Leaderboard

Popular Content

Showing content with the highest reputation on 09/05/20 in Posts

-

Little tip for you with 2824-2/SW200-1s etc. For speed and efficiency, if you pay attention to the date jumper Maintenon bridge, you’ll notice a “tooth” shaped slot cut into it, now if you move the date ring round either by using the quick date or by gently moving it with a piece of rodico so that it lines up with that slot, you can simply lift the date ring out without having to strip the watches keyless/date sections from the watch to gain access.3 points

-

That's for the horizontal plane, OK. Now look at it by all sides. If doubts remove it from the balance and place it on a stacking block. It must be absolutely flat, because even a minor slope will grow when is compressed, and will touch the balance spokes and brake. That had bappened a lot to me, most often im conjuctiom with hairspring accidents, but at the time people here was just saying clean this and and clean that. Which didn't help a bit. Actually the first way to look at this possibility, is listen to the sound, for ringing. Or look at the waveform for spurious peaks. The Chinese machine doesn't do that, but a good PC software doesn't. think I'm going to order some 941, strip out the escapement, clean it, and see what happens with 941. Be reassured, it is not that. Lubrication problems or even absolute lack of it can, at moat change amplitude by twenty degrees or so. But if balannce swings feey, it's something major causimg that.3 points

-

decrease in amplitude does not mean crash and burn looking like it's on its deathbed. The Chinese timing machine really has issues with anything below about 100° that's not even considered a running watch. one of my recommendations is once someone feels they can take apart their practice broken watch put it back together hopefully limitless broken than they found it then typically they want to start repairing watches except that's not my recommendation. You start with a new running movement one of the clones of the 6497 or 6498. Purchased eBay or wherever you purchase your Chinese watches from. If it's a brand-new running watch your preferably of a timing machine you verify its condition. Then when you practice taking that apart and putting it back together if you have an issue it's your issue. if you start with broken watches and thinking that cleaning will fix your problem you are probably mistaken. Now we ask for help we don't know if it's the previous problem that you did not diagnose or whether you have introduced a problem makes it very hard for us to help you. one of the problems with the definition of new old stock is it does not say wonderful perfect watch that happens to be old. Previously on this group there was a discussion of a new old stock German watch that discussion went on at least 10 pages and the watch never really did run well. The final conclusion is the reason it was new old stock was because they never sold in the first place because they were not good watches. So if it's new old stock of something that you recognize that you know is a running watch that's fine and when you get it if you wind it up to run your timing machine that's a good sign but if you have a new old stock is not doing great then at can be an issue. normally I don't like what I call hijacking a discussion. This is where somebody comes in with my watches kinda like your watch help me out. The problem is I consider every watch a separate problem and it really should have a separate discussion. But were going to hijack this thread for at least a little bit. it appears to be that BrianB's as exactly what we need started with a running watch knows what the amplitude was and now it's running itself into an early grave by dying on us. But we know what it was before that helps considerably. Then as a general reminder to newbies it's usually the simple problems that you can't see because you don't have the experience yet. I'm not saying it's the obscure stuff that couldn't be there but if it was running before it should be running. can lubrication be the problem where seeking here well ES but probably not. I saw the classroom situation where a watch basically couldn't even be timed after the students at service debts. I attempted the simulates what that student did by lubricating the entire watch with D5 which was the heaviest oil that we had. I'm suspecting that Greece was probably used on the pivots because even oiling the entire watch including the pallet fork pivots with D5 could not simulate how bad this watch was running. After that the school supplied the students with the lubrication's to avoid those complications. Using 9415 inappropriately will cause a loss of amplitude but not the loss were seeing here. Unless you apply it so incredibly heavy you would have to really really really tried to make it this bad. So how bout experiments because your learning. Remove the pallet fork and escape wheel rinse them off in whatever rinsing fluid you have. Then and no need to scrub them or anything else I think sometimes aggressive cleaning of delicate watch parts could be an issue. Put them back in the watch run the watch with no lubrication other than re-oiling the escape wheel pivots. But no lubrication on the escapement itself see what happens? Oh and timing machine results we really need to establish proper timing machine procedures and pictures for us. All the watch companies for a fully wound up watch never time when it's wound up tight they