Leaderboard

Popular Content

Showing content with the highest reputation on 12/28/23 in all areas

-

Hi guys, I joined this forum a few years ago now and have enjoyed reading the posts and offering help where I can, as well as learning things I didn't know. Although I am a professional watchmaker and watchmaking tutor: https://www.jonthewatch.co.uk/ I still learn a lot from you guys on subjects and watch movements I haven't come across before. I especially enjoyed a post this week by @eccentric59with his walkthrough of an ETA movement that had a plastic fork and escape wheel, which I haven't worked on before. All watchmakers, including professional watchmakers, are always learning something new. It would be incredibly arrogant to say 'I know it all'. Even WOSTEP-trained watchmakers with many years under their belts are always learning something new, even from those relatively new to the art of horology. I trained a watchmaker from Christopher Ward Watches recently and hopefully will be writing them a service manual this year for their in-house movement, the SH21 because they want the expertise I have to be able to train their guys how to service it, which I feel quite honoured about, as I am not WOSTEP-trained. I know I'm rambling a bit, but the point I'm trying to make is that we can all learn from each other no matter where we are on our horological journey, be it professionals, seasoned enthusiasts, or the weekend fettler. I would like to share something with you which is a word of warning, that some of you may not be aware of. This isn't a character assassination or a resentment I have, it's just a fact that might help some of you. Cousins UK: https://www.cousinsuk.com/ ONLY sell to what they call 'Trade Buyers' it is stated in their Terms & Conditions; that means that you need to be a professional watchmaker in the trade to have any real binding contract with them. They are happy to take your money as many are not in the trade, but if what you buy is defective, damaged, missing, or you want to return it to Cousins for whatever reason, you don't have a legal leg to stand on and you may not see your money again. So if you are planning to buy an item that is quite pricey keep this fact in mind if that item is not working properly or stops working a few weeks or months later, then you won't get any redress. Companies such as HS Walsh and Gleave and Co. sell a lot of what Cousins sells for a very similar price and sometimes cheaper, but at least you will have a chance to contact them and make a claim. I buy from Cousins from time to time, but wouldn't buy an expensive tool or item for this reason. Mainly watch crystals, gaskets, batteries, and the odd mainspring. I mainly buy from Gleave and Co in Clerkenwell, London, as they have the expertise to be able to help you on the phone and they are also a small family-run material house that I have trust in and would prefer to put my money their way. Gleave and Co. have integrity. Their website is getting better and sometimes what they have isn't listed on the website, but a phone call (8.30 am to 10.30 am) or WhatsApp message (anytime) will sort that out. Expensive equipment, such as Elma watch cleaning machines, or Bergeon case back removal tools 5700, etc. can be bought from HS Walsh or even cheaper from a German Company called Beco Technic: https://www.beco-technic.com/en/ You have to set up an account with them, but even with shipping and VAT thrown in, it will end up cheaper than buying from a British company. You get a 10 to 15% discount on their prices once you register with them. I was a consultant for watchmakers in Essex who saved about £25000 buying through Bec Technic. I can only tell you my experience and some may have had a good experience with Cousins getting a refund. It took me once over six months to get a refund for a £40 quartz movement that was delivered to the wrong address in an order that was several hundred pounds and after spending about £5000 with them, as I was the buyer of a watchmaking college. Only when I threatened to buy from elsewhere that they refunded me/the college for the missing movement. I hope this helps some of you in some way, as there are more material houses out there other than Cousins.7 points

-

After watching Alex Hamilton's video on improving ultrasonic cleaning, I decided to make a similar machine but using studier components. I first got a chemical stirrer almost identical to the one in the video. Then I got an Indian-made cleaning basket from eBay. After the parts arrived, I set about putting it together. I wanted it to be able to straddle my ultrasonic cleaner, so that the basket can be lowered into a glass jar containing the cleaning solutions. I wanted the basket to rotate slowly while the ultrasonic was on to avoid dead spots on the tank. I also wanted the basket to spin rapidly to spin dry the parts after each cleaning cycle. So this is what I came up with. The basket fits to a 8mm shaft but the chemical stirrer only accepts a 6mm rod. So I glued a 8mm stainless pipe over 6mm stainless tube. The rest was easy.5 points

-

So far, since 2015, CousinsUK has given me an excellent services, including returned items of low value when Royal Mail cocked up. In all those years that I've been ordering, not a single item was faulty. CousinsUK also gives the IOSS service (Import One Stop Shop) for Europe, which I can't find by HS Walsh or by Gleave & Co (?). Anyhow, thanks for the alternative addresses, but for these to have any value to me, they have to have IOSS3 points

-

Is this what it was like in the 80s and 90s for retiring watchmakers ? Poor old sod https://youtu.be/29oO__D8wf4?si=BB54z38LUqm8suMH2 points

-

I think fake. Even if not, it looks badly corroded and with the crown and stem missing, probably corroded inside. Take the back off, let's have a look.2 points

-

Thanks, Jon. I can empathize with both you and Cousins. I have never had to deal with Cousin's customer service, but I have had incredibly frustrating experiences with other companies (not watch parts, but it doesn't really matter). Unfortunately the customer isn't always right. There are always going to be companies with an internal culture with the attitude that the customer is always trying to rip them off. And conversely there will always be customers who take advantage of companies with lenient return/refund policies. Taking either to the extreme would signal to me that the company won't be around much longer. I think what exacerbates a lot of this is the anonymity of the internet. If I have to contact customer service through email, a chatbot or some other non-human method, i am already irritated before I start the process. By the time I get a response I can be downright testy and if the answer isn't "A thousand apologies, sir. We will have the company CEO hand-carry a replacement to you on bent knee and velvet pillow" I assume a completely antagonistic posture. I always try to remind myself that behind all the technology are people (usually underpaid) who take the brunt of my coarseness and I try to be a little more sympathetic. I have learned lately that if instead of "demanding my rights" (Yes, the call of the wild American blowhard) I empathize with the rep "I understand it's company policy to do X, but is there anything you can possibly do for me?" I tend to get a lot further faster. I also have to accept that sometimes the answer is going to be no. There's a saying in Amish country where I live, "too soon old, too late smart." It sounds quainter when spoken with a PA Dutch accent.2 points

-

Yes. I've been filing the tabs. It has improved but still wobbles a bit. Another thing I could do is to shorten the shaft. I'll continue working on it tomorrow.2 points

