Leaderboard

Popular Content

Showing content with the highest reputation on 02/02/15 in all areas

-

Hold it tightly in the movement holder then place the holder into the timegrapher clamp. It worked for me.2 points

-

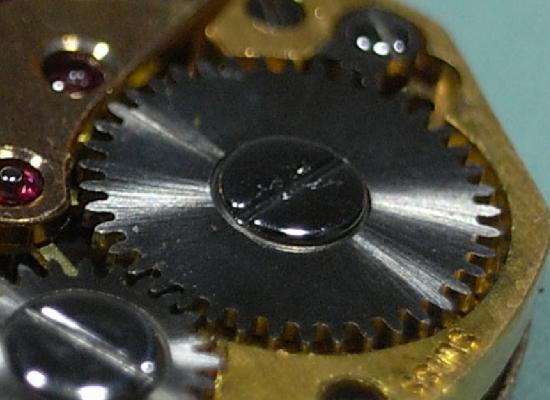

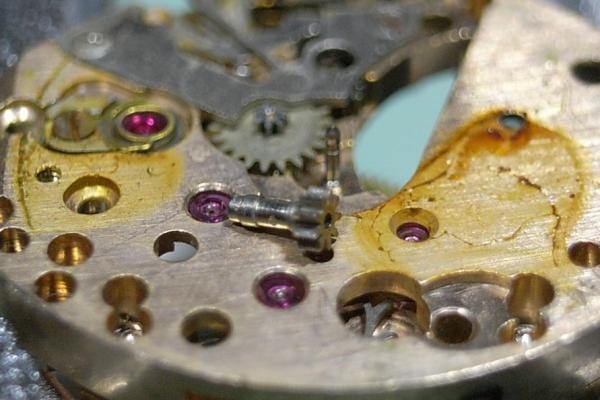

Hi fellow watch friends, back again with another service for ya :) This one is a woman's bracelet watch that were popular 20-30 years ago ... your Mum probably had/has one of these. Now when I say this movement is small, I mean it's small ... I don't think I used a driver over 0.8mm on it. And being small doesn't mean they are more difficult, but you need good optics to make working on them enjoyable. ...yes, that's my thumb! I've worked on a few of these now, and they commonly are held in the Caseback as seen below. So be careful when removing them so as you don't damage the Dial or Hands. Once I had removed the movement from the Caseback, I saw my very first indication that this job wasn't going to be a quick service. Notice that Ratchet Screw? Here's a close-up of it. I see this way too much servicing watches, and it's become my pet hate. King Kong has worked on it before me, and has tighten every screw up to 50 foot/pound ... Arrghhh!! :growl: Needless to say, when it came to removing nearly all the screws, it was a battle; but the battle was lost with the Ratchet Screw and I was unable to undo it (even after applying some heat) and it seared off ... so 1x Barrel Abor and 1x Ratchet Screw to be ordered. My mentor and trainer is a 78 year old master watch maker, and the VERY first thing he impressed on me is not to over tighten screws. "We are not torqueing down head bolts on a V8, these threads are less an a millimeter across ... use a light touch son.", is what he told me. I'm sure some old hands here can also add their words on wisdom on this matter. Ok, end of rant :P Back to the service... Firstly, I removed the Hands and Dial, and as per normal with this style of watch, there was moisture ingress. These types of watches aren't very well sealed from the elements (no Caseback Seal, no Stem Seal), so you'll nearly always encounter some rust removal in the servicing. This looked fairly light corrosion, and I was hoping it hadn't gone further into the movement. Here's one of the reasons this watch stopped. Heavy corrosion around the lower Barrel Arbor pivot. Next, as always, I removed any tension from the Mainspring, and removed the Balance and Pallets. Next I removed the Ratchet (shearing the screw in the process), Crown Wheel, and then removed the Barrel Bridge. As you can see, very old, dry, and dirty grease. Main Plate looked in good shape, which saves a LOT of work ... if this thing is covered in rust you've got your work cut out for you. Pulled the Cannon Pinion, and happily it wasn't ceased, but also is still a good fiction fit. Here's a reference photo of the Gear Train setup once the Bridge is removed. Again all looks good and no damage to any of the pivots or jewels. Stem, Clutch, and Setting wheel are filthy and typical of a non-sealed movement of this age. On to the Keyless Work, and unfortunately rust had gotten in here too. The Yoke Spring was the worst of it, but with a little time and effort, it cleaned up fine. Setting Lever needed a little work too :unsure: So the parts are in the cleaner, having a bath for the first time in 20+ years. And I've emailed the good people at Old Swiss Watch to get a new Arbor and Ratchet Screw. I'll have the assembly post up as soon as the parts arrive, and get this little movement tickin like new! Thanks for reading my post, and I hope this helps and was informative. :)1 point

-

1 point

-

Welcome Morten, I'm sure your horological history knowledge will be an asset to this forum. :)1 point

-

Spiro what's up buddy? Welcome to the forum, I don't recognize the movement....what is the movemnt of type of jump hour in the foto? I've done many baumgartner and Bettlach ebauches and this is what has worked for me: Moebius 8300 oil for the mainspring Moebius 9501 for crown wheel, stem, and winding mechanism Moebius Microgliss D-5 oil for setting mechanism and keyless works Moebius 9415 for the pallet and impulse Moebius 9010 for drive wheels Be careful not to put much oil on the dial side (if at all) because this has cause sticking problems for me in the past: particularly with Sicura spinning discs. I only oil the hour/date wheel spring and locking mechanisms--very little and nothing on the minute wheel.1 point

-

1 point

-

Great introduction Morten, and thanks for showing your workspace. I look forward to your future contributions to the forum. It's the input from the members that make this place so special.1 point

-

Welcome Morten, You have a busy workbench just like mine. This is a great forum that accommodates all levels of horologists. For me personally I have found this forum invaluable when jobs don,t go exactly to plan. There is always someone who will help or come up with a solution or at least offer sympathy!!! Enjoy1 point

-

1 point

-

It's also letting you get used to the delicate touch that is required before working on something more valuable.1 point

-

1 point

-

Stepping away from the work is the hardest lesson to learn. I usually try to step away from something if I make a mistake 3 times on the same watch..usually dropping stuff or having stuff fly off my tweezer. I take it as the stars are not in the correct alignment but its more likely fatigue! Anil1 point

-

If you need to pull the escape wheel out and its reluctant to come out.. make sure you pull it up square otherwise you'll break the pivot. Same for the pallet fork. A pre-soak in Napthpa for an hour will ease the disassembly. Anil1 point

-

Hi Micky, I, like you, have about the same routine! I use my computer chair for the computer but in the odd instance I need higher, it doubles as a watch chair because of the adjusting lever. I made a stool -- maybe like a milking stool but 4 legs -- some time ago with the right height for my classical guitar playing. I use it too as my watch chair. It is not as high as I would like -- for maybe one inch - so the bench (portable one) sits a little lower and that works well so far. The trick is my legs are not bent and I'm in a comfortable position. I really haven't looked for an all in one chair since there is always a compromise and I do hate the noise when working on my watches! Cheers, Bob1 point

-

I think that the chair chosen should be comfortable but also have an adjustable height. I use a draft mens chair that I purchased a few years ago from a second hand shop.1 point

-

Great pictures. That is in a state! These AS movements are excellent quality and I know it is in good hands :)1 point