Leaderboard

Popular Content

Showing content with the highest reputation on 11/14/15 in all areas

-

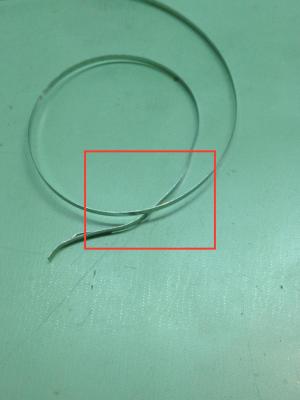

A few weeks ago I purchased off the Bay a non working/for spares Bulova with 6CL movement. However I encountered a couple of gremlins with this watch and thought I would share. On the strip down the first gremlin I noticed that a previous repairer had screwed the train bridge without aligning one of the wheels & left this nice divot. Luckily no damage to the wheel pivot. The second gremlin was the mainspring had some kinks in it However when I measured for a replacement I found that the wrong size spring had been fitted. The height should be 1.40 with a strength of .08 but the spring fitted was 1.25H & strength of .06. This movement was dirty but is quite a simple in design so I have added not to many pics of the assembly. Also apologies re- the pic quality but they were taken with my mobile. Gear train Gear train with bridge fitted it was a bit fiddly to fit Barrel bridge & assembly fitted Keyless side assembled Dial up reading on the Timographer Watch finish just needs a nice strap to make it look really nice Job Done3 points

-

Agree with Ssteel my L&R Vari-matic caught fire. I had it rewired & the machine refurbished. It is now an excellent tool that I could not do without.2 points

-

For the last several weeks I've been browsing the auction sites looking for a cleaning machine. This one caught my eye, especially since it has all the glass containers included. I just couldn't resist. So I bought it. It should be here some time next week. The seller claims it is in working condition, but it needs some cosmetic work. I really can't complain since it was less than $100.00 including shipping charges. This picture is from the seller. I will post some more when I get it. As you can see the paint is in really bad shape, but I have several cans of "hammered" finish paint in the garage. I can finally put those cans of paint to good use. Very exited about this.2 points

-

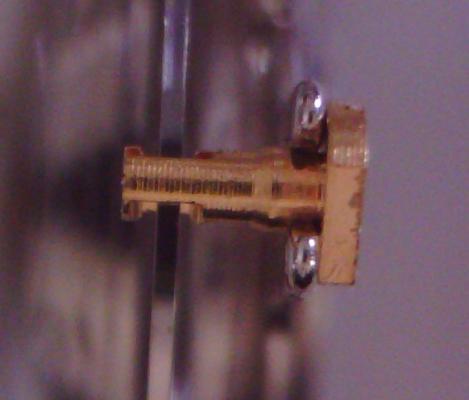

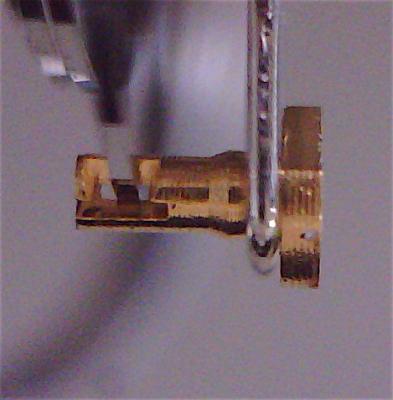

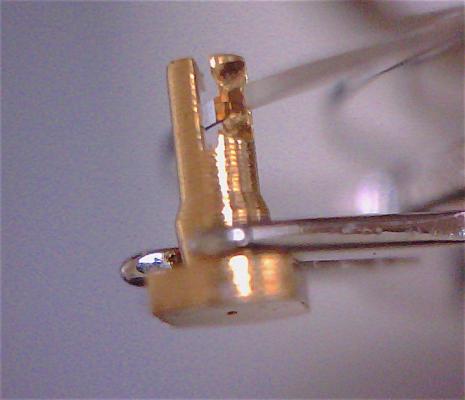

This has turned into a very educational thread. I thought I'd add some pics that may clarify the regulator pin adjustment and the reason for not turning in the wrong direction. You may be able to see that while the bottom of the stud has a straight slot, the hairspring guide is angled from each side. So I would start adjustment from the neutral position, adjust the hairspring angle on the other stud and then adjust the clearance to the mid point. Sounds easy doesn't it, but I think a lot of tweaking will be required to get the correct outcome. And then you can adjust beat error and rate. Good luck with it. Cheers Jim2 points