let it settle down a little bit minimum would be 15 minutes maximum would be one hour. Then.just dial down dial down and dial up and at least one crown position pick one you like crown upper crown down. Minimum of three positions. Then allow us settling time in other words each time you change the position allow at least 30 seconds and then measure for at least 30 seconds. Also adjust your timing machine averaging 20 seconds usually works pretty well it helps to stabilize the readings. Then give us pictures. Without lubrication on the escapement it should run and it definitely should run better than 90°. no matter what it does get us results pictures the timing machine. T so this message does not get incredibly long that lets go to this point and Guinness results. I could go on explain everything but it's going to make for a really really really long message the reality is when your new and you start off with your new pocket watch you really should pay attention to the hairspring is going to be the biggest problem in watch repair for you and all of us. It's amazing what a hairspring can do if it's not where it's supposed to be. It's also really really hard from a lot of people to see where it's supposed to be or not supposed to be. This is where ideally with your new watch you would stare at it you look at as the balance wheel swings hairspring opens and closes. You let the power off and look at it carefully and see if you can tell how far it is above the arms that one is a lot of times really hard to see. As opposed to it looks right and you never really paid attention until oh dear I seem to have a problem then you have no idea what it's supposed to look like because you weren't paying attention in the first place probably has none of us told you you should really pay attention in the first place. Just in case your watch is not magically spring the life which I doubt it will we should have some pictures the balance wheel and hairspring along with your timing machine results personally I'm very happy your balance wheel isn't getting here anytime soon. It have to be careful with 6497's in that they've gone through multiple generations and you do have to make sure you get the right one in the meantime censuses watch repair let's see what we can do about repairing your balance wheel. I should've been paying more attention to your message because if you screwed up your hairspring and then my suggestion of dealing with the lubrication issue is a waste of time but let's do all of it at the same time. Photograph would be nice to see if you get a photograph of the balance wheel looking straight down in one looking and sideways. One of the unfortunate realities of watch repair is you need to learn how to fix hairspring issues or even more important you need to billet diagnose hairspring issues. All of us unfortunately from time to time will have issues and if you can fix those issues. Going to be way ahead of everybody else. Because you cannot always get a balance complete oh I remember I hijack the discussion to discussions in the same thread how fun of the watches you've worked on have you successfully yet got any watch to run decent? Anything that resembled a running watch before like my exempla starting with the new Chinese clone of whatever you have one of those that we can start with then as I think I said above problem is starting with broken watches cleaning them in oiling them will not always fix the problem. This means now you're going to figure out what the real problem is.. But exactly as I said above take to escape wheel out rinse it off rinse off the pallet fork put them back in again no oil on these watches at least on the escapement and let's see how much better or worse they are. That will remove your suspicion that it's the escapement grease. oh and of minor effect is there is the lift angle factor if you don't have the lift angle right that changes things but not super dramatically. It's more of a concern for obsessed people wanting absolute perfect amplitude so pick out one of the watches that you think should be running an amplitude is crap and let's work on that watch rather than a general theme of a whole bunch of watches it makes it too hard for diagnosing.2 points

-

I've had this issue before on pocket watches.. In one case it had the wrong barrel and using a different timing machine with software I could see what the problem was. But on the regular timing machine I couldn't tell what the problem wasn't all that was all over the place like yours.. Even though the manuals the paper tape machines say if you run along enough plot you can figure it out well the center wheel meshing with the barrel occurs at least every five minutes see what the paper tape I wasn't seeing it.. But only with the software this other machine when around the time plot good I see the problem.. If the barrel in the center wheel no longer mesh properly as they teeth come together they will bind up at least they did in my case and on a time plot you can see this slow increase of a problem and then as the tooth past it released and that was an incredible screwup for timekeeping. What you're going to have to do is close the holes that the arbor goes into and you do need to figure out whether it's the plates themselves and or the barrel. Because the arbor might be loosen the barrel equally as bad. But until you get the barrel stabilized so it's not wobbling around you're never going to get this watch to keep time or even run very well.1 point