-

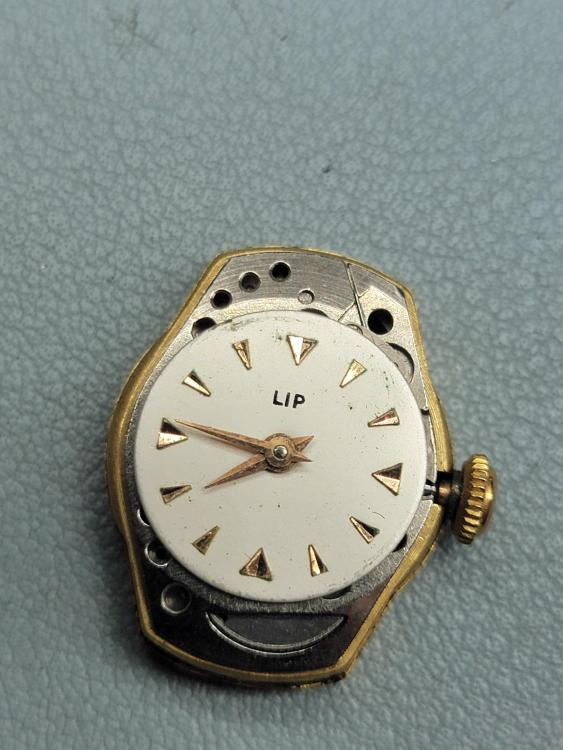

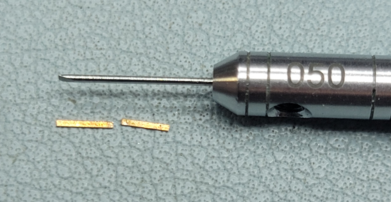

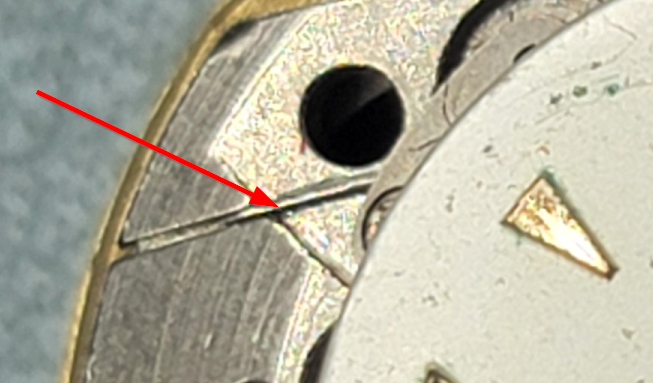

I really do not like working on ladies watches, but when a friend has a sentimental attachment...well...I guess I am easy. This is a French watch (the owner is French) received by the mother of the owner when the owner was born back in 1960. Never heard of Lip, but they made quite a few watches. The service was mostly uneventful except for BREAKING THE YOKE SPRING!!! While removing the yoke, I was pressing the spring away and it just snapped in two. The spring design is such that if fits in a kerf cut into the main plate. The spring is flat. I have tons of springs (shepherds hook, etc.) but nothing like this. So I took some round spring steel (I have lots in all different gauges) and by repeatedly placing it in a vise, I was able to flatten. The width had to be about 0.18mm. If I had a better vise with nice flat faces, this would not have been to hard. As it was, it took about a half hour. Got it!! Done. I show the broken spring with a 50 screwdriver for scale. Also show the replacement installed in the kerf. Getting the timing works wheels all aligned under the plate was a little fiddly, but I managed by using a microscope. As I was working on the spring, it became obvious why it is called "watchmaking."2 points

-

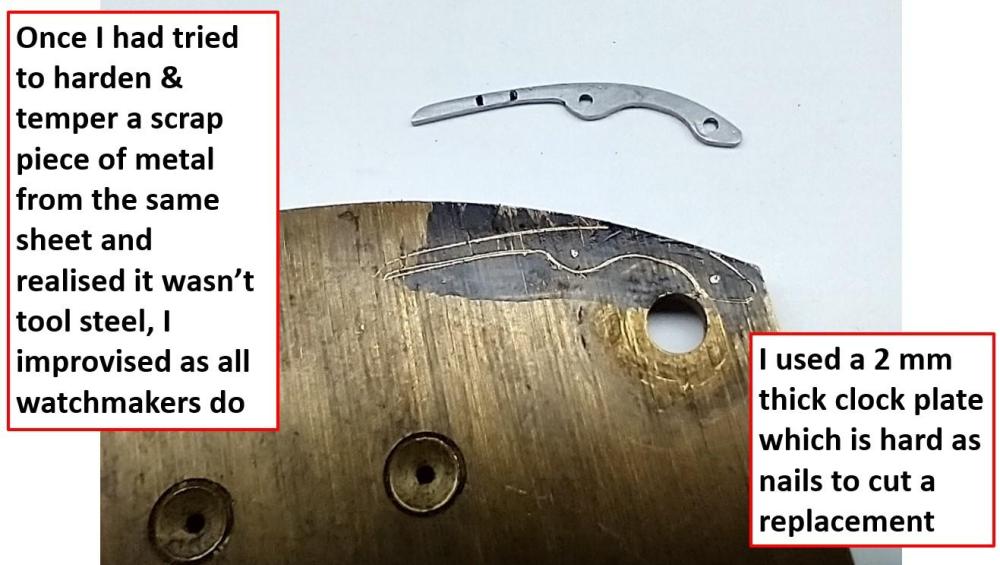

Nice one! As many will already know, watchmaking is about finding a solution to a problem sometimes in not the usual orthodox way. I have found it helps me solve problems by approaching them from a different angle, as you have done, and using what you have in your arsenal. A piece of round steel that needs to be flat, no problem, let's make it flat and fashion it to suit. That's proper watchmaking in my book. Hat off to you! I have posted recently on a different post: This post talks about sheet tool steel to fabricate a part that you can buy from Cousins, which is advertised as 'carbon steel' to make parts and tools https://www.cousinsuk.com/product/sheet-carbon-steel All steel is technically carbon steel, as it has a small amount of carbon content (up to 0.25% carbon), but 'high carbon steel', or what is known as 'tool steel' that you can harden and temper should have a carbon content of about 1%, give or take 0.4% Let me tell you that the Cousins 'carbon steel' isn't a 'high carbon steel', which is also known as 'tool steel', or 'silver steel'. This metal, which is mild steel from Cousins can't be hardened and tempered to make it into a spring or tool and frankly is of no use to man nor beast because it is mild steel. I've now bought some proper tool steel from these guys: https://www.cromwell.co.uk/shop/materials-maintenance-and-standard-parts/ground-flat-stock/c/160202?tab=&query=tool+steel&pageLimit=10&preventRedirect=true&thickness=1mm2 points

-

Hi. I knew one like him in York , retired and gone. Jahn Knovak old school. My workshop in not much better except for the lighting and bench. They were pure gold old guys like him.1 point

