Leaderboard

Popular Content

Showing content with the highest reputation on 02/02/24 in all areas

-

3 points

-

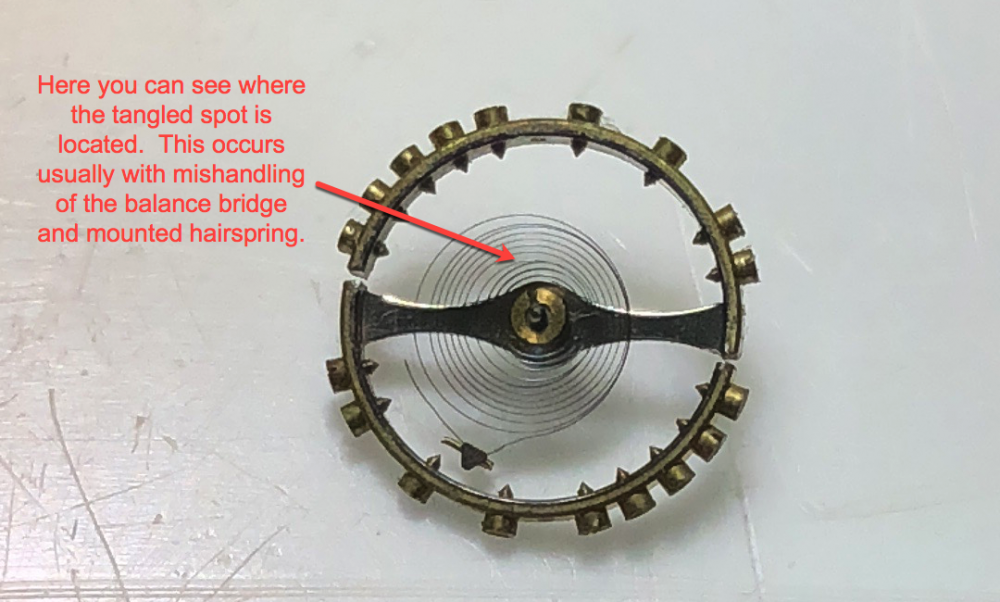

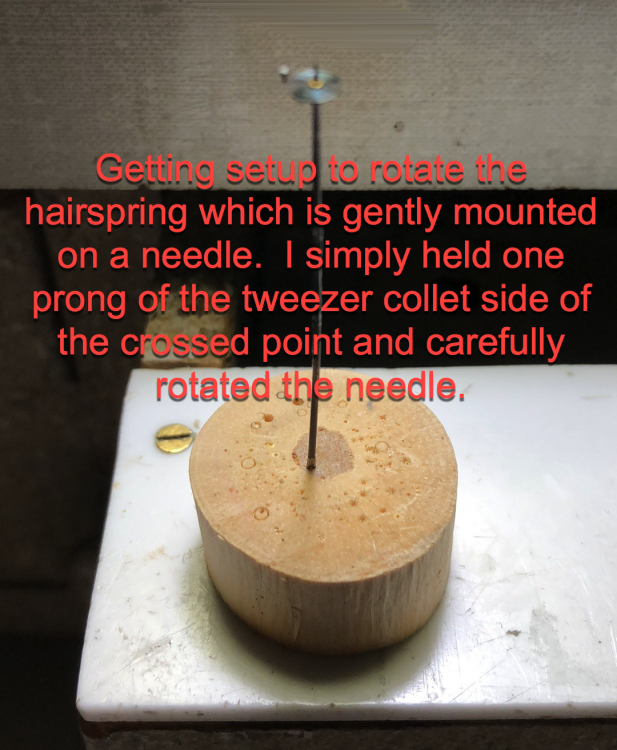

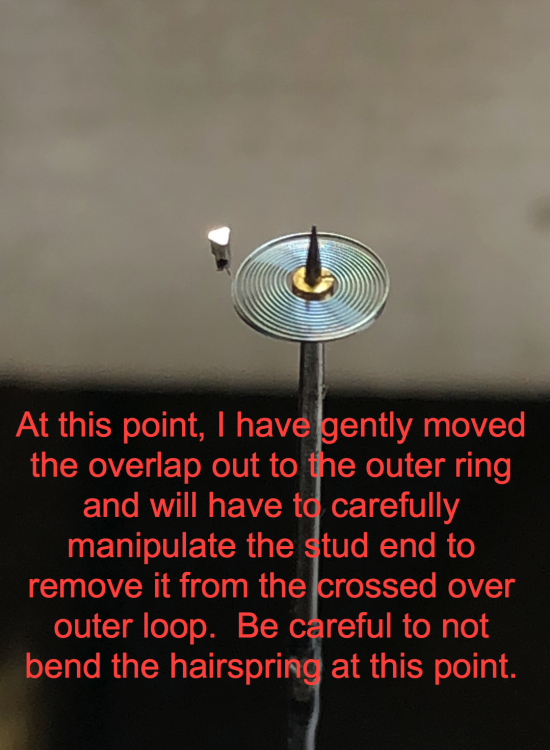

New member here from the US. I have a few old mechanical watches that I've always had an interest in servicing myself. I've done a fair amount of reading and background research, but hope to learn from those on here as well. I started by building a couple of Seikomod-type watches from components, managed to slip and kink a hairspring when regulating one of them, then dove into the deep end trying to repair the hairspring. I had the watch running reasonably again, but at some point with lots of times removing/replacing the balance, I got complacent and managed to break a balance pivot. I'm forging ahead with some simpler projects to gain some proficiency. Cheers, Brian2 points

-

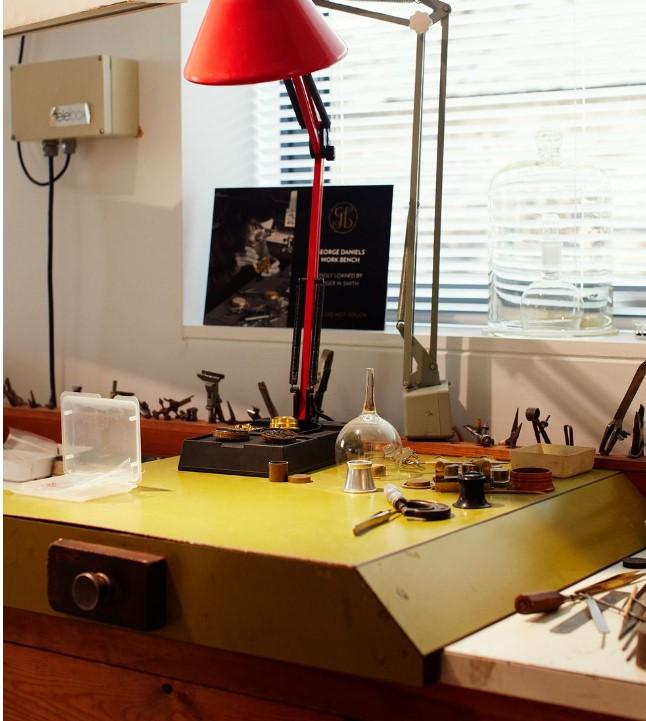

I like them and I find the position of my arms a little more comfortable but they don't make you a better watchmaker! Here's a photo of Roger Smith's workbench with not a pad in sight and look at the stuff he knocks out. And here are the Struthers' workbenches. George Daniels never used armrests either.2 points

-

Very much like the hacking knives i use for woodwork and deglazing frames. Same principle of use, the blades mushroom over with impact above the cutting edge eventually. Stanley blades can be quite brittle though, I'd suggest a brass hammer like you're using here Jon, rawhide would be good if one that small is available to buy. I get the technique entirely which is why i said appropriately vicious Haha, i nearly spat my tea out when i first read it.2 points

-

I have a couple of different ways to use a microscope in conjunction with my workbench. I always say "Move the work to suit you, don't contort yourself to suit the work." So for me keeping myself comfortable when working on watches is a must and I don't like to change the height of my chair to suit the work. But I understand that we don't all have this luxury. The first photo is my height adjustable watchmakers bench next to my microscope bench, so they are on two different levels. The bench the microscope is on is also height adjustable. I don't like to tilt my microscope for personal reasons. It just suits me that way, as I like to have everything in focus, especially when filming and projecting the work onto a projector screen for the class to see. The next photo is of a couple of students workbenches that are also motor driven height adjustable. the one in the foreground is set to a working height and the one in the background is lower to use the microscope on an articulating arm. These workbenches can be made for about £300 to £350 with waxed solid beech worktops, which I think is a good investment, especially as you no longer need to adjust your chair to suit the work, as well as feeling like a total boss when servicing your watches. Think about how much money we have spent on tools, watches and equipment. We owe it to ourselves to build a decent workbench as a priority. My next project is to profile the front of these workbenches using a plunge router and fit leather armrests as I have on mine. The students won't know what's hit them! I'll post some pics later in the year when I've made them.2 points

