Leaderboard

Popular Content

Showing content with the highest reputation on 05/10/16 in all areas

-

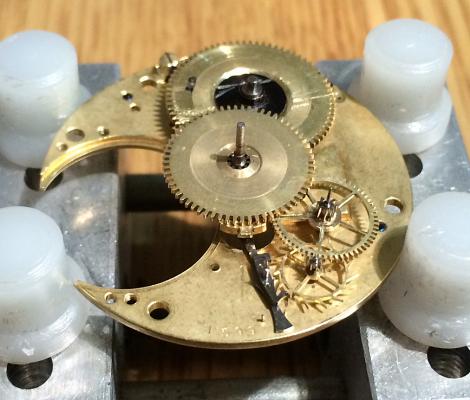

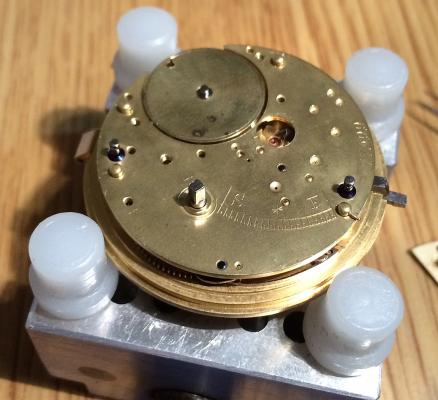

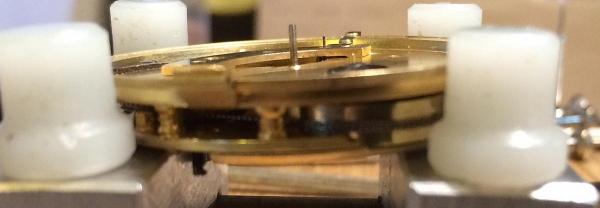

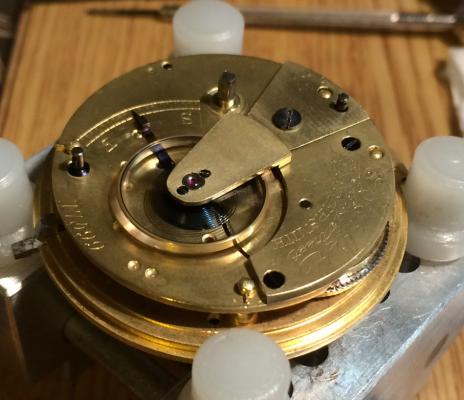

As promised, here's the reassembly of the watch who's fusee I posted photos of: First, here's the bottom plate with the fusee, centre wheel, lever, escape wheel & 4th wheel in position: and the fusee ratchet paw on the top plate: The plates are joined & pivots located in their holes & pins replaced. (This watch was a non-runner when I got it & the lever had a rather badly bent pivot which I straightened & I'm hoping this was the only problem stopping it running): At this stage it's best to fit the 3rd wheel bridge, solely to protect the 4th wheel pivot which also has it's hole in the bridge: Next fit the barrel: and the barrel bridge: Next the fusee chain needs fitting - the hook end goes in the fusee & the pointy barb end in the notch on the barrel Apologies but it's not possible to photograph the actual chain fitting, but after fitting fit the blued steel barrel ratchet, add some tension (say half a turn of the ratchet) then screw in the ratchet click to hold it in place: Now fit the 3rd wheel & replace the bridge: At this point it's worth winding some chain onto the fusee & check that the lever snaps to & fro with a little movement of it with a cocktail stick...this shows that power is getting through the train. Then the balance wheel can be fitted - the staff has a safety roller & jewel peg like a Swiss lever escapement: Here the balance cock has been fitted & it's ticking nicely Part two will come later when I'm satisfied all is well which will take a few days of windings...I'm not 100% happy with it at the moment as after running for a minute or so it kept losing power to the lever & stopping...having said that, after some fiddling it's running now...it could be that the fusee is not giving maintaining power...if it continues to play up I'll have to strip it down again & investigate....anyway, hope that was interesting!1 point