-

that's our kind of working environment . I would have loved to have picked the boy's brain. Ages since i watched that video ,I think he mentioned his knowledge will go with him.1 point

-

Unfortunately it is the same with Beco-Technic, Boley and other German wholesalers. You need to run a business.1 point

-

I have made some changes to my DIY machine over time and thought that I should do an update of this thread. Outer wash basket has been redesigned with larger openings. Prints a bit faster and uses less filament. Also added a bottom impeller to encourage fluid flow through the basket layers. Added a basket layer that holds 4 of the mini mesh baskets. I still have one for holding 3 of those baskets. Drying shroud was made a bit larger. Less chance of the basket rubbing against the sides. Bottom jar baffles replaced with stainless steel mesh along the sides of the jars. The bottom baffles looked to be reacting with the wash and rinse chemicals. The stainless steel mesh has not had that issue. Testing with and without the baffles does show some reduction in the swirling of the fluid. https://www.amazon.com/gp/product/B0BMTY6KH4/ I extended the stirring rod for the basket. My 3D printed extension ended up breaking. I used a coupler and a length of stainless steel rod instead. I did grind some flats on the ends for the basket and the coupler to tighten to. https://www.amazon.com/gp/product/B07P5YZKY5/ The STL files have been updated for the 3D printed items. https://www.thingiverse.com/thing:59051661 point

-

I like that attitude! Thanks for sharing your views and experience, I too believe you catch more flies with honey, rather than expecting that velvet cushion you talked about, although I do like a velvet cushion now and then... lol1 point

-

That's not too bad, as far as a deep lock. Is there much play in the side shake of the escape wheel and/or the pallet, as that might be affecting the lock? Before you make any decision to adjust the pallet stone, banking pins, or anything else, have you serviced the watch and noted the amplitude after 48 hours of running? That is what I would do first. If it is too deep a lock, you will probably see a big drop in amplitude in the vertical position where the escape wheel and pallet are directly vertical with each other. Let's say you have 280 degrees in horizontal positions if you see more than a 30 to 40 degrees drop in vertical then I would think about addressing the lock issue. Take into account this is a Russian watch, so the level of tolerances isn't the same as a Swiss watch, although you can get them to that level with enough work and love. Also, don't skimp on replacing the mainspring, as you want as much in your favour as possible. A lot of the time people are scratching their heads as to why the amplitude isn't good enough and think the lock is affecting this when in fact it is a bad amplitude because they are using an old mainspring and the amplitude would never be high enough. For the sake of a tenner, change the spring. Even if the watch isn't worth that much, it will show you what a new spring can do and you aren't wondering if it is that that is the issue, as you have taken that factor off the board, so to speak. A lot of the time a new spring resolves the problem, but you will never know unless you replace it1 point

-

1 point

-

Great walkthrough which will help many here if they take on this movement. Thanks so much for sharing your experience with us!1 point

-

1 point

-

1 point

-

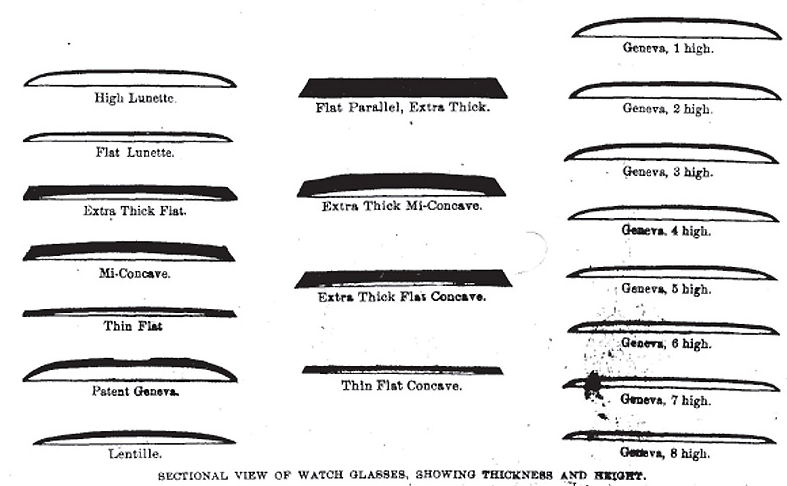

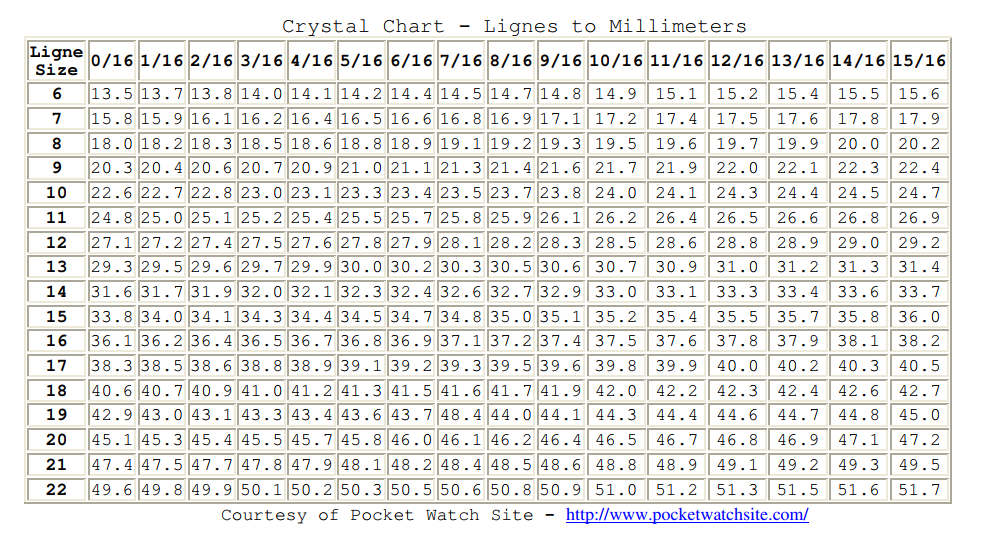

Read this https://blog.pocketwatchdatabase.com/2023/07/31/deciphering-watch-crystal-sizes-the-x-16-and-x-8-ligne-systems/#:~:text=In addition to the diameter,8 indicating a shorter one.1 point

-

Hey all, Sorry I haven't introduced myself before. I've been lurking around here a bit gleaning knowledge as I build up my collection of Seiko Kinetics. The latest being a titanium Starfish which has a bad case of corroded spring pins. I'm a retired electro-mechanical engineer having spent most of my career in the Remotely Operated Vehicle (ROV) business. My wife and I had a house built in the Virginia Tidewater area and are enjoying retirement. My hobbies include watches (natch), woodworking and "making"... Cheers, Chris1 point