-

I used a Robur press and dies to fit the bezel back on. I must admit, it does look pretty vicious, but very effective. You can see why a four jaw bezel removal tool is as much use as a chocolate tea-pot! Taking out the stem is a good idea if you're doing this for the first time, as you don't want to slip. The lugs are never touched when working around the bezel, as you only need to flex the blade a little at a time so as not to touch or damage the lugs Yes the balance was removed first. Don't use the blade on its own because it is only thin and when hitting it you want it to remain as flat to the work as possible without the blade moving about and risking damaging the case and bezel. The Stanley tool is the best thing to hit as there is more stability. Don't worry about the hammer not being perpendicular, as the end of the Stanley tool is resting on the bench. Most watchmakers use a blade to remove this type of bezel, although this was quite a tough one to remove. The trick is be deliberate in your actions. As soon as you are tentative, that's when things go South very quickly, in my experience.2 points

-

2 points

-

Hi guys, As many of you are aware Roland Ranfft passed away earlier this year which is a massive loss to the world of watchmaking. I used his database of watch movements on a weekly, sometimes a daily basis to gain info on mainspring sizes, hand pipe sizes, and the like. I've also bought a lot of watches from the auction part of the site and when I say a lot, probably close to £5000 worth of watches over the past three or four years. I found buying from the site was a lot more pleasurable and friendly than some eBay deals I've done and was never disappointed by what I received and a lot of the time absolute bargains. What I've found over the last three or four years is that chronograph watches, both hand-wound and automatics have increased in value about three-fold in that short space of time, as well as some automatics I've bought from the site, as well as from German and Swiss eBay. Some Valjoux 7750s I bought four years ago for about £150 from the Ranfft site will now fetch close to £400 to £500. Not sure why chronographs have risen in price so quickly. I bought some Landeron 51s and 248s chronograph watches in working order for £90 four years ago and now they'll fetch at least £300 to £400. What on earth has happened for them to increase by so much? Does anyone know? Watchmaking tools have gone the same way. I was buying JKA Feintaster bench micrometers from Germany and Switzerland three or four years ago for £90 and now they'll go for £400 to £500. I saw one go the other day for over £1000 from a seller called 'watchmaker-lathe' from the Czech Republic who seems to have an endless supply of quality watchmaker tools. I think he's got a magic bag he pulls them from!... lol. Worth checking out what he sells, although they go for top dollar prices. Anyway, I feel I'm rambling a bit and wanted to tell you all if you didn't already know that the Roland Ranfft website, 'Pink Pages' is available as an archive at this address: https://web.archive.org/web/20230305223353/http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk The search box doesn't work, but all 221 pages of watch movement details are available which is a bonus. Hopefully, someone will pick up the baton and run with it and resurrect the website, let's hope. Until then, at least the amazing work that Roland achieved hasn't been lost. Share the love and spread the news this is still available. Much love and respect to Roland Ranfft, you'll be sadly missed! RIP Roland...1 point

-

What scares me is the statement "I couldn't get the bridge to seat fully at all 3 screws." You don't seat the bridge with the screws, you secure the bridge with the screws once the bridge is seated and all pivots are in their respective jewels. Trying to tighten the bridge screws when the wheels aren't turning freely is an invitation to a broken or bent pivot. You might want to take a close look at the escape wheel because that definitely should engage with the 4th wheel when seated. Do you have the data sheet for the 7S26A? If not here you go: https://seikoserviceusa.com/uploads/datasheets/7S26A&7S36A.pdf1 point

-

The wife and I are annual subscribers to the local symphony, so classical is definitely appreciated. Favorite composer would be Edvard Grieg. We also have a local Jazz festival every year. I'm a big Chuck Mangione fan and would also include Pat Metheny in my top 2 jazz performers. There was an English band in the '70s called Renaissance that I still enjoy. Heck, I'll even suffer the teenage angst of Taylor Swift from time to time.1 point

