Leaderboard

Popular Content

Showing content with the highest reputation on 05/05/16 in all areas

-

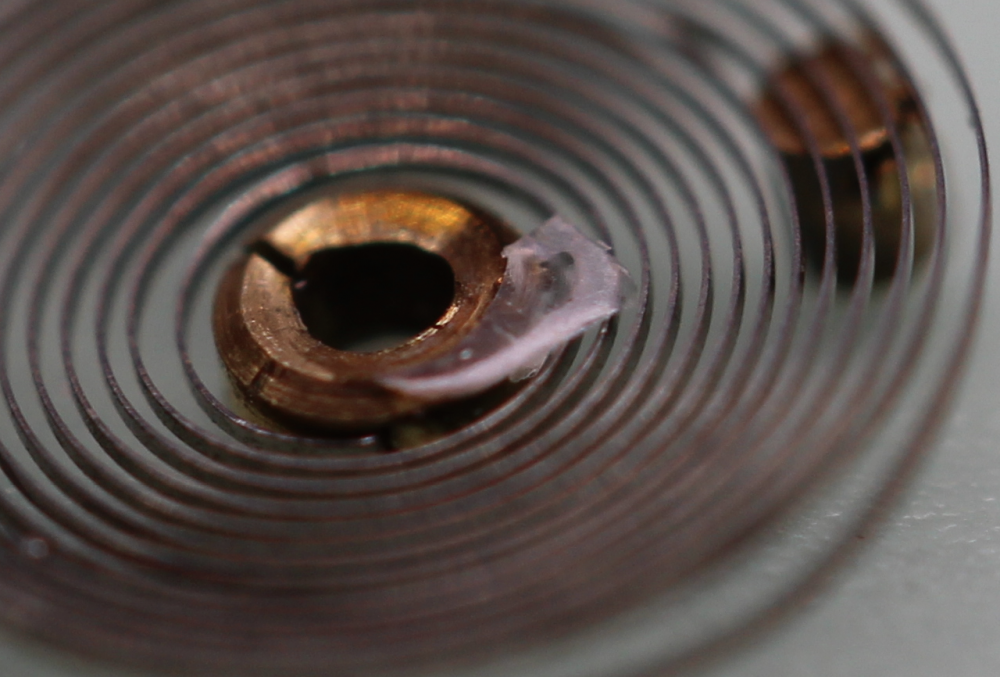

After servicing the movement, the watch had a low amp at around 150º. On investigation I see an irregular bounce to the hairspring. So I thought I would take it off the balance and have a looksee. And this is what I find... So instead of tightening a hairspring collet, we should use superglue instead! Why, why why??? And yes, this watch was gaining like crazy too. It's 6 o'clock, i'm tired - i'll fix it tomorrow (need beer).4 points

-

2 points

-

1 point

-

In respect to cleaning the autowind module Alexander is sort of right... The problem is not in the cleaning but in the re-lubricating, specifically of the reverser wheel pawls. ETA standard advice is to replace the reverser wheels rather than to service them. That way the issues with lubrication go away all together. The problem is getting the tiniest amount of oil in exactly the right place, and if you over do it they just glue up all together. There are ways and means though, and I have as yet had to replace any reverser wheels. The standard work around is to clean the reverser wheel as normal and to mix up moebius 9010 1:10 with naphtha. simply immerse the wheels in the diluted oil and then let them air dry. The naphtha evaporates leaving the thinnest film of 9010 on the wheels. This is what I do and I have no problems. A (possibly) better solution is to use a specially developed lubricant called Lubeta V105 which was devised especially for ETA reverser wheels. You use it exactly the same way as the diluted 9010 and it leaves a thin waxy film over the reverser. I have not used this myself but it does seem to have had good reports from those who have, which it should as it was developed just for this job. Interestingly I have read about it gluing up reverser wheels in movements other than ETA. Then as I said, the standard ETA service procedure is to just replace the reversers and avoid any risk of having to go back in to have another go. What would I be doing in your shoes? I would strip the autowind module down, put everything through the cleaner, dunk the reversers in diluted 9010, then reassemble and relubricate in the normal way. Best of luck1 point

