Leaderboard

Popular Content

Showing content with the highest reputation on 01/22/22 in Posts

-

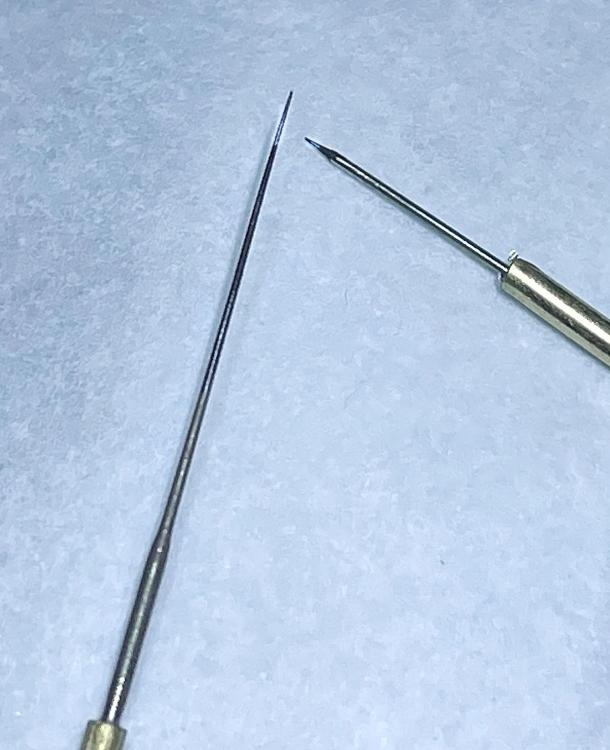

I invent tools for myself Ive not seen or improvements to available ones. These are two different gauges I've come up with. The pin with the white head has a hairspring collet as a stop. You can measure and transfer the length or depth of the work on a micro scale. It works really well for lengths of arbors while turning. The other two taper pins are made from sewing needles turned down. You use a permanent marker or ink marker to darken the needle. GENTLY put it into a jewel or a bushing and twist a couple of times. This will make a witness mark you can then pull out and measure the diameter of where it falls on the pin. You can see in the image where the ink was rubbed away at the tips. You would measure the shiny metal right where the ink stops to get your hole diameter. Both of these easy to make tools have helped me out many times.5 points

-

Out of concern for your safety and good health,,,, disappointment,,, heartattack,,,. LOL2 points

-

There is a strong argument for avoiding ultrasonic cleaning and ammoniated solutions for older work, but in particular, older British work where the brass is hand-hammered. Hammering hardened the brass and naturally introduces fractures which are generally stable, but can deteriorate with ultrasonic cleaning action and ammonia. In my opinion, a French clock of that age should be fine in an ultrasonic cleaner and I’d possibly use lightly ammoniated solution without worrying too much. If it was an English clock from the early 1700’s then eyebrows would certainly be raised. Also, those French clocks are not especially rare.2 points

-

I'll second that advice for any other folks, you've really got a good range of information there! I actually used your method of making belts with fishing line, to avoid snapping the connection on the plastic ones or experiencing excessive vibration with other methods. Mind you my belts were rather too large, but that's a minor detail1 point

-

1 point

-

1 point

-

Always be extremely careful when it comes to dials, you cannot afford to damage them in any way no matter what they are made of. Looks as if it broke away when someone tried to pin it. So tap it out from the back to the front, as you can see at the front it has been flattened, so back to front and tap carefully. Mercury glass tubes you can get here. They come empty, who the hell you could get to fill them heaven knows. I don't think anyone wants to play with that stuff. http://www.m-p.co.uk/muk/parts/pendulums-french.htm1 point

