Leaderboard

Popular Content

Showing content with the highest reputation on 01/05/25 in Posts

-

Well, after numerous futile attempts at getting the outer ring to even budge, I broke down and ordered the super wheelie tool for casebacks as shown by Andy earlier. Yikes! The ring immediately turned and came off. I can”t recommend this tool highly enough. It proved well worth the purchase price of around 90 bucks. Incredible tool. So, now the naughty girl is running strong in need of a total service but that can wait for me to practice a little more on automatics with a cheaper watch. Thanks for all the suggestions, and see you on the next watch.3 points

-

Not quite correct. There does seem to be a trend a very very slow trend of going from incredibly light lubricants for the keyless. The definition of incredibly light would be in the late 50s 9010 and yes they were Apple lemming just about everything of the watch otherwise that would spread like. Now they're all the way up to HP 1300 their increasing in viscosity still using the epilam. So their following a trend of becoming heavier lubricants for the keyless at least. At the rate they're going they should reach the proper lubricants for a keyless which I would suggest would be grease and probably another hundred or 1000 years at the rate they're going. The other amusement is the quantity of lubricants. When I was in school it was explained basically if the instructor could not see that you lubricated you were fine. But in any of the newer documents your to fill up the oil sank as long as you can still see the pivot your okay so something today that would be acceptable would end up in the sawdust Box just a few years ago. I have a suspicion that in the past the watch companies with manufacture their watches and send them out but for the most part they never service their own watches. If anything they would just blame the idiots in the field that would be all of us for the problems but now that they are servicing their watches I would like to think that there noticing the consequences of poor lubrication choices. On the other hand companies are going to much longer service intervals and they just replace anything they don't like so maybe they're not learning at all.3 points

-

The balance wheel is the watch's beating heart, visible in your photo as Andy pointed out. And the mainspring is coiled up inside the watch, its only power source. Good luck with this one. One caution - if you do find it will run and wind it up, don't run it very much without having a watchmaker service it. It will have dried up oil inside which can end up causing more wear and tear. Winding it up to run occasionally would be pretty harmless, but you wouldn't want to have it ticking all day every day for months without being cleaned and oiled.2 points

-

2 points

-

2 points

-

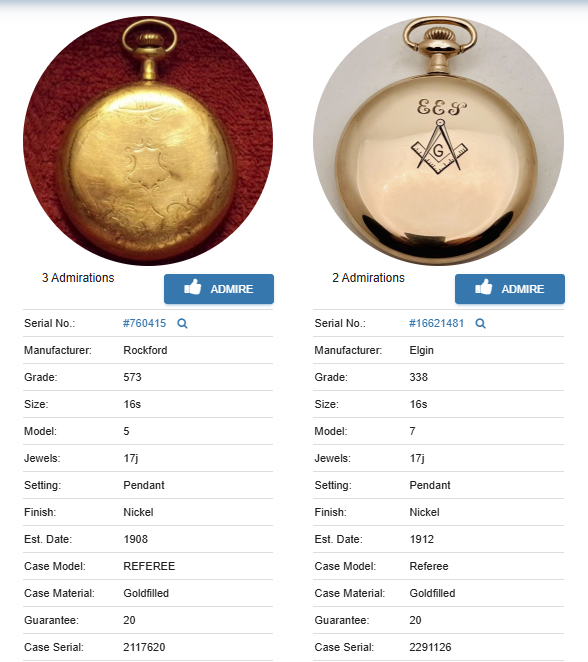

Before winding it, you can find out if it is going to be DOA by looking at the balance wheel. With the back open, hold it flat in your hand (dial downward) and give it a sharp rotating twist. If the balance is good, it should set into motion to oscillate a little bit. If it does not move at all, winding isn't going to make the watch run because either the movement is too dirty and clogged with old oil, or the balance staff is broken and needs replacing. Either of these two is a likely outcome for an old watch. But if the balance does swing a little, look at the dial and make a note of the position of the seconds hand. Give it another twist to set the balance in motion and then look again to see if the seconds hand moved. If it did, next you can try to wind it 4 or 5 turns If the watch has a good mainspring and it starts to tick with a little wind, then you can keep winding it gently. A watch like this will typically take about 16-20 turns of the crown in your fingers before it resists and stops winding at the end of the spring. But if the spring is broken, it will never stop winding and probably won't run more than a few seconds at a time (if that) About your case: The 20 years guarantee means this was a "gold filled" case. Gold fill is stronger than what we would know today as gold plating, because the inner base metal was sandwiched between two thin gold sheets and compressed. The fill ends up being far thicker than modern gold plating. Now that 20 year guarantee refers to how long the case manufacturer expected the watch could be until the outer gold fill started to wear off. Yours is significantly worn off the back, indicating that your watch was well used for a very long time. Because the cases were standardized in size (16s for yours), the watch could eventually be put into a brand new case. The crown is also well used and the gold fill has worn off from daily winding. This exposes the brass underneath, which is more prone to tarnish and corrosion. The crown can be replaced if you want to. The case can also be replaced, but for a family watch I would personally keep it as is if this is an heirloom. (Did you say this was an heirloom or did I make that up or assume it?)2 points

