Leaderboard

Popular Content

Showing content with the highest reputation on 01/09/22 in Posts

-

3 points

-

2 points

-

Always so much to learn. Thanks for the input! My demagnetizer arrived today, and it really worked a treat. Completely demagnetized my tweezers and screwdrivers. I also made a silly time-lapse video of the watch running. Speaking of screwdrivers, I managed to make a little time to get out into the woodshop and make myself a quick and dirty screwdriver caddy from some scrap wood, as well as a balance tack. Because why not combine hobbies? I didn't sand the wood because it was 40F in the shop, even with the heaters going full blast, but I did bring the brass tack up to 1500 grit and finished with tripoli compound.2 points

-

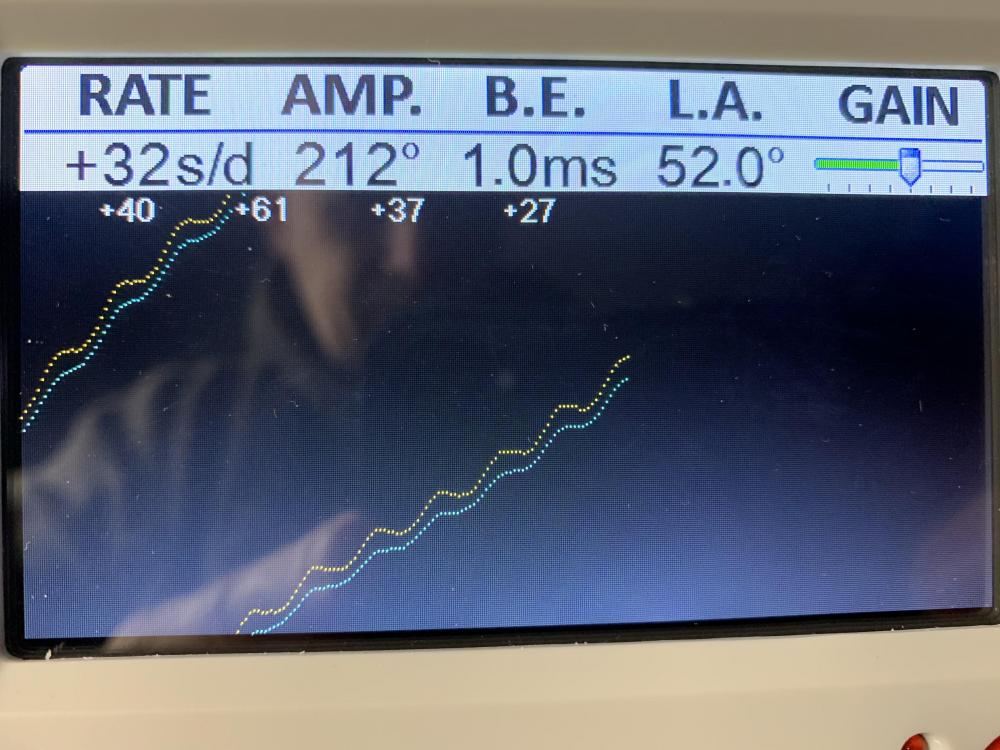

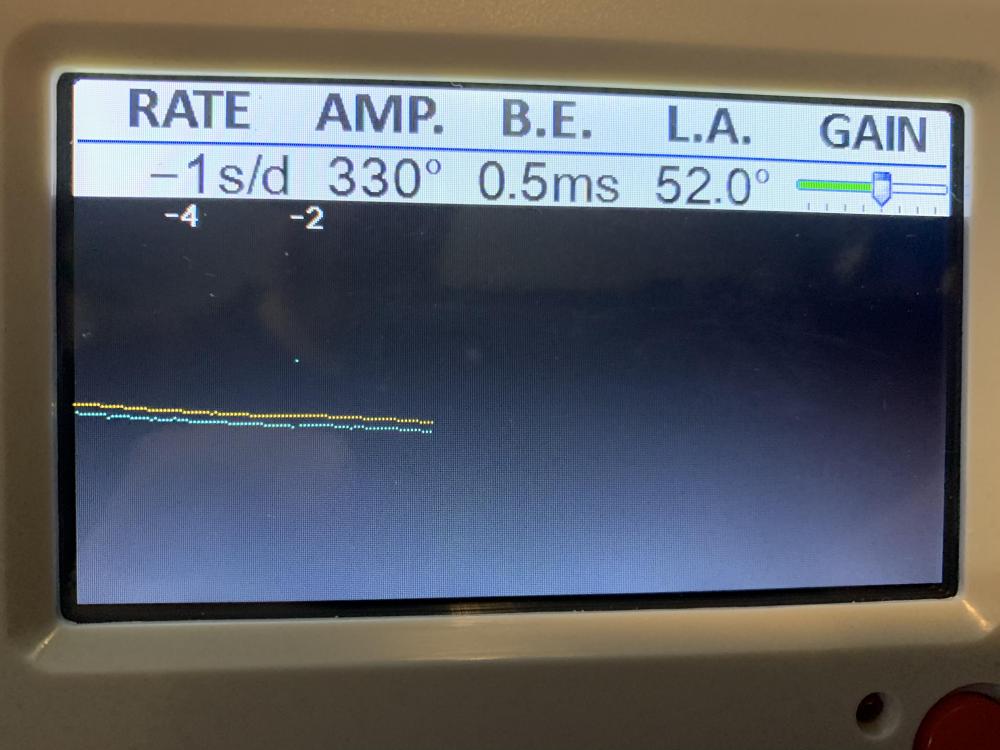

Random thought I assume you demagnetized it? The nice thing about the graphical display is the meaning hasn't changed since the first machine spit out paper. Although some of the timing machine manuals you wonder about the mental state of the people who Were interpreting the results. The one I'm attaching is pretty straightforward. Then I snipped out an image of what it probably is. Then unless you verified the lift angle your lift angle is probably wrong. But that's not going to change the graphical display output only the amplitude. Timing-Machine-Charts.PDF2 points

-

In addition to the visual look if you run the mainspring through your fingers can you feel the bumps and imperfections? If it's your own personal watch you try to straighten it out but even if you get everything straight if you can still feel the imperfections that's not good. Then there's the problem of if it's bent now and you straighten it out is it more likely to bend again when you put it back in the wider? When you're using a mainspring winder you have to be very careful that you don't have one that's too small and physical size and you put too much pressure on the mainspring otherwise you get imperfections like this. In real life the best thing to do would be to replace it.1 point

