Leaderboard

Popular Content

Showing content with the highest reputation on 04/09/15 in all areas

-

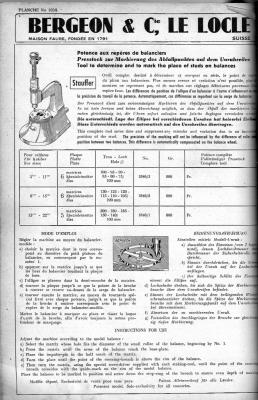

Just finished servicing one of these as part of a task set by my Horology tutor. Thought I wold give a quick walk through as it is an interesting and very good movement that can be had fairly cheaply. The Bidynator was the first Bi-Directional auto movement (Felsa 690) introduced I believe in the 1940's. This is the later 1560 calibre. Here is the rotor that is removed by moving the tiny spring loaded lever down and left to unlock it. This is indicated on the rotor by a small arrow. With the rotor removed the auto plate is revealed. You can also see it has Incabloc shock protection and the escape wheel has capped jewels. Auto plate removed revealing the bi-directional auto module. This movement has 2 clicks, the one on the auto module does not let the power down. The click to let down the power is located at the 2 o'clock position in this picture resting against the barrel ;) With the plate removed the gear train is exposed, notice the twin gears on the third wheel. The lower wheel is slightly offset to the top wheel. These engage with the (indirect drive) centre seconds pinion to prevent stutter I guess? I didn't photo inside the barrel when I took it apart but it has a conventional mainspring hooking, but there is a separate slipping bridle that runs around the inside rim of the barrel. The mainspring hooking, hooks on to this and this provides the slipping mainspring that is required for a automatic movement. The slipping bridle is removed during cleaning and braking grease apple to the barrel wall before re-assembly. NOTE: The mainspring winds in reverse to the more common mainsprings (ETA's etc) This caused a problem with my mainspring winder that can only wind in one direction (Bergeon..Hah!) So it was hand wound in which was quite straight forward. When the gear train has been removed there is a final bridge holding the centre wheel in place. Flipping over the movement reveals a straight forward motion works and keyless setup. Again you see the capped jewel escapement and look at that shock setting, this is a well made, good quality movement ;) Lubricants used were, Auto module and rotor 9010 Gear train D5 & 9010, 9415 on the pallets Mainspring wiped with D5, Barrel wall 8213 braking grease Keyless and motion works D5 & Molykote DX The movement is performing very well with a 48hr power reserve. I don't have a timegrapher at home so regulated it with a digital stopwatch as close as I could. It is still within a minute, 3 days later, being worn all day on the wrist...Impressive. Here's the completed watch.1 point

-

Greetings to you all from the north of sweden!! Here you have another watch fanatic, and I don't want to miss this opportunity and introduce myself to the forum. Daniel is the name and I'm not a watchrepair man by trade, just an advanced nerd so far.. :geek: ..! I've just finished a service on an old front-mounted Cimier military watch with very good results. My ambition is that one day being able to service my latest addition to the small collection... My "new" Omega 176.0012 Speedmaster IV, or 4,5 as some people call them. This is a 40th year present which I have treated myself with. According to the serial, 39xxxxxx, the watch is exactly as old as me, manufactured in the year 1975. This makes it a really early one. The timepiece is in fantastic condition, original glass with no chips and almost no dents on the casing whatsoever. The case is really nice refurbished with the classic sundial pattern and the polished corners and so on. I've fitted a new stem with the "real" crown (st 43238) and have also bought the right omega bracelet(1162-172) for this watch. I'm also very proud to have the original 70s box, very hard to come by in this good condition. The original insert for the box is missing though, so a pillow will have to suffice for the moment. But as you can see in the pictures, the original bracelet is only mounted where it sits in the box. The bracelet which I have fitted now is a really nice, thick, sturdy and heavy bracelet which I found on a website. I understand why they have a thicker bracelet on the new retromodel of the mark II. A thicker bracelet really completes the the bulky 70s style casing and really gives the omega a great prescence on your wrist. As you can see my bracelet also has tapered links and polished sides that lines perfectly with the style on the case. The purist in me just wishes that it was an original omega bracelet... Anyway, this is me and my new best friend... Many thanks to Mark for your absolutely great videos, they really inspire me for my future projects. And ofcourse this already great forum, you've started something really good here, keep it up! :woohoo-jumping-smiley-emoticon: (PS: maybe a service video on the lemania 5100/omega 1045 is something for the future..;-) ) :judge: Cheers to all of you other nerds in here! :thumbsu:1 point

-

It's a method devised by Greiner in the late 50's or early 60's which allows the use of the timing machine to find the heavy spot when you have an amount of positional error. I understand that their method rendered the 'static poising' method to be obsolete (their words, not mine). In the most basic form the method is to test in 8 positions (0 to 7) in the vertical, and find the position where the watch is gaining the most. The starting position is to draw an imaginary line from the escape wheel centre to the balance centre and set the movement on the microphone with the line vertical, the balance being above the escape wheel. This is position '0' Each test you turn the movement clockwise by 45º, the first = point 1 second = point 2 and so on. When you find your heavy spot (where the watch is gaining the most) take the balance off the watch and flip it over so the impulse pin is facing up. Draw an imaginary line from the staff through the impulse pin to the balance wheel rim. This is point 0. At 45º from this point is point '1' and 90º is point 2. Point 4 is at 180º on the balance rim and hopefully you get the idea. So whatever position is gaining the most on the timing machine, you would either reduce weight at that point or add weight (timing washer) on the opposite side of the heavy spot. And this depends on the rate when the watch is in the horizontal. If the watch is slower in the horizontal then you will lighten the screw at the point found. If the watch is faster in the horizontal then you will lighten the screw opposite the point found. If the watch is running at zero rate in the horizontal then you would lighten the screw nearest the point found and add weight to the opposite of that point in equal measure to the lightening. If the balance has no screws then the only choice to be had would be to remove material at the heavy spot, it's not possible to add weight. Two things to note is that, when testing on the timing machine, the watch should be wound down enough so that the amplitude is between 150º and 180º And secondly the watch must be cleaned and properly lubricated first. I hope my overview is clear, it's late and I have enjoyed a few fingers this evening :)1 point