-

1 point

-

I think you'll find with most American pocket watches there were variations for staff. If you're lucky the only variation is pivots size. It's always a confusion to people when they purchase a staff for their pocket watch and they wonder why it doesn't fit? Because the rule is to measure the old and make sure it agrees with whatever you think was supposed to be in the watch. You measure the new staff and make sure its identical in size to the old staff. Spend a lot of time measuring and verifying it is indeed the proper staff. Because quite a few of the staffs will have other variations for the exact same part number. Yes the evil balance tack. Usually American pocket watch hairsprings are pretty tough but they're not indestructible. I've never liked the idea of the balance tack as on some hairsprings like Omega they will be very unhappy they don't like to be stretched at all. It might look nice in the books but it's definitely something you do not want to use. They do want to be careful with your hairspring it can cause you a lot of grief if you're not. Some were on the discussions somebody fix their hairspring and are very proud of the work they did fixing it but then they discovered like you have: shaped hairspring? Their conclusion was that it must've been done before by somebody else. Although my suspicion is in their fixing of their hairspring problem that they probably caused the problem. Then a note regarding parts swapping on American pocket watches? The Industrial Revolution parts books the parts all interchange except why is there a serial number on the watch? There's a serial number to keep the parts together usually on a pocket watch all the plates will have part of the serial number. If you look at the balance wheel the serial numbers usually scribed on the balance wheel. Depending upon how long they made that particular movement for things become even more interesting. There is a 12 size Illinois watch that somebody was going to use in a project and they were very excited because the parts book indicates at all the parts interchange. The problem was the watch was made over 30 years and there were variations which don't necessarily show up in the parts book. That means the ability to interchange parts is nonexistent despite with the parts book says American pocket watches were usually made in batches so conceivably between the various batches of whatever these watches were made there will be variations. Usually all of the escapement components like the pallet fork they're all individually adjusted. So this is where mixing and matching to make a good American pocket watch out of bits and pieces of other of the same type can become quite challenging of verses a modern Swiss watch.1 point

-

1 point

-

For me, it has to be a classical symphony, or a piano concerto. About three years ago, I discovered a classical radio programme that is available 24/7 online from Washington, USA. I 'bluetooth' it into my 5:1 surround sound system. Since then, I have never looked back, or bothered with the outdated and drab; BBC radio 3. In fact, I have absolutely nothing to do with anything via the BBC. I gave up the TV several years ago. YouTube is far more interesting and you do not need a licence to view.1 point

-

I think if it were mine then I’d try to source some scrap Mougin movements. Or similar French movements in the hope that the barrel could be adapted to fit the new barrel arbor if the barrel circumference were the same.1 point

-

The main issue is the barrels that have had poor repairs. There are posts and a vid (see below)on the net showing how this task is done. I can not comment on how easy or difficult it is as I have never attempted it. I have straightened bent teeth with no issues and for those in the UK Mr Fletcher actually shows how he does it in one of the “ repair shop” episodes.1 point

-

1 point

-

Thanks for all of your help.. I deformed all three pin heads with a domed punch, a little loc tite and I needed a machine press to get it back together. I’m very happy with the results. Feels like it should last.1 point

-

Do you know what happens on American pocket watch if one of the screws goes missing? You might ask why would it disappear but they do Fallout with time. So I always check my balance wheels of I'm getting bizarre timing. Then they run really fast until you find a screw or replace it. Isn't that a strange sentence that I said? Hairsprings are more than for just timing the energy of the hairspring is used to unlock the escapement. If you go dramatically out of range of the hairspring for the balance wheel watch doesn't run the doesn't run very well. We just know it's running fast we don't actually know if it's running well at all. So if we assume that it's running well then they hairspring is close enough we just need a timing adjustment. Like findings in tiny balance screws there is at least a couple of holes that I can see on the rim. A tiny balance screw would make a much more dramatic effect in putting 1 million timing washers. All of this is speculation unless somebody with a proper timing machine can do a proper timing analysis as to whether the watch is actually running how well it's running how it runs in different positions. It's really strange how so many watchmakers would only time the watch in one position and never evaluated in multiple positions. So a proper timing analysis my mind needs to be done before we could even proceed with what we can do with the balance wheel.1 point

-

A bit of woodworking The case (was a 1.5L wine bottle box) for the big drill bits which I got as part of a "lots more stuff" is finished. These have Morse taper shanks, so need to accommodate adapting sleeves, drifts and a chunky MT3 to 2 extension. For the latter I made a sort of round nose cutter to work the top tray, all slotting was done by eye on the milling machine. Then two hands of wood stain conceal most mistakes and make everything look vintage good.1 point