-

What?!? A while ago I was tempted to use glue to repair a tricky problem on a watch. I knew that if I EVER used glue on a mechanical watch, I would be on the path to perdition, and I would be lost forvever.... JC1 point

-

1 point

-

Flopin Flip Flop Watchman! You were right! It WAS a broken Mainspring! Yes Pallet Boy! And this can be the work of only one man! You mean the "Overwinder"? Precisely, Boy Blunder! Approval was given by the owner, and the part has been ordered through CousinsUK ... so it should arrive in Australia in around 10 days.1 point

-

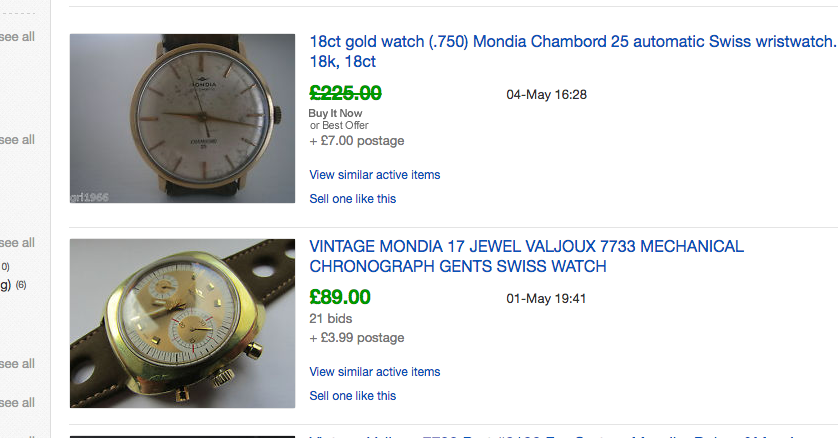

This is absolute nonsense. There are currently 206 listings for Mondaine watches and bracelets on eBay UK. Have they all been challenged? Legally, no-one has the right to claim sole rights on selling second-hand material - otherwise there would be no eBay, no Catawiki, no auction houses, etc.! Will1 point

-

1 point

-

I'll post a pic soon. If you could follow this post I would appreciate it. Little early in the morning here...lol1 point

-

Well, after some problems (balance wheel broken staff and roller) when I began reassembling the movement for which I asked help and advice here : http://www.watchrepairtalk.com/topic/3869-balance-wheel-problem-in-a-landeron-248/?p=39243, I finally went on with the job yesterday. The assembling of the parts is very straightforward in reversing order of disassembling. But as I was expecting the adjusting of parts to get the movement work properly was much more complicated. The main reason for this was that, as I had to replace the barrel bridge, naturally all the cams of the sliding gear, coupling clutch and hammer (that came out from the older bridge), had to be very fine tuned patiently and with successive attempts. Particularly tricky was tuning the depthing between the sliding gear teeth and the dart tooth on the seconds wheel chronograph runner. If there is too much depth the minute runner will jump two minutes at a time, and with too little it will not jump! The cam (eccentric stud) to adjust is this one : The other critical adjustement is the depthing between the sliding gear teeth and the minute recording runner wheel. the cam to adjust is this one: If there is too much depthing between teeth, the chronograph will not run! With these important adjustments solved the remaining assembling was easy with no problems. Finally, I decided not to use the balance wheel I had remade because (I don't know why!), the spring was apparently interfering with the third wheel. As meanwhile I had bought another Landeron 248 movement (as a possible backup for parts) I swept the balance wheels, so that I could finish this service more quickly. ( I'll come back later to the other balance wheel and investigate what is possibly wrong with it!). So, the final result after assembling was like this : I have been using it today for testing and it is fine, keeping good time and with chronograph functions working smoothly as well. It was really a very "hard" job for almost a "newbie" in this hobby, but I was very happy managing to get it to an happy ending. And it gave me the opportunity to use for the first time the "Seitz" jewel tool and a very old "Manhora" stacking tool I had bought some monthes ago. My thanks to everybody who encouraged me and gave advice!1 point

-

1 point

-

I might be able to help you as I'm an old and decrepit watchmaker. But I'll need pictures1 point

-

1 point

-

All the parts are nicely soaking in lighter fluid at the moment - I don't want to contaminate my expensive watch cleaning solution.1 point