-

http://www.nawcc-ch149.com/pw_dbresearch.html I would be remiss if I did not disclose source, I use regularly for Hampdens.1 point

-

0 size, 7 jewel, grade 1, stem wind, pendant setting, made around 1910, ~11,220 total made, if the case is in good shape, as it looks, it should clean up nice, good find, but not great find, like that SBWco 'logo' on bridge, noted different style/material balance screws and does not have huge case screw marks from re-casing, so probably original case, clean dial, no hairlines present. Someone may have stuck pin hanger on to wear, then later a chain on swivel. This watch was not made to hang on pin, otherwise the 12 would be at hinge side, (so you could read it whilst wearing)1 point

-

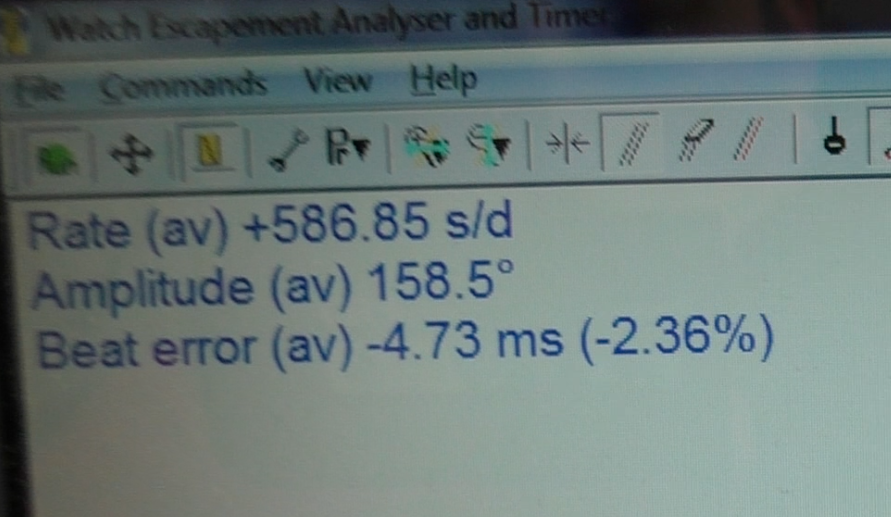

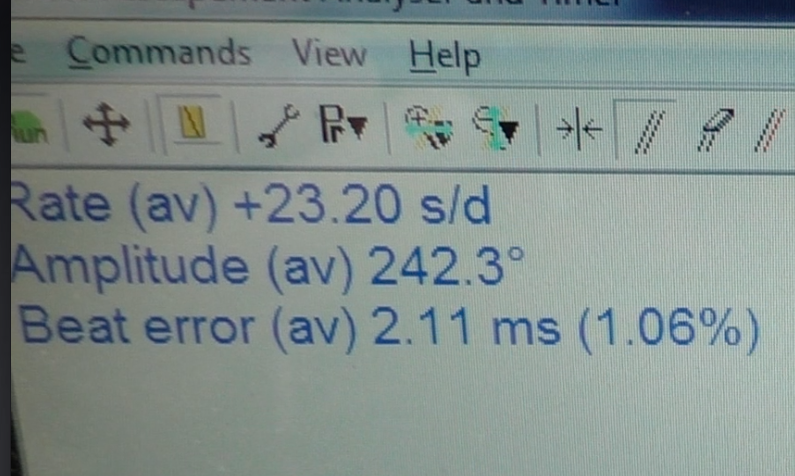

Well, I managed to remove the glue without damaging the hairspring. The collet was way too loose obviously so I tightened it and then remounted the spring. It went from gaining +600s/d to losing around -1000s/d Why you ask?? Well - because some muppet (probably the watchbreaker who glued the spring up and wondered why it was gaining so much) actually GLUED some extra weights to the balance rim!!! I never even noticed them until I started investigating why the watch was losing such a huge amount. I lopped them off and replaced two other timing screws that looked very damaged and hey presto. From this... To a more healthy... Bit of tweaking to do but at least I have something to work with now I made a video which i'll edit and publish in due course.1 point

