Leaderboard

Popular Content

Showing content with the highest reputation on 12/11/23 in all areas

-

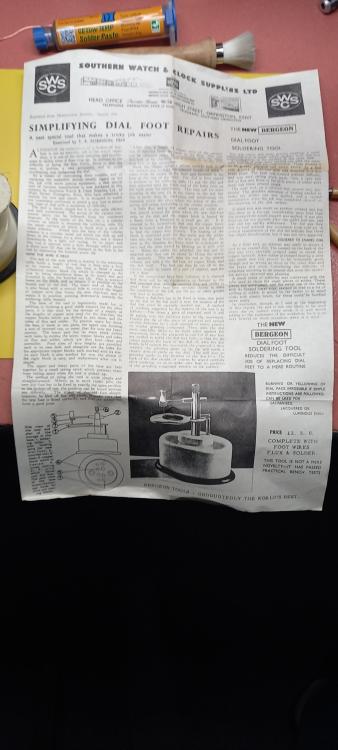

Eyup watch peeps, this is my first real restoration try with my dial foot soldering tool. This type is used with a micro blow torch and low melt soldering paste. Turned out rather well if i say so myself, as you can see from the pictures a piece of copper wire is fitted to the brass heat block at the top. The dial itself lays on a cloth pad, i added a few drops of water just to dampen it down to protect the dial. Marking up the dial foot's position is really important as the surrounding area needs to cleaned up with 400 emery paper to get a good weld, without marking you risk losing the foot's position. So just a small dot from a needle and a scratched in crosshair to sight you in with the foot. The copper wire is held on the dial's back surface by the spring loaded sliding post although you do need some finger pressure as well, as i found out when placing the solder the wire will come off its position. The soldering process is very quick, 30 seconds tops, the low melt bubbles up at 138 degrees and is pulled into the joint quickly, then a quick blast of compressed air helps to stop any heat transfer to the dial. Job done and feels well stuck. The tool was around £50 made by Bergeon, some nutter on ebay has one up at nearly £500. I did post one up last week on tools ebay has to offer, it went for £40, did anyone pay attention?4 points

-

Picked up this little bench vise today and spent a couple of hours sanding the surface rust with 600 grit and cleaning the tape and dirt with alcohol and windex. The silicone suction foot is toast but surprisingly is very stable out to a half inch or more without it. Really like the anvil on top and the fact that the jaws rotate and lock. Just a little 3 in 1 on the main shaft and it looks nice and operates smoothly. Probably could dress the jaws a bit. The longer set are 68mm and the shorter set are 42.5 mm with a V groove both lateral and longitudinally. The metal plate can been seen in the 3.5 mm thick silicone so I think the plate was set in a mold and the material poured in around the metal plate. Spent about 10 minutes looking without success for another. Will continue to look for another but this seems like it could be clamped if I needed to put a lot of pressure on it. The only marking is Japan on the endplate with the 3 screws. Overall pretty decent for $5US. Anyway on the the pictures before and after!4 points

-

nevenbekriev, thanks for your input but you are clearly wrong. Just look at my post where I highlighted the problem and you can see I'm right. I was a clock maker for around 30 years working on high grade clocks and not just repairing but restoring and making the parts. I think I know what I'm talking about. Have a Happy Christmas.3 points

