swap out as much of the setting train as I could.3 points

-

3 points

-

3 points

-

The jewels look fine. It looks like someone has wiped the movement with Rodico (or BluTac ?) and some has remained on the jewels. What ever was used it was very dirty - look at the smears on the bridges. Apart from all the dirt, it looks to be in good condition. Good luck with the service.2 points

-

looking at your picture this reminds me of why it's always best to snap the cannon pinion on when the minute wheels not in place. the worst-case scenario of having the minute wheel in place early would be losing one of the teeth off the cannon pinion the more likely you would see Bent minute wheel teeth or to guess if you're really enthusiastic you could probably break a tooth off requiring repair. just as a reminder when was this watch made? Did they have the Internet back then did the person of access to a watch material house? Yes today it seems so simple look online order the part it shows up in no time but wasn't always the case. Plus maybe had just a really obsessed hobbyist didn't have access to a material house and had a lot of time on their hands and they did make a repair.2 points

-

I used to use a knife like that shown above. But lately, my preference is for a Seiko style knife, which is cradled in the palm and pushed instead. It gives much more force to wedge the blade under a tight snap on back. The key word "wedge". Most beginners tend to use a case knife by levering, like a teaspoon is used to open a tin. But that tends to slip off and scratch the case. There is another thread for caseback opening tools. Have a read of that. There were a lot of good advice given there.1 point

