Leaderboard

Popular Content

Showing content with the highest reputation on 02/12/24 in all areas

-

The story I heard on the thicker top cap jewel (cock jewel) was after lots of practical study, they found that that jewel saw the most impact, so it made sense for it to be thicker. But in reality, I have never ever found a cracked cap jewel on a shock setting, so it seems to have been overkill. But you can't replace it with a thinner one, the spring won't hold correctly- or vice-versa, the spring won't go over the jewel without damaging it. On Jacot too use- This is a tool I use frequently enough I keep one set up in a vice all the time. I also see young watchmakers who supposedly learned to use it in school come to the shop and are useless on it. Aside from typically using far too short of strokes on both burnisher and bow, they always want to have their face right in the tool with a loupe while using it (possibly why the super short strokes). As I was taught, and continue to do, I get the pivot in place and runner adjusted, checking with a 10x loupe. Then, I get my burnisher in place, and from there it's almost like John said "eyes closed in the dark", that is, I'm not peering at what's going on, just focusing on keeping the burnisher in contact with the pivot (i.e. level and to the left), and listening to and feeling what's going on. I'm sitting in a normal position, looking at the tool, but not up close. Usually pinky and ring finger are resting on the right of the tool, burnisher held the same as one would hold a pen. Pressure is between 250g-1kg, depending on the pivot. It does take some practice to develop a bit of feel, but I have shown folks in 10 minutes how to use it and they are successful.4 points

-

To all, I'm a career mechanical design engineer, recently retired. I own a seat of SolidWorks 3D CAD software. I've been a SolidWorks user since '95. If anyone needs a solid model created, I'd be more than happy to give it a wail. I'm a budding watch repairman and would like to give back to this community that has helped me immeasurably thus far. cheers2 points

-

1 point

-

Seiko mainsprings are thin and narrow. Yes, I have borked one. That and their anti-Swiss stance on design kind of swears me off them...except for maybe the Swiss ones...1 point

-

Nah, if you can hold them all in one hand you are fine! But if you need eight display cases it’s a different story…1 point

-

But be careful, there are fake Renatas out there. I've seen "Renatas" leak. I would only buy from reliable sources.1 point

-

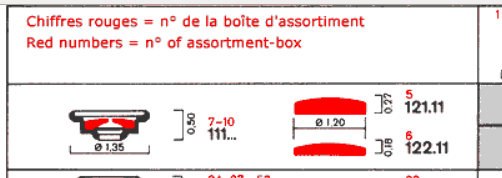

For this movement 30L, the chaton is the same top and bottom 111.10, and the springs are the same 170.03. But the block is different, hence the need for different cap thicknesses. (Why do the French have such similar words for top and bottom, (dessus, dessous). Surely at sometime in history a simple typo must have caused disaster?)1 point

-

1 point

-

It was adding pressure to try to burnish it flatter was what caused my mistake. But now I'm going to have a new balance staff, and new jewels ! Out of interest, does anyone know why top cap jewels are thicker than lower, when they use the same chaton? Top jewel is 121.11 thickness 0.27mm and bottom 122.11 thickness 0.18mm. Why not use the same jewel? That's easy, the chatons are 111.xx where xx is the hole size. These are 10, so I could go to 091 point

-

That was very wisely said Yes of course! If the pivot is badly worn and you need to shave off so much it causes excessive side-shake you will have to replace the jewel. Not sure how that works for a balance staff though as you would need a same-size chaton with a smaller jewel hole!? If you need to change the diameter of a staff that much I guess it is better to replace it.1 point

-

That is what I was told by the person who taught me how to use the tool. The problem with a lot of hand eye coordination things like this is for somebody it may be insanely easy they could do it in their sleep in the dark and for others they may never Be able to work it out. Unfortunately in the world everybody is different and everyone's experiences different which doesn't necessarily make anyone's experience right or wrong. It seems to be a lot of tools that seemingly at one time were very very cheap now are not. Like the vintage black L&R cleaning machines with its three jars that came out in the late 40s at around $49. That for quite a few years when he would go to the watch and clock shows or practically begin given away because a review is vintage and typically were missing the jars because are broken. Now on eBay they use the word vintage and was going to say they started 500 but it looks like they're starting at $600 and up. The vintage machines are actually costing more than the machines from India. So yes it seems to be a lot of tools that have gone up in price dramatically. Thinking about must be in perfect condition if you look at the original pictures of the pivots in this discussion with the amount of scoring on the side of the Pivots burnishing it all down so as nice and even isn't that going to shrink the size of that pivot? Then with shrinkage of diameter isn't that going to be a problem?1 point

-

This coil has been failing since basically the beginning of time. Basically it's not a new phenomenon the prevailing theory way back when was that because jewelry stores and other people change batteries that's why that coil is the first to go out. So basically they were all gone a very long time ago way before any other component in the watch. Somewhere but I don't remember where that I don't remember exactly why but there was a reference to the protective coating would cause a failure I'm guessing where the wire is soldered to whatever it's soldered to. So I suppose conceivably if the protective coating should change its size like shrink it could pull away and because the wire to break probably just about anywhere unfortunately.1 point