-

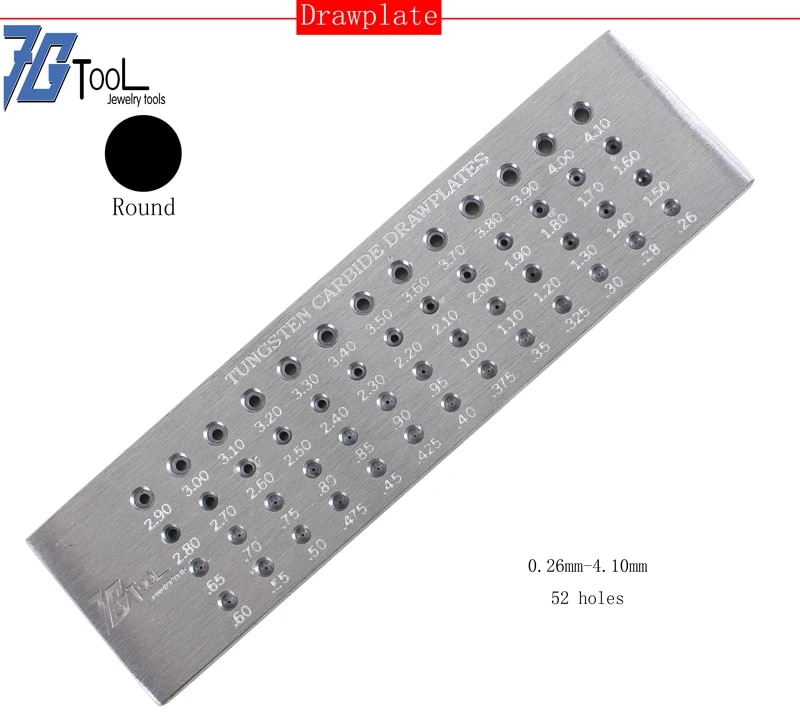

Wishing and hoping. Ah well! too expensive for me. However, in my Christmas stocking is a 'Dial feet Repair Watch Tools Repair Welding and Bonding Watch dial Table feet tool kit'. £28.13 from Ali express. Funnily enough it does not weld, but allows me to drill and glue feet to the Dial. Looking forward to using it as I have nearly a dozen watches awaiting dial feet repair. Only 1 damaged by me when starting this hobby. The rest damaged pre-purchase. Just love sellers don't you?2 points

-

2 points

-

Interesting question so which is better to have a defective watch which is not going to keep time. Or watch that's running the way it's supposed to run which will probably keep time? Watch number one is defective as the mainspring is supposed to slip and you'd should never have that much amplitude. Then that means Seiko number two is running correctly and if you are concerned about timekeeping you can adjust the regulation a bit and bring a little closer to zero.2 points

-

Where worn on the wrist, probably #1 will overbank alot when spring winds to the end by autowinding, so it is a real problem.2 points

-

Picked up this little bench vise today and spent a couple of hours sanding the surface rust with 600 grit and cleaning the tape and dirt with alcohol and windex. The silicone suction foot is toast but surprisingly is very stable out to a half inch or more without it. Really like the anvil on top and the fact that the jaws rotate and lock. Just a little 3 in 1 on the main shaft and it looks nice and operates smoothly. Probably could dress the jaws a bit. The longer set are 68mm and the shorter set are 42.5 mm with a V groove both lateral and longitudinally. The metal plate can been seen in the 3.5 mm thick silicone so I think the plate was set in a mold and the material poured in around the metal plate. Spent about 10 minutes looking without success for another. Will continue to look for another but this seems like it could be clamped if I needed to put a lot of pressure on it. The only marking is Japan on the endplate with the 3 screws. Overall pretty decent for $5US. Anyway on the the pictures before and after!2 points

-

Yup. That's what I've been doing. Solder paste, microtorch. Heat the copper wire, not the dial. The end of the wire needs to flattened, then a bevel placed to give it a slight point. I think that increases the solder wetted area for more strength. Place a ring of solder paste where the copper wire touches the dial and heat the wire about 1 cm above the dial with the flame pointing horizontally. It only takes seconds.2 points

-

This is why when we were in school we practiced lots of practice. As far as breaking a Jewel I would be really curious as to how you think you're going to do that I would list that is nearly impossible to do short of whacking it with a hammer. Losing it yes that's easy to do if you haven't practiced enough but in the case of an the stones on modern shock protected watches those can usually be replaced they can be ordered resizing a jewel can that be done well almost anything can be done but can it be done practically no. In order to resize a stone you would have to mounted in a lathe shellac it in a center position is a diamond file to grind it down a little bit and then hope you get it to the right size but of course your changing things so who knows if it's really going to fit or not. If you really want to reduce the size of something do with a hole jewel that so much easier often times I've modified modern jewels to knock off the corners so that they can be burnished in the older settings. On the other hand I suppose you could read George Daniel's book on watchmaking then you can make the whole setting. It would be very practical your chances of succeeding express it with a tiny hole for the pivot and getting it all done perfect would be almost nonexistent but I suppose if you want to sleep tonight you could know that you could get a book and make the whole thing yourself.1 point

-

Beauty in the eye of the beholder. Can't get into these open works thingies. Don't mind seeing the workings via the back. But I find that the machines works view through the dial is confusing and detrimental to use. As I said Beauty in the eye of the beholder.1 point

-

Sorry to say you have bought what is known as a marriage. That is where a movement and case never started out as being one. The case should have a chiming movement you can see the original holes which have been blocked. If I were you sell it but you won't get much for it. If you see a clock that you like take good photos of it and post them here and I can advise you.1 point

-

Something that might be worth trying, as an electronics apprentice we were taught to stretch the wire, admittedly tinned but should not make a difference, so it was straight before bending to fit the holes on a PCB. This did slightly thin it, you would still need to cut off and square then chamfer the end joint to the dial. Tom1 point

