Leaderboard

Popular Content

Showing content with the highest reputation on 01/14/15 in all areas

-

2 points

-

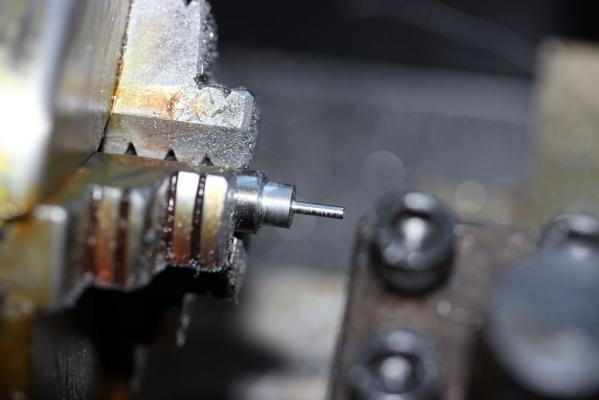

This was a fun project. Couldn't find a suitable pusher for a vintage Breitling and so I decided to make a new one. The old pushers were made of brass and then chrome plated, but as I cannot chrome plate on brass I decided to use some stainless steel instead. Full story, more pics and video clip on my blog.2 points

-

If you haven't already seen this video it's worth a watch, astronauts repairing an Omega X33 onboard the space station, looks great fun!1 point

-

Got this heads up from a friend who warned of a potential virus. He checked with Norton Anti-Virus, and they are gearing up for this virus! He checked Snopes , and it is for real. If you get an email entitled POSTCARD FROM HALLMARK , regardless of who sent it to you.It is a virus which opens A POSTCARD IMAGE, which 'burns' the whole hard disc C of your computer. This virus will be received from someone who has your e -mail address in his/her contact list. It has been classified by Microsoft as the most destructive virus ever. This virus was discovered by McAfee yesterday, and there is no repair yet for this kind of Virus. This virus simply destroys the Zero Sector of the Hard Disc, where the vital information is kept.1 point

-

I just delete everything I'm not 100% sure about, if it's important they can phone me or send a letter :)1 point

