All Activity

- Today

-

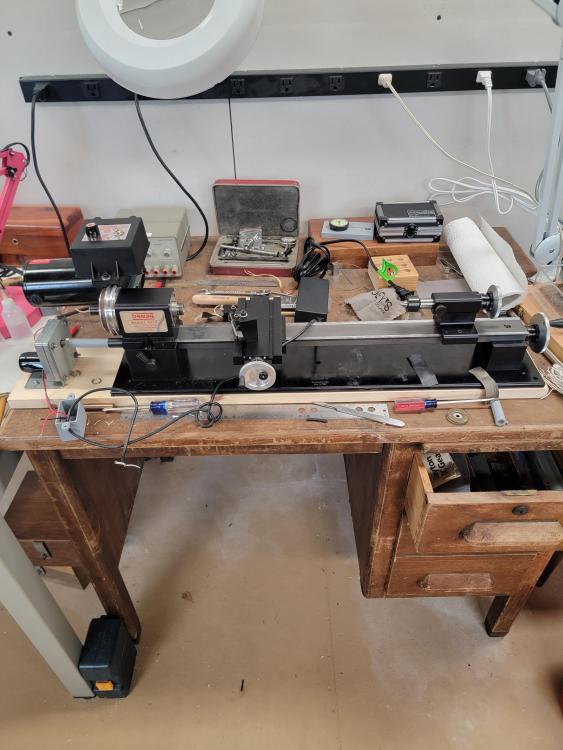

Lathe motor advice

JseTay replied to JseTay's topic in Lathes for Watchmakers / Mini Lathes & Jacot tools and all related

I sure appreciate your comment! I will look into one of those or maybe something similar. I of course will check your video to have a better idea. by the way, that’s a beautiful lathe! Mine is a little peersless, but I just bought a Boley & Leinen that is on its way. That’s the one I am looking a motor for. It comes with a motor, but I want to replace it for one that has a speed controller. -

TomL joined the community

-

This conversation is becoming a very confusing. The etachron system is a very nice system for manufacturing watches. As you know it consists of two components the stud and the regulator pins. Beautiful thing of this system is you can open up your regulator pins center the hairspring and as you close the pins they will close equally on both sides providing you centered it in the first place. It's not like you're going to become closer to one side or the other as the definition of the regulator pins is a bit confusing it's not exactly a slot sort of. I'm thinking maybe a little eight reading will be helpful for you. Then the file name was changed by me at the US patent but the wording of Seiko may or may not actually be attached to it soared up? I just did that so I can find it in my files. Normally patents are in people's name if they work for a company the company name will be there you'll notice the person lives in Japan which is interesting as the name would imply that this is a Swiss product. Somewhere I think I have the patents for the stud and I believe that is Swiss like a lot of things their Japanese and Swiss and then the Japanese let the Swiss name stand as it seems you more popular in case as you read up on the patents of the regulator pins or pin will see and it should explain exactly how and why it works also why it's important to always close at an open in specific directions because the pins actually have a shaped to them it's very hard to see the shape as it's very tiny. As a reminder with this system it's mass-produced. I wouldn't be at all surprised if they use cameras and computers to do all of the adjustments. The meaning of this is that the majority of watches will function as there supposed to and do what they're supposed to do the system will allow us for some minor in tolerance and has more than likely as I said no human hand is ever touched those watches that's the way they left the factory and they work fine. US2007091729A1 seiko etachron.pdf

-

MariusJacob started following Quality Chinese Tools

-

Quality Chinese Tools

MariusJacob replied to Paul80's topic in Starter Tools, Toolkits, Recommendations and Tools Suppliers

I bought an old Bergeon 5555. The bottom of the tank was full of petrified salts, which also corroded the metal parts a bit. I would use just distilled water. -

EBUZZ started following INGERSOLL watch necklace - Unsure of make/model

-

Can anyone help me identify this watch/pendant. It was inherited by me from my grandmother and I am unsure as to what it is. It's a watch/necklace with a blue face with the inscription "INGERSOLL" and "Swiss Made". Have tried looking online but to no avail. If anyone knows a make/model or knows where I might be able to find out about it, that would be very helpful.

