Leaderboard

Popular Content

Showing content with the highest reputation on 09/07/15 in all areas

-

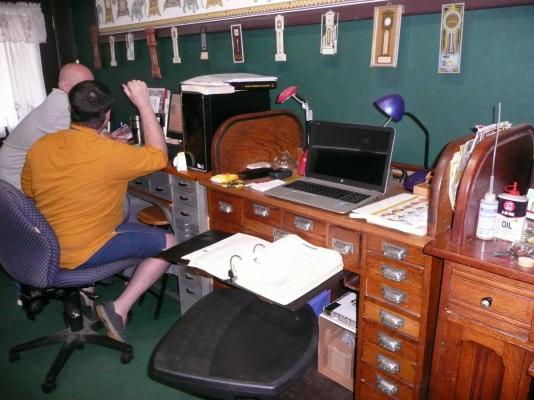

This is the first installment of what I hope will be a series of updates on my experience at the York Time Institute. In Lesson 1 of the Chicago School of Watchmaking's Master Watchmaking Shop Training and Job Guides, Thomas B. Sweazey says, The second sentence of this quote spells out the ethos of the York Time Institute as expressed by its director Daniel Neid. "Dan" is firmly committed to the idea that his students will not only be able to make repairs from stock parts but also, if necessary, be able to make parts when necessary. Not only that he will also be able to understand all the different mechanisms that go to make up the complete watch--including but not restricted to casemaking. My experience so far is that Mr. Neid not only has the knowledge but the tools to put paid to this claim--we shall see. I hope to be able to provide vignettes of how much I will be able to learn and put to practice. For now I am totally amazed--one might say overwhelmed--by not only Dans knowledge of current practices but his avid knowledge of the history of the techniques and tool of this honorable and difficult craft. He has an absolutely amazing array of tools, many of them very rare and practically unattainable. I spent the better part of yesterday afternoon inspecting a multitude of watchmakers lathes; ranging from small bow-driven lathes to modern motor driven ones. Add in a huge number of examples of all the tools mentioned in the Chicago School's manual. He not only has examples of modern tools but their predecessors that date back well into the 19th century. I am looking forward to the chance to try them--especially the bow and treadle-driven lathes. We spent several hours today examining measuring devices, many of them factory pieces once used at places like Hamilton, Waltham and Bulova factories. It is amazing how many kinds of devices have been developed to perform the many types of measurements required for watchmaking. Again, I was overwhelmed and am looking forward to trying some of them. Dan has a good rationale for spending a good amount of time inspecting the tools of the trade: he says it will be invaluable for being able to identify tools at various kinds of sales such as estate sales, yard sales (yes many of his tools have come from such sources). The student (like me) will be able to sometimes get great bargains by being to identify a tool that perhaps its owner doesn't recognize. The other students confirm that they have, in fact, put their knowledge to acquiring lots of interesting pieces themselves. We work in close quarters in a shop chock-a-block full of watchmaking tools and a huge inventory of parts. I once spent some time at sea on a nuclear submarine every facet of which serves some importance towards its mission. It was like living inside a machine. I get this same feeling at the institute. The close quarters serves to create an espirit de corps that I hope I will be able to share someday. The students are inculcate with sense of being a "breed apart" from the ordinary person and take pride in their work. It's also informal but serious and sometimes not so serious. Dan seems to be a good psychologist recognizing emotional ups and downs that can accompany success and defeat. The former receives praise but a gentle reminder to keep focused and not to let them swell the head. The latter is met with the reassurance that our foulups and fumbles are a necessary part of the learning experience; the even experienced students and masters loose parts and break things--underscoring the need to be able to make what one does not have or has lost or destoryed. When we get into a dudgeon over repeated failures Dan says, "Go take a break and don't let it get under your skin." Because it is through failures and even catastrophes that one really learns. One must develop patience and take the time to get the task right. He pays attention to how our tools are organized by task and frequency of use. He helps his students acquire their tools from the least expensive sources--though considerable expanses will be incurred event the. Though students are encouraged try out his many tools and devices to further direct acquisitions by the student. I just bought a nice lathe with complete sets collets. I will spend some of my time restoring it to mint condition. And its not jjust Dan, the other students are willing pitch in by selling the beginner some ot their surplus tool at very reasonable prices. I too donated to the Institute several of my supplies to the general pool can be of help to all students. We are constantly being giving spot tests to see what we've learned. For now my tests are ones of recognition. I'm getting tired to I'll cut this short by showing you a couple pictures of my bench. It's an old bench as you can see with a place for a treadle on the left. I love the feeling that I am working where generations of watchmakers worked before me. My I do them honor and justice. My bench is the one in the middle with my laptop on it. Today they are indispensable for research.1 point

-

Hi, Today I decided to take the balance out of the pack and see how it fit. When I installed it the hairspring coils weren't even. It appeared that when someone attempted the earlier repair and removed the balance the spring was bent slightly near the stud forcing the coils to be pushed off center. If you placed the balance cock down the balance would sit about 1/8" off center. Now that I look at all the evidence there is another hairspring in the box of parts and the part I installed was sitting in a nice green Rolex pack. Maybe the spring was bent originally while installing the balance onto the balance cock. Fortunately I have watched the videos on hairspring manipulation and while I didn't want to practice on a two-toned Rolex I figured it was either fix it or order one so I gave it a shot. Since the spring was bent near the stud it was fairly simple to bend it outward which pulled the coils back into a nice circle and now the spacing is about as even as I can tell under a 20x microscope. No coils are touching and there is a nice movement when I rotate the watch. I should have taken pictures but I was a little grouchy at the time and didn't think about it until I was done. Anyway I want to thank Mark for all his videos. I watched the 3135 videos about 3 times and the hairspring videos helped a lot as well. If there is any advice I could give someone when working on a watch they aren't familiar with is do the research. Look at the tech sheets. Look at pictures and if a video is available watch it. If you know about the spring that wants to run off then you can prevent it from happening.1 point

-

YES SORRY wrong movement did not read the post correctly. However the same scenario is required the dial will have to be removed to see what is wrong.1 point

-

Micky please don't tell me you are plunging the basket down towards the heater! If so then don't plunge down. Just bring the basket into the chamber but don't push the basket plunger any further. Or in other words - keep the basket in the up position I usually have mine running for 12 - 13 minutes in this position with no problems. I also turn the heater on just before placing the basket in the heat chamber and not any earlier Sent from my iPhone using Tapatalk1 point

-

Wow Micky that looks painful. I've always wondered how long to leave it in the drying cycle. I personally only turn the heater on when I place the basket in its final rinse & then when placing it in the heater, I turn the speed to minimum, only push the plunger for the basket down approx 1/3 & time for 7min. Even then the basket comes out hot, infact virtually to hot to touch. What process did you use? as I really don't want to melt mine as well.1 point

-

I don't think that the basket should be touching the heater especially as the new ones are made from plastic. The heater temperature cannot be altered unless you have purchased a different one. The fault has got to be with the position Just try raising it up the shaft a little. If you need to buy a new one, try Walsh's instead of Cousins. They are very helpful and cheaper. They also have shops which you can collect from instead of paying postage. Mike1 point

-

1 point

-

If you could find a nail that is a close push fit in the tube, you might be able to pull it out with pliers or grips. The nail will prevent the tube from collapsing. This is assuming the tube hasn't been broken off flush with the case.1 point