-

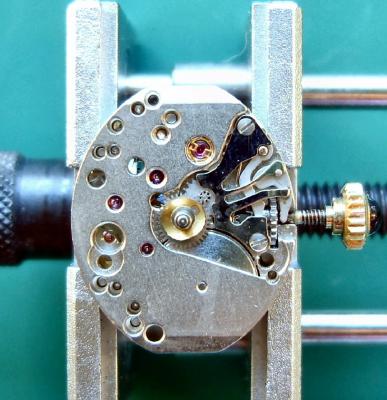

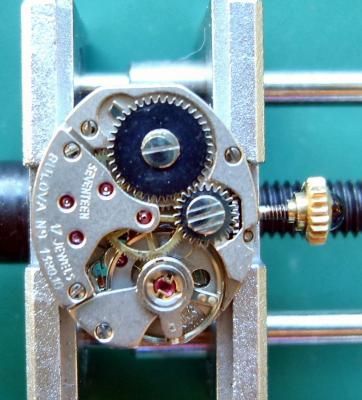

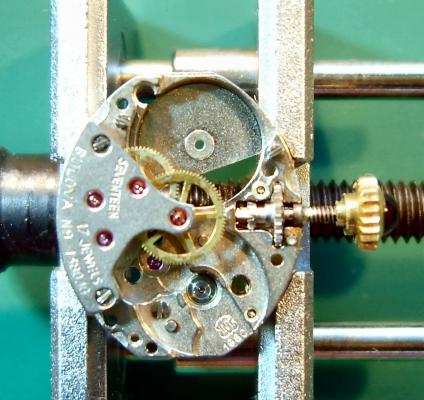

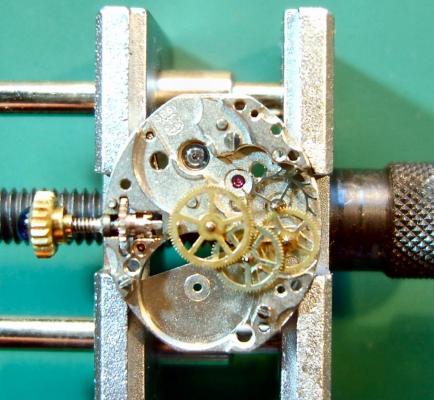

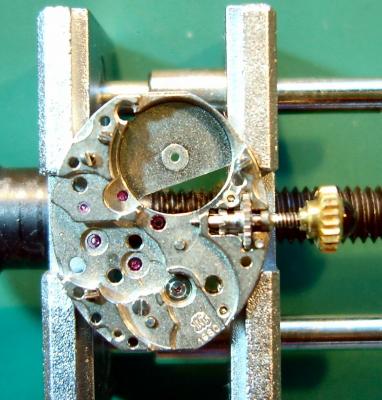

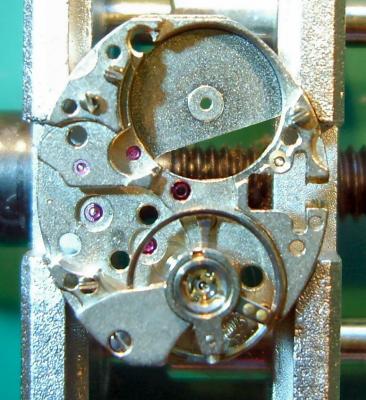

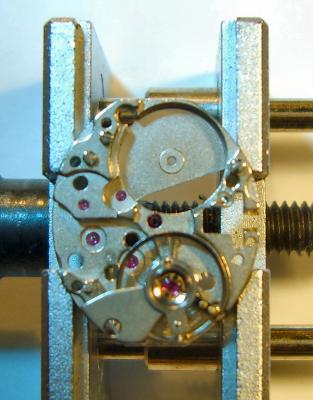

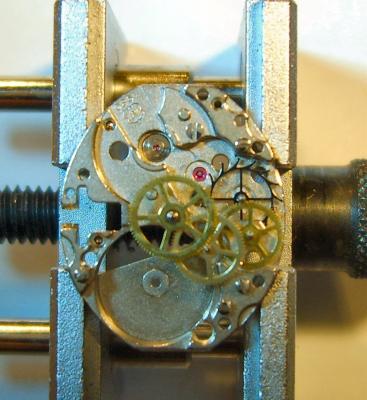

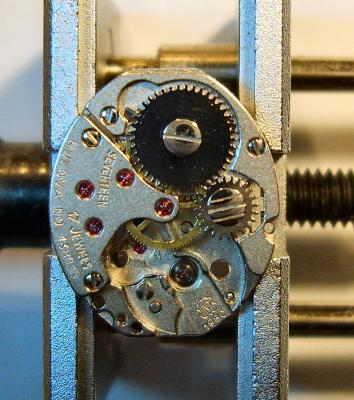

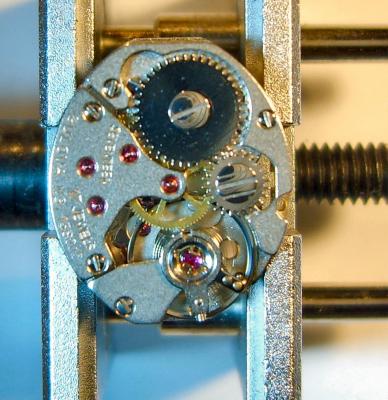

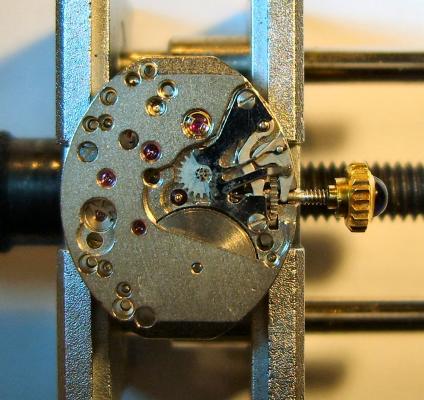

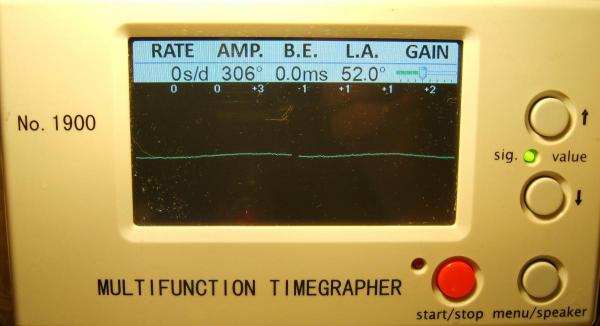

As promised in another post here is the little ladies Bulova Longchamp that I recently serviced. It's a 5.75''' x 6.75''' INT cal.1980 movement which according to Ranfft is also a Durowe 1980 or an AS 1977-5. 17 jewells and a 21600 train. It's my sister-in-law's watch and it came to me because it kept stopping. On the Timegrapher things did not look good; averaging 6 minutes a day slow with a Max Delta of 6 minutes and 20 seconds between positions (yes - minutes!!), average amplitude of 140 degrees, and a beat error of about 4.0ms. About as bad as it gets and still running!! Dial and hands off there doesn't seem to be anything damaged so hopefully this is just a COA and maybe a replacement mainspring. Mainspring let down now I can start the strip down. Balance, pallet fork, barrel bridge, and barrel now out. End and side shake on the train wheels is fine but the train is a bit sticky which does suggest gummy oil. Train bridge off revealing the train wheels in all their glory. The stripped out main plate, train side. Dial side, set lever bridge removed showing the layout of the keyless works. Main plate now fully stripped. And balance reinstalled for cleaning minus jewels. Every thing nice and shiny out of the cleaning machine. The mainspring looks absolutely fine; not set, and laying nice and flat on the bench with no distortion, so I will re-use it rather than replace. Notice the balance pivot jewels and end stones are different sizes. This is something that I always check when disassembling as the differences are not always as obvious as this and if you get the wrong ones in the wrong places it can cause all sorts of fun and games. Mainspring in the winder ready to install. Balance jewels oiled and reinstalled. This is when I check the free swinging of the balance and that the hairspring is sitting flat, with concentric coils, and not fouling anything. On movements that do not have adjustable stud carriers I also eyeball the impulse pin through the banking pins at this point and make any obvious adjustments to beat. I don't expect to get it spot on at this stage but it's nice to start off reasonably close, and you never know your luck. This one is adjustable though. The train wheels back in. Train bridge installed, barrel bridge reassembled and reinstalled. Everything spinning nice and free with some healthy recoil on just a couple of clicks of power on the ratchet wheel. Train pivots now oiled. Pallet fork back in and checked for lock and draw before oiling the pallet stones. Balance reinstalled and starts