Leaderboard

Popular Content

Showing content with the highest reputation on 08/25/22 in Posts

-

I have branched off the Tools & Equipment sub-forum and made it a separate section on the front page with sub-forums on specific topics. I have done this because, as a sub-forum, the Tools & Equipment area was getting way too congested and it was difficult to find if a topic was already discussed. I've moved a heck of a lot of posts from the old sub-forum into relevant sub-sections but there is still about 60 more pages to go through, I will chip away at moving posts into the new categories whenever I have a spare moment, and hopefully some of the mods here can do the same, but in the meantime, please try to help by checking the new sub-forums in the "Tools & Equipment" section and post any new threads in the correct place The old, Tools & Equipment sub-forum has been retained as a "General" sub-forum to the new front page section and no posts have been lost. If you previously posted there and cannot find your post then you can either find it via your profile page or by going through the sub-forums, I have tried to be as accurate as possible so far in matching topics to the sub-forum. New section: https://www.watchrepairtalk.com/forum/55-tools-and-equipment/ Old sub-forum, now part of above new section: https://www.watchrepairtalk.com/forum/21-general-tools-equipment-discussion/ Thanks for your co-operation3 points

-

CAS number for Ronsonol is 68410-97-9. "Distillates (petroleum), light distillate hydrotreating process, low-boiling" CAS for the benzine that everyone uses for watchmaking purposes in Switzerland is 64742-49-0. "Naphtha (petroleum), hydrotreated light" CAS for the naphtha I got when I specifically asked for "naphtha" at my chemical supplier* 64742-95-6 "Solvent naphtha (petroleum), light aromatic" *When I asked, he wanted know why I wanted that specific chemical. Told him it was for watch/clock cleaning. He said "whaaat?! Use Benzine! (the other naphtha)". I tried it a couple of times, seemed to work ok, but the "aromatic" part of its description is no joke- it made me feel ill and those around me. So if you get some naphtha, make sure it's the one the Swiss call benzine- hydrotreated light, 64742-49-0. On that note, even here the term benzine gets confusing: I needed some years back, went to a different chemist and they gave me benzine rectifie instead of my usual benzine leger. He said it was exactly the same stuff, different name. Well it left visible traces when it evaporated... so I got the good stuff again. On an even more different note, when I needed Coleman fuel (talk about a confusing topic, it's some magic mix apparently) for my camping stove, my usual chemist said, "Eh? Just put benzine in it!" No, Coleman stoves have to have Coleman fuel. He insisted, I tried, and I've run many liters of it through that old stove with zero issues.3 points

-

Why don't you guys just use your tweezers? Dip a properly cleaned #3 into a vial, open them slightly to "suck up" the oil between the prongs (capillary action) , then go to your pot and open them fully to dump the oil. Job done and no issues with cross contamination. Repeat if you need more, but usually once should be enough3 points

-

Heh, sometimes being overly passionate (I call it something else but the swear filter here just bleeps it out) for doing something the “right” way makes me blind to other realities. So I tend to come across as being dismissive about things I don’t agree with, as the case here with manually winding in main springs. That being said, let me quote something else I said in another thread for a little perspective: Many people choose to not remove these because it's difficult and that's ok. Most people here are hobbyists and they service these for their own use, so far be it from me to criticize anyone who don't have the skill, patience or equipment to do it. If you charge for your work, then that's an entirely different conversation. So yeah, your circumstances differs from mine. It’s a hobby after all and you don’t charge for your work. Spending 100’s of dollars on something you’ll use infrequently might make little sense to you and that’s ok. Take me with a pinch of salt; my opinion shouldn’t detract you from your enjoyment of this hobby.3 points

-

Quick update. Received a new mainspring for a Gruen 445SS movement. Both the 452SS and 445SS are based on the Pierce 105 movement. However the 445SS mainspring is just a slightly narrower than the one I was using (the 445SS movement is smaller). So far the results are great--dial side up and down about 280 amplitude and in other positions anywhere from 200 to 220, which in my experience is fine for an old manual wind watch. Most importantly, at full wind it doesn't knock anymore. My only complaint is these are old blue steel mainsprings--very brittle and hard to handle. But at least it solved the problem. Thanks all for your input--I'll post a picture once I get the watch cased and ready to go, Cheers -- Levine982 points

-

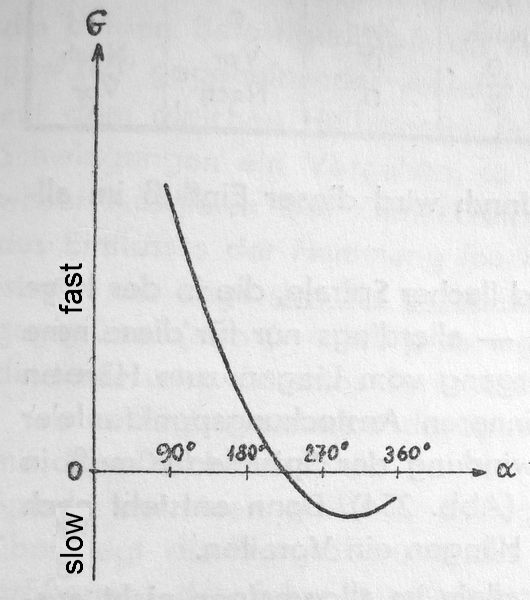

Surely it wouldn't be wise to poise at 220° (but satisfying ). Amplitude is not a matter of numbers chasing. Classic numbers are 270° horizontal and 220-240 vertical. Why? At 220 (vertical position!) the poise error is about zero, as mentioned by nickelsilver. But even in the vicinity this error will be low. At 270 (horizontal position!) a poise error would show - but we are horizontal! All this can be read from the underlying Bessel function: Influence of a heavy spot below center Frank2 points

