Leaderboard

Popular Content

Showing content with the highest reputation on 10/16/17 in all areas

-

Hi There are probably others out there like me who have bought the largely unimpressive A*F Bezel remover - https://www.cousinsuk.com/product/watch-bezel-remover-af-swiss?code=R31399 I decided to try and improve mine a bit by making it more stable, therefore able to exert a more steady pull under pressure. I used an old timex crystal tool I had spare and trimmed the edges of the rubber, and ended up with this: It now works reasonably well (better than before anyway) at removing rotating bezels from clamped watches, and can be used one or two handed - it's certainly a lot easier to exert even pressure and lift. It's still not that brilliant really as it could do with a bigger and stronger lip to go under the bezel instead of mainly using side grip. As per usual I rather rushed the job as I wanted to see if it could work. The ring really needs securing at the top as well at the ends, but it was too late to change when I realised this. Also I should have trimmed the rubber more neatly, but it is fine where it touches the watch. Stephen2 points

-

On behalf of "Watch Repair Talk" moderators, I would like to extend a warm welcome to all new members. This is a friendly place with plenty of knowledgeable people who have varying degrees of horological expertise, the great thing is they are willing to share that invaluable knowledge and help one another. To help us keep things running smoothly, I would ask all new members to read the forum rules and place their posts in the correct sections.1 point

-

I just completed cutting my first balance staff on a lathe. All went well on the balance/hairspring side, including undercutting and leaving enough material to make the rivet. On the roller table side however, i cut a smidgen too much. Is there any way to tighten the roller table on or di i need to cut a new staff? I thought shellac on the post would harden and keep the table on. I still need to jacott the pivots, so am i waisting my time? Sent from my iPhone using Tapatalk Pro1 point

-

Showing off my latest flea-market find. A Camy Jet King 908 from around the mid 70s I think. The 'speedometer' seconds hand is typical of watches from this time. The seller wanted MYR80 (roughly USD20) but when I pointed out that it was not running (the seconds needle was as dead as a dodo) he came down to MYR70, claiming it was just serviced. I bought it anyway because the dial seemed good under the scratched up crystal and when I advanced the time the date advanced as it should. Below pics are after the crystal has been sanded and polished. The caseback has the typical Camy design.. I have another one where the central portion is the same but in gold (just like a Grand Seiko!). The crown seems to be original and has six notches instead of fine lines, similar to Omega. And inside is a FHF 67 movement. When I bought it I just stuffed it in my jeans pocket and when I got back I was pleased to see that it was ticking. Sometimes this is due to heat from your body thinning the old oils enough so that the watch can run. This usually means a service is in order. When I got home and opened it up however, I found a dial screw loose in the watch. On examination of the movement I found it was clean and running well so I just reinstalled the dial screw and tightened up the other dial screw (it was loose). Luckily the wayward screw did not get caught up in the hairspring. The movement was in pretty good shape, even the area around the crown release screw has been spared the butchering you usually see on older watches! The sellers claim that it has been serviced seems true and apart from the dial screw everything else seems in order. A quick polish of the crystal and some cleaning of the case and it's back together and on my wrist! have a good weekend guys! Anilv1 point

-

Look up Dean DK on YouTube he uses a Cowells lathe but I'm not sure which one.1 point

-

You have achieved what is probably the hardest thing to make in in horology. You could have used lock tight; there are many types such as a thread lock tight, many people who make parts on lathes use it. When using a punch you have to be very careful not to split the roller.1 point

-

1 point

-

Turns out you can close the hole in a balance table using the following: Sent from my iPhone using Tapatalk Pro1 point

-

I was waiting for the cleaning cycle to finish and I came across this board. Some of the posters are pretty serious and that is a pleasant thing to see. I have been updating my website to highlight pages that may be of interest to the membership http://historictimekeepers.com/Notes for Watchmakers.htm http://historictimekeepers.com/Microscopes.htm http://historictimekeepers.com/measurement_in_watchmaking.htm I am trying to leave a trail of bread crumbs so that younger watchmakers do not have to learn the hard way like I did. I do need to put together a book list (Jendritski, Perkins, Whitney, Wild, Gazeley, the Argus Shop series, Sherline book, etc) that gets people away from relying on bad information or writers who leave Easter Eggs for the reader to figure out. If people have a topic they would like me to add, let me know. My goal is to fill the space of how things are done which tends to be glossed over. For example, using an adjustable hotplate instead of an alcohol lamp for bluing and shellacking, etc. Things I have found that make life easier and increase the probability of success. Regards, Dewey1 point

-

Rafal, That is a good point. I think this covers two topics: refinishing steel in the modern age (Spoiler alert: 3M self adhesive Imperial Diamond sheets) ; and how I install regulators and cap jewels on balances with screwed cap jewels. I printed your email as a reminder. Easy enough to do; just gotta find a couple hours. But I will. I think I start breaking Notes for Yong watchmakers into subsections for these kinds of topics. First I gotta finish on the Sherline and dead center turns though. A warning to all; I take the Swiss a[approach, if the fit and finish and results are correct, the piece does not care if you did it on a WW or a turns or even with a file. There are lots of ways to skin that cat. I can only talk about what I have learned to produce clean, precise results. I hope you find and share others as you go along. Regards, Dewey1 point

-

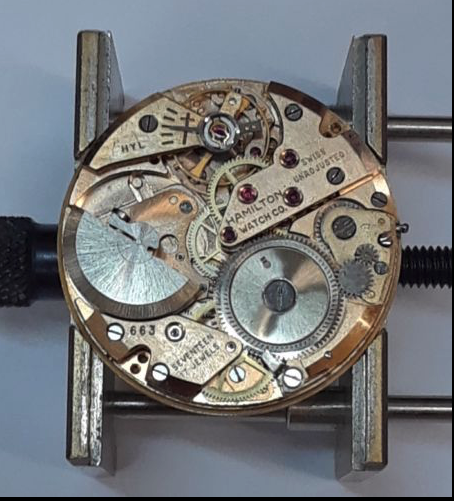

I'd like to share a couple of watches I recently acquired ...... The first is a 1961 Hamilton T-403 Automatic . I had been on the lookout for this one for quite a while as they don't come up for sale very often . This one may be only the 1st or 2nd I've seen offered . It was offered by a professional watchmaker with 25 years at the bench , so the movement has been serviced by him . The case is a Gold filled Asymmetric design and I have seen this model referred to as the Shark owing to the fins of the case design . According to the seller , the watch came to him missing the crown so it has a generic replacement . The hour and minute hands are original . but the second hand was gold and "all - over wrong " in his words , so he replaced it with a second hand as close as possible to the original . The acrylic crystal is new . The movement is the same as used in Hamilton's Thin-O-Matic models , using a micro rotor for reduced Thickness . The dial is a gorgeous original finish with , un-noticeable really , a few tiny dots here and there . The Watch : Next is a beautiful 1965 14K and Stainless Steel Bulova Accutron 214 model watch . As soon as I saw it offered I knew I wanted to claim it , so I upped my Max Bid 3 times . It is a 100% original , fully serviced watch that the seller offered as a Solid Yellow 14K and Stainless 2-tone watch . I asked the seller why he offered it as 14K solid gold . His response was that the gold on the bezel is 14K solid Gold ,....So I dunno ?? Anyway ,....I had to have this beauty , and luckily for me , the bidding was not heavy . So here it is....1 point

-

About 6 inches . My theory was just to free up any old lube . It's still running BTW.1 point

-

Thanks ramrod, I try to keep my desk that way "neat and clean" but only last a few minutes until I begin to work on watches. [emoji1] Sent from my SM-N920T using Tapatalk1 point