Leaderboard

Popular Content

Showing content with the highest reputation on 01/05/18 in all areas

-

I bought myself a car dent removal tool and tried it today on a few pocket watches i had with good dents. Worked great. Just tap frequently and use the right size end depending on the diameter of the dent. They work the tool in small circles around the dent or back an forth for long line dents. Here are my results. Sent from my iPhone using Tapatalk Pro2 points

-

What would be the logic for that, oral tradition possibly? Metal-to-metal linear friction with a decent velocity needs a mediation lubrication agent, and I've seen that confirmed in any service sheet so far,2 points

-

I'm new to horology but have been fascinated with watches for some time. Wife and kids bought me a bunch of tools last Xmas and I'm finally buying old watches in junk shops and goofing off. I travel a lot for biz so tough to commit to a course. Looking forward to making some friends, learning, and my apologies for any stupid questions in advance. Cheers, h.1 point

-

If you are referring to some people not oiling the long pivot.........I presume it's because they are unsure on where exactly to oil it on some calibres and too much oil or oiling it in the wrong place can effect the amplitude. I generally use 9010 for the jewelled side and a small amount of 9010 on the long pivot side. its surprising how many watchmakers I have spoken to over the years that don't oil the long pivot and let it run dry, you would wonder how many return jobs they get!1 point