-

Push the loose stud out of the slot its in Detach both the regulator and stud carrier arms from the cock. Seperate the regulator arm and try to narrow the loose gap. Easier said than done. Bodge job, glue the stud to the arm.2 points

-

Hi The usual cause of failure to drive the hands is caused by a slack canon pinion , I have attached the operating instruction sheet and two tech sheets for your interest. cheers 3158_ETA251.262operatinginstructions (1).pdf 1327501645_289_ETA251.252251.262251.272.pdf 8619_251262vs251264.pdf2 points

-

I just recently tried these polishes (see the link below) and was very happy with the results. However, one must be very careful in the choice of polisher because they have an abrasive effect. The softest one is the way to go. https://www.watchrepairtalk.com/topic/13969-slow-moving-escape-wheel/#comment-1979912 points

-

Absolutely not a problem a Gert. I respect everyones opinions. And ideas often change for me as i progress, something i did last year that i was more than happy with is now an old idea that has been improved upon. At my start i was constantly looking for winders as i thought they were a complete necessity and the few second hand ones i have cost around two hundred gbps. I was sorely disappointed when i found they rarely fitted hence my resignation to hand winding. The problem i have is having to work on such a varied genre, that being old swiss. Your information has given me things to think about so cheers for that matey .2 points

-

Only counts toward initial acquisition cost. Just about every watch needs at least a crystal or mainspring or something, and if that went toward the cost of entry I'm not sure you'd be able to get anything under the 404 bar unless someone paid you to take it! Parts that go into making it good are not tracked at all on my ledger. Only reason to do that is if you're trying to sell it later and make a small profit. I wouldn't even worry about discounting the other 11 that came in the box. If you bought a box with 12 watches for $12 and 11 were crap, but the 12th was a Rolex, I'd personally count that as a $1 Rolex for 404 entry purposes.2 points

-

2 points

-

Hi all iam new to the pocket watch and watch world I found this site when looking for tips on jewels etc and found a brilliant tips on how to do and not do if that’s anything to go by then I definitely want to be a member of this group so hi folks looking forward to reading and asking the community. Take care2 points

-

I have an odd situation and a follow up question. I have made several searches and read several post that really didn't pertain to my issue. I am working on a previously mentioned AS 976 and find the impulse jewel seems to be to wide to fit between the pallet fork horns without help. Since the impulse jewel is unlikely to have grown, I can only imagine that the fork has been damaged or parts have been mismatched. As all the pieces came as an assembly (in very bad condition) from a jumbled box of movements, either is plausible. If the fork is bent, I feel confident that I have not mishandled it. my question is, has anyone adjusted the horns of a pallet fork? At this scale, I have no way of determining whether or not they are now parallel and realize that if they are now, they wouldn't be after adjusting. I can't see why that would be important anyway. I also have no way of accurately measuring the impulse jewel without removing it first. How would you proceed? I'm sorry. After posting I went back to the beach to tinker with it again and found the root cause of my problem. I removed the fork for a better look and found nothing worth noting. So I dropped the balance back in without the fork and found the same problem. It wasn't an interference between the impulse jewel and the fork. It was that the balance screw that swung the largest circle was hitting a nick in the mainplate. It just happened that it was timed to coincide with the jewel entering and exciting the fork. I gently scraped the plate, removing the nick, cleaned up the crumbs and reassemble. It came back to life. That being said, has anyone ever ajusted the width of a pallet fork? Shane1 point

-

My recent staff turn renewed my frustration with measuring distances along the length of the staff. Today I made this. The caliper piece came off of a theta adjuster on an XY table for silicon wafers (probe station). I 3D printed an end piece and then, using a brass washer, reamed out the precision face. I had to do some lapping on a diamond plate to get the faces to align properly. I am within 10 microns I think. Until I turn my next staff, I will not know how well this works.1 point

-

Yes I actually used the number and searched over several .something domains and it always brought up massive chemical supply houses. But it also brought up some version of hexane- which I recall (ok 21 years ago) being readily available in the U.S. at that time. Some digging and knowing that hexane/benzine/naphtha can all be the same, use the CAS # if asking and get the right stuff. My wife, who grew up in Argentina and was curious why I'm writing to my geeks and not staring into her eyes just told me gasoline is called- nafta there. And pretty sure DeCarle says to use high grade gasoline in one of his books, haha. Don't clean parts in gasoline. Do it in benzine, as the Swiss and French and Chermans call it. Or hexane (get the right CAS #) as the yanks call it, or Hexy Bexy Benzinwinee as I assume it might be called in the UK, with the right CAS #.1 point

-

Not a video dedicated to balance wheel replacement, but I did one below. Check from around 8:001 point