-

It's an absolutely fantastic tool but definitely one of the most practice-intensive. The risk of causing damage is unfortunately imminent, and there is a lot in what @JohnR725 usually says, namely that you have to use the tool every day to become good at it. Now, I personally think that's a slight exaggeration, but there's still a lot to it. For that reason, I understand why many refrain from using it, but if you want to get an optimal result, the pivots must be in as perfect condition as the jewel holes. No, it's not your imagination! There are several explanations for the increase in prices, but the main one I think is the increasing interest in watches and repair. For example, about eight years ago when my interest was first piqued, you could buy a complete large set of used Bergeon mainspring winders on eBay for about £300. At the time I thought it was insanely expensive. That time will never come back A tip when looking for tools on eBay is to use German and French names and preferably also other languages instead of English. eBay is usually unable to translate the tool names in other languages into English so they do not appear in the search results. Among other things, that's how I managed to find my latest Steiner Jacot tool in near-mint condition for £170 (€195 )by searching the German name "Zapfenrollierstuhl" instead of "Jacot tool". Most of the time German sellers are aware of this and include the English name but once in a while, they don't and then the number of potential buyers shrinks. About burnishers. I have the Bergeon and the Vallorbe burnisher. The Bergeon is tungsten carbide. The Vallorbe is hard steel. The difference is in my experience night and day. Also, the rounded edge on the Vallorbe is too large for normal wristwatch movements and better suited for pocket watches. I'd be very interested in seeing that video. If you could provide a link to it I think many would appreciate it. Thanks!1 point

-

Yes, indeed. I made sure that the battery was out of the circuit during tests...for the reasons you stated!!1 point

-

Joe at the Nekkid Watchmaker often does this. Here's one of his :1 point

-

Good points @VWatchie - I realise that you can get your money back on many quality tools. The tool is £70 at Cousins, +VAT = £84. Maybe I will get one. But I do have the Jacot tool which should do the job, the only problem being the operator. And I prefer to invest my money in the stock markets.1 point

-

I hand sanded starting with 400 grit (lightly), and worked my way up in grits until I could put a full polish on it.1 point

-

Because of the concern of water here I use 1 percent Liquinox and deionized water, change the IPA rinse every time and into my dehydrator with the fan. No rust. The cost savings, no offensive odors and cleanliness are too good to pass up1 point

-

I am kind of expecting a few "Oh my god what are you doing type comments.... but here we go....) I have been following advice I have found here and there for cleaning watch parts - with very limited access to chemicals and without the expense of a cleaning machine. My process has been to put the small parts into little mesh baskets and then put those baskets and the bridges and plates into a sequence of jars which I put in a cheap ultrasonic bath full of warm (50º C) water. I then separately take balance and pallet forks and just soak them for 20mins or so in lighter fluid before giving them a fast rinse in IPA before putting them in my food drying thing. Jar 1. 8mins or 16 mins... deionised water with a few drips of washing up liquid (Zalo) Jar 2. 5 mins 99.9% Isopropyl Alcohol Jar 3. 3 mins 99.9% Isopropyl Alcohol To be honest my results are not great! So I decided to try adding a prewash to the above list. Jar 0. 8mins deionised water with a few drops of "Muc Off - Drivechain Degreaser" (This is a water soluble degreaser that I have been using in a 1:9 mix in the same ultrasonic cleaner to clean bicycle chains) The difference has been night and day - tray of clean parts! I also had a balance from another movement that was sticking together and had black gunk on the hair spring - lighter fuel had not done the trick so I thought... why not! I put it alone in one of the mesh baskets and put it through Jar 0. and then Jar 1. on my cleaning process before taking out the wet hairspring and gave it a quick dip in IPA and then into the food dryer. Once dry it looked nice and clean - the shellac on the roller jewel looked intact and the watch that I had taken it from that was all over the show on the timegrapher started to produce steady results. Planning to find a junk pallet fork and put it pure degreaser to see if survives...1 point

-

So cunning you could pin a tail on it and call it a fox !1 point

-

1 point

-

Actually the textured burnishers used for pivot work can be seen as ultra-fine files. They do compress the metal, but they also remove some metal, that's the "black stuff" on the burnisher after some strokes. A really fine textured burnisher will have a cutoff point though where it won't really remove material any more. A more aggressively textured one would continue to cut (and burnish)... but, it won't leave quite as fine of a finish on the part. The Bergeons are pretty spot on right out of the box. I had a Vallorbe when I was in school last century but as VW mentioned the radius is too large for most watch work, and the file is useless for watch work (maybe for a center wheel or barrel arbor?). Ha VW posted while I was writing.1 point