Leaderboard

Popular Content

Showing content with the highest reputation on 02/28/21 in Posts

-

3 points

-

It has been a bit of saga but worth it. Finally cut a screw for the 8 days French alarm clock. One of the four to fasten the pillars to the base, three were missing. I am almost sure that all its sizes are in French lignes (symbol: ‴), to begin with the pitch of 4 threads per ligne (0.564mm). The head is 2‴ x 1 exactly. The pitch is easy to get if your lathe has a bunch of gears. But the profile is another story, antique threads have rounded crests and valleys. I can only hypotize on how that could be reproduced in an home shop - not easily. Anyway, just like my Swiss-exiled counselor has confirmed, with a bit of care in tool grinding and cutting the result is working and acceptable. Original on the right.1 point

-

Polishing cases is a very big subject; you can do a 6 week course at WOSTEP for many thousands of bucks and still a debutante (well you'd be better than 90% out there but needs thousands in equipment). Without seeing exactly what you're up against it's hard to say. One big thing, when going for a fine (scratchless) polish is cleaning - clean your case ultrasonically and use different buffs for different grits. The buffs don't forget what was there before and you can't clean it off.1 point

-

Yeah, something got in my head once and I bought a box of 50 Sonalert beepers. They have three terminals (the extra is a feedback terminal) so you can make oscillators. I tore one apart and stole the piezo. It did not work well at all, and I think the problem was that it was pretty thick...perhaps to get a lot of output amplitude...dunno.1 point

-

you can get maybe in small toys or musical cards. they also have quartz watches with an hour indicator. They are on the back cover of the watch.1 point

-

What diameter did you order? From testing I found that the smaller the diameter, the better the "quality". Seems to pick up even less background noise and static the smaller you go.1 point

-

Hi, I think it’s the type of polishing wheels in my opinion. You need very fine fibre wheel. Check ebay. Also check retro watch guy website as he listed in order what he uses. I hope it helps. Regards, Yasser.1 point

-

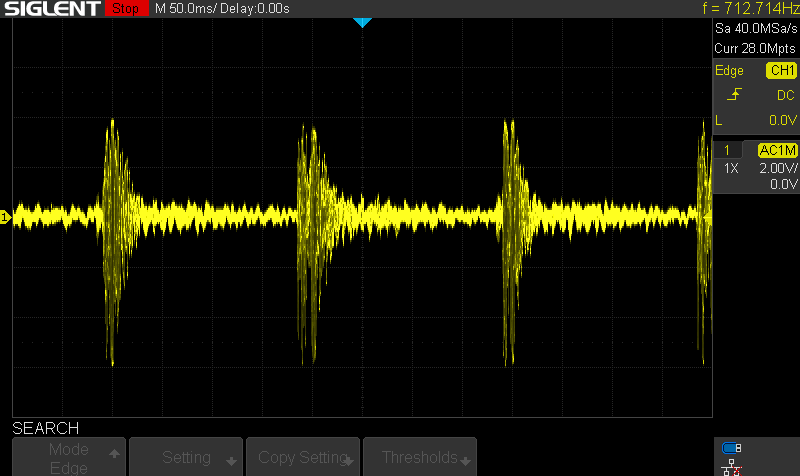

This may be a "tired" thread, but I still keep playing around with my sensor. I did not have any decent piezos in my lab (hard to believe...I have everything else!), so I ordered some. The two-transistor circuit needed a high impedance, so I added a JFET front end. Had WAY too much gain, so I dialed the last two stages down. May need to reduce it a little more. Nice result. Now, no background audio noise sensed (like with the electret), but guess what? It senses me walking across a carpeted floor!! I even have the sensor sitting on a rubber pad.1 point

-

Is that the inner diameter of the barrel? That's the number you want. Regardless, it's a very wide barrel with a very long mainspring for that width and thickness, from what I've seen available. The bridles are standard. The closest spring that I think would fit on cousins is 1.50 x .105 x 480 x 11.5 Non-Automatic GR4143 It's a lot shorter than yours but there isn't really anything of that length in that size. If you're worried about the upsize on strength/thickness you could try 1.50 x .10 x 360 x 10 Non-Automatic GR4125 but that's even shorter. The shorter length shouldn't be too much of a problem, just less reserve. At this stage, I don't think total hours of reserve is your biggest concern. You might try looking on ebay or other places for NOS springs, you might try with your bestfit number of 611 but you'll want a high letter (length), the highest I could find was 611P, which is 343mm. Not sure what letter 567mm is, X is 495mm, so ZZZ maybe?1 point

-

About a 40 degree drop from horizontal to vertical would be normal for many vintage pieces with relatively heavy balances and slow (18,000bph) trains. It's a matter of pivot size to balance inertia. You aren't too far off, and some older Lecoultre stuff is especially bad here- their smaller calibers can have a 70 degree drop in some cases. I've noticed that the escapement locks are often quite heavy on old Lecoultre calibers, and reducing that can help quite a lot. First of all it will boost the overall amplitude, but by reducing the lock you reduce the force needed to unlock, and this is especially helpful in the vertical positions where the balance is already dealing with increased friction. As it is, have a look at the regulator pins; they should be very close, but with the spring bouncing evenly between them. About 2 hairspring thicknesses would be a max gap (so 1 thickness of freedom). If you can close them a little it will already improve the difference between H and V rates.1 point