-

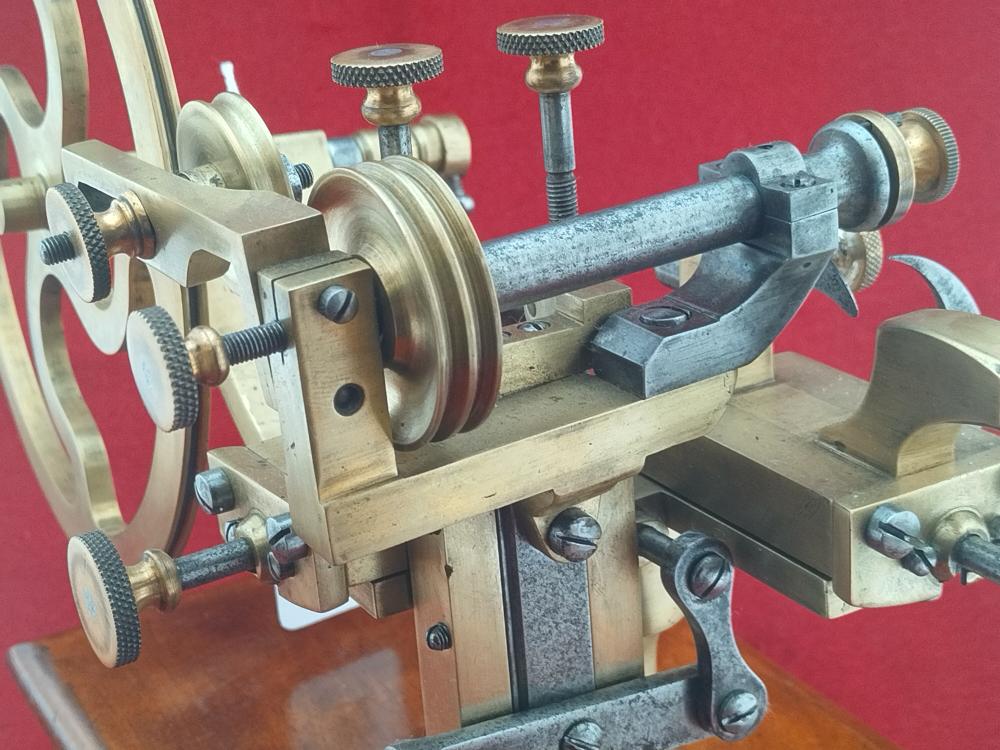

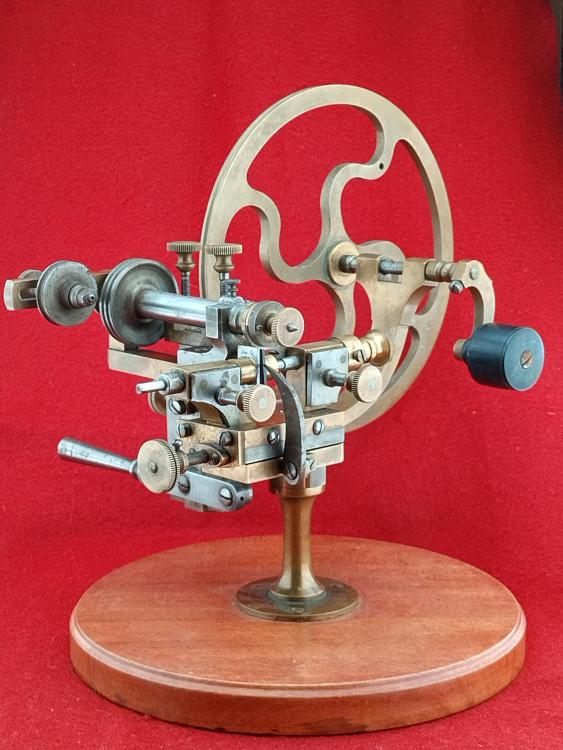

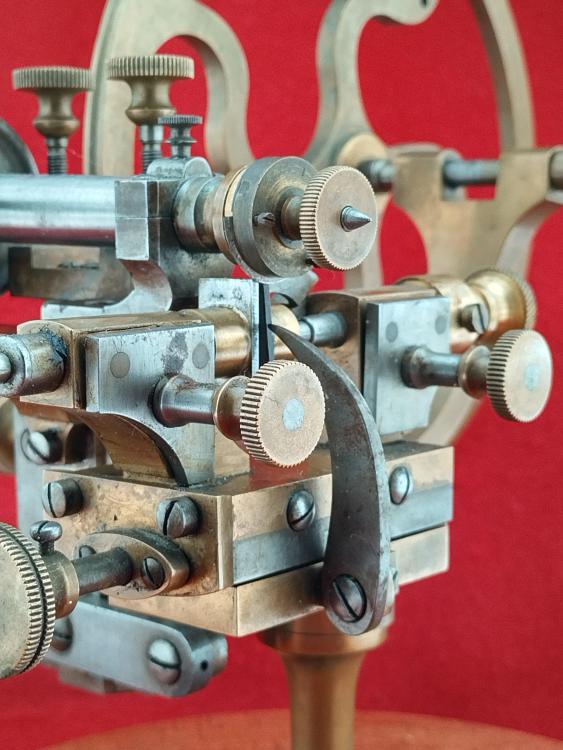

Hi Hector those arn't tools they are pieces of art absolutly lovley to look at, I would have them on display for others to appreciate. wheel cutter and Jacot brilliant. love them.1 point

