Leaderboard

Popular Content

Showing content with the highest reputation on 11/21/15 in all areas

-

Well, a few more folks are like me, a cold wet afternoon and a lump of teflon and Colin has a new oiler holder. Just one of the many little things that plant the seed for others to follow. Encouraged by the success of re-purposing my old Indian screwdriver stand to an oiler holder (http://www.watchrepairtalk.com/topic/3138-i-needed-a-stand-for-my-oilers/) and knowing I had another one in the junk box somewhere, I decided to see what I could use it for so I rustled it up. I had made a quick and dirty holder for some bench tools from the foot of an old sofa that had gone to the charity shop, wasn't pretty but did the job. Using the same method, I popped the stand apart, chucked it in the lathe and marked the diameter and index marks using the index wheel on the lathe to produce six points. Then to the drill press for pilot holes and final holes to suit the tools. Back together and I'm happy with it. And with the tools. They are a pair of hand lifters, a brass stabby thing I made from a clock chime, a steel stabby thing I made from a cheap screwdriver, and at the back, two Indian screwdrivers modified by removing the swivel heads and shaping the bladed into little flats, one with a blob of Rodico which was my go to jewel lifter until I got a proper one. This forum and the posts of the members is great for galvanising one into motion isn't it :-)4 points

-

2 points

-

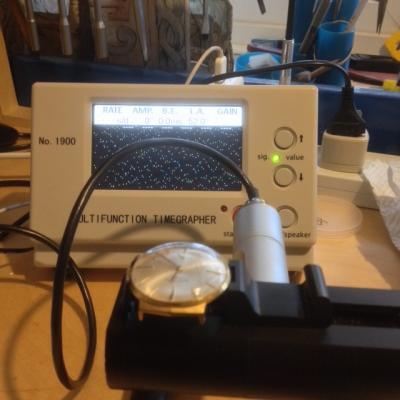

I was asked to look & see if I could get working again a friends watch that was his fathers . It is a Rotary with a Peseux 320 movement. I always put such watch on my Timograph just to see what I am up against well see below. The big issues with this watch was getting the back off to say the least it was very difficult & I had to prise it off using my case opener tool. This tool is invaluable with a tight case back Not my one but the same design The other issues was the movement was very,very dirty & it was a mile out of beat (9.0 ms). The cleaning assembly & lube very straight forward but adjusting the beat was tricky as adjustment was only achievable by moving the hairspring collet. However this pic was after a few tweeks. I did eventually get the beat error down to 0.8ms & settled for that. Fitted a new high dumb cystel job done apart form a new strap required.2 points

-

1 point

-

Thanks Bob . Will put them aside for now . Maybe one day i have use for them . I now some of them are FHF parts . There where a lot of other useful stuff .1 point

-

Hi rogart, My understanding is that each manufacturer has a balance wheel and hairspring (sometimes in combination) for a certain movement. That is an ETA2824 balance won't work on an ETA6498. Of course, if the movement is in the same family the balance wheel will generally work, eg. ETA2824 with ETA2836. Also there are different grades so you may have a regular balance wheel/hairspring combination but you may be able to use a chronometer grade balance wheel/hairspring combination because it is either the same family/similar movement and/or same movement but different grade. Seiko, for example can use different movement parts interchangeable (just as many other brands), only it seems the interchangeability is wider even between "eras" of movements. It all boils down to bps, material used and of course measurements and properties. I wouldn't say your lot is useless, you just need to identify what you have and if not of immediate use, I bet one day they will be useful. Hope this helps, Cheers, Bob1 point

-

1 point

-

1 point

-

1 point

-

:D :D :D :D :D :D :D :D :D OK The main tweek was the hairspring was contaminated with something that the watch cleaning machine did not shift. So I removed the hairspring from the balance & soaked in one dip. After approx. a dozen moves with the hairspring collet got it with a reasonable beat error. After these I ran the watch for an hour or so before the final regulation. Since then I have attached it to my watch tester for 24hours just to double check all was well. And that,s it no more comments please as I have some serious wine drinking to pursue this evening.1 point

-

Just use ronson lighter fluid and let the parts soak a little. You may want to have some pegwood handy to peg jewels and other spots. It works at that level. Cheers, Bob1 point

-

I,m hoping to. The general public just have be made aware & that,s it no campaigning needed just the lack of sales will do the trick1 point

-

1 point

-

I reckon that'll be a Raketa 2609.HA under the snap on case back. A capable little engine with end stones for the escape wheel held in place with spring clips which can be a challenge to reinstall, a tiny little hole jewel set into the tip of the centre wheel pinion for the seconds hand pinion to run in, a lefty for the crown wheel screw (3 slots), a press fit cover plate for the motion works, and a shim under the balance cock. With what looks like a Russian version of Incabloc shock protection and an adjustable stud carrier it's a nice movement to work on and can turn out quite good performance. In case you hadn't guessed, I have done one or two of these :) . Cosmetically yours looks to be pretty good so provided no one has brutalised the hair spring you should end up with a great everyday watch. If you get stuck for any spare parts let me know, I may have some bits and pieces in my goody box.1 point