Leaderboard

Popular Content

Showing content with the highest reputation on 10/10/18 in all areas

-

I was impressed with the project, workmanship and video production and thought you guys might enjoy it. A neat piece work with a rather complex 'secret' stepped lock - hang in there to the end to see how it operates.2 points

-

It's difficult being a moderator on a forum like this dealing with everyone from the professional, through the hobbyist down to the complete amateur who's broken their watch and wants one-off advice or sometimes, frankly, is too lazy to spend more than the 30 seconds it takes to use google to find their answer so just pops it on our forum. I'd like to say a personal thanks to @oldhippy for his hard work and good advice and certainly we don't want you stepping down as a moderator! Some of the changes suggested here, such as a waiting period for new members is a good idea. Heck ... there could even be a nominal joining fee. A few dollars for good advice is nothing for someone who is serious about repairing a watch (even as a one off topic on a treasured watch) or wants to turn their current interest into a hobby or more. This would also not only help with the upkeep of the site but dissuade chunks of that chaff. Just an idea.2 points

-

The proper way, this will depend on your skill is to plug the hole, drill and tap. So you have the correct screw size.2 points

-

The day I finished watchmaking was the day I gave up wearing a watch. I don't have any watches in my home.1 point

-

1 point

-

I think a bigger screw is the way to go. If you closed it in I guess the wall of the screw hole would go from being strait to being curved in so less thread would make contact with the screw.1 point

-

Bergeon sold 4.7 mm punches with a set of collets. There are also collet holding arbors for Seitz jewelling tools, I have one in the big Seitz set. Frank1 point

-

thats not a bad idea, something for the staking set that holds the tap - it would help with small tap breakage where not keeping it straight is the major cause. Its very common with larger, but still small and breakable, size tapping jobs to use a tapping stand to avoid breaking them As for tapping, that's a very small tap. How do tap a stripped hole the same tap size - do you close it in or bush it, or go a size bigger and make a new screw? .....as in if it is really stripped there won't anything left to tap....it maybe its just slightly damaged and needs to be chased/cleaned up?1 point

-

I agree with @Pango and so, yes, frankly you probably need to practice your technique as much as anything. Getting expensive versions of tools will not prevent you wrecking a movement. Cheap screwdriver blades will deteriorate quickly so that purchase on screws is compromised leading to slippage and damage. There's no reason you can't keep your existing handles and just upgrade the blades though. I've always got on well with the A*F Swiss ones. My bet is you've got one of the "9mm to 65mm" versions of https://www.cousinsuk.com/product/adjustable# in which case, yes, if you've got, say, a 11.5 ligne movement you're working on then you've got around 60% of the holder not being supported leading to an unbalanced situation. Assuming you'll stick to movements more around the 11.5 ligne range then you could chop off the excess guide and screw rails and also put Rodico (or even BlueTac) on all four feet of the holder; you should find this makes things far more stable. I have a good movement holder but I often find myself working with one of the rings from the set https://www.cousinsuk.com/product/07mm-to-50mm-plastic-rings for some projects; useful doesn't have to be expensive. And one final comment on magnification. One of my mistakes when I set out was using a loupe with too high a magnification meaning leaning in very close to the movement to work on it. Due to helpful advice on this forum I moved to a headband magnifier to carry out most work. There are professional 'OptiVisor' versions but there are cheaper versions, still using optical glass, which are very good too (look for instance at ebay item 132780644579).1 point

-

My Bergeon set was purchased around late 90s. The MKS set I am not sure as I purchased it second hand off a retired watchmaker in the 80s. I am guessing perhaps circa 1960s. Sent from my SM-G950F using Tapatalk1 point

-

I have an MKS set and a Bergeon set. The MKS set is probably twice or thrice as old as the Bergeon set but the quality is outstanding. The Bergeon punches are prone to oxidisation (near every one has rust and pitting - even replacements from cousins). The MKS punches are as good as new - same storage conditions. If I had to purchase another staking set now - MKS all the way. The only thing I like about the Bergeon set is the inverto function. But I generally still use the MKS punches even if I'm using the Bergeon tool. Sent from my SM-G950F using Tapatalk1 point

-

I have found this site for you. Enter the info and see if it helps. http://www.elginwatchparts.com/ Here is another to try. You can email him. http://www.daveswatchparts.com/1 point