-

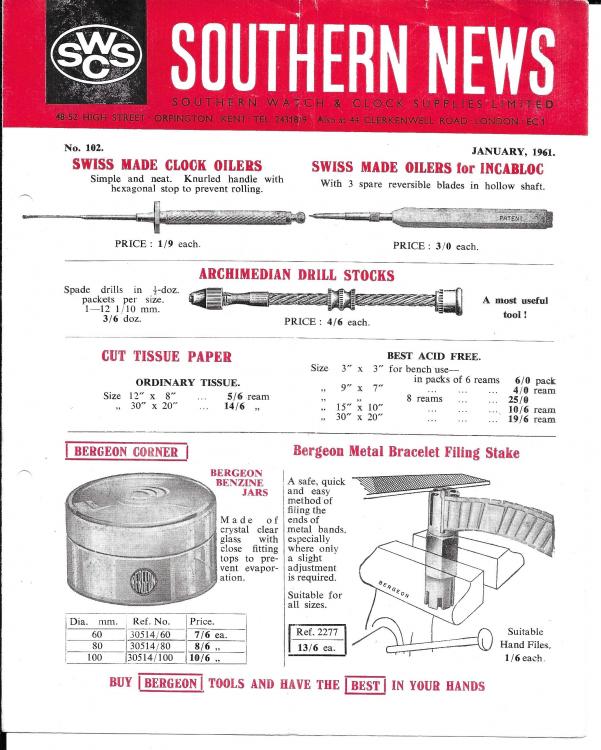

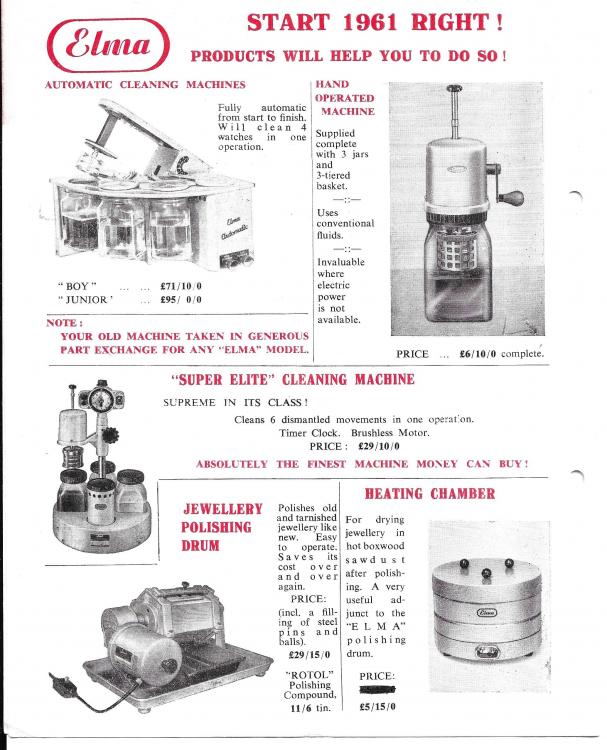

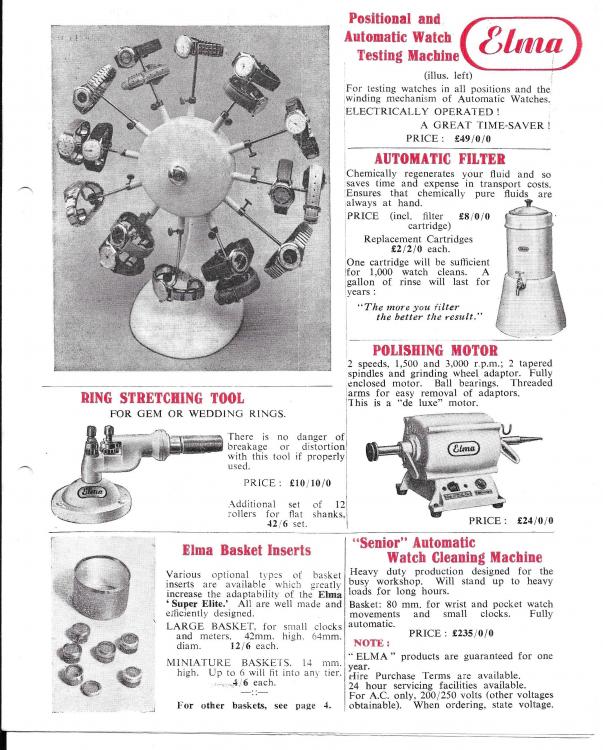

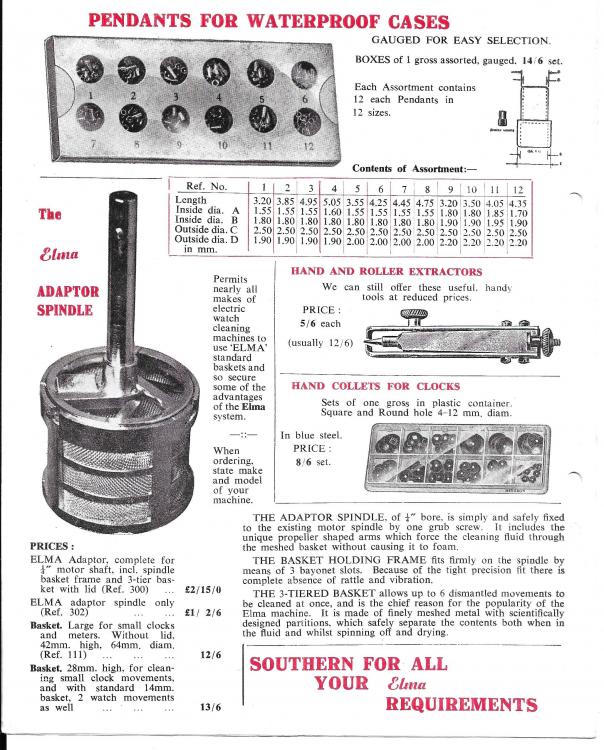

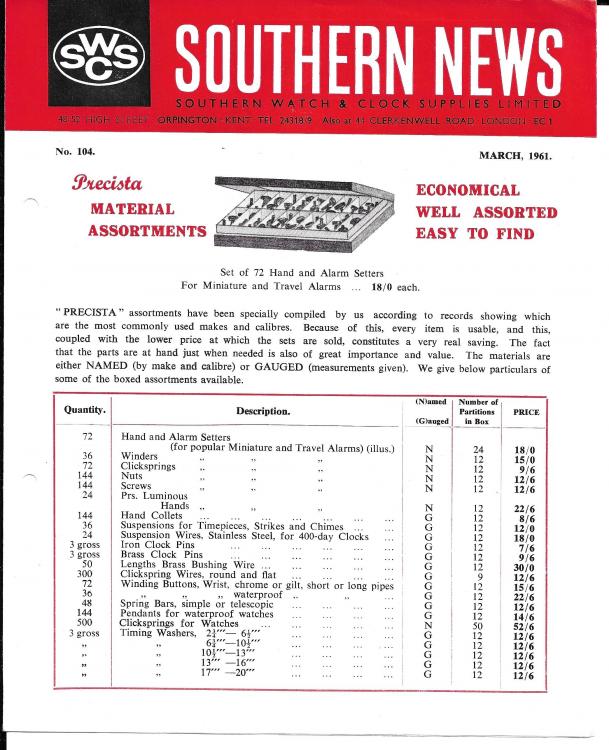

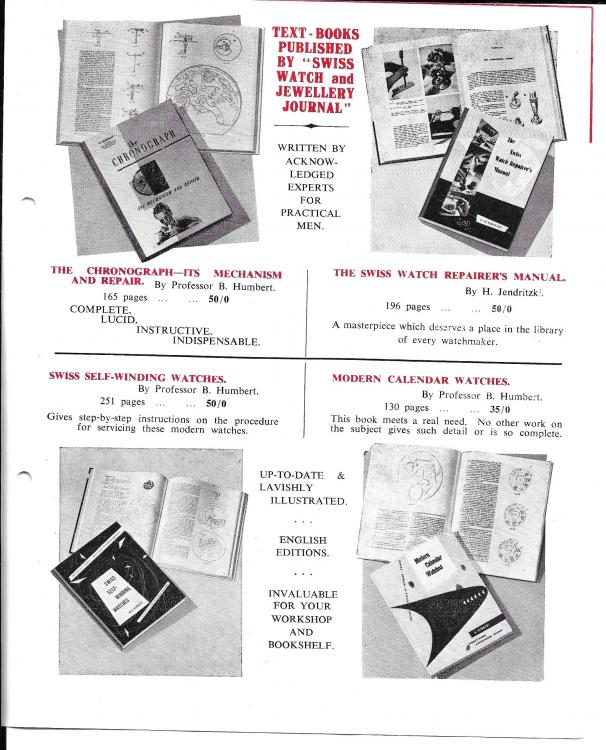

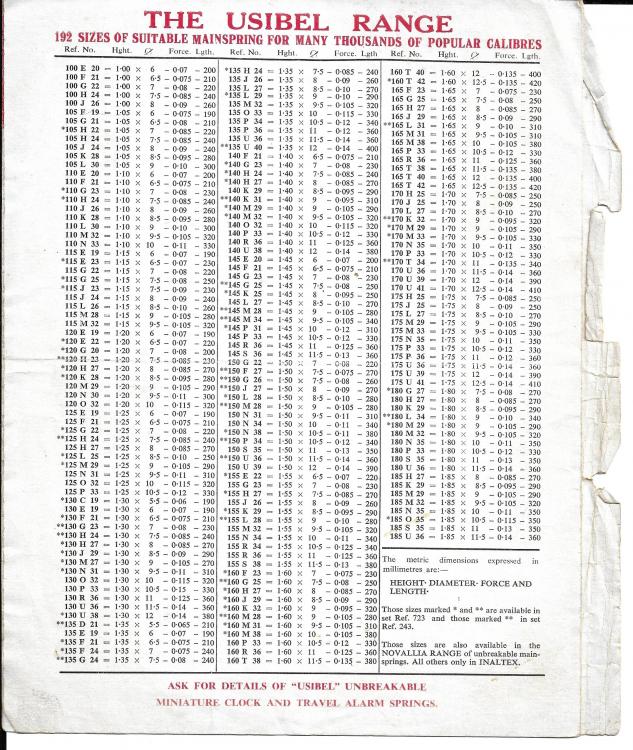

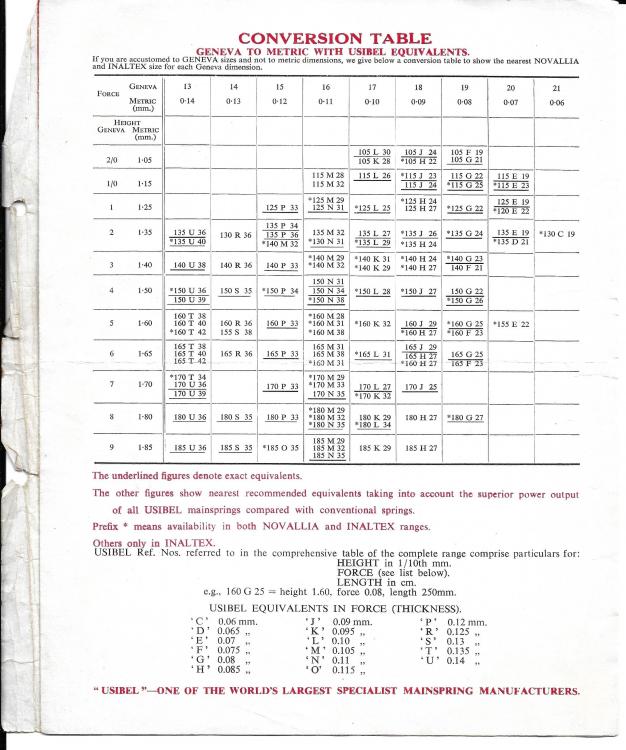

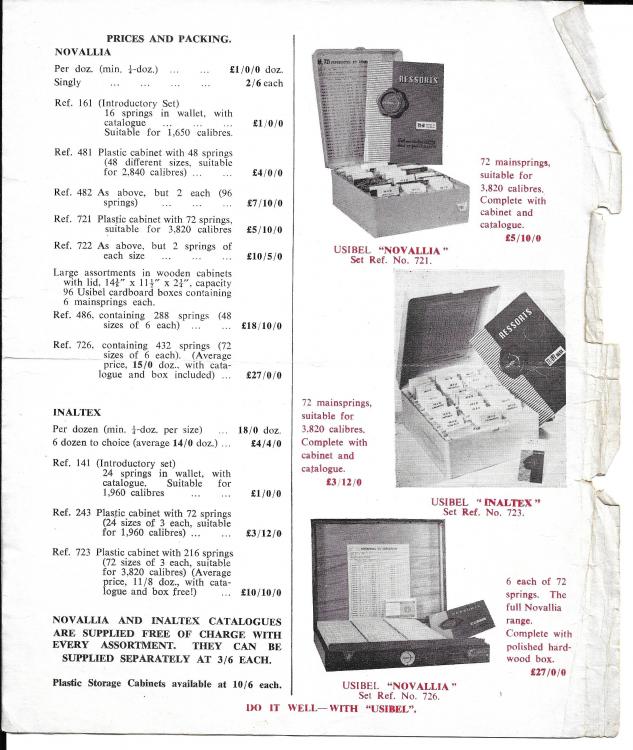

January 1961 Issue No 102 A watch cleaning machine without electricity, would come handy these days. The Elma Adaptor Spindle to be able to use Elma basket system with other watch cleaning machines than Elma. March 1961 Issue No 104 Precista material assortment Swiss Watch and Jewelry Journal Books Prepaid Rush Order Cards (3) Every day we receive several cards which omit the sender's name and address. In spite of our undoubted "amateur detective" abilities we cannot always establish the identity of the sender! Silly customers again! September 1962 Issue No 122 A whole issue dedicated to the "new" unbreakable watch mainspring. An interesting read.1 point