-

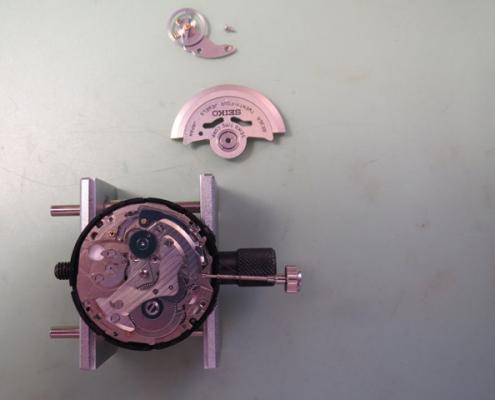

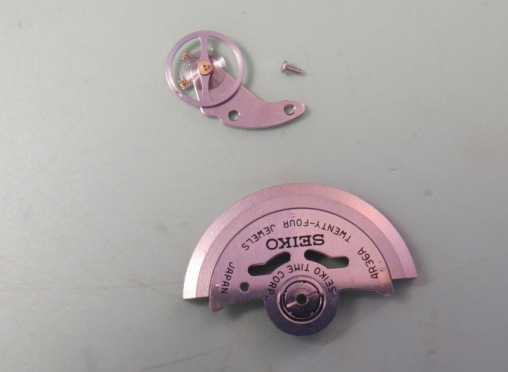

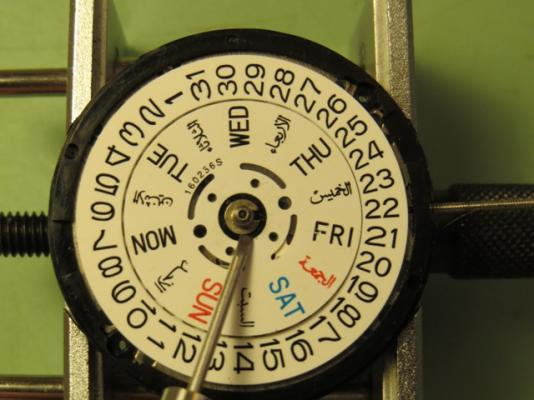

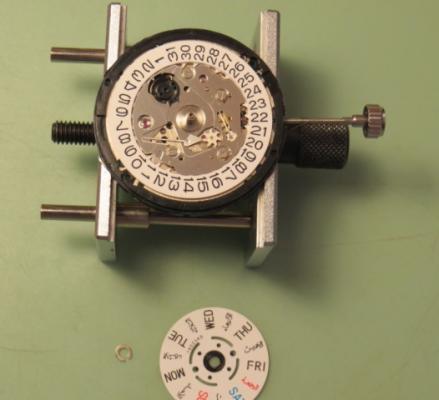

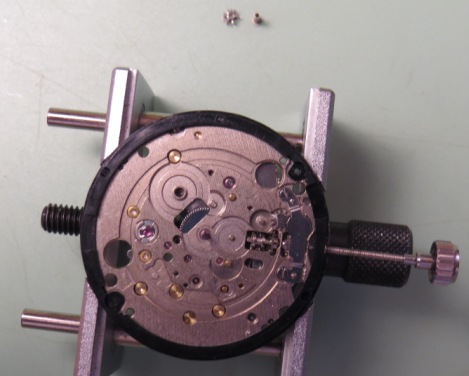

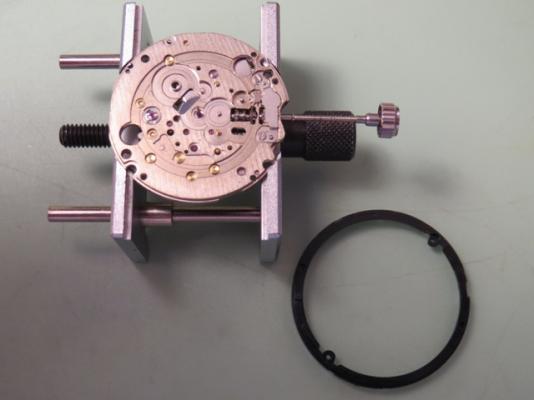

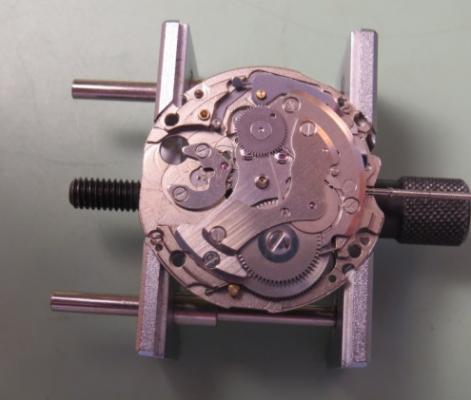

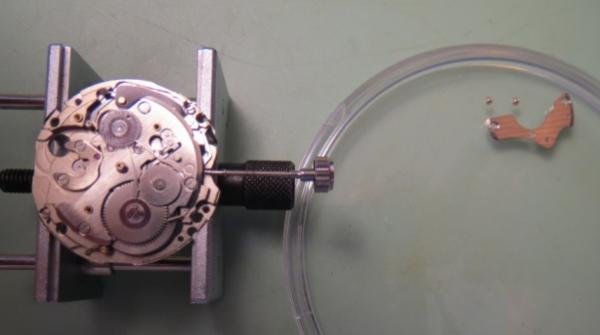

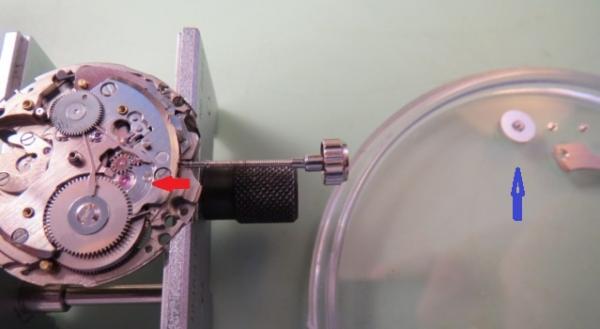

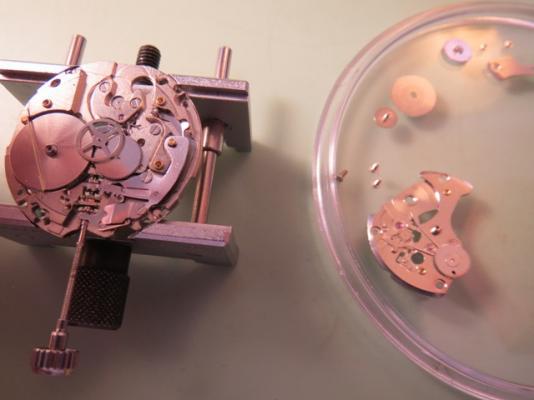

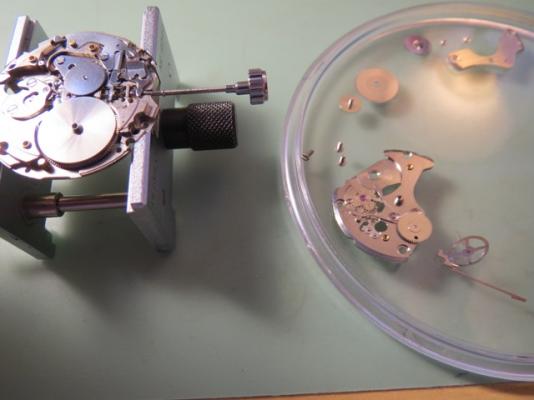

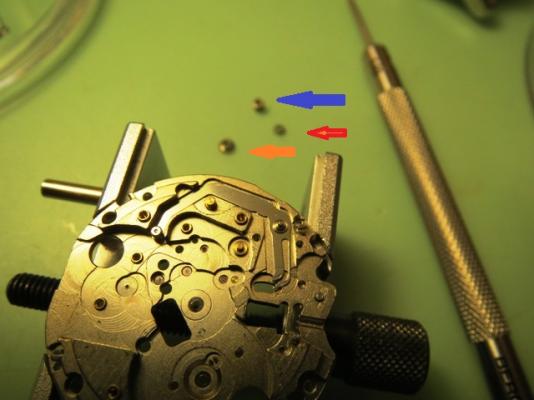

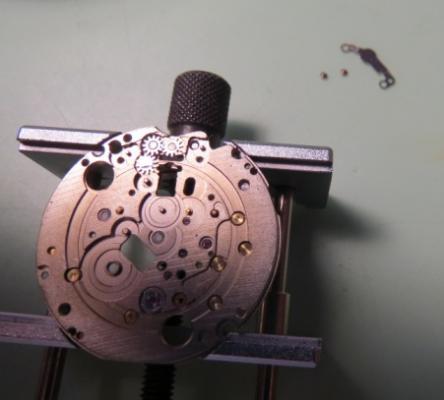

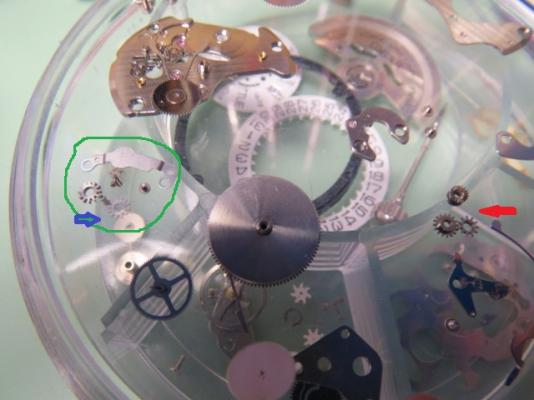

Seiko NH36 Walkthrough This walkthrough complements the 7S26/7S36 excellent walkthrough on this site by Lawson (http://www.watchrepairtalk.com/topic/682-seiko-7s26a-complete-service-walkthrough/). I strongly recommend to check out Lawson's walkthrough first). This is a more recent movement based on the said 7S26. It is a 24 jewels day/date, center seconds, movement with hacking capabilities and manual wind. The ligne is like its predecessors ~12. It is popular in the new Seiko models and Invicta watches among others. In brief, former movements didn't have hack or manual wind. Still, several parts are interchangeable with the older 7Sxx series. Here is the service data: 6810_Seiko NH3 Series Part Sheet.pdf My first step here will be to remove the "oscillating weight" and balance and place in a safe place. Those parts could be easily damaged so we put them out of harm's way. Starting on the bottom side, normal removal of "snap for day star with dial ring" Note that the reverse of the snap has indentations to fit a small screwdriver and lift it clear of the day disc (yellow arrow). This is standard for this movement family and snaps, day disc and date rings are interchangeable. The other picture shows the snap right side up. Under the day disc: Showing the "intermediate wheel for date corrector": Moving on, "date indicator maintaining plate" and related screws. No philips proprietary 4th screw here, all four are the same... Date jumper and date dial: also "Day Date corrector wheel", "hour wheel", "minute wheel and pinion", "date indicator driving wheel" and "intermediate date driving wheel and pinion": "Canon pinion" and the new addition for this movement "Day Date corrector setting transmission wheel E": Removing the "Dial holding spacer" (this one is from a 7S26 not the original one which is thicker): Turn over Baby! Ehem, just the other side view... :) More changes are introduced: We remove the "automatic train bridge" and screws: Notice the added 24th jewel (red arrow) to accommodate the newly designed "second reduction wheel and pinion" (blue arrow) which is much thinner than in previous movements. Removing "ratchet wheel" and its screw (nothing new here): Removing the familiar "Barrel and train wheel bridge with hole jewel