-

Wow! I guess fools really seldom differ. I too use 0.8mm enamelled craft copper wire. After sanding the enamel coating off, it's about the correct diameter for dial feet. I normally cut off about 3" and sand around 1 cm of one end. Then flatten the end and cone the end with a caborundum disk. I usually use about 3 to 4 mm for the dial foot and keep the remainder for another day.1 point

-

Curious if this got solved. A little bit of watchmakers paper under the balance cock will give you the height needed to free up the balance staff in the jewels1 point

-

With the correct leader and the correct length suspension spring the clock will keep good time. The pendulum is the correct one for this type of movement. There is nothing wrong with the case that I can see, the pendulum is a good height from the case bottom, mind you we can only see the back. If I could see the front the arbors and key holes would tell me more.1 point

-

I have the same vice! Got it in a box lot of tools, wanted to give it to my daughter as she does lots of little projects, but the rubber base on mine is also no good (looks better, but doesn't hold vacuum). Cool little vice though, I thought about attaching it to a wooden base large enough it could be clamped to a table or something.1 point

-

I like the double jaws, never seen that before, handy for clamping tall material. Some jaw inserts would add to its versatility. Aluminium, brass, timber, cork , rubber.1 point

-

Watch 2 is running as it should with good amplitude and probably within Seiko's specified rate parameters . Watch 1 has amplitude issues.1 point

-

1 point

-

I agree with @nevenbekriev. Rebanking is a big problem with an automatic watch, which is going to spend a significant portion of its time on the wrist in a fully wound condition. Have you had both these watches on your own timegrapher and seen the "rebanking trace pattern" for no. 1? 340 deg. is very high, but could be just shy of rebanking. Also, you need to use the correct lift angle; 53 deg. for the 6R15.1 point

-

I haven’t seen any product advertised as being for shining watch movements apart from the appropriate cleaning solutions. Any finishing and plating on the movement are very light so prone to be worn away by anything abrasive. Only movement polishing I know of is for clocks and that is normally French chalk and a very soft brush. I would reserve this stuff for polishing non-plated cases. im sure others can add to this as I’m only a hobbyist Tom1 point

-

Endstones are always flat on one side and convex on the other. Use a torch to shine at an angle to see the reflection to check for the flat side. Sometimes the upper jewel and lower jewel are different. If you accidentally mixed them up, try swapping them around. Also, see if loosening the balance cock screw frees up the balance.1 point

-

Yes the end needs dressing square and flat, i didnt shape the foot but i understand what you mean. Once you've removed the excess solder to reduce the foot back to it's original diameter the only solder thats left is on the bottom. Next time i feel i want put a shallow seat in the dial with a round burr.1 point