-

Exactly my thinking and experience. Hairsprings are supposed to be flat, a dandling weight cannot help in retaining that property. Once I asked a member here what is the exact benefit of a balance tack, he said that it to see things, he didn't said what exactly so I tried myself, sadly I couldn't see anything really. Which of course is the correct technique. And I put it back the same way, even if that means that sometime it won't be in between the fork on the first try. Previously my mistake was that I wasn't looking at the lower pivot while driving it to the hole, sometime I spent hours trying going blindly. Nobody had told me, I don't know if it's in the books, found by myself and it works for me. Another great improvement was to go to cheap brass tweezers from the expensive steel one which some people think one can't do without. They grab perfectly and there are no more minute scratches on the cock or balance.1 point

-

Did a quick review of this watch on my YouTube channel. Great little dive watch at the right price. Sent from my iPhone using Tapatalk Pro1 point

-

Thank you for the tip @Lewisbrown1991. I'll keep that in mind ... after I've learned how to actually do this properly!1 point

-

No chance of base metals survival in a long vinegar bath. Shouldn't waste time on this one.1 point

-

I found the link with some history on your watch. I find it a little bit troubling history especially when I try to find a picture of your movement online because it appears to be there were variations in this watch. plus it's a Russian watch and their manufacturing capability for watches has been interesting. one of the problems with the modern timing machine is that you only get a tiny window of display. One time with paper tape machines if you had gear train problems and you run out enough paper tape sometimes you can see the problems. In other words like if one of the pivots was bent this would cause a power fluctuation that would repeat and you can see it on the paper tape. There is some really newer expensive Swiss machines they can run time plots which displays amplitude and rate differently and that we usually show you the variations in the powertrain. The problem with variations in the powertrain or as you noted less smooth than you would like that will cause running issues exactly what you see on the timing machine. Then swapping with parts that need to be cleaned as you can see causes a messier trace because power through the gear train needs to be as smooth as possible plus you shouldn't have any power losses through the gear train even though the gear train itself will always have power losses. One of the problems with randomly swapping wheels around is if you don't know what the problem you're fixing then bringing in new components that may have different problems makes for a really interesting problem solving issues. It looks like from Russian manufacturing that if there's variations which they appear to have swapping wheels may make things even worse because you may end up with incompatible components even though they may supposedly be the same. So you're going to have to go through and check every single wheel and see what the end shake is words that should've a little bit a play how free is that wheel checked the pivots for defects you have to figure out where your powertrain fluctuation is an fix the problem because otherwise your timing will never be consistent. It may be possible if it's only one problem if you watch the rates go up and down and see if it would follow up had her like every so many seconds it goes up and down. Figure out where the or the rate of repeating of the problem we can trace it back to a specific wheel. https://www.2209watchmovement.com/history1 point

-

1 point

-

Pocket corkscrew. https://www.ebay.com/itm/Cavatappi-Vintage-tire-bouchon-Folding-Pocket-Corkscrew/1741913829341 point

-

I'm sure there will be one hundred more ways to do this, but sometimes doing it in a way that is 30 seconds faster might not be of any benefit as long as you don't service a shitload of watches a day. Sometimes it is better to make even smaller fixes in a more methodically manner, in that way you get a sence of the general condition on the rest of the parts, and it minimizes the chanses you will come back to it later just because the dial ring or a tooth got a little bent. This is just a small philosophy I maintain, everyone else is free to do as they please, I have no problem with that .1 point