-

To quote Plato "Its Knackered" so you will not do any damage trying to salvage it as an exercise . But re fitting it into a watch is a no no as there would be no smooth power delivery.1 point

-

Sorry, I was being facetious. I don't see why you couldn't smooth out the odd kink, I've done it. But near the arbor end, it looks totally out of shape, and coned upwards, which is not easy to fix. The other end looks OK though !1 point

-

That is a small ladies mov.t, very simple but somewhat more difficult to work on due to itssize, especially for beginners. It is very likely that without tools or knowledge you will damage it or lose some parts. Below a topic on what mov.ts you should begin with to learn how a watch works, name and function each parts, and more ortantly developed dexterity. If you are serious about learning repair I suggest that you enroll in the training by our Host Mark Lovick at watchfix.com1 point

-

At one time sticker shock would be an excuse not to have a timing machine. Anything resembling a professional Swiss machine would usually be in the thousands of dollars and still is in the thousands of dollars. So that would be a good excuse not to have one. But the Chinese have all kinds of timing machines the recommended ones are the 1000 and the 1900 preferred. Then the pricing of the machines are really interesting in that it depends on who's selling it. Then they can be purchased from the usual places like Amazon and eBay. You just have to pay attention to the pricing usually the US sellers are charging more money Chinese sellers are usually but not necessarily less. Amazon has a 1900 $180 but looks like the seller is in China which explains why the shipping is going to take several weeks.1 point

