Leaderboard

Popular Content

Showing content with the highest reputation on 07/08/22 in all areas

-

@PlatoI know what you mean but the flip side of that is to know your budget constraints and limit your watch projects to stay within budget. That means knowing when to bail on something that's going to take you down a rabbit hole. I understand that everything within a mechanical watch can be fabricated from scratch given the materials and proper tools. I don't need to be able to turn a balance staff or to cut my own wheels or pinions. I'm not trying to become a "watchmaker" - I'm only trying to understand watch mechanics and amuse myself. I don't see myself as ever re-jeweling a plate or adjusting end shake but I want to understand when that is required and what I'd have to do in that situation. I'm never going to have the opportunity to work on a Patek Philippe or a Breguet and that's OK. If I eventually acquire the skill to clean and lube my Zenith (and feel confident that I can do so without screwing up my own watch) I'll be happy.3 points

-

This is today's pocket watch of the day. A defiant with a lovely enamelled dial by fattorini. I've come to know a lovely retired antique dealer and his wife at Bridlington carboot in East Yorkshire. Bought a few pieces from him inc. A pre ww2 engraved glass bowl by Lalique and a couple of nice bigger timepieces ( carriage and mantle clocks from him ). Today a Smiths floating balance westminster wooden case mantle clock to replace the buyer's remorse one i got from an antique shop. and he actually gave me a non working pocket watch that he bought years ago that had never worked. He popped it in his pocket on their way out hoping he would see me today. I had a look for him but only had 3+ reading glasses so all i could see was the hairspring coils looked stuck together somehow. He said if it was any use to me i could have it, what a lovely old gent, thank you Steve and Myra x. Here it is absolutely swimming in oil. A chip pan movement ( Kalle ).3 points

-

Haha. I would have years ago, but this not the case now as neither of us are the others keeper. It was a genuine figure , i will go through the items if it helps anyone. I am as they say in Yorkshire, as tight as a duck's arse .1 point

-

BUT. whenever this was bent in the past, it also was twisted so that when it hit the banking pin (the one by the roller, not the anchor) before the escape wheel tooth could escape. I have done another adjustment to solve this problem. Now the escape wheel is exiting more or less correctly. I will report back later...1 point

-

Hi LWS The atmos clock was a clever invention and from what I have read on the subject requires a thorough understanding of how it works, the bellows being the delicate part. There is a site the Atmosman (Michael P Murray) and also a repair manual on Amazon £29 Good Luck.1 point

-

I repaired my fathers Atmos 25 years ago based on a VHS video tutorial by clockmaker Tony Montefusco (Florida) with whom I had an email correspondence. The video is available on Youtube meanwhile but still has the terrible VHS image quality.1 point

-

I always thought the Atmos was a cool clock, not because of how it looks but because of how they work.1 point

-

Hahaha mate its just way things come out. I cant play with mine I'm too busy helping my missus play with her new toy lol. Oh dear ive done it again1 point

-

Ain’t that the truth. I‘ve also sunk waaaaaay more into this hobby than I should have. But geesh I’m quite the tool, erm, enthusiast. I just can’t help myself. I did tell Rich how to hide expenses from the missus - I suspect she might be reading here so he threw out a low number. Ooops, sorry Rich1 point

-

Haha, i had no doubt that you would be successful . And thanks lol. Reading your explanation prompted me to press the biggest pusher down with my little finger . Ta-dah ( we spell it differently in the UK, might be because we are posherer here ) pushers with spring loaded end pins. Lol.1 point

-

I wouldn't go by the readings your app is giving, I have tried it a few times both with the phones inbuilt mic and a few plugin options an not once has it given results anywhere near the readings my low end timegrapher gives, I use the old Weishi 1000 which works well. Using a marker pen put a small mark on the balance then film it in slow motion, most modern smartphones can do slow motion videos, then watch the playback and see what the actual amplitude is by seeing where the little mark swings to in both directions, you may find it's a lot more than the 100 you app is reporting, hopefully, if not then as others have said above, eather a very weak mainspring or something a little tight in the gear train.1 point