-

1 point

-

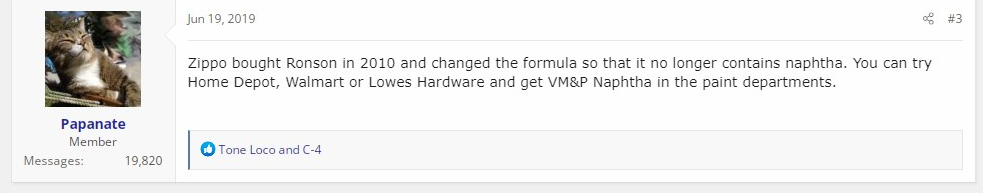

Hello @Neverenoughwatches, It looks like RONSONOL has expunged the word (and ingredient) "Naptha" from its product. One of the Data Sheets I was referring to is 9 years old, and the other 12 years old. The formulation has almost certainly changed since ZIPPO took over, most likely (guess on my part alert!) because they probably just switched to putting ZIPPO fuel in RONSONOL cans, thus achieving an even greater economy of scale than before That would make commercial sense but I have no information to confirm this. I just looked around (again) and found the above (https://bit.ly/3PUDhlL) but this source is hardly what I would consider reliable (no sources, no corroboration). The point I was trying to make, but probably not well, was that the hydrocarbon complex that they are using now and "Naphtha" - which is a name given to a family of hydrocarbon distillates, not a specific product...a little like when we say "Jet Fuel" - may have the same ability to dissolve contaminants in watch parts regardless. Isn't that what matters? Is Naphtha in RONSONOL any more? My guess is probably not, based on what's on the label and anecdotal evidence. Is C08-C14 Naphtha? Not according to what I've found so far, but you may know more than me about that. Will RONSONOL dissolve watch contaminants as effectively now as when it contained "Naphtha"? Only running controlled tests will prove or disprove that, and that's where I will be pointing my attention because if it does then I have no need for "Naphtha" being in RONSONOL. It wouldn't matter. Hope that's clear. That said, if there was something written in err in my previous post I want to make it right, so people reading this are not led astray when reading this stuff. So...do you think there is an error now now? Where? Let me know and I'll take a closer look tomorrow when I get up (it's 23h15 now) and fix things up. g. ----1 point

-

So as it seems benzine legere aka naphtha hydrotreated light is pretty darn close to Ronsonol, and is the "proper stuff" (used in countless Swiss factories and workshops), and the cheapest I can find Ronsonol is 9 dollars for 355ml, at Walmart in the U.S. (it's 7 bucks for 125ml here), and a liter of benzine is 10 bucks here in Switzerland, JDM's long fought battle to promote the "good stuff" is justified. Much cheaper and almost certainly more pure (still don't know what all is exactly in Ronsonol "distillates" plural in the above description).1 point

-

Thank you for your patience and understanding. Please don't mind me as well. My wife frequently says that no dead horse is safe within my reach. As you have suggested some of our situations are different and we all must make our own living. For some of us that living supports and furthers our hobbies. For others it's a necessary obstruction to them and their progress. Without the support of our more experienced members providing their knowledge and encouragement, the rest of us would not, could not improve. An apprentice would not only have that knowledge and encouragement but also supervised access to his master's tools. After acquiring his own skills and manufacturing his own tools, would set off to repeat the process with another enthusiastic youth. Apprenticing virtually has its drawbacks. Thank you all.1 point

-

I'm not a chemical expert by any means, but I would bet a Coke and be 99.999999% sure to win that the stinky naphtha is stinky by nature, not to dissuade misuse. Methylated spirit is based on ethanol, so the potential for misuse it there (and the methanol they add is pretty much impossible to separate by normal distillation processes). I can't see why anyone would misuse naphtha; if they want to huff something for a buzz maybe, but there are easier to get chems for that!1 point

