Leaderboard

Popular Content

Showing content with the highest reputation on 04/30/15 in all areas

-

So I found this in a junk bin and decided to fix it up a bit. It took a little work but I found the information. The watch is a quartz Seamaster Jubilee (MD 396.0969) 1432 caliber, 6 jewels, created in 1983. The first thing that needed to be taken care of was figuring out what model it was, and to do this, I had to remove the caseback. Problem? Well, just looking at it tells you it’s a snap back, but there was no **BLEEP**in’ place for purchase with a case knife or any other tools I have. Finally, I pulled out the superglue and a Nut. Glued the nut to the caseback, let it cure overnight, and the back popped off easily. Let the caseback/nut sit in acetone overnight and the glue completely dissolves, leaving a clean back. After doing the necessary homework, I was able to source a gen stem and crown, in Poland of all places, and put in the order. Now it’s time to remove what’s left of the broken stem Since it was broken flush with the tube, there was no way to grip it But here I was both lucky and unlucky. The stem slid out easily enough when I could access it through the case next to the movement, but that also meant there were problems with the keyless. As you can see, there is no visible stem release, so to get to the keyless, I first had to remove the electronic components And now we have the exposed keyless which will have to be disassembled to diagnose. Turns out, the keyless just needed to be reset. So, service and reassembled, it’s now time to replace the stem. Definitely too long, so I needed to cut and file it down to proper length. Nice snug fit in all three positions (here it’s in position 2) Test and reassemble electronics Then it was just a matter of completing the service and reassemble. I’m buffing the case now to give it a nice shine, but since I kind of wanted the aged look to be kept, I’m not doing much more. Not touching the dial, but I may relume it. All in all, I enjoyed working on this. It’s a bit of history, sentimentality, and intelligent design that lends to the understanding of why Omega is what it is today.2 points