running straight off. I love this moment, it gets me every time. Keyless works back together and lubed. And onto the Timegrapher for some tweaking. Not a bad result considering the starting point and nothing has been replaced. Finally re-cased and ready to go home. The resulting stats at full wind plus about 6 hours; Position Rate Amplitude Beat Error Dial Up +4s/d 282 degrees 0.0ms Dial Down +3s/d 270 degrees 0.0ms Pendant Up -13s/d 242 degrees 0.1ms Pendant Down +5s/d 227 degrees 0.2ms Pendant Left -19s/d 237 degrees 0.3ms Pendant Right -2s/d 248 degrees 0.3ms Power reserve of >42 hours. I could possibly get the rate and amplitude more consistent with a bit of hairspring tweaking but given the size of this little baby and the (very high in my case) risk of making things worse rather than better I have decided to leave well alone. I know my limitations and when to quit while the going is good. If it were my watch then I may have been tempted. On the wrist (which is what actually matters) it is running close enough to spot on as to not be able to distinguish any error at all after a week of wear so I am happy with the end result. Sorry about the somewhat dodgy point of focus on some of the pics, I hope that it doesn't detract too much. Will try harder next time :-)1 point

-

That is perfect, thank you so much, this will help me and I'm sure others, I'll save this for future reference too. Thanks again.1 point

-

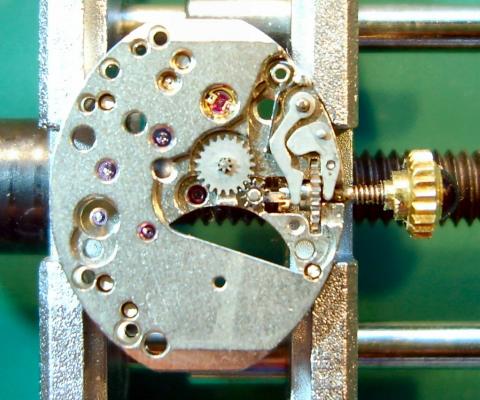

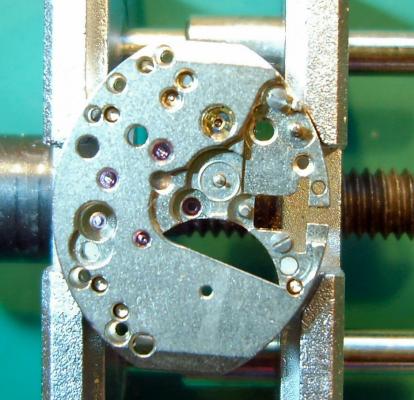

Hi Bob, here you go; The screw on top is threaded into the top of the arbor and forces the points of the star down onto the ratchet wheel whilst engaging the hole in the star washer (which has flats) with the top of the arbor (also has flats). The ratchet wheel hole is round so there is no direct coupling between the wheel and the arbor. Torque is transferred from the ratchet wheel to the arbor through the friction contacts at the points of the star. When the spring is fully wound the auto wind system continues to turn the ratchet wheel but the friction couplings slip preventing any damage to the winding set up that would otherwise result as the mainspring is fixed to the barrel with no slipping bridle. To dismantle this arrangement you have to immobilise the star washer with heavy tweezers so that you can undo the screw. If you don't hold the star washer the whole thing just spins.1 point

-

While re-assembling the Omega 561 I discovered a small screw when I stretched out a piece of Rodico. It was nothing to do with the 561, I lost it months ago when working on a Smiths. So the moral of the story is check your Rodico when you loses things! :-)1 point

-

I'm actually really in favour of this clock corner as who knows what us fellow tinkerers may get into!? But shouldnt it really be called Clockboys Corner? :)1 point

-

It's inspiring to see a watchmaker who doesn't RND a watch because parts are no longer available. THIS is the difference between a Watch Repairer, and a Watchmaker. Bravo Mark! :goodjob:1 point