-

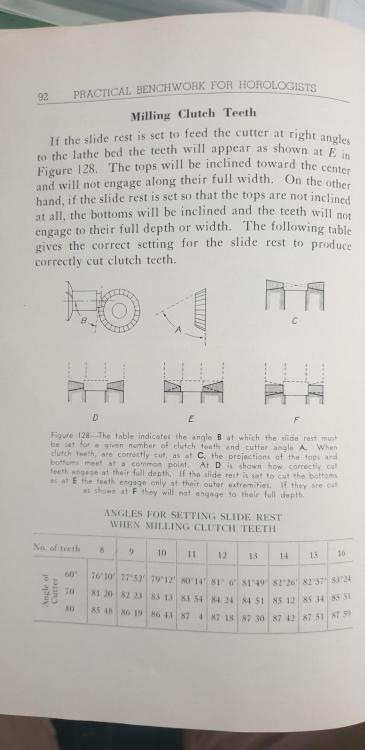

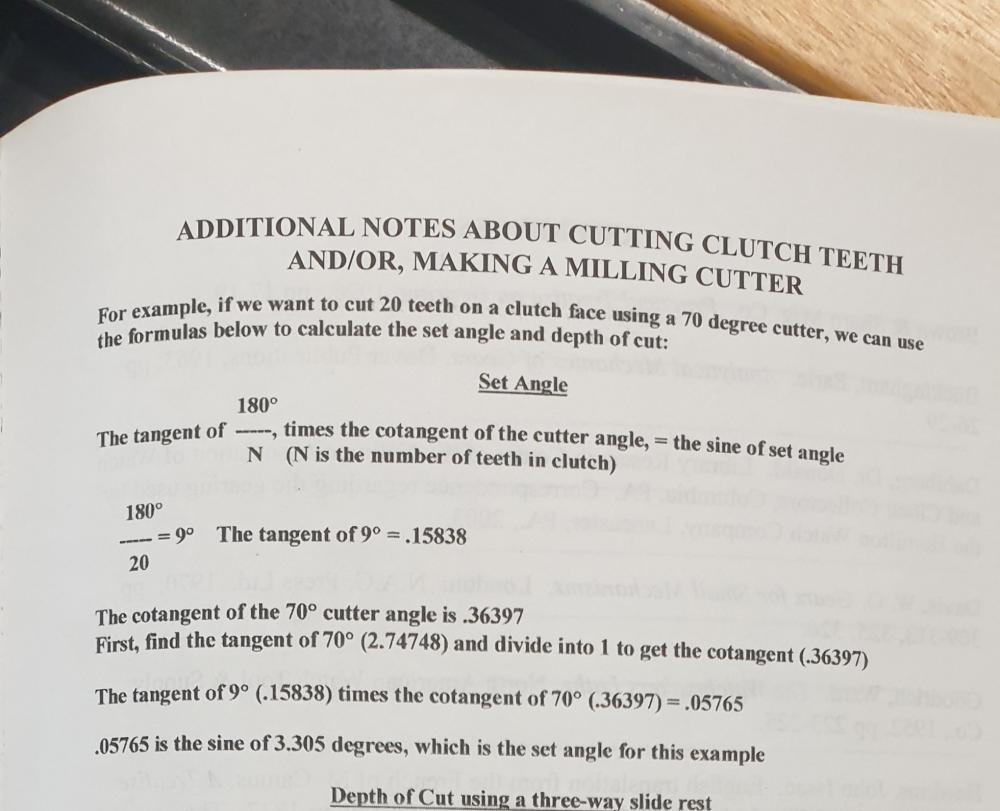

Wait are you T+T+T? Good vid (as are most of theirs), but they missed something it seems almost everyone does when making a winding pinions- the feed of the angled cutter isn't in a line perpendicular to the axis of the pinion, it's a specific angle depending on the angle of the cutter and the number of teeth. This ensures full engagement of the teeth from periphery to center. You can see it in this excellent illustration from Levins' Practical Benchwork for Horologists. They include a chart with the set angle for various numbers of teeth and cutter angles. Sometimes the cutter angle isn't a nice round number 60/70/80 degrees etc., like this tiny Piaget 430P winding pinion. It's 67 degrees, which I've seen and done before and probably explains why I happened to have a 67 degree cutter in my collection. Plugging that and 8 teeth into the math (from Robert Porter's The Clock and Watch Makers Guide to Gear Making) gives a set angle of 10.14 degrees, or 79.86 depending how you view it, which falls neatly between the numbers in the Levin book. You can see how tilted the axis of the dividing spindle is in the milling setup- quite pronounced. Worked great, and a big thumbed-nose to Piaget for making the part so weak to begin with AND not selling parts!1 point

-

According to the web Zippo bought Ronsonol in 2010 and the proportions of the fuel is 70% light hydrotreated distillate and 30% hydrotreated light naphtha. consensus seems to be its the same and safe to use, and when evaporated leaves nil deposits, and is not miscible in water.1 point

-

Have a look at the Jules Borel site Their database is quite extensive and has a look up freature by make/model. There is also Esslingers and Otto Frei again in the US. or Cousins uk, A.G.Thomas, Gleave and co in the uk. Second user spares , welwynwatchparts.co.uk and speedtimerkollection.com in europe. just a few for you to check out you might get lucky.1 point

-

I saw Marshall do that on video once, it looked pretty slick to me (pun intended). g. ----1 point

-

Hi again @Stuart2 A good hint there from @Neverenoughwatchesas Lapanouse/Rego/Cimier are all linked. If you think it's a Lapanouse then you're probably on the right track. The only other breadcrumb I can offer is this: https://www.etsy.com/uk/listing/1150979085/fine-solid-continental-800-silver Look familiar?! Note this does have a brand on the dial of 'Cervine'. A look on Mikrolisk.de shows this name is also linked to manufacturer/brand names of Achille Hirsch, Invar, Climax Watch, Vigilant Watch and Century Watch. Could be worth a quick google images around these various names to see if you can spot your movement as likely they would have tried to use common movements for economies of scale.1 point

-

The highly respected Dutch watchmaker Kalle Slaap puts a drop of WD40 on the screw and let it soak a while. But seeing the screw heads in your pic I wouldn‘t do anything other than just unscrew.1 point

-

That is so. Also at one time you could buy a selection of T ends which enable you to adapt the normal type spring to fit the barrel.1 point