-

Every time I have the privilege of teaching a new class, I try to explain just how incredibly important it is that the students don’t compare themselves to each other. I think I manage to explain it fairly well, but I still always struggle to find the right words. Today, however, I happened to stumble across a short video with Denzel Washington that really hit the nail on the head. I found it so inspiring—and relevant for those of us striving to improve in repair and service—that I wanted to share it: "I don’t care who’s doing better than me because I’m not in competition with anyone else. The only person I need to surpass is the person I was yesterday. Last year, I was different—I’ve grown, improved, and learned so much. That’s what truly matters. It’s me versus me. Every day, I wake up ready to push myself further, to challenge my limits, and to become the best version of who I can be. I refuse to let someone else’s success diminish my own sense of worth. Their journey is theirs, and mine is mine." ~Denzel Washington2 points

-

2 points

-

I would have other ideas but don't see the point let me quote something is from your message above. Maybe that's indicating a problem? Should we explore this? That's interesting it cannot be wound by the crown and I really like that the word Well let me quote It's in capital letters cannot be wound by the crown how sad let me quote something So basically my first liner so indicates it can't be wound by the crown which you're telling me again did you know Seiko watches typically can't be wound went crown? Well let's not entirely true older Seiko is that were hand wound could be wound where crown and quite a few of the newer watches can be wound with the crown. But Seiko thought of that problem and you can turn the ratchet wheel screw which is what I set up above. If you like I'll get you newer tech sheet that explains That I believe in the newer tech sheet is looking at for a slightly different watch which could be wound with the crown but it also suggested you could wind the ratchet wheel eight turns and you're all wound up I don't think you grasp the possibilities of what a timing machine is used for. The number one use that I use one for is diagnostic purposes timing is a secondary purpose of the timing machine at least for me.2 points

-

1 point

-

I know I may be a bit OTT but I don’t like the idea of not being able to burnish the anchor pivots of the torsion clocks I restore, I know nothing moves very quickly and the anchor only rocks back and forth but if I burnish the pivots ( I don’t polish just burnish) it removes another variable because torsion clocks need to be as friction free as possible, anyway after a bit of thought I have found a way to mount them in the lathe. Dell1 point

-

Well, the local auction had this up for sale, got it for £55 in fully working Condition. Now I’ve done some reading through past posts on wiring, heating elements and so forth, I have come to the conclusion that baskets are the main problem. Now mine doesn’t have any, so a Quick Look on eBay and I’ve found some generic baskets that I can fit. I have ordered a 20cm length of 15mm diameter alloy rod that I’ll mount up on the lathe and bore an 8cm diameter hole 5cm deep and drill and tap a hole for the grub securing screw. Once that end is done ( motor end ) I’ll turn my attention to the basket end as I don’t know the inside diameter of the hole on the basket frame. But once I do I’ll turn the rod down and again drill and tap a hole to secure the frame to the shaft. The machine does take up a lot of space on the bench so it might have to live in the garage with my clock cleaning US tank and rinsed and steam cleaner and other bulky tools. Hopefully I can make it fit, if not it’s out to the garage.1 point

-

If space within the clock allows, I would solder 2 wires to the gold contacts and run them outside to a battery holder. This way, I can use a C or D size battery and run the clock for years. But remember to use "super heavy duty" batteries and not alkaline batteries. Alkaline batteries produce water when the chemicals inside react to generate electricity, which leads to leakage.1 point

-

Hi Hector if there is no adjustment in the cock (elongated holes) that’s the way I do it. Adjust the crutch. A way to tell you which way is tilt the clock untill the beat is even then move the crutch to the high side .1 point