-

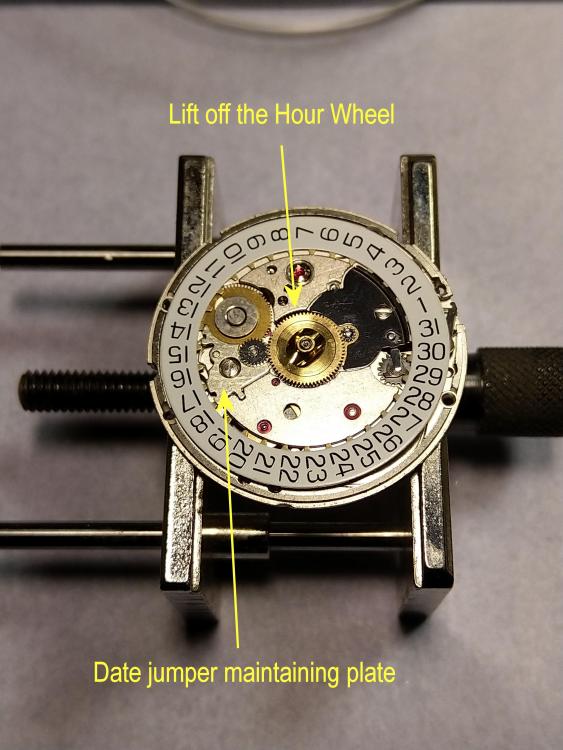

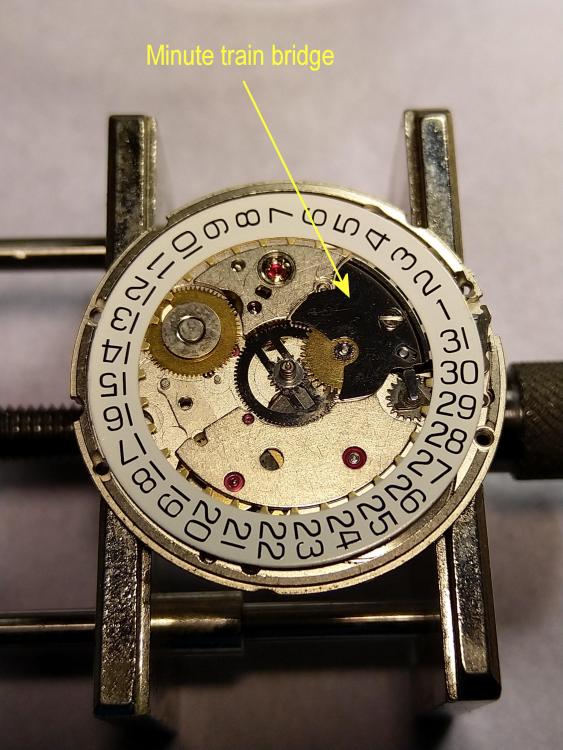

I pull the minute train bridge (I call it the keyless cover) and then release the date wheel without taking the other side apart. Unless there’s a problem, best to leave it alone. Plus it’s faster to get it sorted and back to other tasks. But, there is certainly value in doing it “the right way” until you understand the working better.1 point

-

The screw might come loose if the bearing is bad, the screw mostly is attached on the top of the automatic winding mechanism, not the barrel arbor . The screw head is tightened onto the inner ring of the bearing which allows the oscillator to rotate the outer part of the bearing which is attached to the oscillator weight. If the balls inside the bearing isn't moving then the inner part of the bearing might move too and slow but sure loosen your screw. If you used the wrong screw, slightly to wide it will case the same effect.1 point

-

Its Lemania based eta c01.211 with plastic parts. Sent from my iPhone using Tapatalk1 point