-

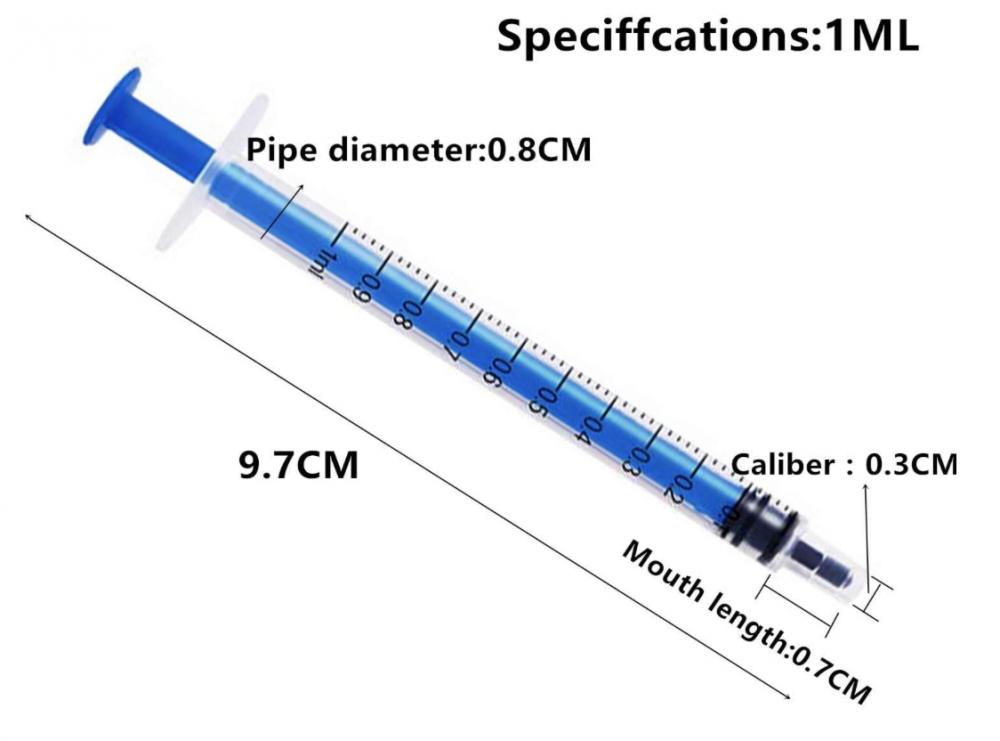

I work in Chemistry research, and I’ve never been able to clean out the silicone oil on these black plungers… the silicone oil always appears in analytical work if you use these types of disposable syringes. The silicone oil doesn’t affect water based solutions as used in medical patient injections etc, which is where they are meant to be used. The largest oiler I have appears to pick up around 1uL of oil (visually, not sure, unable to measure), so by using it repeatedly, I transfer enough oil into my oil pot for a week’s worth. The residual oil on the oiler is small enough that there’s little wastage.1 point

-

Thanks for this important remark! The syringe incl. plunger should be cleaned before use. I use a syringe out of glass. With a 1 ml syringe you are able to dispense very little drops of oil.1 point

-

The black seal on the (disposable) syringe plunger is lubricated with silicone oil. Also, I think the amount of oil taken out with a syringe would be way too much for a week’s worth of oil in an oil pot. If you really wanted to go down this route, an Eppendorf 20uL mechanical pipette would be better than a syringe, but those are very expensive. You would also have to use disposable pipette tips.1 point

-

1 point

-

@Zero You're right, of course. MY APOLOGIES to @12052 for hijacking their thread. I got too excited about my own interests. Sorry. Back to the subject at hand: In one of the books I am reading (de Carle) mention is made of the convenience of immersing entire movements in ultrasonic cleaning machines in order to evaluate them in situ post-cleaning. What is not mentioned in that passage is the nature of the cleaning fluid in the ultrasonic cleaner. The other day while visiting one of the several "Watch Streets" in Hong Kong - a place called Ap Liu Gai - I saw a streetside Watchmaker apply RONSONOL directly to a Seiko movement that was still in its case and then shake it to see if he could get some action out of it. I am pretty sure that's NOT the way to go - but that's what he did. I saw it. Obviously, I am not advocating such an action on your part, because I do not know what the consequences might be for you - but I did see it happen, so it is clearly one of your options if you know what you are doing. The question, as with most things, seems to be more like when you can safely do this rather than if you can safely do this. In its current formulation, ZIPPO and RONSONOL (Liquid Lghter fluid) are composed of 70% white/clear petroleum distillates and 30% naphtha. That's what the Material Data Sheet (MDS) says. Both components are highly volatile petrochemicals that, if they can reach them physically, will certainly "dissolve" whatever oil-based contaminants that might be gumming things up. But be careful - they will also perform a dissolving action on any other other oil-based "things" in the movement, which may include things you didn't want dissolved. To answer your question directly, it depends. If the movement is sufficiently disassembled (i.e. the dial has been removed) and the movement has no sensitive parts and the movement has ample replacement parts if you end up dissolving something important and, and, and.... This is why best practice with all machines is pretty much the same: Disassemble, segregate parts by cleaning modality, clean parts using the modality that is appropriate to their nature and usage context, reassemble, lubricate, test. That's the protocol that I am striving towards with the micro-machines we call clocks, pocket watches and wrist watches. So the question then transforms from when and if to should. I don't think, normally, you should soak an entire movement in lighter fluid. I think you should take them apart "properly", clean them "properly", assemble them "properly" and lubricate them "properly" as they were designed to be engaged with by the people who developed them. Watch movements are not designed to be engaged with in any other way, and this truth is deeply embedded in the social pattern we recognize as Watchmaking and its attendant practices. Hope that helps.... g. ---- Disclosure: My own experience with Watchmaking so far, this thread and other comments I have come into contact with on this Forum have motivated me to start writing a paper entitled "How (and Why) We Clean Things" that I will be circulating to potential publishers for peer review later on this year. I am encouraged to produce written work as a Tutor and Lecturer at PolyU, so I seek out puzzling and paradoxical things in everyday life and write about them. The work is still very much under development, but when I am finished I will (naturally) make it available to this group once it has finished peer review, probably some time next year. Academic publishing wheels turn very, very slowly.1 point

-

Very good point - I have split the topic into a new thread.1 point

-

Really making good progress on this now. Barrel bridge and setting lever spring are sorted. I replaced the mainspring with the one recommended by cousins (and also on Watchboy's database) and sadly the watch knocked somewhat at full wind. I replaced the spring with one 0.005mm thinner and it now runs well, with about 295 degrees in the horizontal positions and 265 in the vertical. Timekeeping is good, so it's time to reassemble it. The only fly in the ointment is a broken movement fixing screw. I've had a few attempts at making one to match, from pivot steel. I used a razor blade knocked on a #4 file to cut the slot, and a cheap Indian die. First attempt is a good fit but it doesn't look too smart. I made the cap too thin and the finish is rough: Second attempt, still rough: So I've been experimenting with duplicating a variety of screws and finishing them more finely, however I'm struggling to get the crisp finish the original screws have. I I just burnish them with a ruby stone and then an arkansas stone the finish is crisp but not fully polished. If I mirror polish them I lose the crisp edges. I'm using improvised tools (green rouge on a cocktail stick in a rotary tool: Any suggestions for a better way to do this with basic tools would be gratefully received.1 point