-

I would open the banking pins slightly to increase total lock. If it has solid bankings, move the pallet stones out about 0.005mm.1 point

-

The case is gold plated or similar,;a thick coating, that's the 20 year guarantee. Wind it a few times, see what happens.1 point

-

1 point

-

Yes I'd expect they'd use the same balance and they do look the same as yours so probably the easiest fix.1 point

-

Here's the details for the case from the same pocket watch database. https://pocketwatchdatabase.com/guide/case-companies/wadsworth-watch-case-co/grades/Referee?filterSize=16&filterJewels=17&filterMovementSetting=pendant&filterModels=all&filterYearStart=&filterYearEnd= If you look at your serial number 2272120 and then check these other 2 examples you'll see the dates match your movement as being pre 1912 so more than likely it's original case.1 point

-

-Forget what anyone else is doing just concentrate on being the best version of yourself- thats what I used to tell all the folk I used to train at the gym.1 point

-

I think I have eight WW lathes and one Sherline. Two were inherited. Then a Levin with collet-holding tailstock and Levin cross slide and Levin 4-jaw chuck appeared on FB marketplace. The guy got it from his grandfather. Had no idea the value. Needed to make a truck payment. Got it for $300. That makes three. The problem with the Levin was that it had a long bed...maybe 18" so I wanted a typical WW bed. Ended up buying two more Levins that had only the headstock and bed. It was an error on my part. Same guy was selling both and the delta time between them on Ebay was short. I wanted to get at least one but ended up with both. That makes five. Then I was playing around on another auction site and ended up with a complete Paulson for $119. As I recall, I was expecting not to win, but had put a bid in to track the value. That makes six. Then some guy on FB marketplace advertised "clockmakers tools." He had rented a bay at a small airport and all this stuff was in it. He had no idea. Anyway, it had a Moseley lathe (I think) and a FULL SET OF LEVIN COLLETS, along with a bergeon bushing tool with lots of bushings and some other stuff (including a grandfather clock which is now running at home). All that for $500. Then I recently bought out a deceases watchmaker for $1200. Got another lathe with that. That makes eight. I dont need them all...obviously. My main lathe is the first Levin. One lathe at home is dedicated to sharpening. One lathe at this watch shop is also dedicated to sharpening. A 2020 Nitro Z18 Bass boat with a 150 horse Mercury motor is selling for $38,999 right now in Abiline, TX. I got less money into this little hobby...but not by much. I do enjoy fishing.1 point

-

1 point

-

A quick search brings this up https://mb.nawcc.org/threads/what-are-marshall-system-watch-parts.83846/ they were a material house in the ‘70/80’s and no longer exist. if you are looking for parts folk here maybe able to point you in the right direction but will need photos, movement identification and the part needed. Tom1 point

-

I originally got a cheap USB microscope. Useful for examining parts, but totally useless for working on a movement :There's a slight delay, and as it's not under your line of sight like a stereo microscope. Is there any way you could try out a stereo microscope before buying one? They are a game changer. I do 95% of all work under one.1 point

-

1 point

-

1 point

-

The screw holes are round so that is the way it is. before you tighten the screws are you able to move the cock if so that will alter the beat. You do find clock crutches get bent it can take a while to get the perfect beat.1 point