-

Very true. And I do feel very uncomfortable forcing people to introduce themselves before interacting in other areas. But I am willing to listen - this is a membership site and we all have a stake in it's success. The reason why I have never forced introductions in the past is because people should have choice - new members have a choice to introduce themselves as well as existing members have a choice to simply ignore their questions. I must say - I am a little disappointed that this is an issue as the original intent of this forum was to be a help towards others with less knowledge as well as a community where all levels of horologists and enthusiasts could come together and simply be - and be relaxed. With that in mind - I have a solution, and it is a very very simple one. .... 1. I am not going to enforce an introduction policy, but I will make it more clear that members of this site will consider it polite if people do so first. ( I will work on making this prominent in the welcome email and I will make this clear with a information box at the top of the forum which only new members will be able to see). 2. If a new member posts a question without introducing themselves then, and here's the simple part, existing members who may be offended by this do not have to participate in that thread. We even have an ignore function on this forum if you feel that strongly about it. 3. Any member, both new or old who harasses new members, and it's reported to me, will be warned - persistent harassment's will result in a ban. A Word Of Encouragement... One-hitters who don't even reply sometimes are extremely annoying. Especially if you have crafted a three paragraph response with pictures and the OP does not even acknowledge your reply. It sucks. BUT - remember this. This is a public forum which gets indexed by search engines. Your replies are never a waste of time - it's all good content which will be read many hundreds or thousands of time - there is no telling how many people you will have eventually helped - with this in mind, it does not even matter who starts the conversation, your replies and the passing on of knowledge will stay on this site for people to find for years to come. It's not a waste of time.1 point

-

I have said this before and I will say it again - if anybody is spamming, being offensive or trolling or generally not following the forum rules then the "report post" function is the way to go. It is simply not possible for me to monitor and read every single post. I asked for moderators and literally one person put their hat in the ring other than oldhippy who was recommended. I am still open for mature members of the forum to be considered. Mods not only get greater powers to help with these issues but also get a say in how the forum is run. I am happy to take suggestions and I do try to keep the forum running smoothly ( especially with the technical side and security updates). I can understand your frustration but rant posts are not the way to go - perhaps contacting me via PM would be good. However, I'm not deleting this post as I'm interested to hear from other members as well on this subject. As for the issue of trolls - this is regrettably a side of the Internet which will not go away - that being said, if anybody joins the forum and is found to simply be trolling others then they should be reported and they WILL be banned. As for the issue of 'one hitters' in the q&a section - we have had a small discussion regarding this and I am working on a strategy. You're input above is along the lines of what I want to put in place whereby new members will not be able to post in the q&a until they have been upgraded. This may involve automation though so it won't be perfect. Sent from my SM-G950F using Tapatalk1 point