-

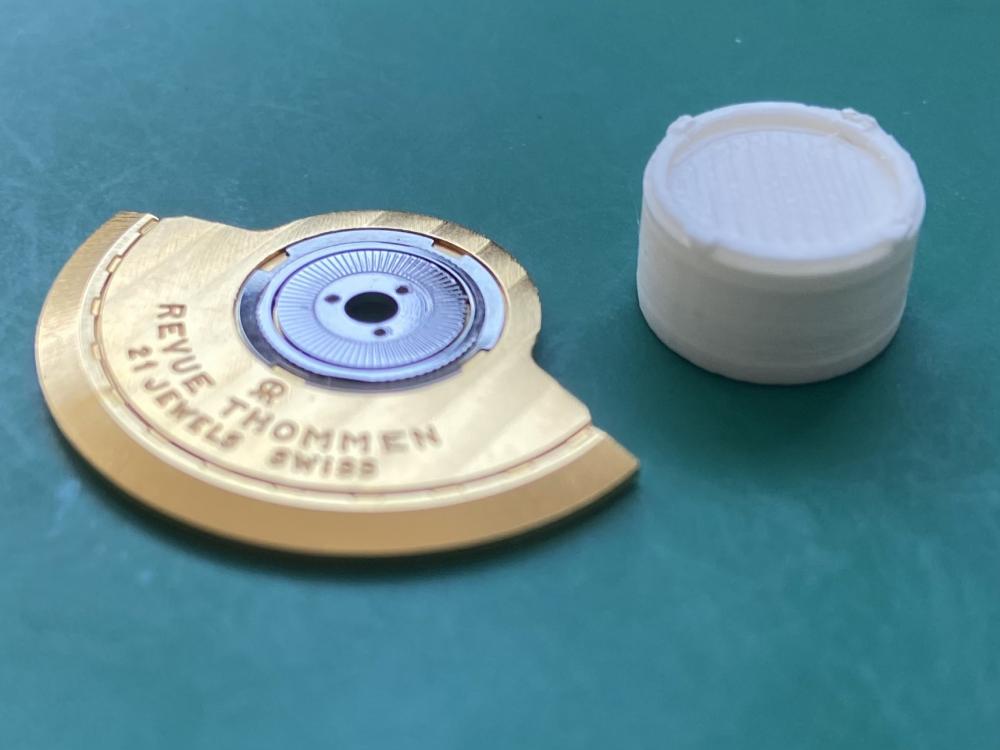

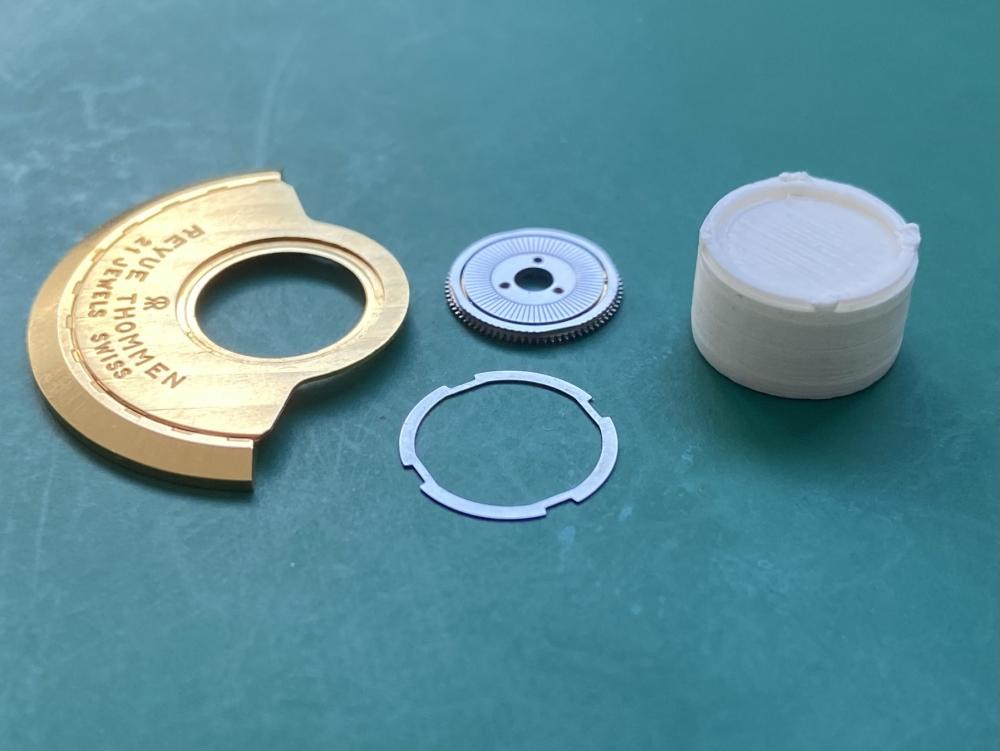

Hi @Gramham, nice to meet you. The design is free and open-source (free as in free beer). You are free to use it or change it as you please, you can read the CC 4.0 license to know more. Eg. there is a member here (AndyShap) who prints it as a service, and he seems to have gotten some pretty good feedback on his page. Yes, it has gone through many iterations and is currently on v0.9, complete changelog is on GitHub. However, v0.86 is currently the most proven and tested version. You can download them here, and read the changelogs if your want to know more: https://github.com/vishnu350/rs-mainspring-winder/releases Have you started on Mark's classes? You can print anything you want as you need them, just measure the mainspring barrel diameter of your chosen practice movement and go for it. PLA should be the best as most printing services are more familiar with this material and you will get better quality out of it. For infill, i would recommend 100% as I have never tried anything less than that. Do let us know if 50% worked for you.1 point