-

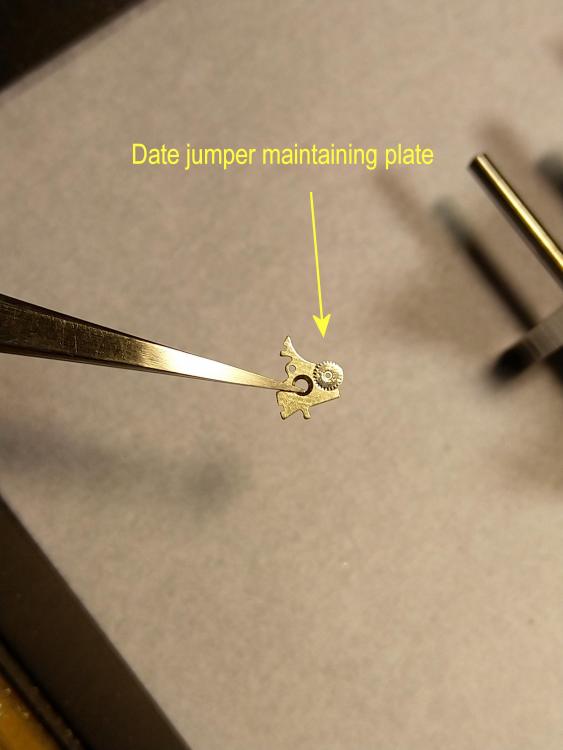

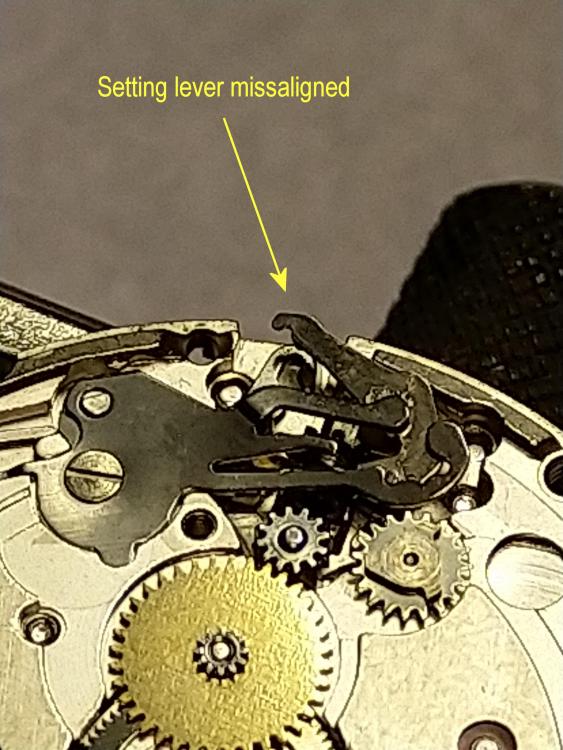

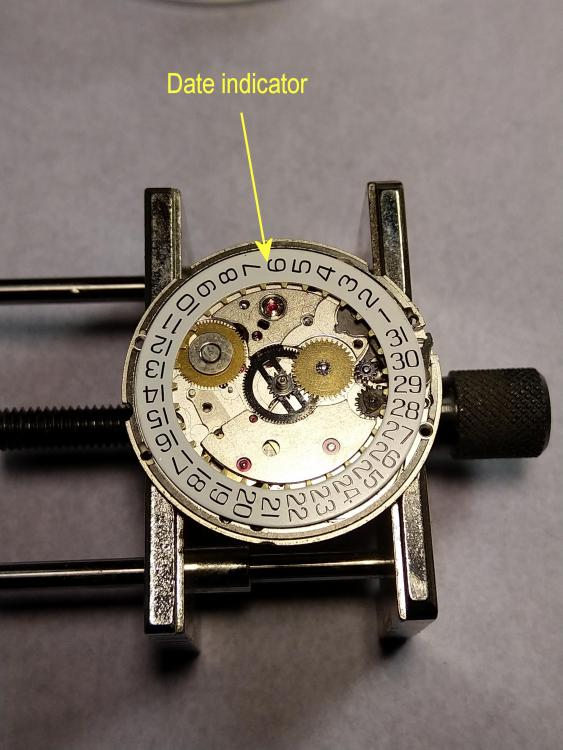

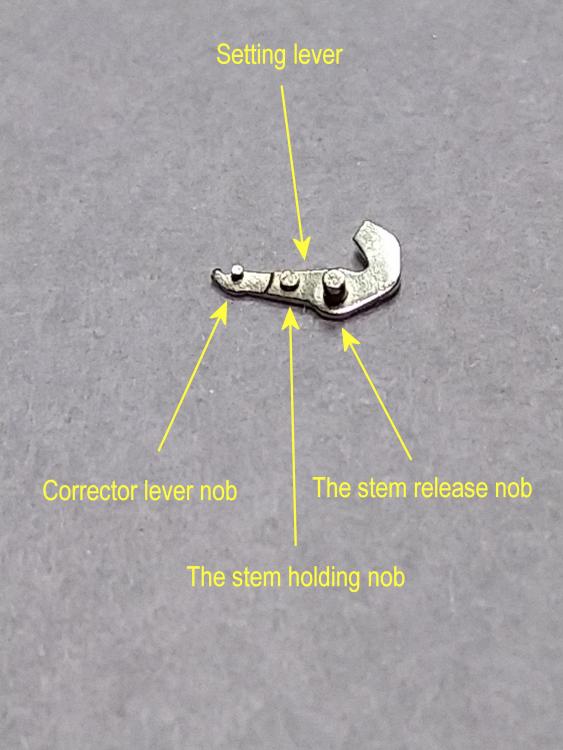

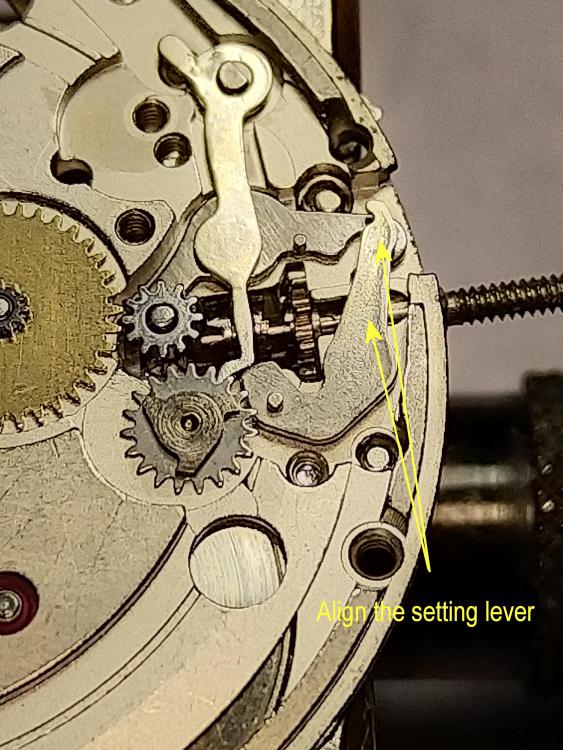

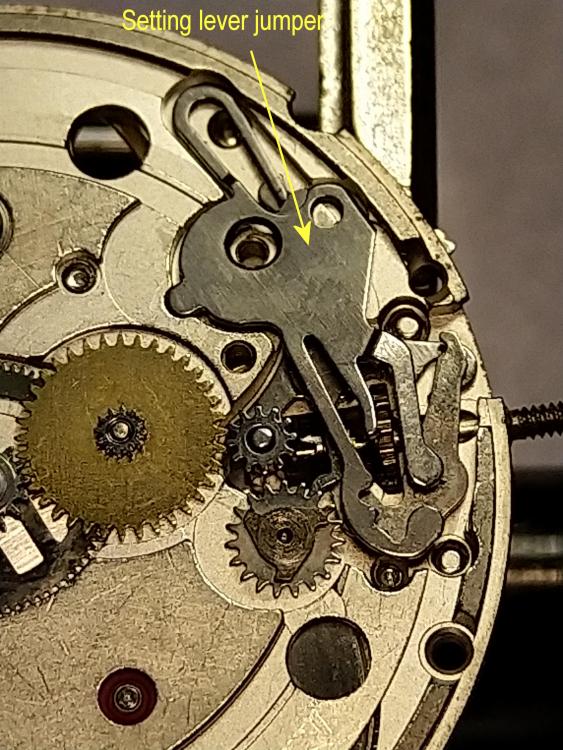

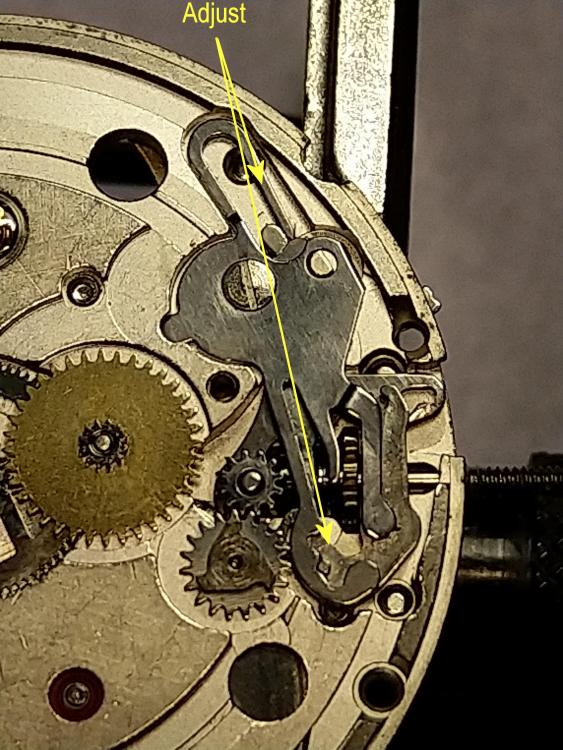

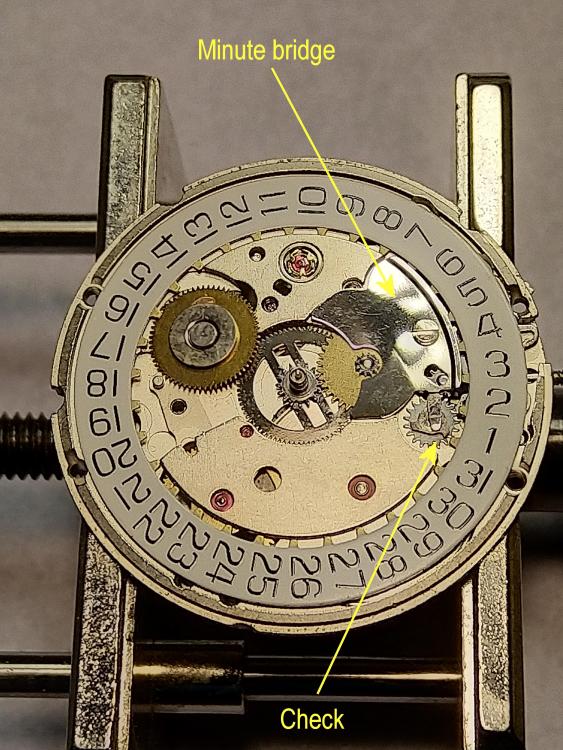

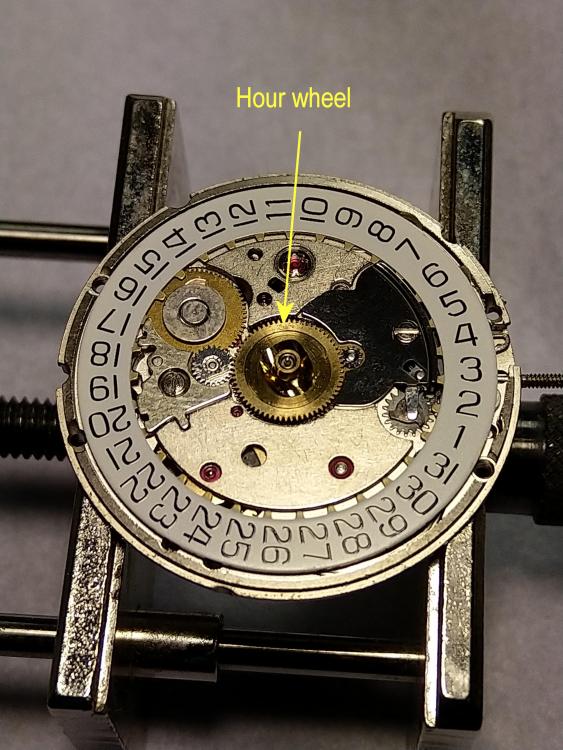

Yes it is safe to do so since the click is securing the barrel at this time. I very seldom post pictures without saving them in a PDF but since the pushing the pin too deep is a common accident I will do a small walkthrough in the wrong section, guess one can show what happens in one picture but not how to correct it. To begin with I usually just take off the oscillating weight, just to ensure it will not be in the way in the movement holder. It is kept in place with one screw. Since the stop lever is operated by the sliding pinion, we will assume the lever is still in place but is not working because of a faulty keyless work. Now one can safely put the movement in the movement holder. I now lift off the hour wheel. Next I remove the date jumper maintaining plate. I think it always is best to remove the date indicator so you don't risk to damage it and create more problems. Since this small instruction probably is applicable on other movements too, I would warn that the small pinion on the plate sometimes can be very loose so keep track of the parts. Next, we remove the date jumper. Now we remove the minute bridge, when taking these away keep track of which screw belong to what since they sometimes are slightly different. Now you safely can remove the date indicator. Now one can see what really happens work when one push the setting lever nob too deep. The lever