Leaderboard

Popular Content

Showing content with the highest reputation on 08/11/16 in Posts

-

Another jewel altering adventure. The Nachtigall movement i am working on had an oval shaped roller jewel which i was breaking during repivoting. Yes, i should have removed the roller table but dont have the removing tool yet. It was no problem until the whole thing flown away from the pinion polishing tool. Used that for the first time and didnt hold the polishing file securely. Back to the topic. I have measured/calculated the hole dimensions in the roller table on a microscope image. Luckily i had a brick-shaped jewel in the correct size and then i started grinding it from the edges... First friction fitted, then started using hot glue. Co@rse grinding on honing stone and then polishing on soft copper plate with a drop of polishing paste on it. Looking good to me Now the longer sides... Just a tiny bit more from everywhere... Almost perfect fit. To make it shorter i have mounted it in a pin wise wrapped in soft copper. I was very carefull at this point... didn want to brake it after 6 hour of grinding, measuring, grinding...... Checking clearance in the pallet fork. Yes, it was flown away once. I could find it in the laptop keyboard... It stays in place friction fitted and working excellent!. You may know that i dont have a center wheel yet but if i push a bit harder on the 3rd wheel the balance is overbanking. It seems that the amplitude will be ok.4 points

-

ANother great find in the movement. After grinding another impulse jewel ... ... and trying to true the balance in the movement i have noticed random sideshake. The balance cock hole jewel was not secured. Looking on it closer its obvious that it was replaced improperly. It seems to me that the material is just hammered over the jewel. Not to mention that the hole is way to big for the pinion. I could find a jewel close the desired one in the lot bought from Redrooster. Not secured yet, just mounted to check the balance. The hole is a bit tight but will check again after polishing the pinion which also need some care. Oldhippy: i hope the music is of Your taste3 points

-

2 points

-

Thanks for the responses. The prize goes to geo. I removed the weight pivot plate and refitted the bridge. Problem gone. Demagnetised it and voila. Thanks all!2 points

-

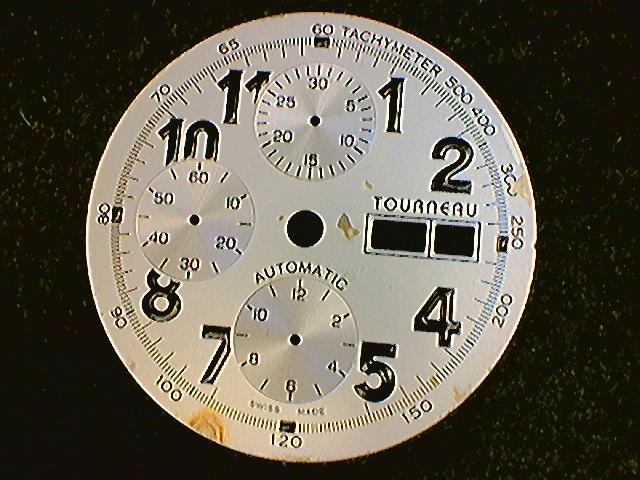

I purchased a Tourneau 7750 a while back on eBay. The watch was a mess. For one thing, the dial was glued to the main plate - missing the dial feet and it has some discoloration. Here's how it started. I finally got around to having the dial restored by International Dial. They didn't have the exact die, but they did find a suitable substitute. While they could have created a die to match the original I didn't want to incur the expense. Some pics of the dirty movement... The watch also had a Rolex crown (I think it's a fake) and the stem was soldered to the crown. You can see it in the following pic: Here it is on reassembly - preparing to attach the hands in my Bergeon movement holder: And the finished product - note I have a new crown on order - so the fake Rolex is still on there for the time being. This watch is a gift for my son.1 point

-

He's redoing his website as it will soon be his only sales outlet as he's had enough with eBay.1 point

-

1 point

-

1 point

-

I think the OP is saying the the crown was pulled out at the last stop, not removed from the watch, neither the case back was opened at all. That a perfectly safe way of extending battery life and even the movement one, even if just by a small fraction.1 point