-

EBUZZ joined the community

-

I can't remember where, when or for how much, but I got myself an epilame bottle just like that from one of those Chinese sites (like Alix), and as I remember it, I felt it was affordable. It was much, much less than £175 and I'm perfectly happy with it. I think it was the following post that inspired me:

-

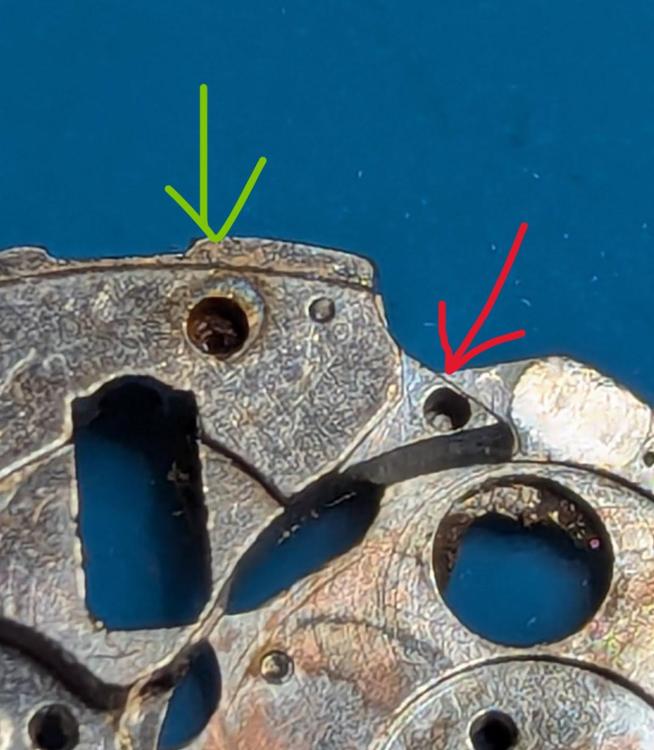

The winding stem was stuck completely, and had to saw through the remaing part as well. Now there are two parts remaing on the base plate. After a two-day dip in isopropyl alcohol these parts can be moved around their axes, although with great resistance. The part marked with the green arrow is the "setting lever with axle" according to the Seiko repair manual. For the part with marked with the red arrow I didn't find a specific name in the manual. This is a photo from the back, the holes marked with corresponding arrows: According to the manual it should be possible to pull out the "setting lever with axle", but what about the part marked with the red arrow? Can its axis also be pushed out through the hole marked with the red arrow?

-

Lathe motor advice

Dell replied to JseTay's topic in Lathes for Watchmakers / Mini Lathes & Jacot tools and all related

I use a Jack industrial sewing machine motor on my Pultra I can’t fault it although I have converted from foot to a potentiometer the torque even when running slow is excellent. check out my videos on YouTube to see it in use @torsiondell. Dell -

Yes, I understand that in te Etachron system the regulator block is turned anti-clockwise. If I look at the spring in relation to the pins as I turn the block the gap appear to be "closing" and the spring is now closer to one pin than the other. Closing is not the correct term because the pin gap is always contant but in relation to the spring the gap appears to get smaller and smaller until the spring is actually on the pin.

-

Quality Chinese Tools

ColinC replied to Paul80's topic in Starter Tools, Toolkits, Recommendations and Tools Suppliers

I have one of these (different colour scheme) very happy with it! Not so happy with the recent results... but that is nothing to do with the tester. My wife wanted a waterproof watch she could take on holiday so I fixed up a nice Mickey Mouse Seiko 5 for her. But after getting a non runner working nicely it failed the pressure test with water seeping in around the crystal -

RichardHarris123 started following Photos of your youth

-

-

This is wrong. We have been talking about the regulator pins because conventionally the regulator is two pins, or a pin and a boot. The Etachron regulator is one round pin with a wide slot down the middle for the hairspring to sit in. To regulate, the pin is rotated anticlockwise (viewed from above) which brings the rear inner and front outer corners of the slot equally closer to the spring. You can download a document with detailed instructions here: https://calibercorner.com/etachron/ Can you please post some photos to show what you mean by "flatten the spring"?

