Leaderboard

Popular Content

Showing content with the highest reputation on 03/19/16 in all areas

-

The latest update before opening the chemical brewery. Finished the polishing with a 6000 grit. The polishing didn't go 100% smooth, that is to say that during the polishing I discovered that all 4 corners, at which the bracelet was soldered to the watch-case, had cracks. Be it minor, compared to the one initially clearly visible, but still in need of repair. Same repair procedure as crack#1 was followed. Also the base-material isn't of the highest quality and I didn't polish the inside till "mirror" finish. The bracelet is about 1mm thick and to remove all the pitting + polishing both sides would make it very thin. With a loupe, the surface isn't 100% and I'm now getting to a stage whereby a too rough cloth starts to make visible scratches again. Just water cleaning. I think it's good enough surface for plating and to compare the results. As for the Stainless Steel wands; I learned that these are a no no when submerged plating is used. The Stainless steel anode will "dissolve" and bring foreign material in the metal-solution. However, for brush-plating this should be less of an issue (in my mind at least). If the sponge just covers the donor-material, the amount what dissolves from the SS wand should be negligible and the electrolyte fluid is not the expensive fluid in which the donor material is dissolved. A carbon-anode is used for submerged plating. For the cathode it doesn't matter what kind of material is used, as long as it conducts, and can handle the current. The cathode, the part which comes in contact with the fluid, will get plated too. I will start with brush-plating, however not directly on the "sweat & tears" bracelet, but first some sample material. I'm still awaiting donor-material which I bought from our Chinese eBay friends. Also the electrolyte has to be mixed and then we get some life in the brewery :) As soon as there is something new & interesting to report, I'll be back. On the picture, left bottom, you can still see the first repair and even though it feels smooth, not sure if the two different metals won't show up after plating...... Some of the spots are dust particles.....that's goes fast on such a smooth surface with a dog running around..... the little scores are from a too rough cloth. I will give it another 6000 grit polish, by hand, just prior plating. Looks like even looking at it will already scratch it.......... :D Next time in the brewery. Can't wait till I get to taste the samples ;)2 points

-

Not as costly as most on here but I like it. Didn't look like this when I received it though. Seiko 6309-50002 points