-

https://www.ebay.com.sg/itm/385042344168?mkcid=16&mkevt=1&mkrid=3423-175132-2357-0&ssspo=ggjmobmftxo&sssrc=4429486&ssuid=v36TsHWBSw-&var=&widget_ver=artemis&media=COPY I'm having a slight problem with the basket. The cage is a little crooked when it locks into place. And that causes a very bad wobble when the basket is spun at higher speeds. I'll investigate this tonight and see how to balance it properly. Yup. As expected, the cover is crooked. It is probably sand-casted and was distorted right from the start. I'll try to mitigate the situation. Failing which, I might have to fabricate one out of plastic or aluminium.1 point

-

1 point

-

Hi, I'm Dan from Canada. I am a retired federal law enforcement officer and currently a volunteer firefighter. I have been interested in watch restoration for a while and would like to try my hand at it. I have always enjoyed working on different types of equipment, woodworking, and reviving old hand tools (and making my own tools). I enjoy watching different YouTube channels dedicated to watch restoration and repair and would love to be able to do it myself.1 point

-

Ha! Okay based on reflexive properties, from now on I am going to refer to each of my vintage Timex as a Rolex of low grade watches.1 point

-

1 point

-

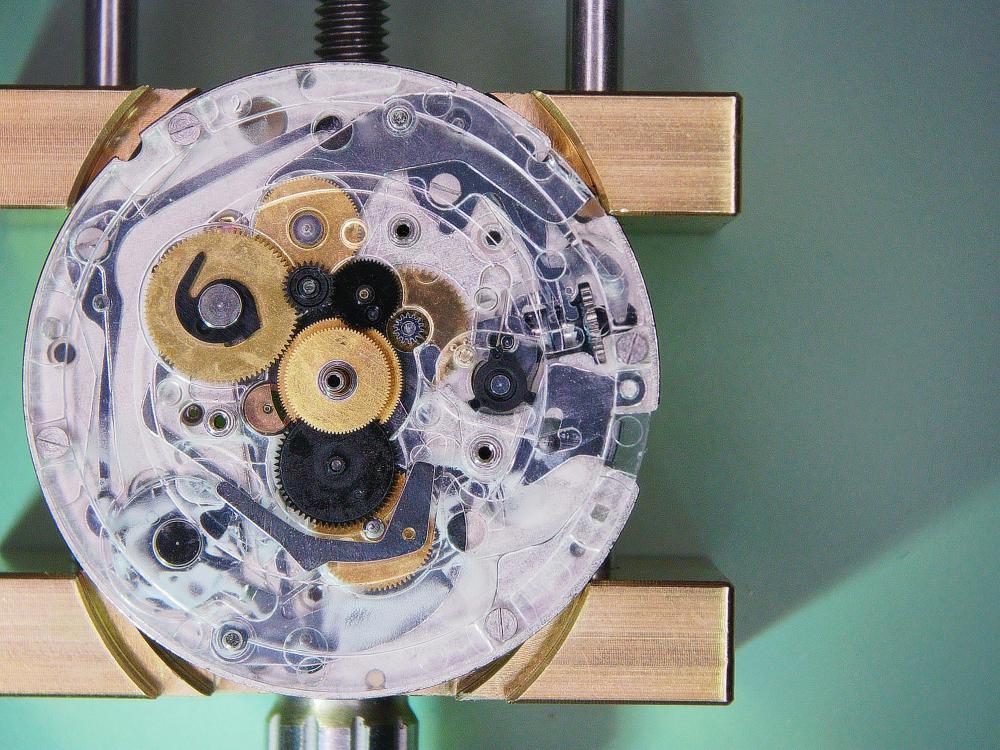

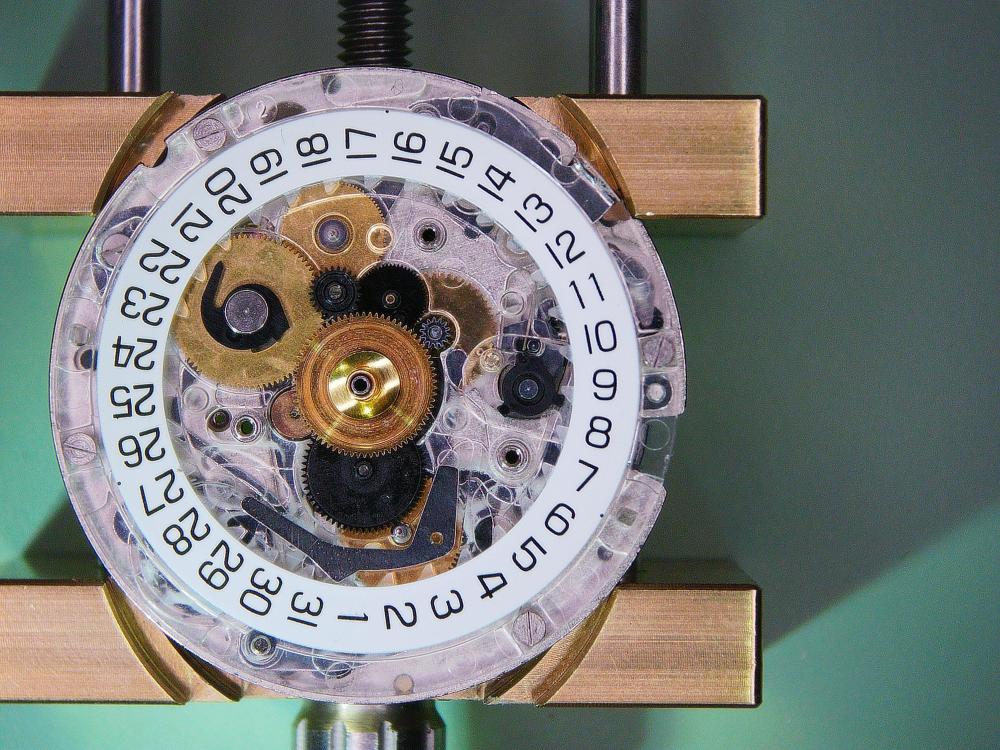

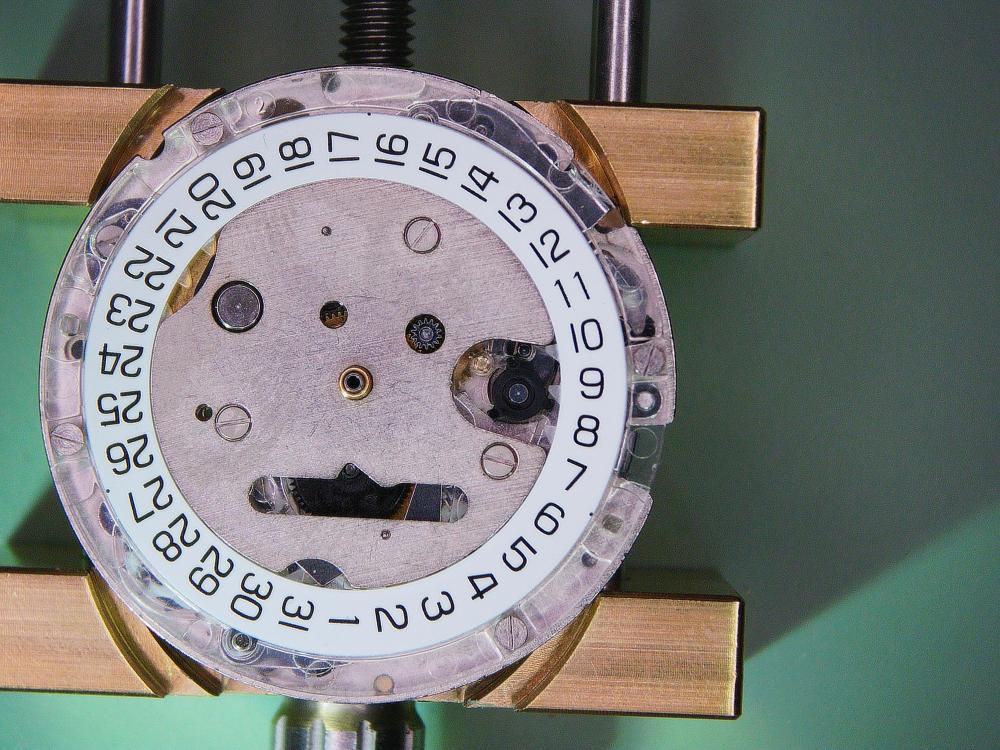

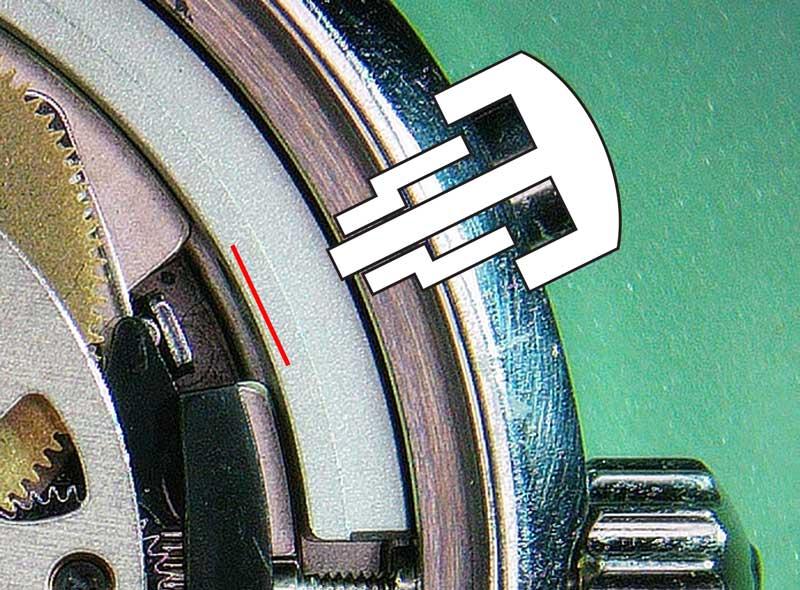

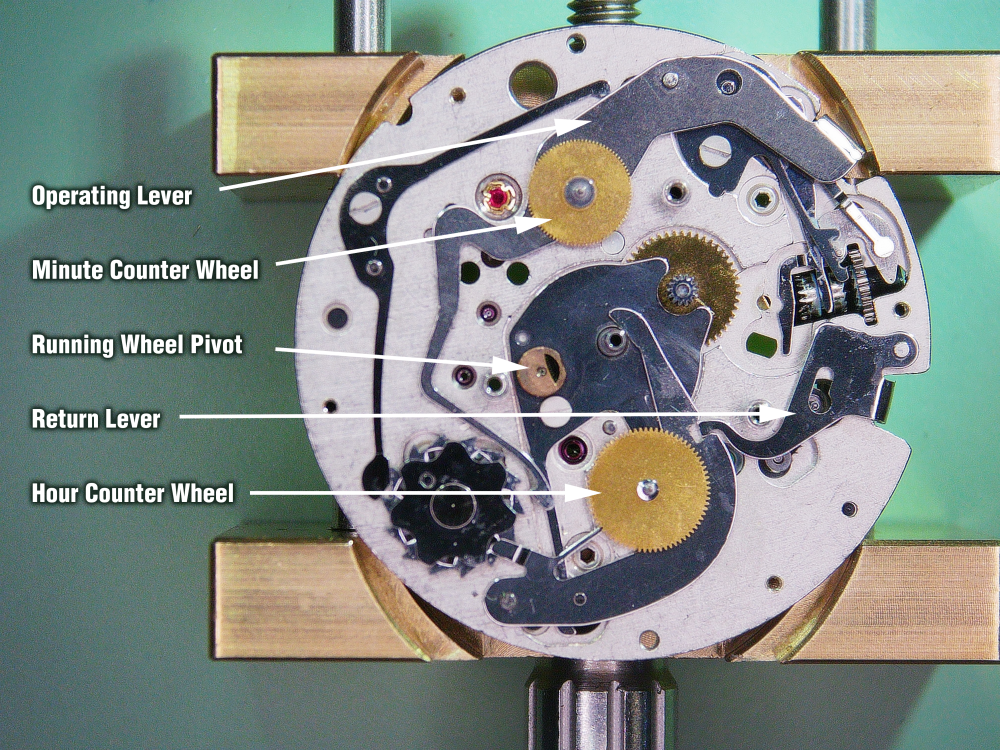

The Motion and Calendar Works. The canon pinion is trapped under the minute recorder bridge when the chrono works was assembled. Above the plastic plate are the minute wheel, minute running wheel, the hour runner and several intermediate wheels. The thing is that running wheels are driven by the minute heart, although it sets the hour runner as well. This is a two level wheel dropped over the canon pinion with the heart on the bottom and the hour runner (large black plastic wheel) in between the upper and lower wheel of the heart wheel combo. When you slide the heart cam wheel over the canon pinion, you have to hold it about halfway down to be able to slide in the hour runner or you won't be able to get the hour runner to drop on its post in under the upper wheel of the heart wheel. And you then have to retract the hammer so the heart wheel will drop all the way down or the other wheels won't mesh properly. I'm sure the engineers at the Swatch group were chuckling when they thought about someone struggling without a service manual. I should at least get a