-

That's great and a sharp looking watch as well. How does you feel (as if I have to ask)? Hooked yet? Shane1 point

-

1 point

-

I can understand Plato’s attitude, But it’s a shame he is n disenchanted as his input was always good and informative. the watch repair game is not cheap. If it was not for the Chinese tools being available at reasonable cost it would be hard work. I myself have a limited amount of tools some home made but effective in carrying out the required task but limit myself on un regulated spending. It all depends on how deep you want to go and the skill levels you have. We have said on WRT may times the best tools in the hands of an idiot are just scrap. NEW, Ihave three lathes and poke about on them when required but used to make bits on a Myford 7 for accounting machines, rivet posts and shafts. Used HSS cutting bits though tungsten bits were not available then1 point

-

you're missing the minute wheel. Your options are to find an assortment and see if something will work that would be the easiest and cheapest probably. Otherwise you can make a new one or have someone else look through their assortment and/or make a new one. I don't suppose you have access to a time machine? If you can find somebody who stocks vintage movements for parts and other was a material house specializes in vintage watches may be. Otherwise know there were never spare parts stocked for this watch or basically any other watch in this time frame. It can only get spare parts if they're made in sufficient quantity and later in life. So some company was mass-producing a watch there might have been spare parts but these are almost not quite handmade more than likely hand finished. You probably need a mainspring when you get the old one out we can figure out what you might build put in the area probably have to modify the end may be depends on what they had on the end for the mainspring. If you're lucky the balance staff isn't broken otherwise it's going to be a lathe's project. Basically watches like this are restoration projects they're not your simple clean lubricate toss a few new parts in an offer and running plus the other problem of 100 years of your watchmakers or someone who thought this was a toy problems can happen from that alone.1 point

-

Word of the day. Gentle. I cracked the first jewel I tried to remove because I forgot that. Other than that, you need to make a note (using the micrometer reading on the tool) of how deep the old jewel was and fit the new one at the same depth. After that you fit the wheel and check that the end shake look correct.1 point

-

Sounds very wrong lol Very thorough and articulate Shane. You should write books1 point

-

Hi Charette. Yes in a direct line of the pallet pivot hole, the dead centre of the banking pins and the balance staff pivot hole. Easier to see without the train and escapement being in the way, as you progress in your learning make it a habit of checking this before other assemblies are made. Pocket watches and a lot of vintages watches dont have an adjustment arm on the balance assembly to allow for easy adjustment of the watches beat. Where the hairspring stud fastens in this situation is in a fixed arm so instead of adjustment being made from the top at the stud end of the hairspring it has to done from underneath the balance cock at the opposite end of the hairspring where it attaches the innermost coil end to the collet. The collet is attached to the top of the balance staff. This adjustment can be risky for a beginner as you are having to get in very close to the hairspring. My preferred method is particularly risky as a screwdriver is inserted between the coils or from the centre of them through the top but i find it the quickest and most accurate way and generally only takes one attempt to put the balance in beat. Another way would be to mark the collet's position, remove and then reposition it, still risky and may need more attempts. So unless the balance has a very poor beat error maybe stay away from this adjustment until you have gained some more experience . This is where you would be working if you were to try.1 point

-

yes not lubricating the escapement is going to lose a lot of energy there. When you put it together you should see if it looks like it's in beat? That is before you wind it up.1 point

-

Waaaoowww! I wasn't expecting so many answers. Thank you for all your comments! At the moment, the watch is disassembled, and I have started reassembling it slowly and carefully.1 point