-

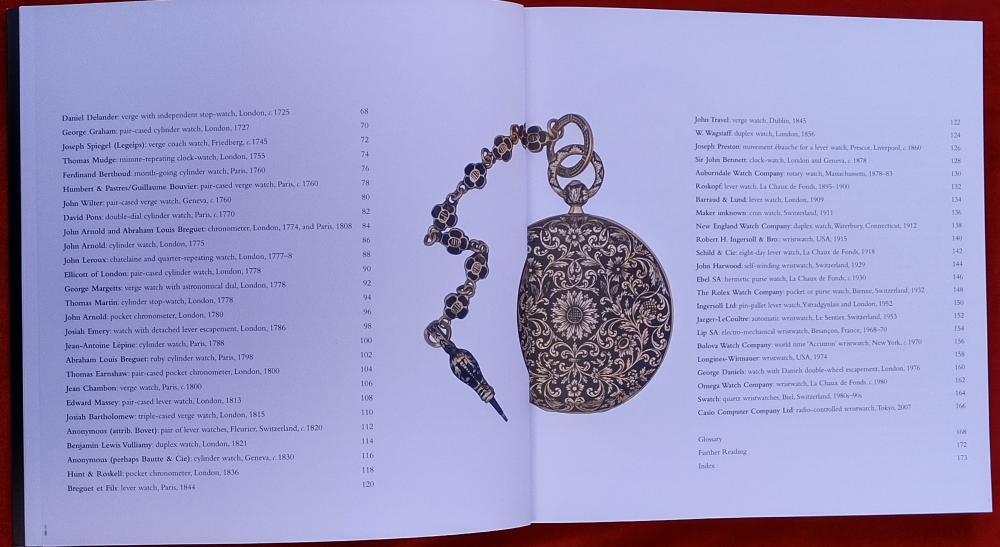

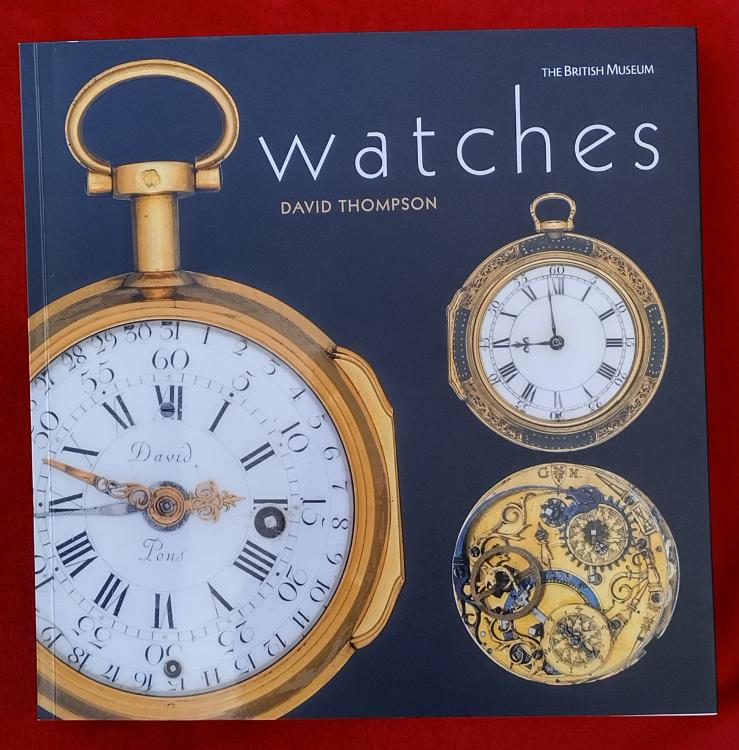

My last toy I received with the same shipment: I took a picture of the cover, content and the introduction of the book I bought in the British museum. Have a look at it, an incredible collection with more than 4500+ pieces a lot of them with great importance. (the pages didnt fit into my scanner, hopefully readable)1 point

-

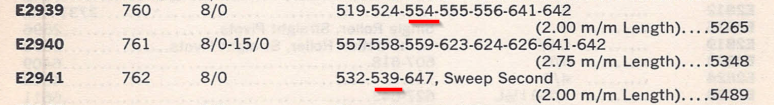

Having worked on a couple of 539s recently, I can offer a few thoughts. Getting a donor 539 is expensive. They are well known and sought after. I had a 539 missing balance wheel and balance cock (came with a watchbench full of stuff). After considerable research, I found that the 554 shares the majority of the components less the sweep second (it uses sub second). These go pretty cheap--recently got one to my mailbox for $34. I robbed the balance assembly and brought my 539 to life and it is happily running. Even though the center wheel is different between the two calibers, I bet the cannon pinion swaps...some research might confirm. NO IT DOES NOT...PROBABLY HAS A CLOSED END. SEE CLIP FROM THE HANDY MANUAL Are you missing the entire sweep second wheel train? That will be tough, if so. I sent you a PM that gives you the solution you need. ACT FAST. No. The internet was created by Al Gore back in the late 70s. This watch dates in the 40s.1 point

-

That will quickly progress to a microscope and then a bigger better microscope1 point

-

Appreciate your tips! I probably will try to find a donor movement seeing as the sweeping seconds works are all missing as well. Luckily the train looks spotless. Apart from eBay, are there any places you guys go looking for donor movements? I stubled across Dave's watch parts yesterday and am loving the early 2000's style he's got going no 539 parts though unfortunately.1 point

-

1 point

-

1 point

-

Lol . A man after my own heart mate. Why buy it when you can make it how you want, you've even tongued the seperators in. I have the same chop saw somewhere. Great for garden furniture and feature walls. Nice one Lui, i love to see recycling mate. Initially missed these posts.great work lui. I wouldn't have worried about the 0.5 beat error, acceptable for this age and movement.1 point

-

1 point

-

1 point

-

Welcome Gary. It sounds as though you were destined for watch repair. Your background for fixing things will be a huge asset for you. The logical understanding of taking mechanical devices apart fault finding and then reassembling to working order is the essence of watch repair. But then sooooo much more to learn. Everyone is very helpful and friendly here occasionally a little barmy but thats par for the course and makes here fun as well. Enjoy matey.1 point

-

Hi Gary, Welcome to retirement Sounds like you understand taking things apart and figuring out what's wrong. The big difference with mechanical watches is the size - everything is tiny! Here are a couple of things to look at that might help: Animated web page with lots of information. YouTube showing how a watch works. Mark also has online courses that you might consider: https://www.watchfix.com/ Welcome to WRT. - Gary1 point