piece of cheese at the end of this labyrinth. The one (and only one) thing they did to make assembly easier is to not have to but the day jumper spring in until the cover plate was on. When you put on the hour wheel and cover plate, the spring just drops into position in the plate through the slot. Maybe that's my reward for getting this far. To wrap things up, all that's left is the dial, hands and recasing the movement ... at least you'd think that. And you'd be wrong. First, you have to put the movement ring in the movement BEFORE you put the dial and hands on (ask me how I know that, too) And then you clean the inside of the crystal, blow off the dust from the dial and ... wonder why the chronograph doesn't run. The pusher doesn't reach the operating lever. Wha? The illustration shows the watch how I received it. The pushers were in good shape and looked original but they were much too short with this movement ring. The red line illustrates the maximum depth the pushers travel. I could find nothing about this but the ring was beefy and had holes that looked like they could accommodate extensions, so I ended up buying a couple sets of varying diameters and lengths to get a proper fit. It does seem to work, but I have no idea if that's the way they watch shipped from the factory or if these are the original pushers or if I just missed something. My theory is that the original owner dropped the watch, popping out the shock jewel and spring and took it to someone to repair. When the person opened the back and saw the movement they threw their hands up and gave the watch back, unknowingly dropping two pusher extensions and one cap jewel on the floor. that's the only thing I can think of to account for the missing pieces. I got everything back together and put it on the timegrapher. After a little tweaking I have it running at +/- 15 seconds 320° amplitude and BE of 0.2 to 0.5 depending on position. At this point I'm letting it run for a week before I look at the timing again. The winding works is pretty simple. Really just a single wheel with a click and the rotor -- it only winds in one direction. And now the final peculiarity. With the the chronograph running, the minute and hour counters don't "jump" but track smoothly with the seconds hand. And THAT should be all folks, but just today I saw another one come up for auction on eBay and put in a bid ... WHAT IS WRONG WITH ME??1 point

-

Marry Christmas, Good to know that the reset problem is solved. To say something for the date change, will need to see the back side of the day wheel (with the arrow), and the lever with the arrow when the wheel is not in the movement1 point