-

1 point

-

Out of curiosity on the Omega watch site I have below with that correspond to your watches? The problem is their old and old watches are much harder to find parts for. If they Were not extremely popular you probably won't even find a parts listing. There are genetic catalogs that list Omega replacement crystals you might find one there. One of the problems with the Omega case numbers are the case themselves could've been made in a variety of materials. If the crystal has a metal ring inside it would normally correspond to the color of the case. So if you had a gold colored case you haven't gold colored ring. Stainless steel would have a white ring or silver color. If you have the old crystal you should feel the swap the ring as often times that ring holds the movement in place. Then I'm guessing these cases probably don't have a metal ring which means in a round generic watch crystal of the right size and height should fit. Then I did find numbers for you just make sure the dimensions look right and a lot of luck finding those crystals. https://www.omegawatches.com/en-us/watch-omega-cosmic-omega-ko-2606 062PN0316 D31.60 H3.00 https://www.omegawatches.com/en-us/watch-omega-cosmic-omega-ck-2471 062PN1058 D32.4 H3.71 point

-

Thanks everyone for your interest and advice. There were two issues, I think. These movements often have 0, 1 or 2 shims under the balance cock. This movement had 2. I removed one of them, the end shake reduced and things improved significantly. I also had a careful re-look at the balance spring and it had a few unusual twists and the end curve was eccentric. I removed the spring, smoothed all that out, refitted the balance and re-cleaned and lubricated the balance jewels. The end result is that the movement is now running nicely - the amplitudes are now as expected. Thanks JohnR725 for your explanations which make perfect sense. And yes, I’ll get into the habit of documenting the watch performance on the timegrapher before servicing - allows meaningful comparison. Thanks for the prompt. As I said, I’m new to all this. Lots to learn. Thanks again! Until next time, John1 point

-

Please post pictures of the broken part, microwelding could be a possibility. A genuine clasp would be expensive and difficult to obtain.1 point

-

Guys firstly I must say that I am impressed on all the fantastic vintage watches you all collect Recently I purchased these 2 from ebay First is a Precisa automatic of unknown year but looks maybe 1960 ish Second is a Tissot manual wind of unknown years as well Maybe some of you may know brand and how old? Both these are very nice shape Precisa is gold and Tissot is rose gold1 point

-

Don't be fooled by the word grease, 9415 is a very clever grease, it is what is called thixotropic, which means that under normal contitions it behaves like a grease, but when it is hit by a pallet stone it momentarily becomes a super slippery liquid before reverting to a grease again. The result is a lubricant that is thick enough to stay in place when it's not lubricating anything, but which becomes fluid enough at just the right moment to do its job.1 point

-

1 point

-

1 point

-

Then it's always nice to show us a picture just because we like to see pictures. This is where I'd like to record the before servicing and after servicing numbers. It's nice to see a comparison and see if you've increase the amplitude improved the watch etc. Did you notice an interesting problem here? Who cares about the rate sort of what about the amplitude? 330° dial-up Then you lose 44° dial down and actually have better amplitude in crown down? Typically dial up and dial down should be very very close to identical in amplitude. Then personally I always like to look at the watch in six positions four separate crown positions and dial up and down. Here's something fun try an experiment in dial-up let some of the power off the mainspring bring the amplitude down to about 280° and then tell us what sort of time keeping you have? I suspect your regulator pins are too far apart which is why you're having an amplitude timekeeping issue. Then you have to take care your pivots because dial-up and dial down can not be that different it's very bad if a crown position is better then a dial position not impossible but it's just really really bad to do that.1 point

-

Etachron (and their likes) studs are not attached with shellac, instead a special cement is applied at controlled temperature. I do not recommend washing mov.t parts in heated US, as it does nothing which a regular soaking in the same solutions doesn't.1 point

-

There should be another little identical pinion on the plate with two posts. When the rotor engages turning counter clockwise the first pinion will engage the large wheel, rotor turning clockwise will pivot the first pinion away, bringing the second pinion into engagement with the large wheel. It's a clever and simple design (and the setup to keep the center seconds hand steady on these is very clever too).1 point