-

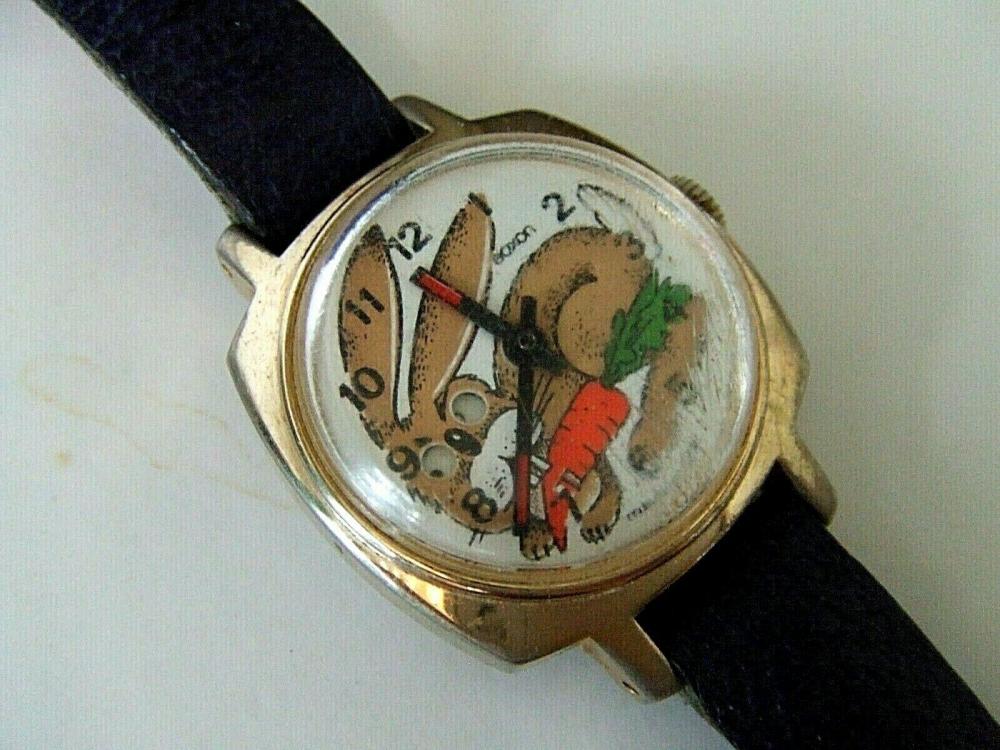

This was shipped out to me yesterday, should have it on monday.. was a steal at a whopping $35.00. Only bad thing is it looks like someone has swapped out the original cathedral hands for this set, not sure why but I doubt I can source an original set, oh well. Will probably just resell it once it comes at a good price and let someone restore it.1 point

-

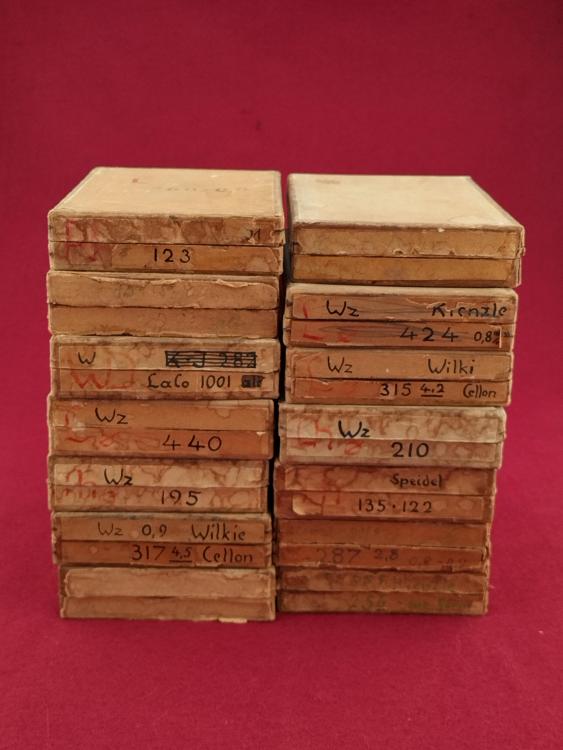

One step closer to become the "Crystal man". These are also from Germany. Acrylic watch "crystals" made for Kienzle, Laco, Speidel etc. I kind of see burn marks on the tools. Does that mean that the tool was heated up to ease the forming? https://en.wikipedia.org/wiki/Kienzle_Uhren https://en.wikipedia.org/wiki/Speidel https://en.wikipedia.org/wiki/Laco_Uhrenmanufaktur1 point

-

that's a good question. Cousins has some 3133 parts but no 31659 parts listed. the russian watches forum over on watchuseek has a parts wanted thread, some of those guys may know or may have parts you can buy.1 point

-

1930s for early 1900s pocket watch. When I'm in the nude, I mean mood...... VID_20200612_135726.mp41 point

-

Here are the photos. I'm convinced it is fake now. But I got this with other watches. I like a couple of the others, although one of them was an old Hamilton and when I noticed the lume I got out my geiger counter and sure enough... I'm not sure what I'll do with that one. I'll glue a nut to it tonight and let the glue cure for 24 hours and then we can see what's inside.0 points