is popping out and misaligning the most of the parts in the keyless work. Now the setting lever jumper is taken off and inspected. This one still looks good. There are three small pins or nobs on the setting lever. These has to get into the correct places in order to get the correct function. One now can see the pin holding the stem isn’t very high, so it will just take a gentle push to get the stem released. Most of the times the corrector lever is still in place. Here you make sure the yoke is in the sliding pinion groove and everything lies flat and nice as in the picture. The setting lever can now gently be lifted into place. At this moment I put the winding stem into place so I can be sure the setting lever comes into the correct positions. Make sure to align the pins in the setting lever to the correct places. The stem pin goes into the groove in the stem and the corrector lever pin goes into the hook shaped part of the corrector lever. Now you just position the setting lever jumper onto the movement and tighten the screw loosely. Don’t fasten it whole the way yet just tighten it until you feel a slight resistance. With the setting lever jumper secure in place you now can push the yoke spring and the lever spring into place. You can see the correct positions in the picture. With the springs in position and loaded you can tighten the screw all the way. Now you gently can put the date indicator into place again. Make sure the date indicator driving wheel and the date corrector isn’t pushing at the date indicator. Put the minute bridge in place. Just make sure you took the correct screw so the bridge isn’t squeezing on the date indicator. Here I accidently moved the date indicator driving wheel a bit but we just push it back in