-

Well, what I expected was at least 250 with the old one and above 300 with the new. 190 is bad, and even 233 is far not enough for new spring. See, sometimes there are wicked watches that will not run as we want. Good balance and cleaning/lubricating is sometimes not enough to bring them in good shape. Can You evaluate the escapement action? Is there good 'draw' of the lever to the banking pins? Is there wear in barrel bearings or in the bearing for the arbor in the barrel bridge and traces of rubbing on the barrel and the plate?1 point

-

1 point

-

Sorry to see that. Actually, will not advice to touch the ratchet wheel. You can work on the click only and it will be possible to solve the problem by bending it a little in a manner that it's tip gets lifted above the surface of the table Thus, it will be able to catch the part of the teeth that is not damaged The tip of the click is smashed, but it is soft and will be possible to form it right onse it is lifted. Lifting must be done without damaging the rivet of the click, so no force to be aplied to this joint. Put sctewdriver tip under the tip of the click to get it lifted as much as free play alows and then press the midle part of the click, this will bend it in needed way. The table should stay on flat hard surface.1 point

-

https://web.archive.org/web/20230305223353/http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk1 point

-

1 point

-

1 point

-

1 point

-

If there is nothing to grip. How are you going to cut a slot. From the photo I can't see if it is protruding or not.1 point

-

1 point

-

Thats fine, as long as it wasn't the word i thought it was1 point

-

1 point

-

Most of the quartz watches have a hacking feature. If you pull the crown to set the time, the watch will stop. Make sure you have the stem fully seated.1 point

-

Hi Richard you are right using metal tweezers and shorting pos to neg equals battery knackered.1 point

-

I don't work on quartz movements but don't you have to be careful not to short the battery?1 point

-

Hi welcome to the forum. Can you post pictures of the watch and movement please we like to se what we are at. Possibilities are battery dead or low voltage, needs to be above 1.3volt on a meter. The coil may have been damaged check surfactant for bright spots and the contact wires again may have got Broken , visual check. After checking these items come back if you require any more assistance. If you find the fault let us know. Thanks.1 point

-

Thanks for finding this. Even though the search function doesn't work, I find using the "all" function quite acceptable. I have also been using the ranfft.org site as well, however I find the search function somewhat clunky. Hopefully the internet archive site will stay on-line indefinitely.1 point

-

Russian vintage if you mean from the 60's or 70's leave them alone they are not well made, can be fiddle getting the wheels between plates, threads on the screws are poor. Certainly not recommended by me. There calendar works are a nightmare with an abundance of very fine springs that will not sit in their designated spot and would sooner fly to the moon then stay in the movement.1 point

-

OK...more like a "place" than a "center." I will be spending half my time here, so I needed some way to do horology. Since Accutrons need a subset of my tools, and I have about 50 to work on, I decided that I could setup to do just Accutrons here. I still need a cleaning setup...working on that! I have the microscope, test set, and the hand tools. Today, I took an Accutron that was not working, opened it up, adjusted the index and got it running. It needs a cleaning, but I was proving the tool set to see if anything was missing. Hopefully I will solve the cleaning methodology over the next couple of weeks.1 point

-

1 point

-

1 point

-

1 point

-

The days certainly fly! I've been in school for 13 months now, but there is still so much to learn. I wonder if I'll know enough by the time I graduate? Today was a big day, tool-wise. I got my new Lorch lathe (see box at far right next to bench with closed roll top). It's a beautiful set, probably from the 1970's. It's almost complete. This plus my 1920-vintage Boley allows me to do almost everything. I'm also working on a nice little Japanese wristwatch. It's not very expensive but it has some nice and fairly innovative features and, consequently, is of different design than I usually work on. It has a cracked jewel so, as an exercise using my new lathe, I'm going to make a brash bushing to replace the jewel. I wouldn't normally do this except for practice using my lathe. Also I recently re-jeweled a watch that had brass bushings; so there's a sort of symmetry between the two operations. Finally, we put in the finishing touches to a student workshop off-campus where we can work together practicing various skills. We will work, help and challenge each other and prepare questions to ask our instructor the next day.1 point

.thumb.png.631b6ce1a9961a4559e3c51739097349.png)