-

2 points

-

1 point

-

Yes Hi, I've become fascinated with watches lately, particularly older mechnical ones. Why? I don't know, however I find ithe whole thing very exciting and thoroughly engrossing. I have a background in mechanical engineering as well as motor vehicle repair and am really looking forward to doing some tinkering on a micro scale. I've been searching for sometime but finally I bought a project at the market this morning for peanuts: an Amida Castell which the salesman said was automatic. He gave it a shake and it ran briefly but kept stopping. On the way home I took off the back and thought the movement looked very clean, and didn;t appear to be an automatic, popped it back on, gave it a wind and it started running and kept running for some time. I timed it and it was losing a second each minute, however that seems to have sorted itself out and keeping time much better now. The watch looks alot more attractive in real life than in the pictures, particularly the dial. Plans are to buy some tools: screwdrivers, and oilers, a loume?, maybe a small ultra sonic cleaner and strip it out, clean, lube and reassemble- if this doesn't destroy the watch I will firstly be very happy and secondly replace the crystal, and then find a band. I'll get stuck into reading some of the info on this site, thanks to everyone who's set it up. No doubt I'll have problems but I'll do my best to learn and do a good job. Inside the backing case there are inscriptions for at least two seperate dates which I guess might be a service record of some sort. the last one appears to have an 88 or 85 at the end1 point

-

1 point

-

Here are a couple of PDF's for the 221X mechanism. In the past I have posted info for the 214 and 218 only so this is an addition for Bulova tuning fork Watches. The 2210 has a quite funky tuning fork with its curvy tines. The Index wheel has 270 teeth and the watch Hums at 440HZ which some of the musicians amongst us may recognise. Anyway before I drift off on one here is the info:- Accutron 221.pdf Technical Letters 2.pdf Cheers, Vic1 point

-

I just picked up another Seiko 6138 - 0011 for $125 less then the first one . Needs some TLC . Original owner in the military that wore it until the small sub hand fell off and is still under the crystal . He said it wasn't dropped or anything like that and had been regular serviced previously......I hope so . I'm also hoping that it has the original solid link bracelet like my first one . It looks similar in the photo .1 point

-

I had this once with my neighbours quartz watch. It seems to be effected by her magnetic bracelet that she wears for arthritis. When she moved the bracelet to her other wrist the problem went. I still have my doubts about this but that was only thing that was changed & the problem went.1 point

-

I guessed something was wrong because the spring just seemed too low in the barrel. When I went on cousins they gave a different size to what I was measuring. To double check I went on Ranfit web site & they also gave the same size as cousins. My GR catalog does not show the 6CL so I measured the height of the barrel just to treble check 1.40 fitted. There is a formula to work this out but if you go to this link it works it out for yea. http://www.nawcc-index.net/CalcMainspringLength.php1 point

-

Which movements are you talking about? Which batteries were used?1 point

-

1 point

-

It works on a similar principle to those case wrenches you see for some watches, only this covers every size from 17 to 34. You fit a ring over the crystal that is slightly too big, and will be slightly smaller when the ends are squeezed. I've been experimenting with some old crystals on watches and it works beautifully - you do need to make sure the ring isn't too tight initially or you risk squeezing to hard. It works just as well putting them back.1 point

-

Excellent John, thank you, today I've learned more...and my wish list became bigger! :) Cheers, Bob1 point

-

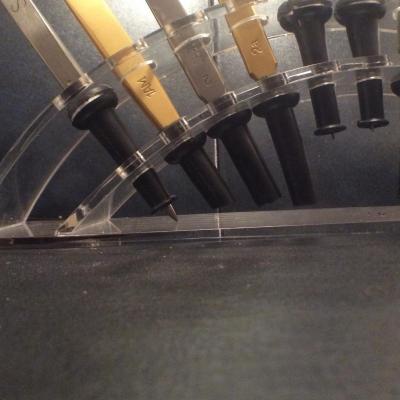

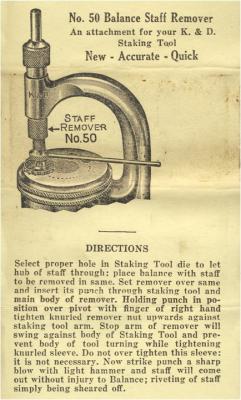

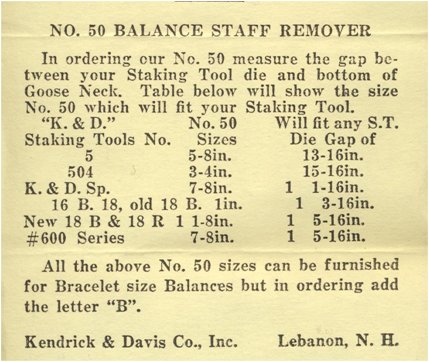

What's interesting is missing tools for removing the balance staff plus his staff grinding tool extremely expensive and if you're not careful bad things happen. Specifically if you're not careful you grind more than the staff and you make a nice hollow into the balance arm. Then if you are grinding out it's always good if you would measure which are grinding out just to make sure that whatever you replace with exactly matches. Then as pointed out Missing is the Platax tool I've attached photos of something else that's missing.1 point