-

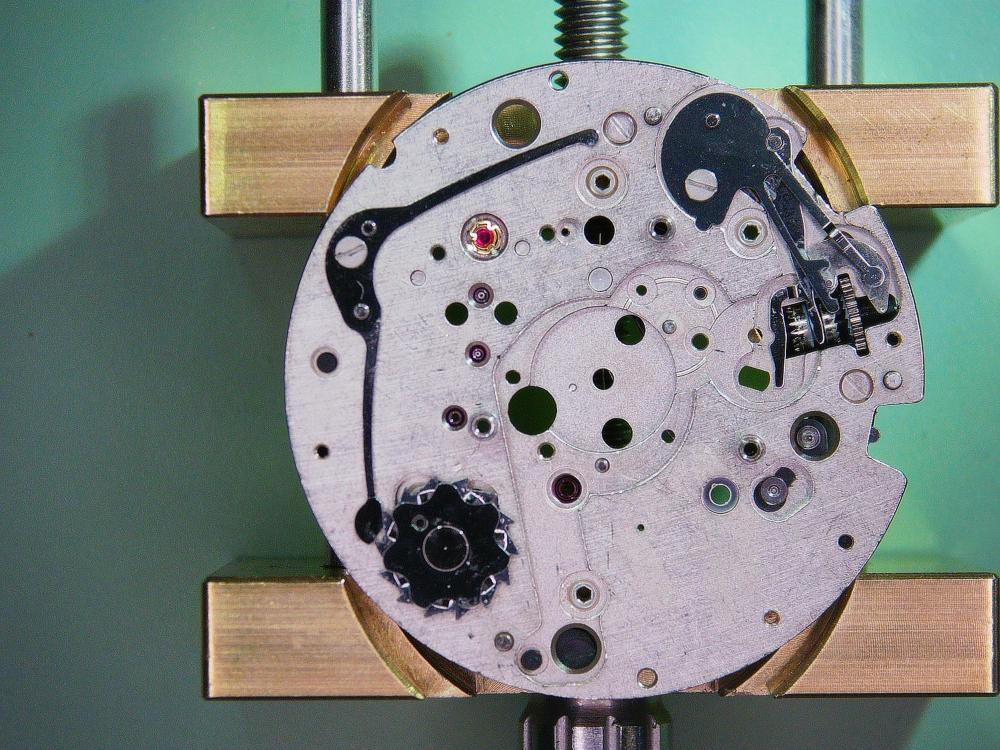

That was a hard find, since the available documents are for the Omega and Lemania movements which use a more traditional escapement. Beginning the rebuild. The first thing that went together was the keyless works. This has to go in before the chronograph side because the plastic plate that holds most of the chrono levers in place covers most of the keyless. Oh, did I mention that the chronograph complication is on the dial side of the main plate? Nothing special with the keyless works. Pretty standard ETA stuff. I suppose this is technically a column wheel chronograph, but to me it seems to incorporate a good bit of cam action as well with the column wheel attached to the main plate with a fixed stud rather than a screw. Since the plastic plate that holds the minute and hour counter wheels in place also has the date jumper and date quickset attached with studs and cover the shock setting, now is the best time to clean and lubricate it. As JohnR725 pointed out, the Swatch group hates independent and hobbyist watchmakers by using the three notch version of the Novodiac setting. The is a version of this setting that has one notch where you can insert one leg/dimple/bump, whatever they are called, of the spring under the lip and rotate it with two pair of tweezers, but NO, ETA had to use this one where even with three hands it would be difficult. You need a special tool to press the legs of the spring -- and ONLY the legs -- so you can simultaneously capture them under the lip of the setting. Great, another single purpose tool. I found out the hard way that assembling the chronograph works makes assembling the train side much easier. The center plate/spring had a brass piece attached that is the pivot hole for the runner wheel, which is fit from the train side and makes it next to impossible to install the train bridge if this wheel isn't in its pivot. At this point the levers and wheels are in place simply by sitting on posts or with only one side in a hole. The minute and hour wheels have heart cams on the underside and are in contact with the levers, which are now under tension from the springs. One false move and it's watch-part Jenga! The plastic plate secures it all in place. (sorry, I don't seem to have a shot of the plate without some of the motion works, but I am NOT going to strip the movement again just to get it. ) Next, the train side. See you in the next post.1 point

