Leaderboard

Popular Content

Showing content with the highest reputation on 02/27/17 in Posts

-

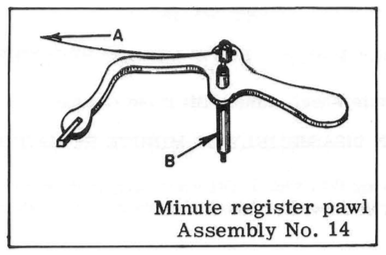

I thought I'd break this out as a separate narrative from the Pierce Navigator repair I posted here. Anyone who has done an old chronograph repair is aware of how delicate part 8270 (minute recording jumper) is. The Pierce 134 movement is put together quite a bit differently from your normal chronograph in that it has a vertical clutch arrangement as opposed to the laterally engaged coupling clutch found in the more common Venus and Valjoux chronograph movements. As a result of this uniqueness many parts, while functionally the same, are designed in a wholly different way. The Pierce minute recording jumper (pawl) is different from the typical jumper piece in that it is not a spring, but rather a pivoting lever which is held in tension by the thinest of wires. The wire needs to be manipulated in to put the jumper under just enough tension to hold the minute register wheel static until activated by the intermediate wheel. Too much tension will cause the watch to stop when the elapsed minutes are recorded, and too little tension will allow the minute register wheel to spin freely. Unfortunately it is not uncommon for the wire providing tension to fail after manipulation. Here I have a jumper in which the wire has broken and the jewel (well, actually it's just a cut piece of steel) has come lose. Initially I though it would be a simple fix to replace the broken wire. I used some 18 gauge electrical wire which was composed of several strands of thinner copper wire. Stripping the insulation off, I took a single strand of the copper wire and assumed it would suffice. Under the microscope it was evident that this approach wouldn't work. Even the smallest copper wire I could find was several times thicker than the wire I needed. Using the bench micrometer I measured the thickness of the broken wire at 0.05mm. To give an idea of how thin this is, I snapped a picture under the microscope of the wire next to a human hair. The wire is on top, the hair on the bottom. Armed with hard data I was ready to take a second shot at the challenge. Using the internets I found a company in the UK which could supply nickel wire in the same thickness. I placed an order, then added a couple spools of varying thickness just in case (and to make the product to shipping cost ratio a bit more reasonable). The wire arrived in due course and was exactly as described. I began my repair by knocking out the brass pin which secured the old broken wire to the pawl. A sewing needled was used to knock the pin out. The "jewel" was then replaced using a bit of shellac and a alcohol lamp. Now it was time to replace the spring wire. I cut a length from the spool and threaded it through the eye piece on the jumper. Naturally this was done under a microscope. A replacement pin was inserted to hold the wire in place and the excess was trimmed off using the scissors on my Swiss army knife (they seemed to be the perfect tool for this job). As you can see had two jumpers to repair: I'm very pleased to have been able to repair these parts as they can be quite expensive when purchased second hand; from personal experience I've seen the Valjoux and Venus jumpers cost between $30 and $120 USD which is quite a lot for a little bit of steel. Pierce parts can be hard to come by also. I currently have two Pierces in varying stages of repair so the jumpers will come in handy. On a side note I don't vape so I have no idea why tiny nickel wire is necessary for smokeless smoking.1 point

-

Hello everyone, I'm happy to be here. I am an electronics engineer by profession -- so tiny, delicate components are nothing new to me... but working on watches provides a mental satisfaction absent from that work because with timepieces, I get the opportunity to actually SEE how the parts interact. I also find that, when I look at a movement in detail, I can't help but to think about the craftsmen and engineers who designed and built such fine and intricate machinery. Looking forward to participating more here. Ben1 point