-

I struggle with this issue a lot as well. Even simple household items rust very easily for me if they aren't good quality steel. Colored silica gel are great. But they expire really quickly if the toolbox or storage container isn't airtight. In my case in just a matter of days, color changes from orange to dark green. If you buy in large batches and didn't store them properly, be prepared for a shock when the whole batch expires. Sometimes, they even arrive in the mail already expired, and if you got the non-colored version then there is no way for you to find out. Its a borderline scam. Also, I don't recommend the oven/microwave method to recharge these, as you really don't know the quality control of these little balls. For all we know they could very well be tainted with uranium or cyanide. Or whatever. So to really solve this problem, I use two things together: 1) An airtight drybox: I find the best are the ones camera enthusiasts use, they even come with hygrometers (shows humidity levels). I like the cheap Nakabayashi ones: https://www.nakabayashi-global.com/products-all/capaty-dry-box 2) "Branded" rechargeable silica gels: Eg. https://www.eva-dry.com/product/e-333-renewable-mini-dehumidifier-2-pack. Pop this in the box along with your tools, close the lid and watch the hygrometer go down. If it doesn't, then just recharge it.1 point

-

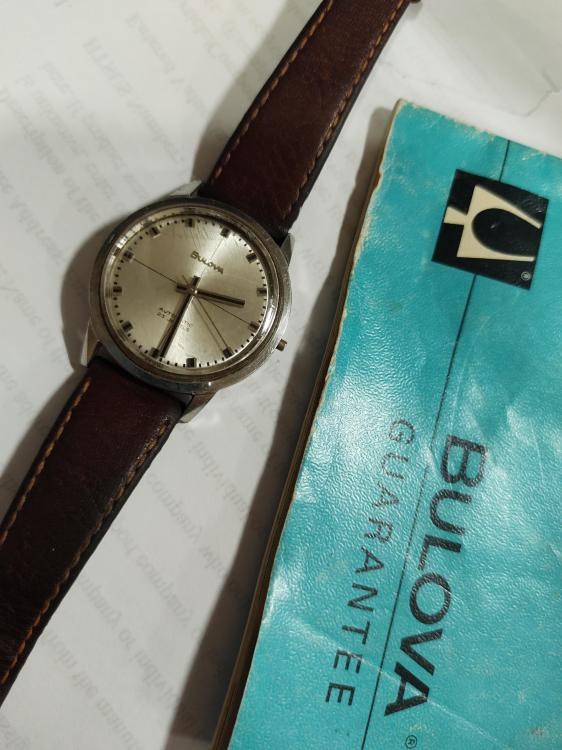

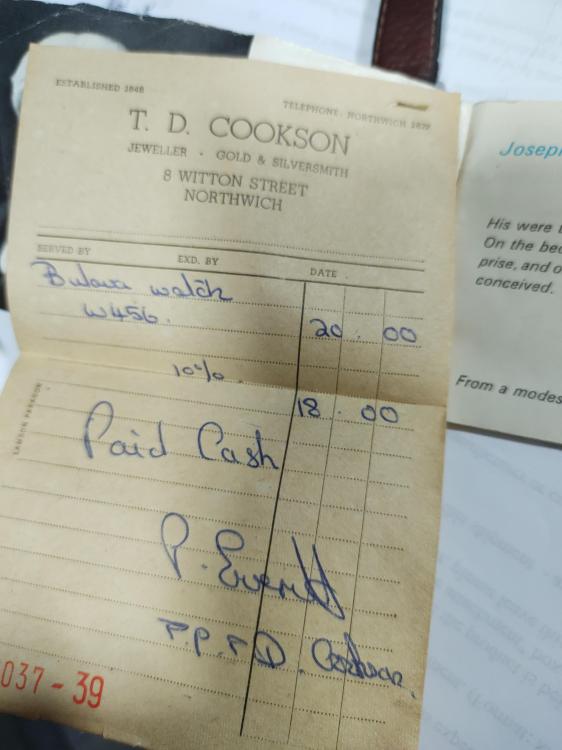

This ebay seller lists parts for an 11ANAC and also lists a #576 Date Indicator. However, the 11ANAC didn't have a Date Indicator so it is likely from the 11ANACB or 11ANACD. Perhaps message the seller and see if he can provide more info. EDIT: The seller has the dial from the movement listed as well, and I have the same watch. The movement in that watch is an 11ANACB. Also, you might try here. There are some Bulova interchange guides here.1 point

-

0 points