-

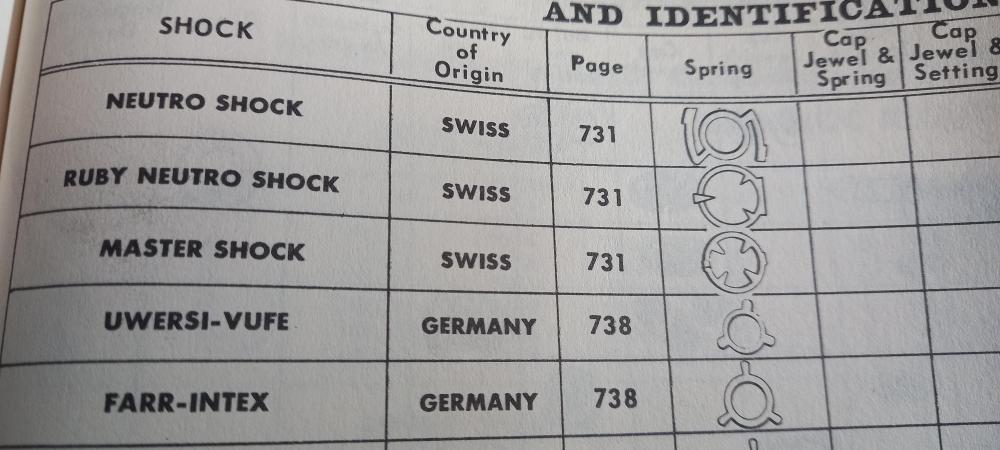

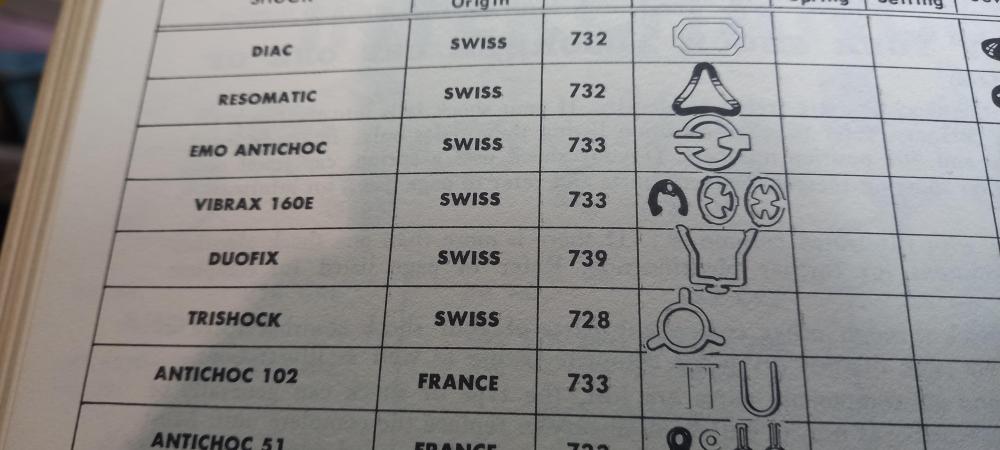

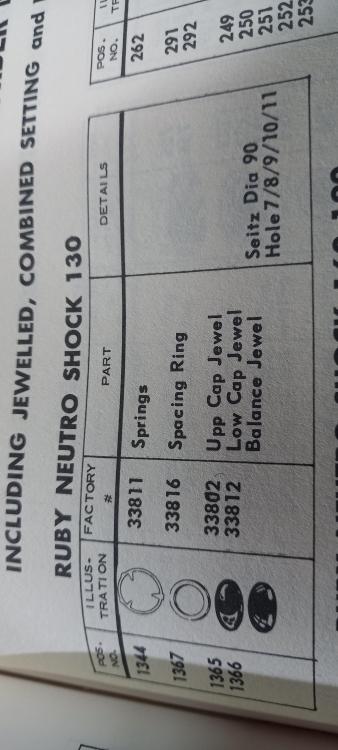

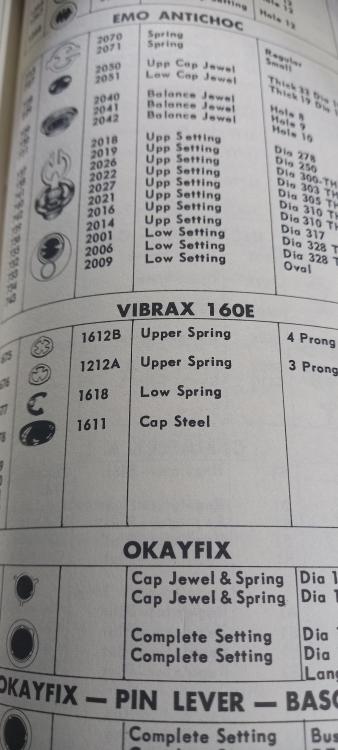

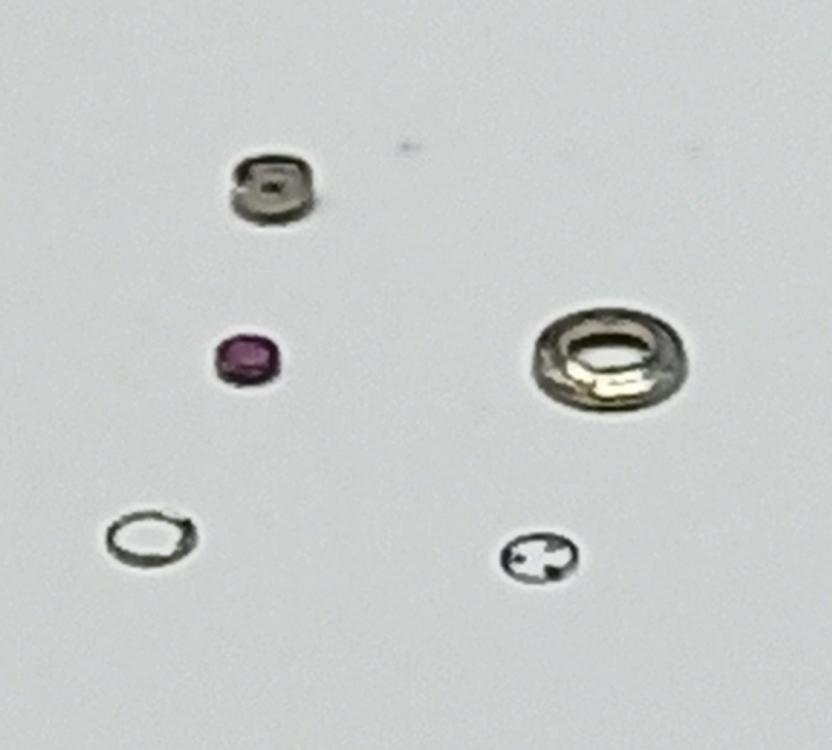

Can you get a clearer picture from directly above please. There are a few similar to this one with prongs. If they are sharp pointed then it's probably a Ruby Neutro Shock. They are quite common in a few Swiss movements, so as you can imagine this question pops up regularly. Last time it came up I decided to strip one down. I'll see if I can find the thread. https://www.watchrepairtalk.com/topic/28824-as2066-balance-staff-jewel-cap-spring-adjustment/?do=findComment&comment=2436481 point

-

1 point

-

@AndyGSi @mbwatchthank you for your help! I was able to get the case open and get the movement serial number. Can you please help decipher what all this means in layman’s terms? https://pocketwatchdatabase.com/search/result/waltham/184676391 point

-

1 point

-

Going back to the start, what's the watch and how's the spring damaged? The problem here is even the cheapest SP10 is probably more expensive than the watch itself.1 point

-

No need to apologise. We just need to understand the problem. I understand now @AndyGSi. Still doesn't help finding the right movement.1 point

-

If it's just the hands that don't fit the new movements then your best option is just to get new hands that will fit. As always it's best to post photos with your query as it makes things a lot clearer. Edit I've just realised that the day/date are hands (not numbers on dials) and as such your only option is to get a movement with then in the correct position to fit through the dial.1 point

-

Sorry confused now. The dial is held in place with dial feet, and yes, they have to be in the correct position. The hands fit onto various pivots, centre wheel etc. Does the dial not fit or the hands1 point