place. The date jumper comes into place. Push the jumper so it ends up between two teeth’s and not under the date indicator. Put the date jumper maintaining bridge into place. Check the date jumper still is between the teeth and not under the date indicator. To be able to test the modes fully you have to put the hour wheel back. And that would be it. Since you picked the keyless work apart one could clean of the parts and lubricate them while you are at it. Correct lubrication procedure can be found here. ETA2824-2_en_es_it.pdf1 point

-

1 point

-

I just wanted to post and say thank you to MarkR. I received the screwdriver sleeve today in the mail and I appreciate it very much. My original set was 0.80, 1.00, 1.20, 1.40, and 1.60. Then I bought individual 0.50, 0.60, 2.00, 2.50, and 3.00 screwdrivers. Being very picky as I am I really wanted the 5 new screwdrivers in a sleeve as I don't work on watches every day and I don't keep the screwdrivers in a stand. Mark very kindly sent me a sleeve he wasn't using. Then I made new cardboard inserts for the tops of both sleeves so I could put the two collections into size order and have 0.50, 0.60, 0.80, 1.00, and 1.20 in the first sleeve and 1.40, 1.60, 2.00, 2.50, and 3.00 in the second sleeve. Now all is right with the world and I can get back to working on my friend's watch. Thanks again Mark!1 point

-

1 point

-

1 point

-

You can join the NAWCC website forum and discuss clocks free of charge there are many people just like this site that would be happy to help you with your clock you dont have to be a paid up member of the NAWCC. And any new clock helps those members who are compiling a database of serial numbers The logo on your clock is of a style commonly used between 1914 to 1934 