-

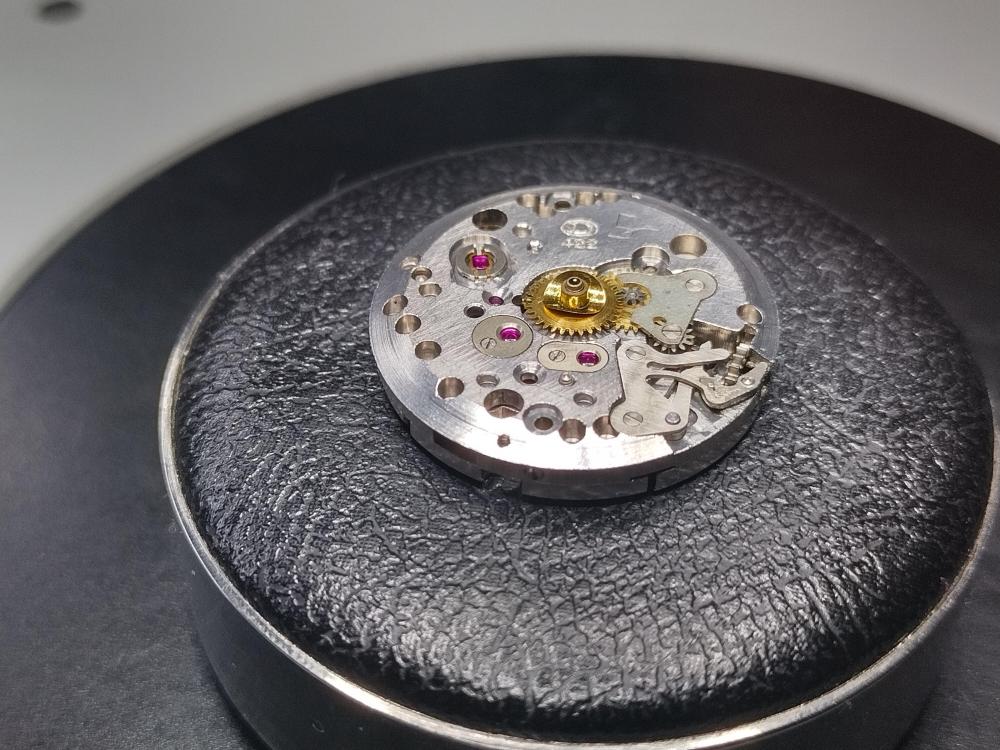

EB8420 finished casing it recently This is a practice watch. I got a tray of EB8420 movements without balance wheel, a tray of EB8492 with balance wheel but without mainspring barrel and a box of new EB8420 dials. Now the balance complete is interchangeable or it is just a maybe because i could not set the beat to 0 ms as I already hit the balance cock and cannot move the little arm any more... maybe I need to play with the HS colet now. Anyway I purchased a tray of EB8420 too plus found a set of scrap hands in the scrap box. Unfortunately I have no dial rest and I dont know how to source it and where to find good looking hands. I tried to take apart the pushers to completely clean the case but the pusher screw glued or "locktited" in and when i tried to turn the screw i just broke it of... so I tried the other pusher and I broke that too... ok lets take another case all looked good for a while and then one button just fell off... i did not even touch it/push it.. the screw again was broken again at the same place, where it goes into the pusher.... two cases wasted... (dont think i can find pushers individually for this case/ cousins do not seem to have them) anyway it has a nice performance apart from the non 0 ms beat error. (as far as i remember it was around 0.5ms) These are also ready a nice little Westclox and a Laco with Durowe 422. They are on a test run at the moment. https://17jewels.info/movements/d/durowe/durowe-422/1 point

-

Hi Get hols of Ward Goodrich's book "Watchmakers lathe its use and abuse". Or De Carles book. As far as Gravers go its a personal choice, Usually tungsten carbide, and the shape prefered depends on the use the graver is being used for and the type of cut required.1 point

-

So i think I've figured it out with a little research. This is definitely a Record Dirty Dozen, one of around 25,000 built towards the end of WW2. But with a Nato redial for a safer lume. The radium dials were decommissioned in the 50s then the watch put back into service with the new dial. The serial number on the dial was given to the Record, a few other makes had the same treatment with a different serial number, IWC, Timor and Omega. After the watch's eventual complete decommissioning it was sold to the general public, this may have been anytime between the 50s and possibly as late as the 70s . This is indicated on the caseback by the bottom serial number which is its decommissioning civilian serial number. Decom. Date either 1952 or 1976. Either first 2 or last 2 numbers I'm not sure which yet. I'm inclined to believe 52 as the caseback has a watchmakers service mark of 1963, but this is a complete guess. Personally i would have picked the last 2 numbers of 76 so 1976. Bit more research needed. The designation W10 came about in 1957 when the ATP watches were decommissioned and sold off to the public. Any remaining DDs in service that went into the stores were awarded this new W10 designation along with the new safer Tritium dial.1 point