-

For a few dollars more, you can get a swiss-lever watch that will be 100 times easier to work on and everything you learn on it will be fungible knowledge going forward.1 point

-

As you may know, I am now selling these on eBay. By this time, I have printed MANY of the kits and housings. I print in PLA and have no issues whatsoever. I think printing in PETG or ABS shouldn't be an issue at all.1 point

-

This must not be taken as an absolute statement. Ammonia is aggressive and other stuff may also be damaging under certain conditions. We have reports of sophisticated plating, like rhodium, being damaged with even relatively short exposure, so caveat emptor. I don't remembered whar was the professional solution blamed for that. Personally i think that problems, overspending, waste of chemicals and time largely descends from the fixation for "cleanliness" that some people, beginners but even advanced have. I understand that because this kind of OCD goes hand in hand with watchmaking, but sometime we read things like that one must use an U/S cleaner for a bracelet that needs no more than hit water, dish detergent and and 1 minute with a toothbrush. Or leaving parts in the ultrasonic for 30 minutes! Overdone / aggressive cleaning is just like excessive lubrication, not only it does not do any good, but actually can create serious issues.1 point

-

Untrue! You say no one is 100% infallible, but my local FedEx contractor (previously discussed above) defies this! They are absolutely 100% infallible (at being flawlessly fallible)! They also defy the good/fast/cheap 2/3, as they allow you to pick all three (to fail at)! They've continued their perfect track record this week with some plumbing parts. They somehow pulled off the hat trick of costing more than USPS, delaying delivery, AND destroying the package and everything in it! Marvelous display of perfect imperfection. It shouldn't be possible, but they pull it off flawlessly with a perfect track record. (The seller was told in no uncertain terms to not ship FedEx because exactly this would happen, they agreed to ship USPS, and it was even printed on the receipt... Now they get to deal with insurance and agreed to reimburse me to just go buy it locally... pretty much defeating the purpose of every aspect of the transaction for both parties.)1 point

-

Hello All, I’m relatively new to watch restoration and repair. I live in Australia. FWIW, over the past months I’ve been experimenting with approaches to ultrasonic cleaning. I wanted to avoid Naphtha and other volatile organic solvents as much as possible, especially in combination with ultrasound. I found a product manufactured by an Australian chemical company - it’s a sodium metasilicate based powder marketed specifically for water-based ultrasound cleaning of small machinery parts, electronic PCBs and jewellery. It’s economical, odorless and rinses without residue, leaving a nice shine. It removes dried, old lubricant very well without pre-soaking. Here’s my cleaning flow: US with the sodium metasilicate based ultrasound solution Rinse in warm water US Rinse in 99% IPA Hand dry with blower while I inspect the parts. The balance and palate fork I clean by hand in Naptha, with special attention to the pivots. I’ve found pushing and twisting the pivots in to a “magic block” white foam cleaning block/eraser to be effective and gentle on the pivots. This is simple, cost-effective and works well for my hobbyist needs. Watch industry standard cleaning products are expensive to source down here. Just though I’d share. Cheers, John in Tasmania.1 point

-

@Mark Just chipping in here - I'm a software engineer in my day job and I've worked on a few projects that touched billions of users. To be fair, 250 doesn't seem too bad (but it obviously depends what you get out of it). It's hard to know without knowing the actual traffic patterns and usage, but here are a few suggestions that come from the top of my mind: It would probably make sense to limit the upload size of media to this forum (especially videos) -> most can probably be uploaded to youtube and shared here via a link. This way you'd defer the storage cost to youtube for the small sacrifice of ergonomics (I'll let you judge if that's appropriate and something you'd consider) Similarly with images, once they get uploaded to the forum, I would recommend trying to compress them somehow (using lossless compression could still save you ~20% of the original photo without sacrificing any quality). A common practice is to assign images a unique name based on their content and cache it for a very long time. Regarding the email provider -> I would quickly compare the pricing, see if anything has changed since the last time it was setup. Most software as a service products have massive margins and often times just asking for a discount could be enough (or if you are comfortable commiting to a 1-2 year deal or something is always something that will make the sales folks very happy and make them offer that discount) Last but not least, I would actually check how many of the 50k emails are being replied/opened. If majority of them are idle or inactive accounts, I would probably proceed and maybe send everyone an email with and honest email with a fair question of asking them if they still use their account and if they want to unsubscribe As a quick question, regarding the 80GB SSD, is that because of the database size or is that separated? If that is so, it may make sense to clean/vacuum some database tables that have accumulated over time (session tables for example) and reclaim some disk space.1 point

-

Being blunt, I'd blame the Russian mechanical watch first, and then after proof, the Chinese electronic instrument. Simple test, place another good watch on it, does the the same, or what it does? The calibration procedure for the machine in unpublished, and unknown outside the manufacturer.1 point

-

So finished reassembling and lubricating my grandfather's ETA 1080 today and took a couple of pictures of it before putting it back into its case. For anyone interested I assembled the movement in the order shown by these pictures (000A.jpg, 000B.jpg, 001.jpg to 073.jpg). The pictures were taken during disassembly so the parts in the pictures are somewhat dirty. The pictures were intended for my personal use, so some of the text and coloured arrows might seem somewhat cryptical. And finally, a slow-motion video of the balance in motion can be seen here. This watch was last used some 40 years ago or so, so just wonderful to see it tick again! This was my first ETA movement and compared the Vostoks and Poljots I've been working on before I must say the fit and finish is indeed a notch or two better. I really enjoyed doing my first Swiss watch (except for the Unitas 6498 in Mark's watch repair lessons).1 point