-

Than you so much for taking the time to write such a detailed and informative post. It really helps. So, another question: With the Etachron system the stud pushes into the carrier but the angle on the vertical plane of the stud is based on the carrier arm. I expected it to be flat but I have seen some movements where it is bent slight down meaning the stud is pointing slightly inward at the bottom and the spring leaving the stud is affected. Is this something that is done at the factory to flatten the spring? I played around with manipulating the spring vertical angle as it leaves the stud and it has a significant effect on how it goes through the pins and also the angle of the coils on the other side of the balance. I can flatten the spring by adjusting the angle it leaves the stud. Now I know the NH35 is a mass produced movement so not the best quality but is the stud vertical angle ever manipulated to flatten the spring?

-

Quality Chinese Tools

nico replied to Paul80's topic in Starter Tools, Toolkits, Recommendations and Tools Suppliers

Because the water is very hard with calcium where I live, and I saw that on a youtube demo ... Maybe it's unnecessary... -

Quality Chinese Tools

nico replied to Paul80's topic in Starter Tools, Toolkits, Recommendations and Tools Suppliers

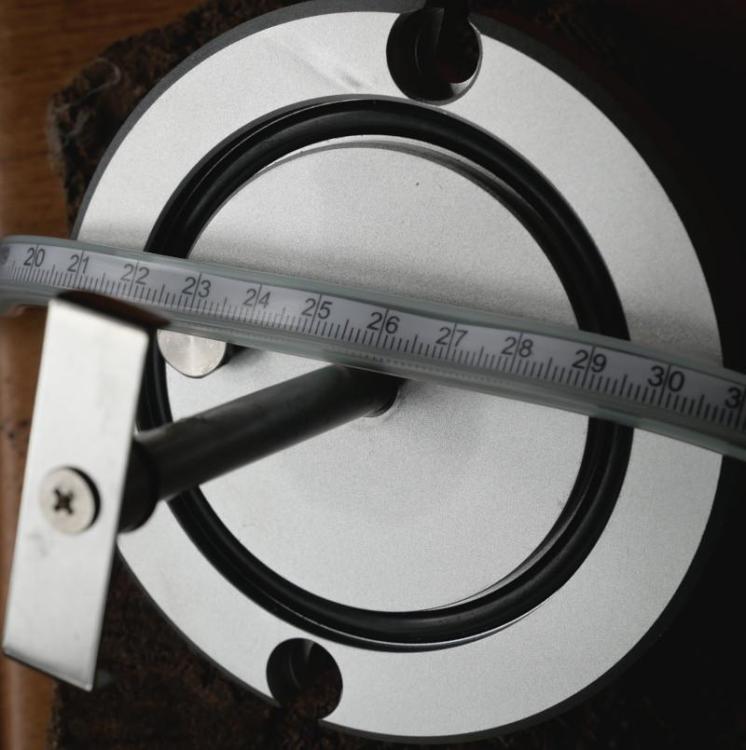

Just received today: For only ~60$ * (*) ~140$ with shipping and custom fees. 3.80 Kg The pressure should be able to reach up to 6 bars. The glass is thick The closing system seems to be sturdy. The plunger lever(?) and the valve: The plunger lever locking system (I will make a notch on top to note the opening position): I put 3 bars at let it for 20 minutes, the pressure didn't leaked at all. Next steps: Quick wash, maybe put some silicone grease on the seal of the lid ? First test I'll do: Put deionized water til the red line Put a diver case in the tank, keep it outside the water Pump (10 ~ 20 times?) to reach 3 bars (0.3MPa) Wait at least 1 minute Dip the case into the water Gently release the pressure and observe To be continued... All comments are welcome -

mbwatch started following "Wobble stick" centering technique, and T rest height?

-

Hi all - I was just watching Clickspring's series making a custom faceplate and he demonstrates the "wobble stick" technique for centering. I was already familiar with this and it is all straightforward. But how does one set the height of the T rest so that it acts as a truly level fulcrum? Or does it actually matter if the fulcrum is perfectly level with the hole you're trying to center? As I type this I'm realizing there should not be any motion at the other end of the stick even if it is at an angle relative to the work, and isn't pointing even with the tailstock center. Do I have that right?

-

Khan started following Bent screw

-

JohnR725 started following About repair watch's jewel.

-

Typically watch manufacturing companies will purchase parts to their exact specifications including the jewels. This means that typically you may not find an exact generic replacement. I'm attaching a PDF of a book that explains how to replace jewels. Seitz book.pdf