-

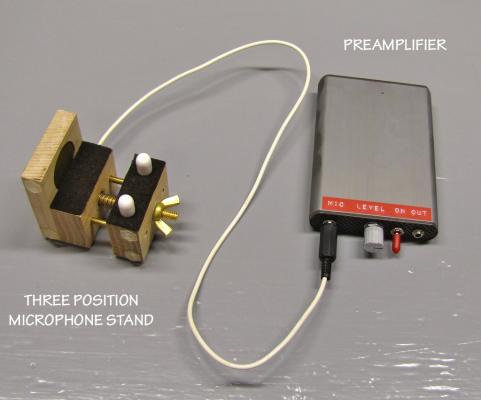

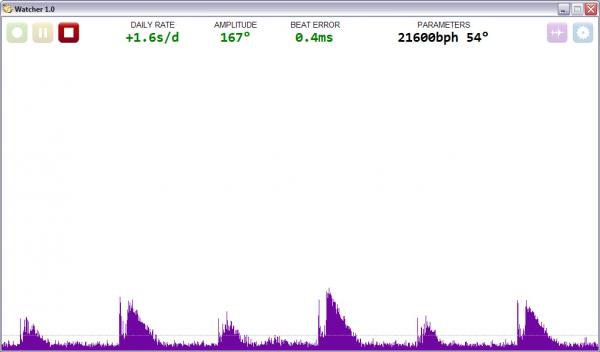

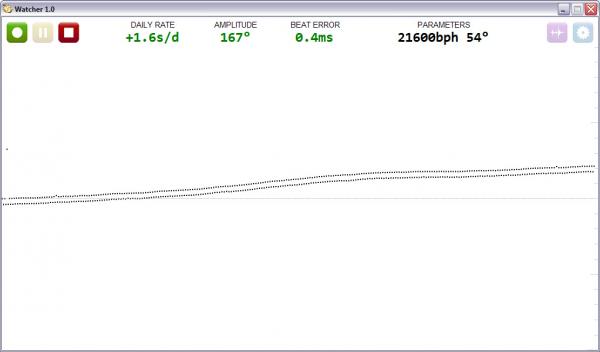

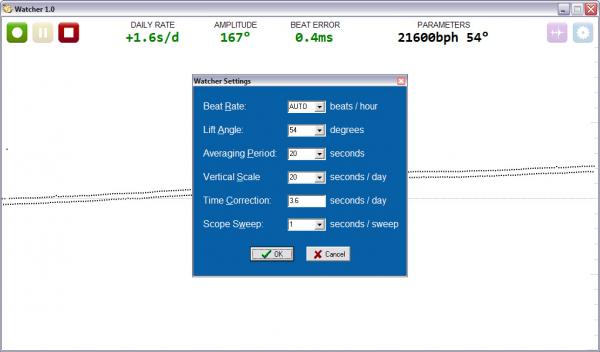

I'm a watch DIYer, having serviced two watches myself, partially using tools of my own making. One thing I've been working on over the last few months is my own PC based timing machine. I've finally got something working reliably, and thought I'd preview it here. My plan is to eventually write up a detailed article on my web site describing how to build the hardware, and providing a download for the software. I may also produce a "pro" version of the software with more features, to be sold for a reasonable fee. Here's the hardware, all home made of course: The next picture shows the timing trace from my "Black Lagoon", a modified Invicta 8926OB with a Seiko NH35A movement (yes, the amplitude is quite low and tends to fluctuate, topping out around 220 degrees - apparently this is par for the course for Seiko movements): In this picture, the software is in scope mode, showing directly the ticks and tocks. Notice how with this movement, they alternate in loudness. Since the scope mode was run after the timing mode, the scope also shows the threshold that was used by the timing mode to detect the start of each tick. And this is the settings window: Here's a brief list of features so far (I have to resist creeping featuritis): Numerical display of daily rate error, balance amplitude, and beat error. Horizontal "paper tape" mode with sub-pixel vertical resolution that can show fluctuations that are too small to see on a typical stand-alone timing machine. User selectable averaging period. Rate determination using linear least squares, which gives a more meaningful reading than just naively averaging the rate. Automatic signal and noise level determination. There's nothing to adjust. Aggressive noise filtering in the software to keep the hardware simple. Automatic rate detection for common rates. Simple, uncluttered, fixed-size display (1024x600). Scope mode to aid in diagnosis of various watch faults.1 point

-

1 point

-

I see once a drier made out of a wood box with a hairdryer blowing through it and seemed to be working.1 point

-

Hi Lab, The best time to bring up this subject is right after your partner has splurged on a new dress /kitchenware/kitchen etc. Another good tactic is if you know people with bad (and expensive) habits...like drinking/drugs/crack (the drug, not the other type)... And compare this to your relatively harmless hobby. (This will obviously not work if you indulge in said bad and expensive habits yourself!). Anil1 point

-

Just had the same problem on a Smiths TY, managed to remove the old one with a pair of needle pliers and tapped the new one in supported by rodico and a suitable anvil. Brutal but seems OK. Need to get a staking set really, but when I tell the boss how much they cost I am offered the choice of having my head tapped with a rolling pin or the frying pan.1 point

-

Ah, I love these early Roamer watches - that dial is very sweet. You often see Roamer watches advertised on eBay as "Breveté" models - when all that "breveté" means is "patented", in French. The serial numbers on the outside of the case back indicate the variations on the movements over the years, and this is useful in dating the watch. I recommend this excellent reference site: http://roamer-watches.info/gallery.shtml1 point

-

I might be able to help you with the stem Clockwatcher. I'm going out shortly but will have a look when I get back home.1 point

-

Thanks all for the suggestion and tips. It will be quite a challenge for a greenhorn and this going to be a slow and cautious project. On the crown, as interim measures I may try an after market crown with generic stem since this item is not part of internal movement and can be easily replaced later on, its okay to temporarily use an alternative while the genuine item on "work in progress" No doubt the crystal needs replacement, it will be like opening a treasure chest once it's open, was told this watch never had any service since new. It will be quite a while before I can strip the watch, it's a long way to get the needed tools.. and it's quite costly as well. In the mean time, there is always a few Seikos, Orient and Citizens for target practice :) Affnan1 point

-

1 point

-

Honeybee welcome to the forum see vid attached on how to remove scratches from your watchband. To replace the crystal the movement will have to be removed from the case. Then you will have to determine how the glass is attached. If it is a pressure fit you will need a crystal removing tool or glass press then measure and purchase the new one from a supply house. https://youtu.be/DpB419oxCjQ1 point

-

Jim, welcome to the forum. This is reasonably common with replacement glasses. When I order I will usually obtain the one above and the one below and whatever I don't use goes into my parts collection.1 point

-

Welcome Jim - enjoy the forum. Whenever I've replaced watch crystals, I've gone to a repairer friend of mine who has a massive stock. We get the so-called correct size out of the packet only to discover, sometimes, that the bezel actually needs either a size smaller or larger - in spite of the packet labelling! It can certainly be a problem.1 point

-

1 point

-

1 point

-

hi everyone, i wasn't sure i needed a staking set until i bought mine. it opens up a whole world of possibilities that are not there without it. i now focus on buying watches with broken balance staffs as i can replace one in a few minutes now. removing and replacing jewels, roller tables etc. etc... you can pick up a watch with a broken staff for a fraction of the price of a runner. i use my set all the time and it has paid for itself over and over.1 point

-

Oh wow. I started this hobby with old movements and continue to work almost exclusively on old watches. I have not worked on such a pristine timepiece as this ever. My G*d that thing sparkles more than a Chopin piano concerto--sensational. Thanks for posting. JC1 point