-

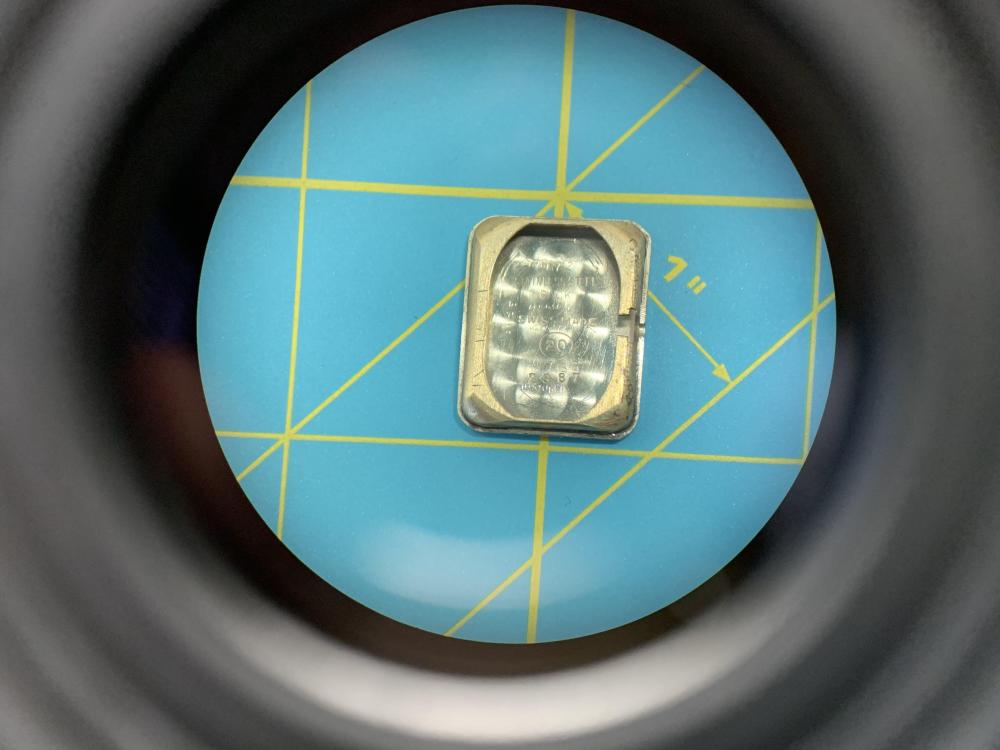

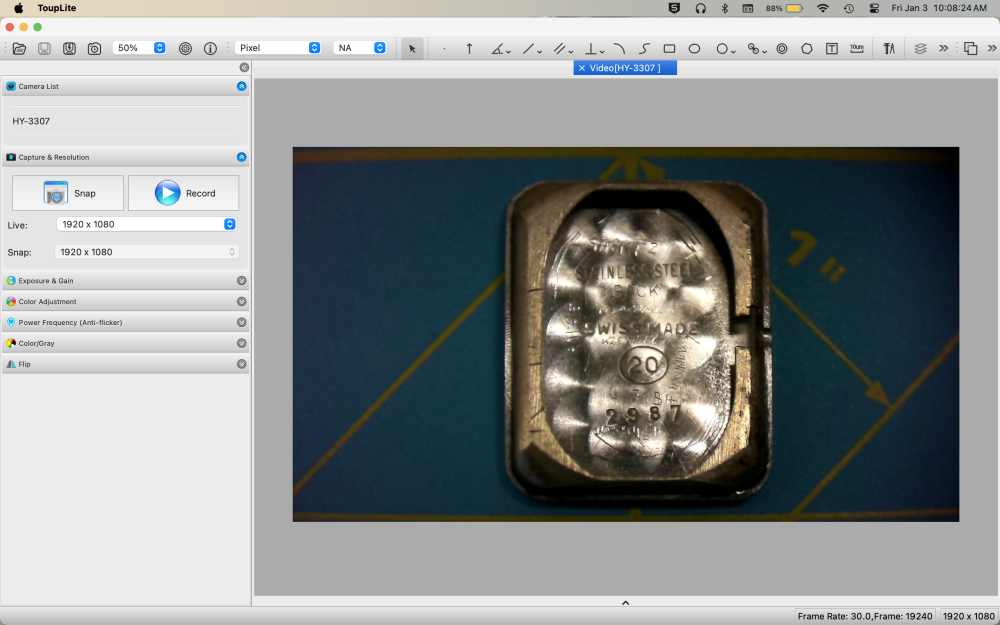

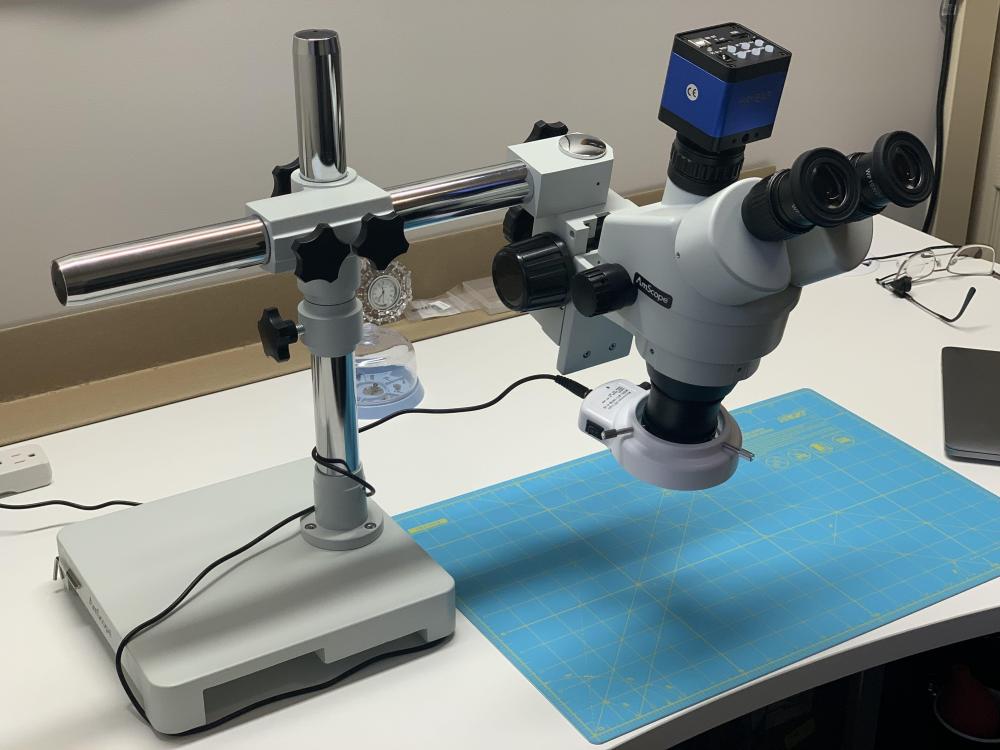

Back in this post, I promised a (brief!) review of the microscope I purchased from AmScope and camera from AliExpress. Brevity seems to have escaped me -- perhaps this was more complex than I thought! The AmScope order was placed on November 18, shipped the next day via FedEx International Economy, and delivered November 22. At US$120, shipping was expensive. But microscopes are heavy, and I wasn't up for the 10,000 km round trip to pick it up! And it got here pretty quick considering it travelled from the east coast of the United States to the west coast of Canada. Canadian federal and provincial taxes were collected by AmScope, so the order sailed through customs without delay. Everything was well packed and arrived undamaged. As expected, the camera from AliExpress took a little longer to arrive, but no complaints from me as I prioritized low cost vs. speed of delivery for this component. Ordered November 18 and delivered December 4 (still quick all things considered). The microscope was easy to assemble but took me a few rounds of trial and error to get it situated on my workbench 'just right.' I have the microscope head tilted back toward me on a 10° angle which seems just enough to allow me to control placement of screwdriver blades in screw slots. This means that the very top and bottom of my view are ever so slightly out of focus, but not enough to have an impact on any work I've been doing. So far I'm really impressed with the microscope. It is a huge ergonomic upgrade for my tired old body, and at least doubles my ability to do precision cleaning, inspection and lubrication. The ring light feels a little cheaper than the microscope (light weight plastic vs. heavy metal construction). But it does a good job and was inexpensive. It has a rheostat to adjust brightness which I really appreciate. I typically run it closer to it's lowest setting when zoomed out and on full brightness zoomed in. The power cord is unsightly but generally out of the way without much effort. There is a switch to turn the light on and off (separate from the rheostat) and a little green LED that lights up when the unit is connected to power. In my perfect world, the green LED would turn off when the light is switched off, but that is really more of an observation than complaint. The camera arrived after I was pretty familiar with the microscope, and I think that was beneficial to my learning curve. The microscope had a long adjustable tube with no optics that was to be used for mounting the camera. I didn't use that at all. Rather, I installed a 'Focus Adjustable 0.35X C-mount Adapter' between the camera and microscope. This