-

So here it is. I couldnt wait to post this as I'm over the moon with it. I've wanted one since i started collecting. Would you believe i asked the universe for it ( the right way ) two weeks ago. So a couple of weeks ago i was at n.cave e.yorks carboot talking to a guy about watches . He had a couple of non descript clocks that i wasn't interested in but i asked if he had any watches. He said no not with him but at home he had a w.w.w. ( very large clue as to what is coming )wristwatch that he had had fixed but had broke again. I asked if he wanted to sell it and if so bring it in two weeks time when i come back up this way to see my sister. He said ok. He told me it had a blackface and he thought it was an Ingersoll. I wasn't aware Ingersoll made www watches and had never seen one so i thought maybe he's mistaken. So anyway keen to go back yesterday morning, i mooched around the carboot for an hour taming my anxiety and excitement ( i dont like to rush a universal gift, its not respectful and can get taken away as quickly as its given ). In doing that i also picked up a lovely 404ish clock. Eventually i made my way over to the guy's inside stall. Now then matey how's you i said , gud he replied, I've brought you something. He searched through a carrier and i was thinking it cant be much of a watch to chuck it in a carrier bag. A minute of searching and i thought hes forgot it never mind. Ahha he says pulls it out and hands it to me ( the watch ) . I look at it and look at him. Then I look at it, and I look at it , and then I look at it some more. Oh crap its a w10 military watch. He tells me the mainspring has gone, i said no it hasn't, its just fully wound. Have a look inside he said if you want. I had taken a screwback remover a loupe and a piece of rodico with me. I undid the back and peered inside. Its a Record i said, oh at least i know what it is now he said. I had a little prod with the rodico, unfortunately one of the staff pivots had broken, the top one. I said what do you want for it, he gave me his price I'm not saying how much but it was cheap. I said no i cant give you that, so he came down a tenner. I said no i cant give you that either. He said I'm not taking any less that that for it, i said i know your not, your going the wrong way. He looked at me confused, i said take your first price and double it. He looked at me even more confused. Mate its worth more than double what you want , I've got to fix it but I'm happy with that if you are. He wouldn’t take double and we settled in the middle. I gave him his money, we chatted for 15 mins and then shook hands, before i left he said i think i have a couple of pocket watches at home, ill bring them next week, if you come again you can have them. Wow Universe what have i done to deserve your praise. So here it is. As far as i can tell up to now. Its a redialled record dirty dozen (possibly). The movement is the same as the Record DD, the dial serial number relates to the Record. I have yet to date it yet but the movement 022K according to ranfft started being manufactured in the 1920s. Anyone that has some serious knowledge on military watches, i would be so grateful for any help working out what i have here. Here it is i absolutely love ❤ it .1 point

-

1 point

-

1 point

-

I've run about 10 watches through my Janta/Pearl machine and during the 1st cleaning cycle on the last watch the unit stopped and won't turn on again. I've left a message with the seller but haven't heard back after 5 days. I was also having another issue where the arm the basket is attached to kept wanting to not stay in a fixed position. So as it was in the "spinning" mode when spinning off the cleaning/rinsing solution, the arm would quickly just shoot to the top of the unit, spraying the fluid everywhere. I ended up having to stand next to the machine and hold the arm in place during the spinning cycles, which was extremely annoying. So now I have a $600 door stop0 points

-

Definitely not, I could not afford a new lathe or any new collets. To be honest, I'm losing interest in watchmaking as it's getting far too expensive to be any fun with a limited budget. So much for this place being a fun and friendly forum! I've successfully serviced a Lemania 283, so that's as about as complicated as I hoped to test my mechanical skills... back to the electronics with a steady hand My tools will be on eBay soon, bye.0 points