frame", notice the familiar "long screws" inherited from previous designs: This bridge has been modified also to add the manual winding mechanism. More on that later. Removing the click and the "fourth wheel and pinion": At this point we remove the rest of the loose bits ("Third wheel and pinion", "scape wheel and pinion" and "barrel complete with mainspring": Then we remove the "Yoke spring" and characteristic "long" screws (different from the ones used in the balance cock and "barrel and train...bridge": Removing the "yoke" and the "setting lever", note how the lever shape has changed from the previous models: The story so far after removing the "center wheel bridge" and its short screws, the "center wheel and pinion", "pallet bridge" and "pallet fork": On the main plate, showing the added "balance stop lever": And the "day-date corrector setting transmission wheel A" (red arrow), "winding pinion" (orange arrow) and "clutch wheel" (blue arrow): Close up of what is left on this end: Removing the "guard for day-date corrector setting transmission wheel" and short screws. Underneath the "day-date corrector setting transmission wheel C" and the "Day-date corrector setting transmission Wheel B": After removing the transmission wheels B and C we are left with the built in wheel on the frame: Notice that transmission wheel "B" (blue arrow) is thinner than its counterpart "C": Next: "Barrel and train wheel bridge with hole jewel frame" disassembly:1 point

-

If you've not read through Robs link yet you may want to look at the battery change procedure (hopefully you can click on the picture to embiggify it).1 point

-

I'm going to object to the word obsolete unless the current catalog lists every single mainspring that the obsolete catalog has. One of the problems with watches is the companies decide that their obsolete then there no longer listed in the current catalogs yet we keep bumping into the watches then there's no way to look up the parts.1 point

-

As already said the strength (thickness) is the most important and the height, the length just needs to be as near as what ever is available. The other thing that can sometimes be a pain to match up by ordering by size rather than calibre is the centre that goes around the arbor, sometimes if the arbor is too small it doesn't hook properly. Sometimes with older stuff you just have to make do with what you can get and make it fit. I would be more concerned about the condition of the escape wheel, hopefully it is just dirt and will clean up.1 point

-

David Boetcher’s reverse engineering calculator that you will have found on vintagewatchstraps is the way to go here1 point

-

Yes you got lucky, it didn't help that my reamers were probably around 50 years old and not the sharpest. I've since bought myself a new set of Bergeon reamers should I get caught out again.1 point