alone did not provide enough adjustment to allow simultaneous focus of the camera and eyepieces, and I ended up adding a 2mm spacer between the camera and 0.35X adapter to get the camera focus synced with what I was viewing in the microscope. I wasn't sure what size spacer would work best with my setup, so I purchased four sizes: 1mm and 2mm spacers, and 5mm and 10mm threaded adapters. These all came from the same vendor on AliExpress (link below), and were so inexpensive that paying extra for the ability to have some trial and error flexibility worked well for me. Instructions with the HAYEAR camera were not great but enough to get going. There are basically two different ways to use the camera: First, I tried connecting camera with an HDMI cable to an external monitor. Works as advertised but I didn't like having a big LCD monitor on my workbench, and my HDMI cable is a bothersome brute that I also didn't like having around the workbench. When using this setup you need to power the camera with the supplied power adapter, and photos and videos could be captured to an SD card (not supplied) placed in the camera. There's a remote control (that didn't come with a battery, or even an indicator of what kind of batter was appropriate) that is used for taking pictures and such. I didn't like anything about this setup, but it did work. Second, I tried connecting camera to my MacBook Pro with the supplied USB cable. This eliminates the power adapter, the LCD monitor and the unwieldy HDMI cable from my workbench. Much better! Tricky part here was getting software on the computer that could capture photos and video. HEYEAR's website has software, but it is a bit hard to find and install, and didn't work well. I ended up downloading software called ToupLite from another microscope vendor. It is the software that HEYEAR's is based on, but with all the functionality I required working properly. I took some photos with my iPhone through the eyepiece of the microscope to compare what I see vs. what the camera sees. First two photos are with the microscope zoomed all the way out, first through the eyepiece then the HAYEAR camera: Next, zoomed all the way in: Here's a screenshot of the software: Here's a shot of the microscope in its working orientation: And swung out of the way: And finally, links for everything: AmScope SM-3TPX Simul-Focal Zoom Trinocular Stereo Microscope 3.5X-45X Magnification on Single Arm Boom Stand (includes 0.5X Barlow lens) AmScope 144 LED Intensity-adjustable Ring Light for Stereo Microscopes with White Housing HAYEAR HY-3307 Digital HDMI USB Microscope Camera 16MP 1080P HAYEAR 0.35X C-mount Adapter C-mount Spacers If you've stayed with me this far, thanks for reading! Let me know if you have any questions. Cheers!1 point