-

Usually on quartz watches when the stem is pulled out they drive for the analog stepping motor is stopped but the quartz crystal continues to oscillate. So the watches in an extremely low power mode and will start up when pushed in. How long do you plan on storing the watch? The reason for asking is every time you take the back off you risk getting foreign objects falling into the watch quartz watches really don't like anything any form a contamination that a mechanical watch would just grind through quartz watches will not. Then continuously opening and closing the back is hard on the back gasket. So I have the spec sheet for the movement below it looks like they have a three year recommendation for battery life. So beyond three years definitely take the battery out if you plan on wearing the watch occasionally just leave the battery in. http://www.citizen.co.jp/miyota_mvt/download/pdf/spec_2105_15.pdf1 point

-

1 point

-

I don't know if there is an official procedure written down? So for me it's mixup as strong of a solution you can get apply heat to the point where it's boiling, Or very close to boiling. They do have to watch it as it will dry out. Which is not really a problem just add more water. As I have it on the stove I usually have it in a Pyrex container in a regular stove pot that has water so I don't have to worry about something bad happening with alum getting all over the stove. Although I did break a Pyrex container once because the whole thing dried out so you really do need to pay attention to it and not wander off. So when it's working you will have little bubbles coming up from the steel part. I really can't remember how long the last one took it's been quite a while. So basically the stronger the solution the hotter it is the faster it works.1 point

-

1 point

-

If it is a u-clip style then this should help. Watch Band Adjusting - How to Remove U-Clip Expansion links.1 point

-

Where did you get the dial and hands? I love what you did! Cheers, Bob PS. And the matte finish bracelet to go with the case!!!1 point

-

1 point

-

Hi Roger, thanks for posting the Omega information. Here's my take on it. The ratchet wheel and reverser mechanism apply force to the barrel arbour and spring. If the internal barrel is not lubricated then the spring may not slip as required, this would not be a good situation and could lead to damage of the auto mechanism. The fact that placing the bridge onto the movement without operating the auto wind still suggests a magnetic problem to me.1 point

-

Wow, another mind blowing presentation. Incredible work! PS. Your tweezers look like they were made by a blacksmith!1 point