-

1 point

-

Spot on! I'm due to start on French striking work within the next month (after my exams next week), carriage clocks there after im assuming. Yeah we have a couple of lathes here, a Cowells 90CW and a Unimat for clock work and I was also fortunate enough to have been left a Lorche 6mm watchmakers lathe buy an old watchmaker we knew well. 5 years is what my Dad did but mine is technically 3 years, although I very much doubt I'll know enough by then!1 point

-

Thought it was a chronograph but the Chinese have fooled me again! Sent from my SM-G900F using Tapatalk1 point

-

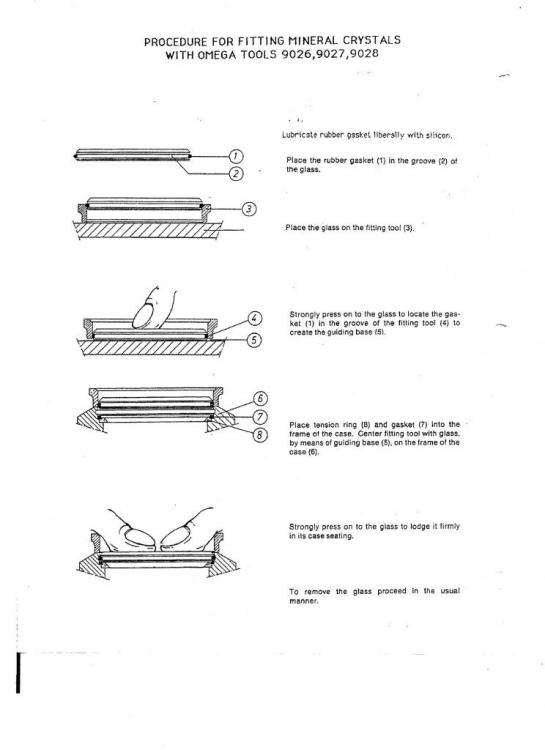

Crystal gasket is 088NS5091 . But you also need a small gasket that sits under the crystal. That is so the crystal doesn't rub on the movement. or case. 088NS08021 point

-

The mark II crystal is a little special . It has a small groove in the middle of the crystal. There sits a small thin o-ring. You will need a special tool to press the crystal in. Have changed some but every time i am letting a watchmaker do it. That has got this plastic tool. Search the net for Omega mark II crystal tool.1 point

-

1 point

-

It can be found online starting at $13, seems to be mechanical from the description, comes in a gazillion finishes... I don't know where Switzeriand is, might be a Chineese province, I'm not sure...1 point

-

Nothing wrong with Gaffer tape, you can fix anything with it.1 point

-

Well not only have I gotten her open but.... Sent from my iPhone using Tapatalk1 point

-

Thanks Geo. This certainly helps a lot! I just finished this one. Some more pictures but pretty uneventful. I did some regulation but I wasn't able to get the beat error below 2ms. I assume I did harm the hairspring a bit. But that's just fine. This is all about experience. My conclusion: a movement that wasn't working anymore is not working again. I consider this another success. The dial was in this condition when I got it btw. Also I don't have a case for this movement. I also learned something about reverser wheels and lubrication as well as working with the balance wheel. Thanks for contributing. Cheers Alexander1 point

-

Today I cleaned the remaining parts and started assembly. First was the keyless work. As I mentioned earlier, I found a replacement for the rusted two rusted parts, the yoke and the setting lever spring. Works like a charm now. Then I fitted the incabloc. This one comes with an extra holder. From what I saw this was done to the 1960's. Later the incabloc was mounted directly in the spring. I assume that it was not possible in the early days to fix the incabloc spring directly in the plate. But this is only a guess. Oiling the cap stone worked like a charm this time. The videos about oiling that were shared in my 2551 thread helped me a lot in the entire process of lubricating this movement. In the picture above you can see the incabloc assembly fitted to the plate.1 point

-

I got this diamantine power to polish a glass crystal. I am not sure how nor with what to mux to power to use it. I read that it is to be mixed with oil? Does anyone have experience with this to polish glass crystals? I don't think mine is Sapphire but not sure. It houses a Valjoux 7750 and the case brand is Lorenz. Any info appreciated!1 point