-

This video show the utter importance of always demagnetising a watch before attempting to regulate it.1 point

-

1 point

-

All tested and now given it it's maiden voyage with a Seiko 200m Divers Watch.......... Failed at first test...... Serviced watch and full refurb...... greased seals and then left off the Bezel to see around glass seal....... Took it to 6 Bar, safety glasses on....... and.............. All fine, no streaming bubbles....... All for under £40....... better than the cheapest Chinese one at £150 plus custom charges.................1 point

-

Looking good Affnan now there is no excuse for you not to work on your watches and post pictures! :) Cheers, Bob1 point

-

Hi number98 Check this out! From Ranfft: Fig. 1 Fig. 2 Fig. 3 ETA 2824 Features automatic sweep second date: quickset option: hack feature Data 11.5''', Dm= 25.6mm, Do= 26.0mm H= 4.6mm (H= 4.7mm with ball bearing) F= 1.2mm T= 1.8mm 17/21/25 jewels f = 28800 A/h power reserve 40h Balance staff ETA 2801 Stem W3408 Mainspring / battery 1.20 x 11.0 x 0.115mm Hands 1.50 x 0.90 x 0.25mm Comments about the data Remarks 1971-1979, 1618952 family/generations: 28800 A/h 2801: manual wind 2804: manual wind, date 2816: manual wind, day, date 2824: automatic, date 2826-2: automatic, big date 2828: automatic, day, date 2930: automatic, day, date, Triovis regulator 2834: automatic, day at 12h, date, 13''' 2836: automatic, day 2 languages, date 36000 A/h 2819: manual wind 2806: manual wind, date 2817: manual wind, day, date 2826: automatic, date 2832: automatic, day, date 2837: automatic, day 2 languages, date 2838: automatic, day at 12h, date, 13''' suffix -1, -2, J2: generations, variants not all versions in all generations Example, year: signature; shock device 1) ca. 1975: Solvil & Titus Geneve, Swiss Made, 25 Jewels; Incabloc 2-3) ca. 1975: 014, Eterna-Matic, Brevete Swiss, 25 Jewels - Patented; Kif-Ultraflex Not for Sale! The movements presented in this caliber finder are not for sale. This is only a data sheet for identification and evaluation of the movement calibre, as well as for approximate dating. So there you have it, different families! No 2892 here. If you search Ranfft, you will find that the 2892 is a "different animal" for this purpose. Of course this is not written in stone and I might be wrong (I welcome corrections) and in the end there might be interchangeable parts here and there but not necessarily what you are looking for. In any case, I wish you luck with the project and please keep us in the loop! Cheers, Bob1 point

-

This has been a fascinating thread. I don't understand any of it but that hasn't dulled my enjoyment of following people who DO know what they're talking about. Even if I had one of these timers I wouldn't know what to do with the results but I hope, in time, to get a handle on all this. WAGF John1 point

-

Not so much after your bookmark rather I had a glimpse on your blog. Very well done, clear and explained professionally. I will keep visiting your blog and learn and I am sure you do not mind do you? :woohoo-jumping-smiley-emoticon: Thanks1 point

-

I don't have both movements here to check but I don't think it's possible (from memory).1 point

-

Hi number98, like Bob I wish I had an answer for you. Without having two movement in front of me for comparison, I wouldn't even like to hazard a guess. :(1 point

-

1 point

-

I appreciate the vote of confidence but honestly I'm more into trial and error here! When I have enough crowns, I deep them in alum and heat. I'm using an old coffee maker to keep it warm. Then I brace for the surprise! ...meaning some will come out OK and some won't! Since they are -- so far -- for my own hobby (not customer's) I don't give it too much thought. I usually replace those crowns with new ones on the watches I service and if I can recover the old ones, then it is a bonus! One thing it is not advised is to use this method for diver, screw on crowns since the alum will cut through and spoit the whole spring/housing setting. Anyway, I have to go now I'll post more if I can think of anything els. Cheers, Bob1 point

-

1 point

-

Aha - Kenton was the original name of Timex. You won't find this in any of the histories - which attribute it all to Waterbury - but it sounds as though your watch was on the cusp of Kenton becoming Timex. They've used a Kenton case - probably new old stock - but put Timex on the dial. You do occasionally see Kenton watches on eBay - but no-one seems to realise that they're early Timex.1 point

-

Completed with worktop mat and Ikea lamp, will get a better rectangular watchmaker lamp if I can get it here at reasonable price. Now I can do more hours on it. Affnan1 point

-

Did this two years ago . It's a Seiko which i didn't repair . The other watches are old russian Slava watches . The frame is a thick black one . Inside i have a 1,5 cm thick sponge material and some velvet on top of that . The parts are pressed against the glass .Some of the parts have to be glued in place .To stay in place until the back of the frame is installed .1 point

-

1 point

-

1 point

-

1 point