which is really the tail end of Gustav Becker production and encompasses the time when Junghans took control of the company, which is also the time serial numbers went awry and away from the linear numbering system used before, the backplate also has a letter M stamped on the right hand side this is significant and will also allow those in the know to determine the age of the clock. Junghans took control of GB in 1926 and serial numbers reset starting from number 1 on Westminster chime clock's and 400 day clocks so I would say your clock is a very early Junghans ownership period Westminster chime clock made at the Freiburg factory . Regarding the striking on your clock if you open the Bezel at the front check to see if there is a cut out along the edge of the dial with a little lever this will be the silent strike switch. The P14 number on the clock refers to the correct pendulum length to be used with the clock I think this is a metric measurement so would be a 14cm pendulum.. I hope this will help you with your clock.1 point

-

1 point

-

So replies to you all and many thanks. Before I go any further I'm a rookie here so if I ask "too much" just let me know. Andy Thanks. Old hippy I find it hard to believe but who knows.....Wow! Thanks for the links...The PDF was great. WLS1971 Not ready to Join NAWCC quite yet for $90..But great links and thanks My gong is identical to the video provided although mine will not trigger the mechanism to chime on the quarter nor hour gongs on it's own. I can trigger chimes and gongs by lightly tapping down on a lever I find 3/4 of the way up the right hand side via the rear. Is there a lever that turns the chimes on and off? See attached pic of trademark, model (I think) and serial number of 560.1 point