-

So watch companies publish all sorts of interesting specifications for watches. We can freeload off of other companies to get an idea of what we should be looking at. So some companies will specify the freshly serviced watch fully wound up should have an amplitude between various degrees. Omega publishes what the watch should be doing at the end of 24 hours. After all you want the watch to be able to run at least one day. They do care about timing specifications fully wound up and And at the end of 24 hours but They only care about amplitude being a certain minimum at 24 hours. So as I have the specifications looking through the very lowest acceptable amplitude is 160°. The numbers vary with the various watches.So the most common at the end of 24 hours is 200° the difference is based on the running time of the watch. Modern watches can run at least 48 hours they're going to have a higher amplitude at the end. So the watches at 160° tend to be watches it have much shorter running times like in the 30 hour range. So anything modern should be better than this and it still has to keep time within their specifications. So you're 160° as a guess is not at the end of 24 hours it's probably fully wound up? So basically amplitude is an efficiency test. Other ways to test the balance wheel without power on the watch supply energy to the balance wheel the started to rotate and it should oscillate back-and-forth over quite a few seconds before it comes to a stop. Then a lot of times we turn it upside down because sometimes the problem only occurs in one position. But basically the balance wheel has to have very little friction or you're going to have timing and running problems. So problems for newbies with watch repair is there's a lot of places where you can have problems that you're not going to recognize. They hairspring has to be absolutely flat and not touch anything other than at each end and where the regulator pins are.Depending upon the watch a lot of times this is a really hard to see even by us seasons people that know what were looking for. So simplistically a lot of places for newbies to have problems. Then we rely upon your description to help you diagnose as a newbie you can't necessarily give us what we need which is why we need a photograph.1 point

-

1 point

-

I would suggest a gents automatic with day and date. Anything by bulova (calibers 11xxx), omega1000 series, or a Seiko. JC Sent from my SM-G925T using Tapatalk1 point

-

Other alternative is set your multimeter to measure AC and connect across every permutation of pairs of pins and tap the mic to see if you can get a response.1 point

-

Should be able to identify two pins which carry the audio signal by using a multimeter. I think piezo transducers usually measure in the K.Ohm range. This assumes it is passive and does not contain a preamp.1 point

-

I'm not knocking DeCarle books but it is a hell of a lot harder achieving this task then just reading it from a book. An experienced watch repairer would find it hard, if the collet gets damaged then finding one that fits will be very hard indeed, after all it has to be the right size, height and width.1 point

-

1 point

-

Yeah, that's a 5-pin DIN. If the mics are passive then they would likely only use two of the five terminals. Will need to try and find a schematic which shows the "pin out" for the Witschi mic cable in order to find out how to wire an adapter cable. I will have a look, but do post one if you find one.1 point

-

What you have is a 30-hour mass-produced cuckoo clock; there is a knack of fitting the chain, it is possible to do that with the movement still in the case. They are called bellows that make the sound; todays are made out of synthetic material. Old antique original cuckoo clocks the bellows were made out of goatskin and the clocks would stand on tables they did not hang on walls and they were spring driven with a fusee movement. Well done in sorting it out, they are fiddle little sods and many clock repairs will not touch these modern types. It has a good beat as well.1 point

-

Probably. I have a bunch of brass pins though and honestly I find them easier to work with than shellac.1 point

-

Amazing work you have done there @RyMoeller. Hats of I don't smoke either but think the wire is used as resistance wire? It glows when you put electricity past it.1 point

-

Personally, I'm agin'it. It's a form of vandalism being fobbed off as "art" which term covers a lot these days. Vintage parts--especially jewels and hairsprings--are too hard to come by these days so I hate to see them embedded in resin. Besides, how hard is it? Not half so as the time and skill required to be a watchmaker, I'll bet.1 point

-

Today is a somewhat shabby Girard Perregaux manual winder with sub seconds, which is my latest favorite look. The movement is an adjusted caliber 03BE. Most parts are exchangeable with the AS1130, which is great. This one is a strong runner and I did replace the mainspring, but other than that it was a bargain at just over 20 dollars. There's a lot of examples of these selling from South America (Argentina in particular) but they usually are quite expensive. J1 point

-

Here are bracelet pics, (before/after) after masking off center high polished links, used same pad to create satin look finish, returned to give center links a bit of work, I found spare movement now just need a dial and chapter ring to fit. I'll be sending out for new crystal today, so it'll be some time before I can get back to it.1 point

.thumb.jpg.659e45086cdb83afb64c371dfb284dba.jpg)