-

In the video I run it at full speed for a short time. It's stable though. It's still seems to be important to try to balance out the basket when you fill it with items. I think I'll keep some spare screws on the side to balance out any bridges cause those seem to weight the most. Otherwise, when I run it in the machine I usually run it pretty slow so it doesn't foam up. I was actually surprised to find out that dropping the basket too fast created a lot of bubbles. When I lowered it slowly and turned it on, I was foam free.1 point

-

Which will be a lot cheaper now than having your oven on full blast for 40 mins. A fiver to cook a Sunday lunch geez, our government needs to get this sorted. . Unless you wait till you cook dinner and do your nut roast on the bottom shelf. Badum-cha. Tommy Cooper eat your heart out.1 point

-

it looks like it's available yes it can be purchased http://www.julesborel.com/s.nl/it.A/id.201511/.f now I'll show you how we get here for future reference http://cgi.julesborel.com/ one of the things important to remember when looking up parts on this site is you actually have to know who made the watch. Because often times watches will have a name on the dial and even a name on the back plate but isn't actually who made the watch. I'm not explained that aspect because that would take up another several paragraphs. Okay so then you can find a company name click on that go down the list and find your model number but before clicking on the model number notice a reference that the base model is 36. So all the parts under your actual part number are unique to your watch but we need the base model for the click spring so go back to 36 click on that and you should be here. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=X_ZDYI\ then even if for some reason they didn't have it but the action we do you see all the watches and across references to you can start looking on eBay or other places for broken stopwatches except of course people will tell you which stopwatch that have but still you go maybe find a box broken stopwatches or something Gidget clue what you're looking for 430/259 CLICKSPRING Price Each $ 7.40 then you get the important things you get that number the 430/259 that's the important number because armed with that number you can go here http://www.julesborel.com/ make sure when you're copying and pasting the number some sites are more picky than others make sure that there is no blank spaces on either side your number I can't remember one of the sites I go to if there's a blank space of just come back as no even though it is yes. so in the top right is the search category of the search box hit the search icon and you'll end up in a page with what it's found sometimes you'll find lots of things in our particular case it comes herewith just one item http://www.julesborel.com/home?search=430%2F259 then all you do is click on the boxand then you should be at the link which I gave at the very top of the page you will note that the price is going up by a little bit but at least it's available I would suggest ordering more than one they used to be but probably not anymore because they don't actually list this used in watch parts if you ordered three you paid for to the third one is free but as they don't your price breakdown like that they probably don't do it but still I would order more than one because you might need it again if you're working on a lot of stopwatches otherwise just by the one and while you're on the website see what else you have the purchase because shipping for one click spring is going to be expensive1 point

-

I did one of these just the other day with a similar issue; that spring lever holding down the seconds pinion can be bent, thus losing tension, when the second hand is fitted without supporting that spring. On those movements you should use a staking set to fit the second hand, or provide a means of support under that spring when fitting the hand1 point

-

10 month in Hello again to all. Just an update on progress of a beginner. And a few observations. I began in December 2021. My wife has 3 old pocket watches. That are dead. “I know!” I said to myself. “I’ll fix them”. I’ll look up on the Internet, and it will show me what do do. I’ll buy one of those watch sets and Bob’s your uncle (English saying). All will be well. The set arrived. I pulled the watches apart. What am I looking at? Don’t know. What do I do? Don’t know. How do I do it? Don’t know. Some Internet sites are doing repairs. I’ll buy a cheap watch that I can repair. Did so. I was not running. Now I have 12 watches and movement. None working. What goes where.? My weekly spends of £10 was going every week and nothing to show. Nothing was ever fixed. What am I looking at? Don’t know. What do I do? Don’t know. How do I do it? Don’t know. Looking on the Internet I found YouTube. There is a plethora of sites where people show you what do. Not! In actual fact there a very few who are into showing their skills at the teaching level. Less that 2 dozen. That’s not many. All bar two are amateurs. There are many who show off. “I started last week, and this is how I have worked on a Chronograph, and it is now pristine”. Wow! I can learn from him. Not. But as you begin to understand you realise why you can’t. Their skill level they portray is way beyond even my level after 10 months. The ability to use tweezers correctly to remove and turn jewels over for cleaning for example. What did I do right. Well, I can say in my favour, I typed the words ‘watch forums’. I found ‘Watch Repair Talk’, and information about Mark Lovick. Wow! Cant afford that. Look elsewhere, Buy a cheap course. Did so. The video was made in 1987 and was converted from a 16mm Cine camera and it was about pocket watches. They did give me a refund. It took me over 3 months to save and buy Marks course. Should have done it in the first week. What he offered me was information and guidance. Learn the principles. Practice. Repeat, repeat, repeat. It won’t work first time. Redo. Practice. Where am I now. What would I do differently. In actual fact. Not much. Working my way forward has given me hours of pleasure. I subscribe to 22 YouTubers and eagerly open each. They are great to learn from. I spend almost the same time practising. Can I disassemble safely? Yes. Very rarely screwdriver slip or ‘ping’. Can I clean? Yes. Hand clean then Ultrasonic to degrease and wash twice. Can I assemble? Oh yes. Do they work? Yes.. ish. Need to practice to overcome low amplitude. Am I getting there. Oh yes. One of the things that I have been told by a number of people is quite correct, but as beginner it is totally impracticable to practice. Don’t start on movements, or dead watches. Trying to find the parts for movements means that you have to buy another movement, or more than one because the donor is just as bad. The dead watch is just as bad. Why is is bad? Because it is broken and needs a part. Buy a movement for the part. Back to square one. In hind site, it is the correct thing to do. But where would I now be? Most running watches are in excess of my months saving. I would never have started. But I have. And I have to say it is great fun. What information would I have helped me? None really, as this is voyage of discovery and you can only discover by error – practice. The best thing I have learned is, system. Have every tool in its place. Put everything away each time. Have a label on each box that contains the watches and note on it details what you have done or need. Where will I go from here? Deeper into the hobby. I’ve given myself two years to learn enough to service my own very expensive watch. I bought it in 1968 for my 18th birthday. Regards to all. Ross1 point