-

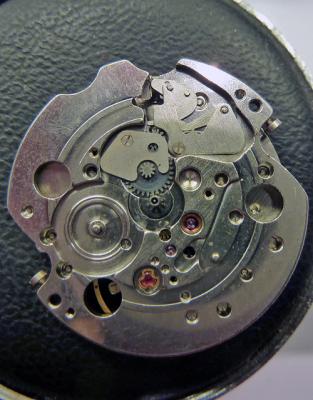

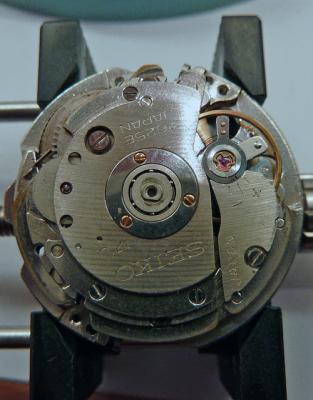

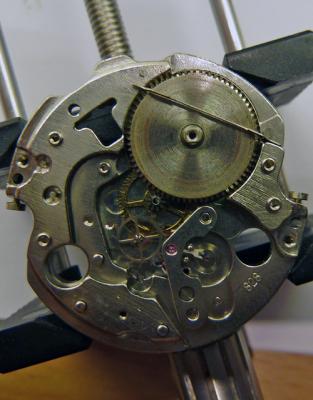

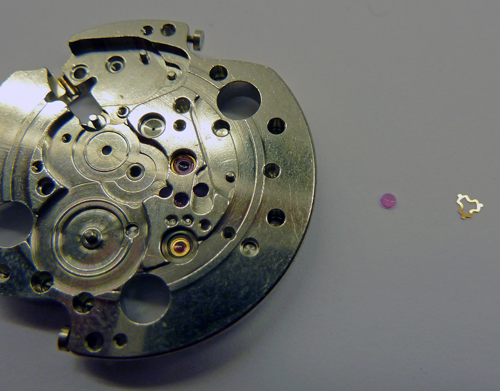

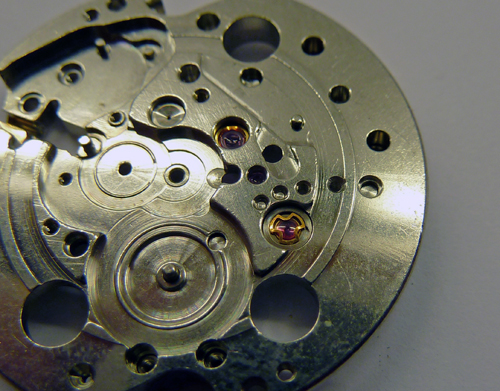

Picked this up recently for a snip from an excellent fleabayer in Japan: A fairly clean item from August 1968 with a good dial. Being a bit of a fan of Sportsmatics, I haven't come across this particular model before & wrongly thought at first that it had a cyclops crystal retro fitted. Further research showed this to be the original configuration, however the crystal was in fairly poor nick & appeared to have been polished a few times in the past. After some more detective work the part number was obtained & amazingly Cousins had one in stock: So far so good, although the rotor sounds a little rough (not uncommon on these). Lets see whats inside: Bit grubby with a scraping rotor, but the bearings seem OK, so the rotor gets bent upwards slightly - don't frown, it's what Seiko recommends! Out of the case, dial & hands off, strip down the dial side. Note the broken setting lever spring, I have a donor movement from a previous project and will replace this: Turn over & rotor off: Remove the winding gear: Strip down the above, a bit of wear on the magic lever but appears to work fine, clean lube & reassemble: Onto the main stripdown: All in bits & cleaned: Lower Diashock dismantled, cleaned then reassembled: Then it all goes back together: On to the dial side, setting lever spring replaced: Into the case, reattach winding gear, rotor & caseback on: The original crystal was used before the previous step to protect the hands, this is now removed the dial is given a final clean before putting the new crystal in place, which pushes on under finger pressure. The crystal is held firm by the bezel, which is a problem to fit as all of my dies are shallow & bevelled, unable to push the bezel down, so 2 pieces of 40mm waste water pipe are cut to suitable length, one piece is then fitted onto a stepped flat die, the other has a section removed and placed inside the first: Works a treat. Finally, with a new tan alligator strap fitted: It looks like the crown has been replaced with the wrong one in the dim & distant. Hopefully this will be rectified in due course.1 point

-

Totally agree! My nephew calls being jalf an hour late "fashionable"...I call it rude!1 point

-

Hello all, I have tended to buy new cases to house some of the old beaten up watches I took a liking to. Sometimes with the likes of old trench watches the cases were chromed and effectively, through various causes the chrome has worn or blistered / lifted off leaving the nickel or whatever underlying layer it is, visible. Now I am aware there is a school of thought that says that the watch should look like its age and the harm it has undergone is merely evidence to the rich tapestry of life it has been intertwined with etc., I have some agreement with that and I can go along with it for normal wrist wear but water damage, dings and bad scratching and simply beaten up or other sorts of abuse etc. are a bit more than normal wear. Also Its one thing getting satisfaction from getting the movement serviced and running like a charm but when you put it all together again and it really looks pretty bad despite working perfectly, it is a bit of a let down and saleability (should I ever actually let one go ) is greatly affected. I got to thinking about whether the cost of professional electro-plating was viable or not - initially I admit that this is largely curiousity as I doubt it. After looking into electroplating at home and researching it some time ago but then deciding it was not for me ! I left the issue on the shelf. However it surfaced in my mind again and I sent off a few random mails to specialists in the area I live, not really expecting much interest. From the majority I was right but there were a couple of positive responses. One was subject to a £40.00 minimum payment caveat so that was out of the question as regards viability. The other seems more promising and he will quote if I send pictures of the items in question. It may all turn out to be a waste of time - who knows ! However, I will follow this up as I mentioned earlier I am curious to know anyway. I will advise if anything positive and promising turns up. Cheers, Vic1 point

-

1 point

-

Today was a Black Monster day for me. Picked this one up from the ‘bay for about $70 including shipping. The seller stated that it needed to be repaired. I simply adjusted the rotor a little bit, and it has been running extremely well. Have been wearing it for two days without any issues. The bezel has a few scratches, but that does not bother me at all. I just love the lume on these watches.1 point

-

I have one of those, I use it to great effect by placing it over important documents, I find the documents stay where they are. Sorry, couldn't help myself, I didn't find them as useful as others have, because the precision, i find, is lacking. But you may find that it works fine for you. :D1 point

-

Nothing wrong with punctuality and accurate time. I personally don't believe in the "fashionable late" thing. For me, it spells "you lost your opportunity, try again next time...IF EVER" . It is funny because the more accurate our time telling instruments become the less punctual people seem to be...punctuality is a lost art in some parts. Oh, well, it doesn't matter as long as watches exist and we can keep our hobby/profession going. Let people being late so we can show them first our watch of the day and then the door! :)1 point

-

I did so frustrated when i was going to mix some two component epoxi glue. When i press there always come from both tube? Making the mixture always wrong? Always comes more from one of the tubes. Metal tubes are better in that way? But now i have some Epoxi crystal glue i only want very little of. What to do? Yes i cut the pressure button in two halves. So i can press each one individual. Little crud but it works.1 point

-

I agreee with jdm Timegrapers are great and much better than a lot of the apps but they do come at a price. £110.00 plus depending on the model (I have the 1900) The cheap ultra sonic may be quite low on the vibration front but does a job for £6.00 and I started off my tinkering with two of them. My slightly larger Ultrasonic (46K vibrations and 600ml metal tank) was less than £20.00, naturally it works better that the cheaper ones and using jars, I have and no fumes to contend with. I personally will not be buying a "proper" watchmakers ultrasonic as it is not warranted for the amount of watches i fiddle with. As with all hobbys it depends how far you want to go, what you want or maybe what funds you have available.. I would advocate "baby steps" to start with. Cheers, Vic1 point