-

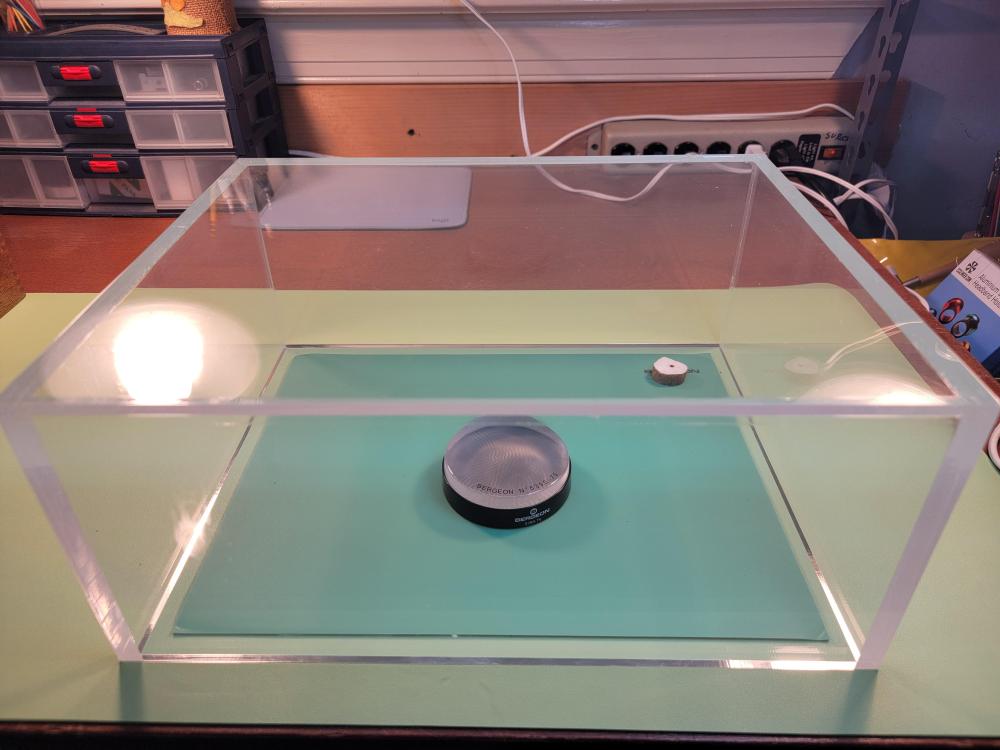

I've had one of those circular magnifier lights but was disappointed in it, so I went to a couple of the artists clamp-on lights that I put 100 W equivalent LED bulbs in. That gave me good light but I still needed more direct light right over my work pad so I bought a nice LED desk lamp similar to the one shown above from Cousins. It clamps to the edge of the work bench and is tall enough to where the vertical arm doesn't get in the way. Also, as you can see, my bench is in the garage and my biggest challenge is dust, hence the glass baking pan upside down of the work pad. Since that picture, after looking for better non-glass alternative I ordered a custom plex display case and just received it. I probably could have made it 3" high rather than 6", but being a rookie I still lay things out on the pad as I disassemble because and leave them there overnight.1 point

-

Hi. Just because the leader came with the movement doesn’t mean it’s the correct one. I have an Enfield such as yours , and as stated by Old Hippy the crutch is midway in the leader slot, so until that’s sorted any other adjustments etc will cause problems. Fix the leader crutch as it should be then start from scratch knowing that the clock conforms to spec.1 point

-

You can keep an eye out on eBay. They do come up for sale once in awhile. I'm not sure if the Indian made cleaning machine basket will fit. The unit attaches to an 8.0mm shaft. The build quality is acceptable. Might need a bit of filing off the rough edges. https://www.ebay.com/itm/385042344168?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=ggjmobmftxo&sssrc=4429486&ssuid=v36TsHWBSw-&widget_ver=artemis&media=COPY1 point

-

I thought I'd seen the brass taper pins on cousins site. The pin is fitted to the outside of the hairspring, when I've done them in the past i have filed a flat side onto the pin to fit against the hairspring. Doing that makes it possible to square up the hairspring before pushing the pin fully home1 point

-

notice in this example the problems with charging money what if no money had exchanged hands on this? families are always very interesting with how they handle money situations. Some families are very good I'd especially when somebody dies dividing up stuff everybody's happy there's no problem in other families well the family ends and they never a talk ever again or they're unhappy for ever because of somehow they got shortchanged in the universe. At least with friends you can hopefully find new ones but losing your family over seemingly silly little things isn't necessarily a silly little thing to happen. when I was in school learning watch repair the instructor explained the importance of proper paperwork. In other words whatever is done to a customer's watches documented. Customers are interesting they remember paying money for something not always quite sure what they paid for. Like they got their crystal polished and now the watches running wonder whose fault that is? So it's very helpful if you can demonstrate that according to the document here we polished your crystal and advised you that you should get your watch repaired because it needs to be serviced as opposed to now you're servicing the watch for free because you didn't document anything. Shop that I work at all incoming items are photographed everything is documented. Quite a few times that document is really saved our whatever expressly with engraving jobs where somebody was careful to document the item was scratched or is cracked or was broken or something as opposed to did we do that? Documentations extremely important and I bet you on all these hobby fun jobs are not thinking about photographing the item writing it up maintaining books and documents after all this is a fun project are just going to help your boss out or something yes we all like this but part of this discussion is it never goes 100% that way. We explained all of our customers that everything we now touch is going to take at least six months or longer. We have a huge backlog of watches. So everything is carefully explained and do they understand 100% of the time? notice part of this discussion is well basically playing Russian roulette. Most the time things will turn out fine but that tiny percentage of somebody who doesn't understand or somebody who doesn't want to understand. Or somebody who's going to always be unhappy no matter what. We are doing these repairs for fun having lack of fun and permanent unhappy friend relative whatever not really what you want to be doing. At least we doing this commercially if they go way it's just a lost customer that's still an issue but it's not a lost spouse or maybe a spouse to now complains to every single day because her brother's watch doesn't work right or something. Even if you did explain all of it were dealing with the percentages is a tiny percentage of bad that will come of working on other people's stuff if you're not doing it as a professional. Then even if you're doing it as a professional that are still a tiny percentage of unhappy customers it set tiny percentage that ruins it for everybody and you really want to deal with them if you don't have to especially when watch repair is supposed to be a fun hobby1 point