-

https://www.mediafire.com/file/eqbhdor949r0ilp/bestfit_part2.pdf/file Book ll I sent two copies of book l apologies.1 point

-

I don't think ebay care these days jdm. I have reported loads of fake clocks and they don't bother. So I have given up.1 point

-

1 point

-

It's good that you're panicking Early because the technical communications are still there. Like for instance 30 seconds ago I just downloaded from this link As you are using an example of 7750 PDF.They just don't jump off the website like they used to you have to stare at the website and then go all I know what I'm supposed to do and then you'll get there and you can get your technical communication but don't worry at some point in time they will all be gone. I doubt there's anything they could do to cousins other than just not give them anything new not that they probably give them anything at all anyway. https://shopb2b.eta.ch/catalog/product/view/id/69714/s/7750-7750-5/category/24/ The access the soon or someday to be forbidden knowledge under penalty of death Start at this link https://shopb2b.eta.ch/ Get confused okay maybe that's just me. Notice how the top of the page it specifies mechanical or quartz pick whichever one you like and then go from there. Then under each of those categories you can pick whatever you want view all will work. Then you get the images of all the various movements that are left that we can look at click on those and it looks like 2019 is the age of all the technical bulletins.1 point

-

Ha, found a rusted case screw that you access from the back but catches the front edge of the case. Its going in the cleaner to get the rust off. It looked like a lump of poo stuck in there....missed it on my careful search....the first time. LOL!1 point

-

1 point

-

Hello Vincent and welcome to the forum, well done with the career change wishing you all the best .1 point

-

There is always the tiny possibility that we can get a replacement and deny you your fun of making one. Then it's a shame it wasn't the right kind of stopwatch? Some stopwatch is have spare parts. Their hiding so I went online and snipped out some pictures for you. This particular example actually has a note that the parts are hiding under something. Other times it's not at least I remember it's not always shown that this is where the parts are hiding.1 point

-

1 point

-

Most watchmaker lathes have plain bearings. The majority are hard steel spindle on hard steel stationary bearings, some have bronze bearings and some cast iron. Almost all are adjustable for wear (the only one I know of with no provision for radial wear is the Steiner design). All of these are what is known as "constant loss" lubrication. That means you put oil in the bearing, and it works its way out during use- either from gravity, or being slung onto your shirt. The downside it you have to check and top up the oil frequently. The upside is they are very tolerant of lubrication differences. Like John said you can use just about anything, and always, something is better than nothing. I have seen machines that are for all intents and purposes the same as a watchmaker lathe regarding the bearings, with many 10s of thousands of hours of industrial use, and they are almost always still in very usable condition. In larger machines where there is an oil reservoir, like large engine lathes, you have to be more careful about oil type. What John linked to above goes into it; essentially motor oils are designed to pick up any wear particles and then carry them to the filter where they are removed. In a machine tool, the idea is any wear particles will return to the sump and then decant out; with a motor oil they would be recirculated causing damage. In a constant loss system they will just become part of the oil mess on and around the machine. As I have a bunch of machines I don't mind buying a 5 liter jug of oil. I use an equivalent to Mobile Velocite 10, with is an ISO 22 oil for spindles. If I ran out of that I wouldn't hesitate to use sewing machine oil, or 3 in 1, or whatever oil was at hand. There are folks who repackage Mobile and other maker's oils in pints and sell on Ebay, I think a pint is about 10 bucks and should last an average occasional several years at least. I think it was mentioned above, but for cross slides you will want a slideway oil. You won't hurt it with other oils (but do not use grease!), but it will work better with slideway oil as they have tackifiers which help it stick to the different surfaces without causing "sticktion". Mobile Vactra 2 is the standard, and any other maker will have an equivalent, you want an ISO 68 slide oil. Again, can be found in smaller quantities on Ebay.1 point

-

Looks as if its as dry as a bone. A clean and oil I think all is needed. To be fair you never know until you take it all to pieces and checking the wheels such as pivots,teeth,pinons and the pivot holes. These movements are made of a soft type of brass and steel.Always use a good mainspring winder to remove and re-install the springs. When it comes to the floating balance both ends should be jeweled, a tiny drop of oil on both ends then work the balance up and down a few times to make sure the wire is oiled and that should keep the balance nice and free and floating. Oil the pallet pins but not to much and every other tooth of the escape wheel. The rest of the movement should be oiled in the normal way.1 point

-

Many congratulations for the detailed post. I really like this discussion. Interesting and informative. I would like to ask a question. Does the 12-hour counter advance hour by hour or 30 minutes at a time? mine advances every hour, but in the counter I see that half hours are also marked. Thank you1 point