-

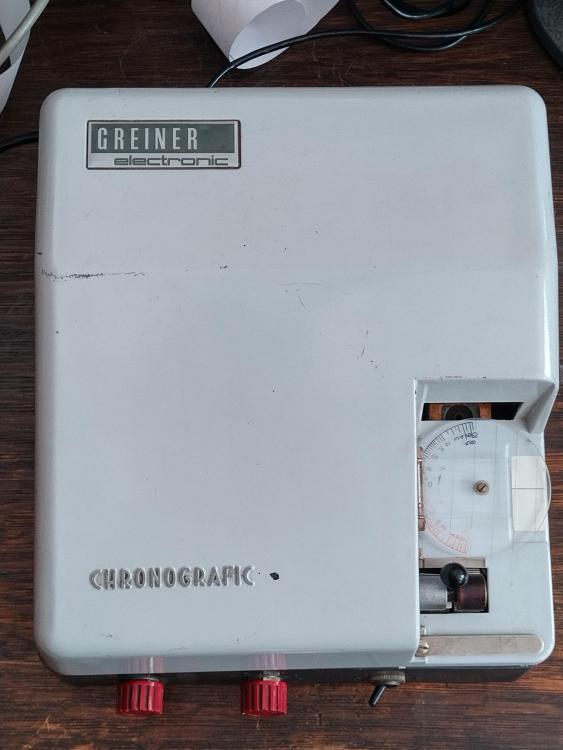

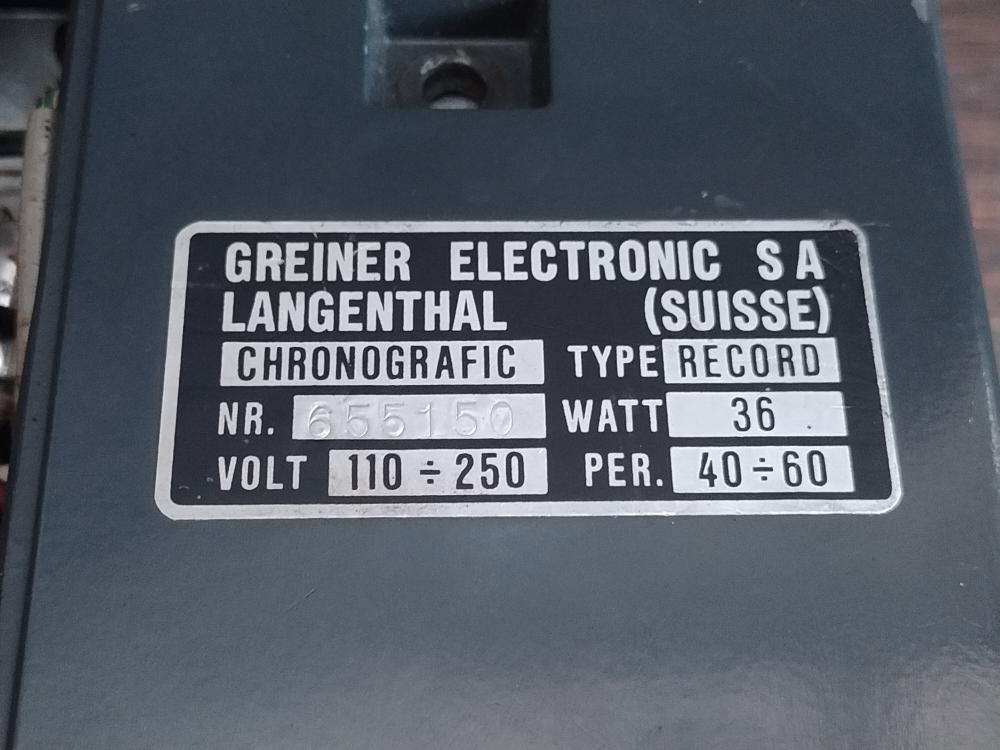

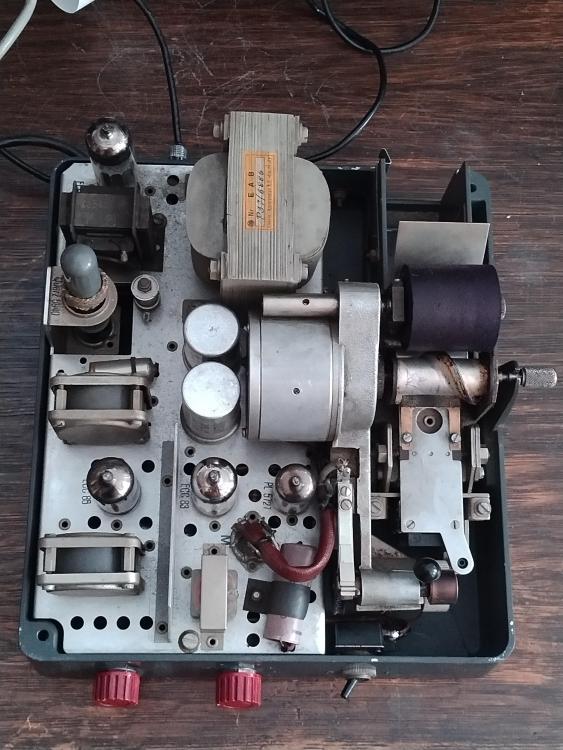

I brought my Greiner Vibrograf Record down from the attic. It would not print, already figured out that its switch is faulty but unfortunately it does not stop it working. It is always on. What is amazing is that I contacted Greiner and they sent me a Manual and a circuit diagram within an hour!!! Valves! Record_Schaltplan.pdf Record_Manual_E.pdf1 point

-

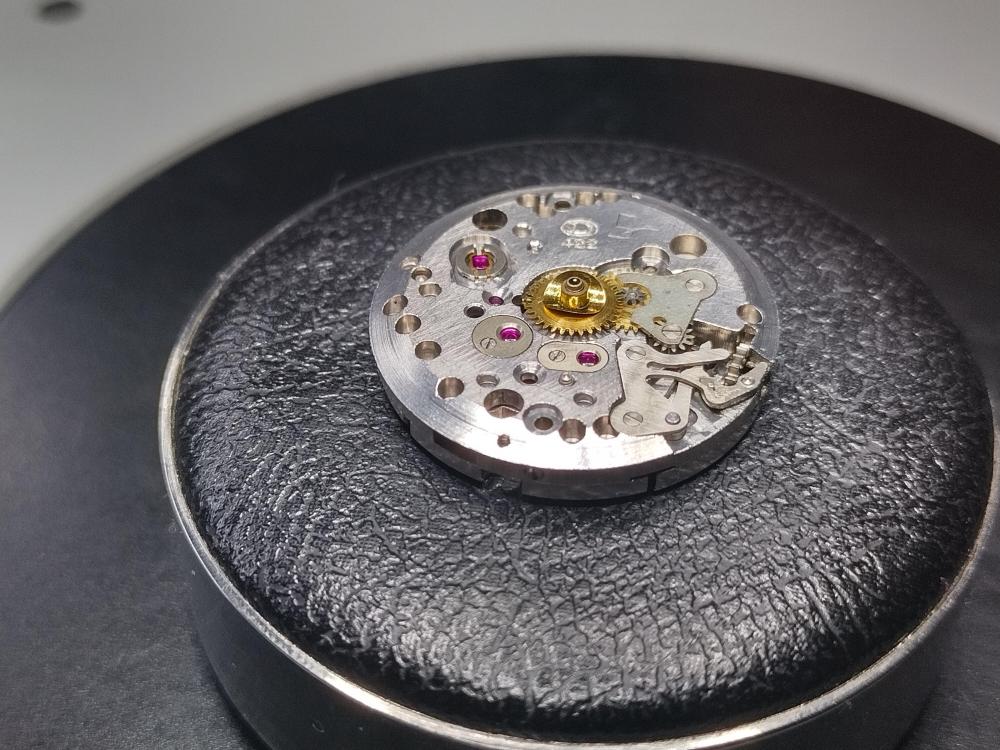

EB8420 finished casing it recently This is a practice watch. I got a tray of EB8420 movements without balance wheel, a tray of EB8492 with balance wheel but without mainspring barrel and a box of new EB8420 dials. Now the balance complete is interchangeable or it is just a maybe because i could not set the beat to 0 ms as I already hit the balance cock and cannot move the little arm any more... maybe I need to play with the HS colet now. Anyway I purchased a tray of EB8420 too plus found a set of scrap hands in the scrap box. Unfortunately I have no dial rest and I dont know how to source it and where to find good looking hands. I tried to take apart the pushers to completely clean the case but the pusher screw glued or "locktited" in and when i tried to turn the screw i just broke it of... so I tried the other pusher and I broke that too... ok lets take another case all looked good for a while and then one button just fell off... i did not even touch it/push it.. the screw again was broken again at the same place, where it goes into the pusher.... two cases