-

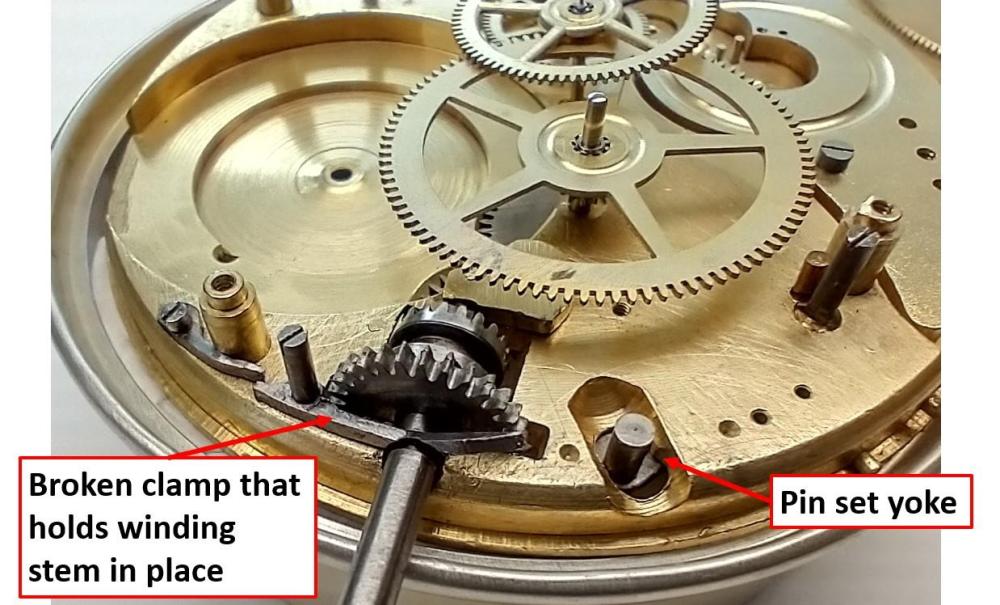

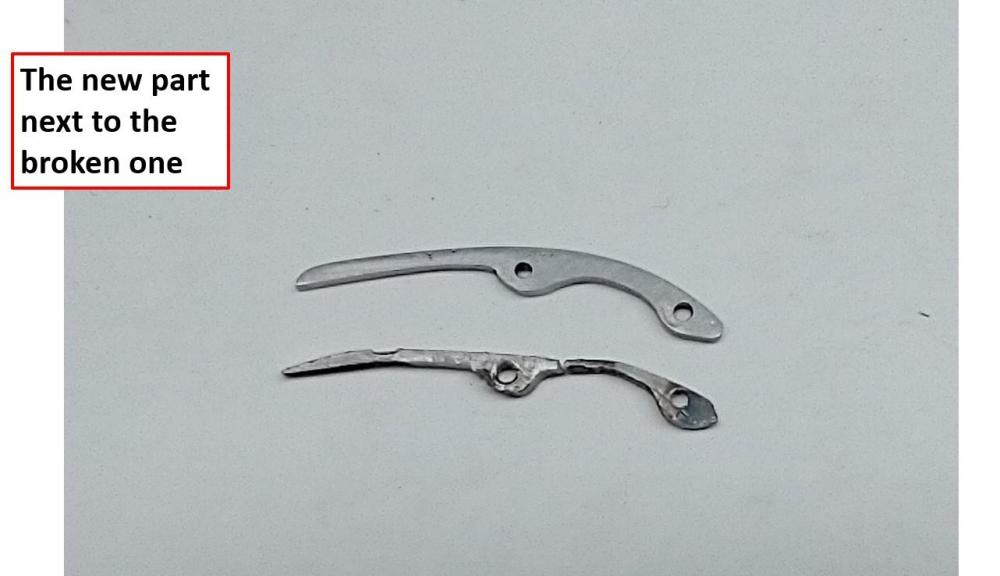

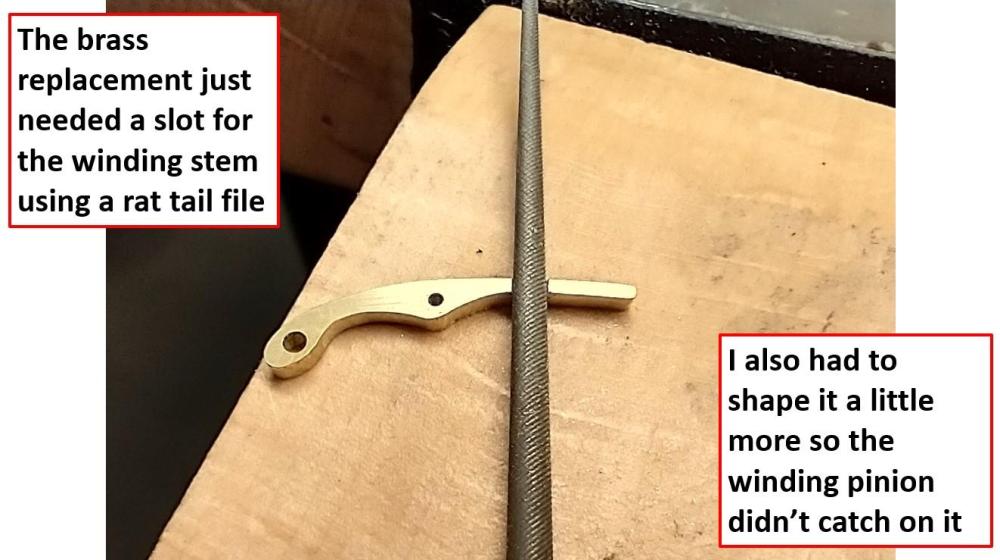

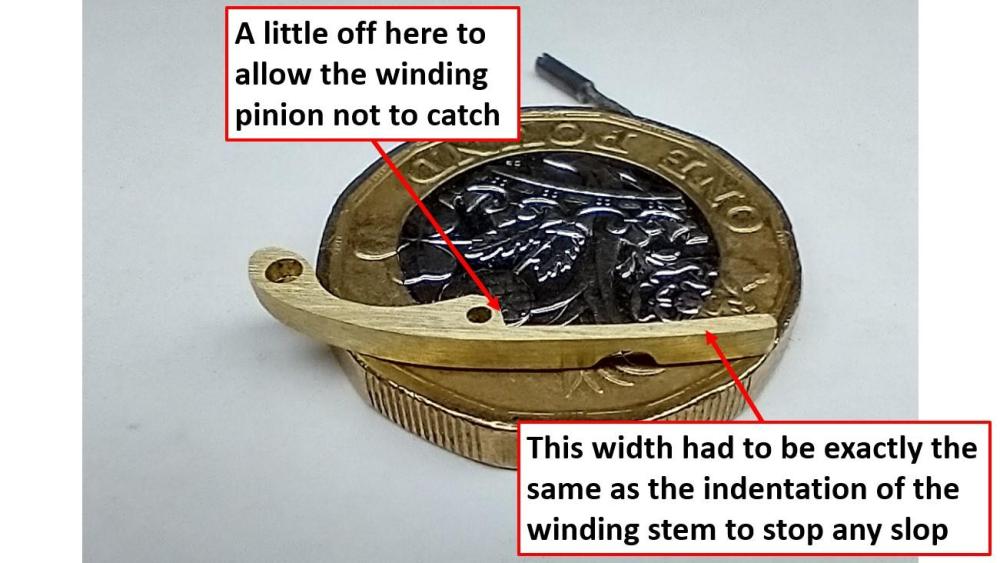

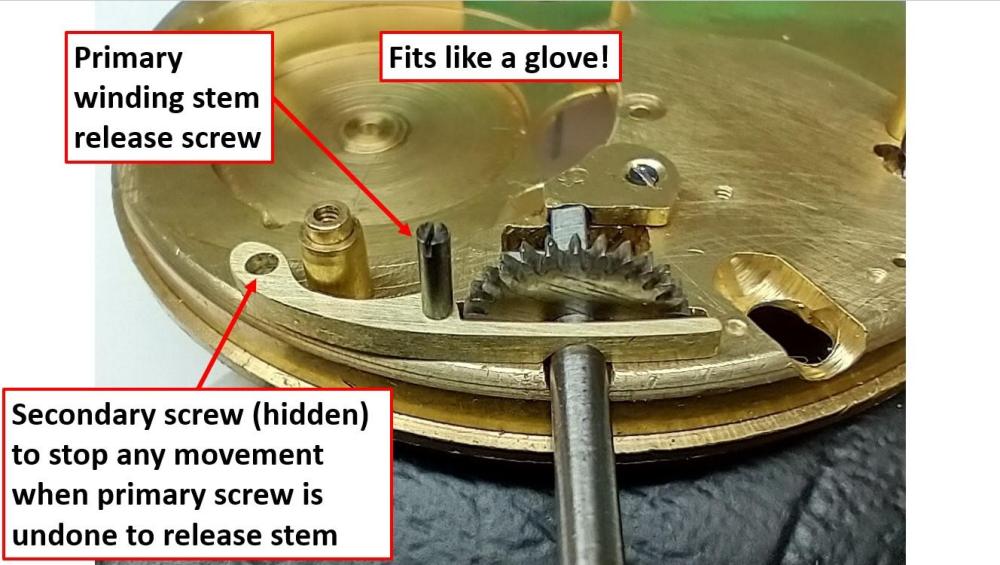

Hi all, I recently had an 8-day watch/clock to service and found that the winding stem fell out of the watch very easily. It is a pin-set movement, so the winding stem shouldn't be able to move. It should only wind the movement. My first thought when I was handed the watch was that there must be a part that was broken for this to happen. The movement doesn't have a setting lever, as the watch yoke is pushed toward the motion work to set the hands, but it does have a part that clamps over the indentation in the winding stem and is held by what can only be described as a winding stem clamp screw. This screw when loosened will allow the winding stem to be removed from the movement. Anyway, when I started to disassemble the movement my guess was true that the clamp that held the winding stem in the movement was broken. It looked like in the past someone had fabricated this broken part as a replacement for the original and had used metal that wasn't hardened and then tempered, so the inevitable had to happen and it broke. Probably when someone thought to set the hands that the winding stem should be pulled out and not realised that it is a pin set, or what is commonly known as a nail set watch movement. I decided to get out my tool steel sheet and fabricate a new clamp and then harden and temper it, only to find that once I had spent some time cutting the shape with a coping saw and filing it to the correct size and shape the sheet that I bought from Cousins wasn't tool steel, or what Cousins refer to as 'Carbon Steel' but some crappy sheet of mild steel that their Chinese supplier had ripped them off with. So, a word of warning here. If anyone is intending to buy a sheet of this crud from Cousins to make keyless work or tools etc. you'll be wasting your time and money.1 point

-

Tissot calibre 781 Disassembly (Please sort the images by name in ascending order) Tissot calibre 781 Assembly (Please sort the images by name in ascending order) Tissot calibre 781 ranfft facts Some time ago my brother handed me this Tissot dress watch from the mid-1960s housing a Tissot calibre 781. My brother collects watches but doesn’t tinker with them (yet). Anyway, I thought it would be interesting to give this Tissot 781 an overhaul (you always learn something). It did seem