-

So, I’ve started to reassemble my grandfather’s ETA 1080 and went about it as I always do, with the train wheels. However, when mounting the train wheel bridge I just couldn’t get the pivot of the escape wheel to reach into the cap jewelled pivot hole on the bridge (seen in the first picture in my first post above). Scratching my head, I removed the escape wheel and inspected it, suspecting the pivot might be damaged. It was not, it looked perfect. So, I tried it again and by holding down the bridge with some peg wood, I could get the pivot to just barely reach into the jewel hole. Yet, as soon as I tried to secure the bridge the pivot would fall out of the hole. Having struggled with this for probably more than half an hour, I began to feel pretty frustrated. I’m not a very technical person, I don’t have a lot of experience of watch repairing, and in all honesty I guess I’m not too smart, but all of sudden I realized, or rather remembered, that the jewel hole on the dial side has a cap jewel as well and that the escape wheel pivot on the dial side probably fell too deep into the jewel hole as I hadn’t mounted its cap jewel. Said and done, I oiled the cap as instructed above (it worked out perfectly, thanks!), mounted it on the dial side and then tried to mount the train wheel bridge again. Bingo! This time around the escape wheel pivot reached into to the jewel hole on bridge perfectly. At this point, I felt pretty proud of myself! Well, just thought I’d share in case someone else who’s new to cap jewels happens to find this thread in the future. I'll try nickelsilver's method the next time around which would have eliminated this problem. Thank you all for helping out!1 point

-

Well, it's not just bigger, it has colors which are quite useful, not just to take better pictures, but to show which "side" the beat error is, as the yellow and blue lines will invert position. The other features include a 10x accuracy resolution mode, configurable measurement interval, and rate rage. Actually rate range is adjustable as mentioned above. I think the minimum "detected" amplitude is about 100 deg, but when things are really bad that doesn't really matter, as the pattern or just looking at the balance is enough.1 point

-

The Chinese timing machines are interesting as far as the internal programming goes. The earlier machines have limited ranges in just about everything. I think they only did 0 to 4 ms beat error. Then the newer 1000 and the 1900 appear to have the same internal programming but the 1900 has a bigger graphical display and some minor enhancements. What would be interesting if someone With a 1900 machine and a watch with a floating stud to make this easy slowly push it all the way to that extreme and what do the numbers indicate and what does the graphical display do. So the real problem is when things are out of range what does the timing machine tell us? The Chinese machines try really hard to always show something obviously lacking error handling capabilities. The witschi machines usually just will not display anything at all. Then for that problem you switch the machine to rate only Beat and amplitude are not displayed or calculated and usually get a display.1 point

-

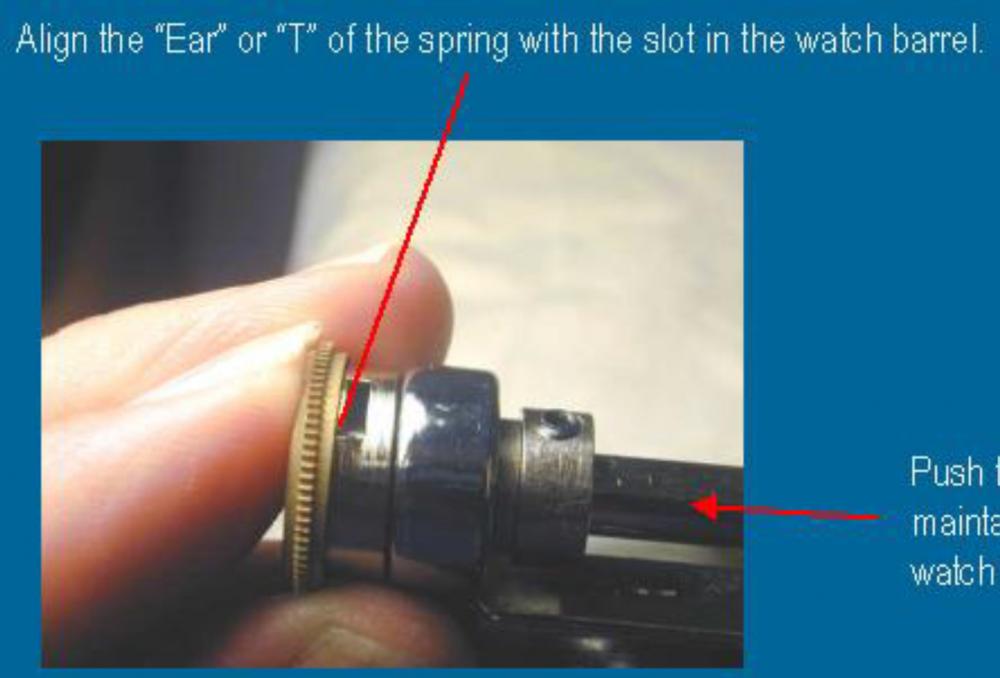

Using a mainspring winder with T end Springs works great if you remember to leave a little bit of the spring out. so insert starting with the little bit of spring sticking out first in the barrel followed by the winder. Rotate until the T is over the hole. Then using, I usually use a large screwdriver push until the T is in the hole. Because if you don't get it in first it will not just magically pop in place all by itself. Then pushing on the T holding it in place you can now push the spring out and it will stay word supposed to be.1 point