wasted... (dont think i can find pushers individually for this case/ cousins do not seem to have them) anyway it has a nice performance apart from the non 0 ms beat error. (as far as i remember it was around 0.5ms) These are also ready a nice little Westclox and a Laco with Durowe 422. They are on a test run at the moment. https://17jewels.info/movements/d/durowe/durowe-422/1 point

-

I always wanted one and I always knew that there is no space for it... I bought it anyway... so far I could not come up with a sensible idea as where to put it... Both of its locks are made in the USA maybe the whole desk was made there. One of its lock is not working, so today I became a locksmith too. If you close the top it locks all of the drawers, both sides and the middle one too. Very very nicely made.1 point

-

Thank you. This very week I visited one of the recycling center with my pallet buster from Screwfix because I used it that much with heavyweight hardwood pallets that I had to buy another one, I straightened the old one. Beside of it there was a bucket full with used nails I pulled out of them, difficult to lift because of its weight. I have a trailer I load time to time with free pallets coming from FB marketplace. Some of them are only good for burning but some of them are really nice straight and clean, some of them are bulit to transfer heavy industrial equipment and they are hardwood. The crates are also hardwood and the wood they are made from usually have a nice texture. Of course the wood has the nail holes but it's easy to live with it, sometimes it even looks good.1 point

-

1 point