to run and being a 17-jewel manual wind watch I thought a service shouldn’t take too long or pose any challenges in particular. Anyway, when I removed the case back, I noticed to my surprise that the balance had stopped. I thought “that’s funny”, as it was fully wound and had been ticking along fine while I was looking at the dial. Going deeper I realized that the one of the balance staff pivots was broken off. So, I called my brother and told him the bad news and that I had no experience replacing balance staffs. Well, my brother didn’t become too upset about this but simply told me to keep the watch and possibly repair it in the future if and when I would learn how to replace a balance staff. I wasn’t sure I was ready for it, but life is unpredictable so I thought that it was now or never that I would learn how to replace a balance staff and get the necessary tools to do it. Long story short, I did learn how to replace a balance staff and the watch is now ticking along just fine. In the process I got first class help and illustrations from my fellow Swede @HSL, and if you are in the process of learning how to replace a balance staff, I do recommend reading the following thread where you’ll find HSL’s (and other helpful) posts about this “Staff replacement, balance wheel wobble”. To call this post of mine a “Service Walkthrough” is perhaps a bit of a stretch as the pictures don’t include any oiling suggestions and/or tips/instructions. Nevertheless, I’m thinking that the pictures still might be useful to anyone servicing this calibre and perhaps pondering in what direction the main spring should go and/or what screws to use where, and so on.1 point

-

I am not a pro, just a hobbyist. The 2nd order that I placed with Cousins showed up in my mailbox without any contents. Just an empty envelope with the flap torn open. Rather a poor packaging job on their part IMO, not even putting a strip of tape across the flap and just trusting the envelope's adhesive. With how heavy the contents were, they really should have packed it in a box, not an envelope. I was out £216. Contacting Cousins led to some frustration, as their CS rep nearly accused me of lying and he basically said, "we ship tons of packages and haven't had that issue". Now, who is lying? I had to pester them before they would file a claim with Royal Mail. It took about 6 weeks before I received the refund. I have placed other orders with Cousins since, but I won't buy expensive items from them again.0 points