-

A man who makes no mistakes, makes nothing at all. I like the saying, if you try to do things sooner or later you will f&&k up. The only way to make no mistakes, is to do nothing.1 point

-

40 years of working in the construction industry you learn to improvise, make-do, use whatever you have and think on your feet. Construction involves the use of so many different materials, often its a case of which material suits the job best. I'm waiting for the day I can use concrete in a watch ...a dail maybe . Usually a quick look around your environment will provide your needs, 2 days ago I used one of my mother in- laws table placement mats as a white board to sketch an idea for a watch part graining technique for MB to look at. Much to her annoyance and to my joy .1 point

-

Thanks for your ideas! Have you got an old credit card that you can drill a hole into or push a pin through and drop the card over the cannon pin. Any card , library card supermarket clubcard etc. Gym card, building merchants card, costa coffee loyalty card, old man's drinking club card, casino member card night clubcard, pole dancing stripclub card, gentlemen's club card , Blue Oyster club card, Club Privė club card etc etc .1 point

-

Thanks everyone! The reason I showed the second video was so that you might be able to see that, because I suspected that was an issue BUT when I remove the balance cock screw it didnt seem to matter that the spring was resting on the arm. But you have now explained that let me try and address this and report back. Thanks again everyone!1 point

-

A lot of the old Russian watch movements had a shim under the balance cock, if that is missing you will have problems. I know the RAKETA 2609 had one.1 point

-

1 point

-

The primary reason I unloc the setting is to check the jewels for damage. So with the jewels in place, clean in ultrasonic machine, then if the oscilator is happy with the jewels ; ie oscilating freely for at least 30 second with a mild blow from puffer, call the jewels clean and undamged. This setting is no worse than rub-in ones, just as bad. Good luck.1 point

-

Pretty sure this is a swiss ruby neutro shock, your picture is not clear enough but there aren't many like this stupid design. Vibrax is another but the catalogue shows a steel cap. Ive stripped a similar one down which i think is from a citizen, japan also used some neutro shock types. Clipping off the stud holder releases the regulator arm then you can get in with a sharp blade to prise the setting out of the cock. This is about as far as you can go with disassembly unless you want to risk bending up the spring prongs . Getting them pressed back down tight over the cap will be near impossible. I thought the setting had a seam at the bottom end that might press apart, so i gave it a go . It came apart but nevet to be reassembled, split in half and from inside there is no seam so everything goes in from the front. Personally i would break it down to the setting and flush it out best you can then push oil in from the underside with a whisker. Of course yours may not be identical, so post more pictures as you strip it down.1 point

-

Yes, take the mainspring out, clean and lube. I've worked on about a dozen of these in the last 4 months--let me know if you need qny help. One thing to definitely look out for is play between the barrel arbor and the bridge--not correcting that will casue a significant loss of amplitude. Also, do you have any plans for the donor case? I'm in need of one for a movement I have. If so, PM me. Thanks1 point

-

Haha. I had just had the very bad news that my son is now not moving out this week, if at all. Its surprising i actually came back to post anything. The ver should have been "wtf do you mean you're not leaving now ".1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)