-

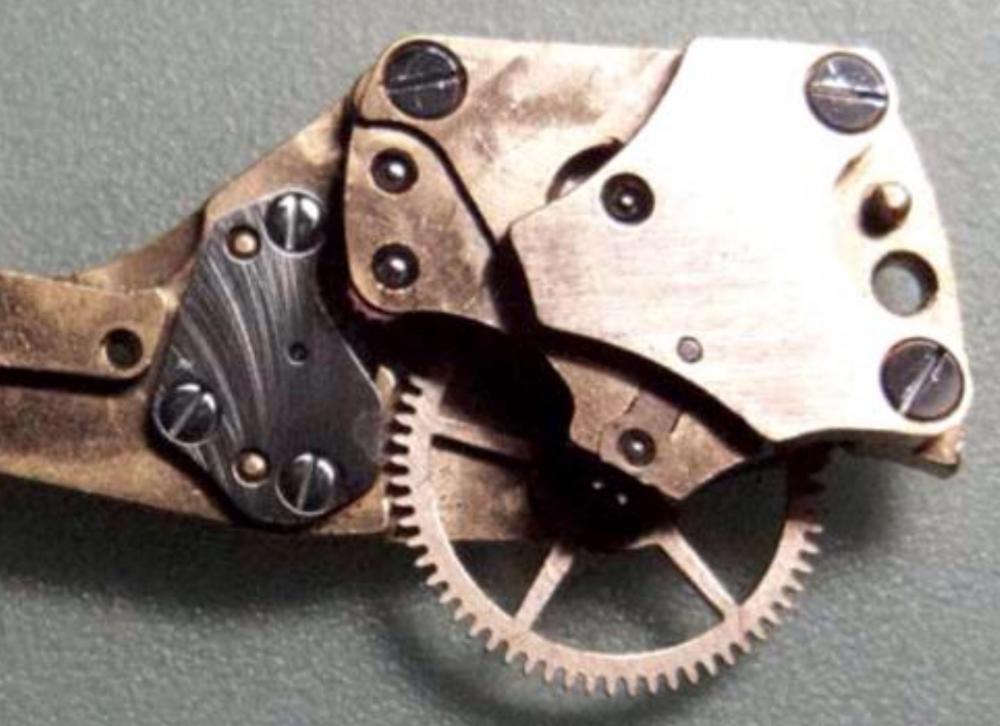

I havn't worked on a 565, but I have worked on a 561 and that is pretty much the same. I really don't think the problem lies with the centre second damping spring. If it is distorted causing increased drag it will slow the watch and if it distorted causing too little drag it will cause the second hand to stutter, not increase speed dramatically. The effect of too little drag is clearly indicated if the watch is held vertical. As the the second hand climbs against gravity, it will appear OK, but when dropping with gravity it will be very unstable. I think there is a possibility that the small steel plate underneath the auto bridge may be magnetised. Compared with screws, it is a fairly large chunk of metal and if magnetised will definately stand a chance of influencing the swing of the balance. Here are a couple of pictures from a 561 that I worked on showing the steel plate. I suggest that you demagnetise the complete watch when assembled and see how things go.1 point

-

Nice walkthrough Jaycee a movement I have not seen before. The barrel/ mainspring set up is interesting. If I have a winding in the correct direction issue I just wind the spring in the wrong direction then I then push the spring into a suitable washer, turn over the washer & push the spring into the barrel (The same method used with a new spring)1 point

-

Jdm, i guess you did not look at the stem well, i made the same mistake myself before, if i attach extender to that bit then gap that needed to be lock with keyless work will disappear, there must be some gat there to keep the stem in otherwise when you like to set the time stem coming out easily, by the way i fallowed johnR745 advised and i ordered ETA 6497 stem which i think is going to fit my watch hopefuly. But thanks for thelp you guys are realy helptul.1 point

-

While the magnetised screw can be the cause, two other things come to mind. 1. the seconds pinion sping may be misaligned, causing drag. This is a common problem with indirect seconds movement. On these movement the automatic module restricts the downward movement of the seconds pinion to some extent but if its misaligned or bent it could cause running problems. 2. The autowind has screws on the bottom. Are they in the correct position/correct screws? If the head is too tall it may interfere with the balance. To eliminate the magnetised screw being the cause (if you don't have a de-magnetiser that is), remove all the autowind gears, screws etc and install the bare auto bridge. If it runs fine then you need to demagnetise the screws or double check the screws are correct. Its quite easy to identify magnetised screws as they tend to stick to your screwdriver. HTH Anil1 point

-

1 point

-

1 point

-

So googling your watch I did find the company but I can see they were too many help. One of the problems with companies claiming to make watches is they really don't make them themselves they just sell them. So that means they have zero spare parts for anything. So if you Google watch you find it to 17 jewel 9730 hand wind which seems almost useless. Then to track down the movement becomes more interesting as the only reference to it seems be back to the watch you have almost of no help. So did find a catalog of movements page 5 appears to be the one you have. The problem with Chinese movements will be getting a part perhaps. It would be nice if you could get the stem out so we could see it and measure it. The reason is looking at the movement disregarding all the complications vaguely looks like a clone of a Swiss movement. On the same page just below this movement is 9211 looks vaguely like a eta 6497 so if you're lucky perhaps it uses the same stem. http://www.ptsresources.com/beta2/movement/catalog.pdf http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_6497_11 point

-

I would be interested to hear how the dial cleaning went..for me it usually starts with some light soap and a fine brush and ends with sandpaper before hitting the internet for a replacement. Anil1 point

-

One more thing regarding screws... screws that hold a movable part would have a 'shoulder'. Example the screw holding the 'click', without the shoulder, the screw will keep on tightening against the click rendering it immobile. You will find this on the calender (day/date) wheels as well. Sorry for multiple posts. Anil1 point

-

1 point