-

1 point

-

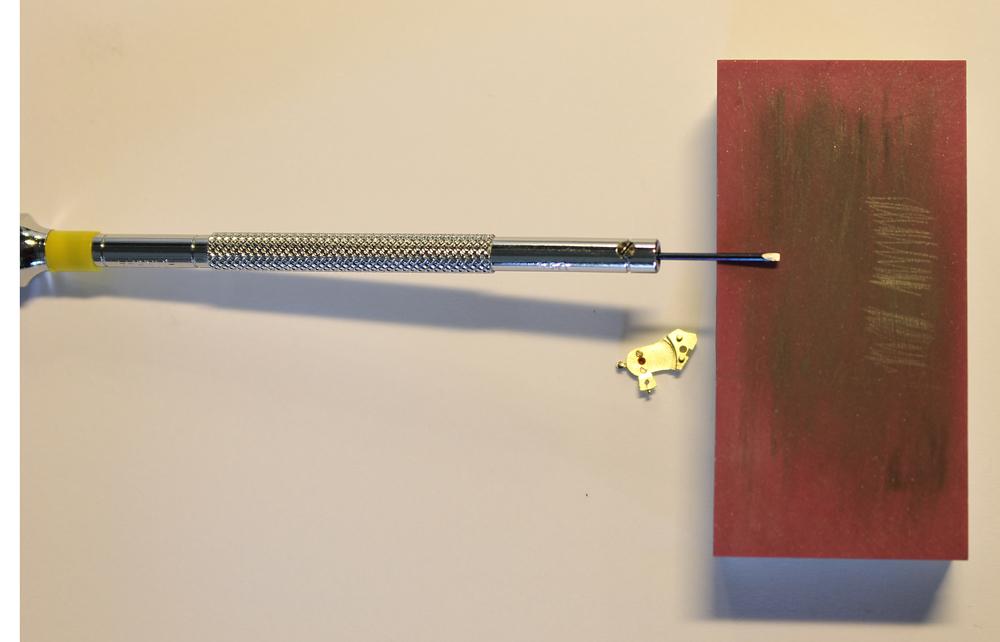

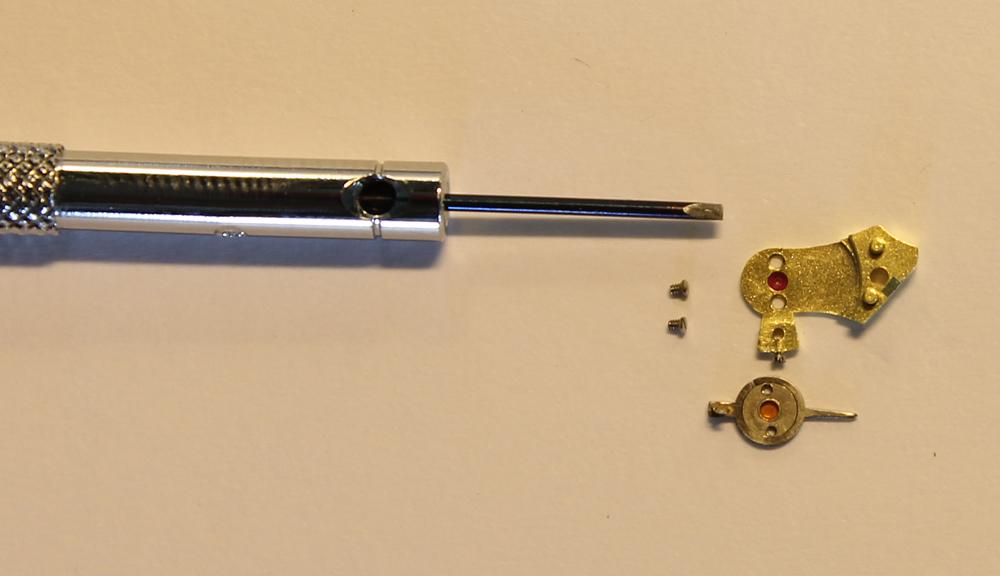

Totally dissatisfied with the results above, I decided to strip the movement again and let the parts soak in Zippo lighter fluid. Old oil seemed to be the culprit and some serious pegging had to be done. This time there was no easy "opt-out", the balance jewel in the balance bridge had to be properly pegged and oiled. I decided to get the delicate balance out of the way first. As described above, the 0.8mm screwdriver was too big, the 0.6mm screwdriver fitted, but proven to be too weak for the task. I decided to customize the 0.8mm screwdriver blade by dressing the sides down to the full length of the screw-slots (about 0.7mm) and flatten the tip of the blade until the blade had the maximum amount of "beef" and fitted the screws-slots snugly. This would give my the highest, and the final, opportunity to undo the two screws. Lo & behold; It worked !! Now I could do a proper oil job, but pegging the extreme small bore of the ladies movement balance jewel was another challenge. My experiences with these tiny holes are that if you get the tip of peg-wood in, it brakes off easily. Next to that, once you got the peg-wood in, while rotating, your fingers slide & rotate down. Once the fingers are to the end of the peg-wood, and some more pegging is required, you either have to pull the wood and try it again or; try with the peg-wood still in the jewel-bore to get your fingers back on top of the peg-wood ........ with a very high probability that the peg-wood tip will brake off; stuck in the jewel Some kind of solution had to be thought of, perhaps this has been done before, but so far I haven't seen it; the screw-peg ® ! I had a small box of toothpicks. The diameter was 1.6mm. One of my screwdrivers is 1.6mm. I removed the screwdriver steel-tip and with one of the toothpick ends cut off, the toothpick is a press fit in the handle. The toothpick-tip can be sharpened multiple times by either a knife or dressing it on a diamond stone. Now, with the peg-wood tip in the jewel, you can rotate as long as you deem required. I also found to have very high control over steadiness, direction, rotation and applied pressure. Works like a treat !! Back to the movement; Pegged & pegged again every hole till spotless. Pegged every pivot. Installed the balance to check free movement and re-check the impulse jewel line up with the center of the banking-pins. With now both cap-stones oiled, the balance rotated freely and smoothly. Same with the pallet-fork; installed the fork and it rocked backwards & forwards on its own weight. The wheel-train run with the slightest touch on the spring barrel. Sounds good !? ....... hmmm, not so........ with the movement assembled, it still doesn't run happy. An amplitude of below 120 degrees is hardly something to brag about. It also stops after a few minutes, continues again after a little shake .... perhaps pallet-fork / escape wheel area ? Still a beat error of over the 7ms, whereas the impulse jewel was spot-on the center of the banking pins ..... Hmmm ....... Being Dutch, I will say: "Luctor et Emergo" .......1 point