Leaderboard

Popular Content

Showing content with the highest reputation on 12/29/24 in all areas

-

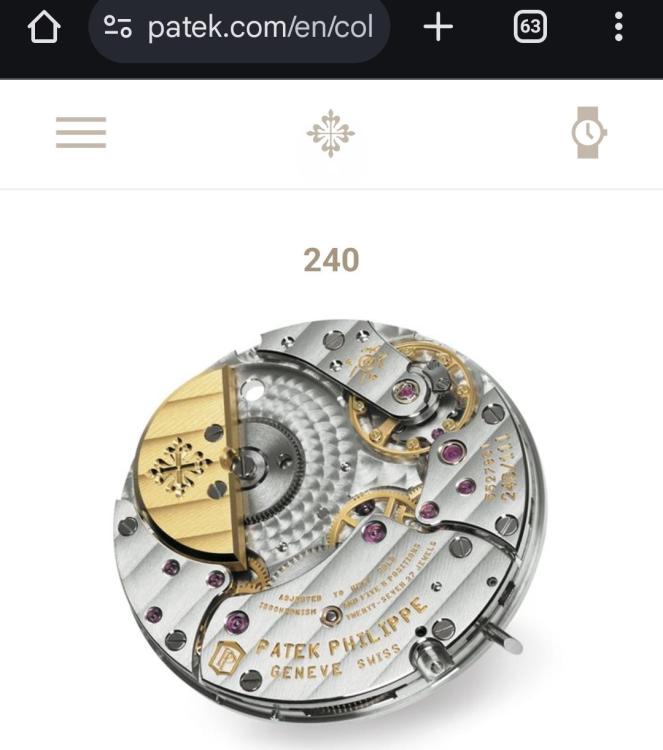

Hi everyone! I have something very special coming in. A Universal Genève micro-rotor movement from the early 1960s (well, with a watch around it, haha ). The movement is only 2.5mm thick and was for decades the second thinnest automatic movement (only surpassed by the Piaget 12P). Its movement engineer Gerard Berret, later joined Patek Philippe as the technical director behind the almost identical-looking and famous Patek cal 240 (which powered many references of the Nautilus and Golden Ellipse). Apparently, Universal Genève even sued Patek for patent infringement, but settled out of court.6 points

-

3 points

-

I see now - the crown and stem engage with the canon pinion through a different set of wheels than the gear train. So it’s possible for the hands to move when I use the crown and stem vs the gear train. The canon pinion does not easily slide over the pivot of the centre wheel - I need to push it and there is a perceptible click when it sits in place. So I assumed that it was a good fit. However after reading all your comments and watching the video it seems the symptoms I am experiencing are typical to a loose canon pinion (including a very easily moving hand when I use the crown and stem). So, I’ll try tightening a bit and rechecking. Thank you, as always! I’ll report back ASAP!3 points

-

3 points

-

I have to say that I nearly didn't post this: I felt embarrassed to have made such a blunder. But this forum is so supportive it felt safe to share, and it might save someone else from making the same dumb mistake. And if others have a chuckle at my expense ... I'll survive.3 points

-

2 points

-

I'm still unsure as to which term is which, the best I could find was that sunburst relates to dials and sunray is an engraving technique used on steel wheels Anyways nice to meet you Michael , tbh I much prefer using our real names or a form off, some I use first Initials after I discover their name in case they prefer to remain anonymous. Over time here many of us become what i would consider friends, colleagues in clockwork collaborations . I think I can put quite a few of us in that category. Which is nice to have that an extended framework of neutral friends. Rich. It was just a matter of time Michael before you gave in Harry ?2 points

-

2 points

-

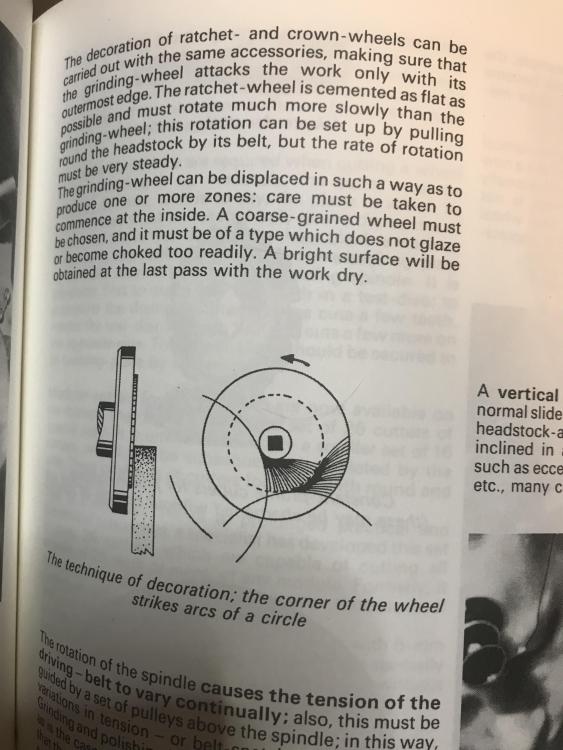

Ahhhh okay thanks for that. I knew snailing required two rotations, but was thinking that sunburst was done with a rotating part and radially moving, but not rotating abrasive. This method could produce nothing but circular graining, though when that is fine enough it does have a similar effect on reflecting light. My next challenge is getting the internet to agree on which finish type is "sunburst" and which type is "sunray". I think what I want for my ratchet wheel is "sunray" and my sketchy attempt produced something a little like sunburst (as found on dials). Here, it sounds like they're spinning a brass brush that rotates across the full diameter of a stationary dial for the conventional sunburst dial (though they call it sunray) - so both rotations in the brushing tool, part stays fixed. https://www.timeandwatches.com/p/dial-making-at-glashutte-original.html I spend enough time here now I can scale back the anonymity, and I have observed that real names are used pretty frequently. My name is Michael.2 points

-

Oh don't you worry about that Tom...I HAVE LOOKED...2 points

-

First focus on escape wheel jewel. First take a look at this video Of course, everything is possible without special tools here. But yes, replacing the setting for bushing with press-fit jewel is possible and is good option too. I will need better photo of the jewel hole now, as what I sow in the other thread is little bit frightening as the hole may be ruined already.2 points

-

2 points

-

2 points

-

2 points

-

Removing the shellac from just one side would probably be very difficult. Additionally, there's a significant risk that the pallet stone will come out of position. In practice, cleaning the entire pallet fork from shellac will likely be easier and better. After a hundred years, the shellac has probably become very brittle, so I would think it's an advantage to replace all of the shellac. It looks bent. In an ideal scenario, it would be soft enough to bend back to a straight position. See the example under the heading "Guard Pin" in the following post.2 points

-

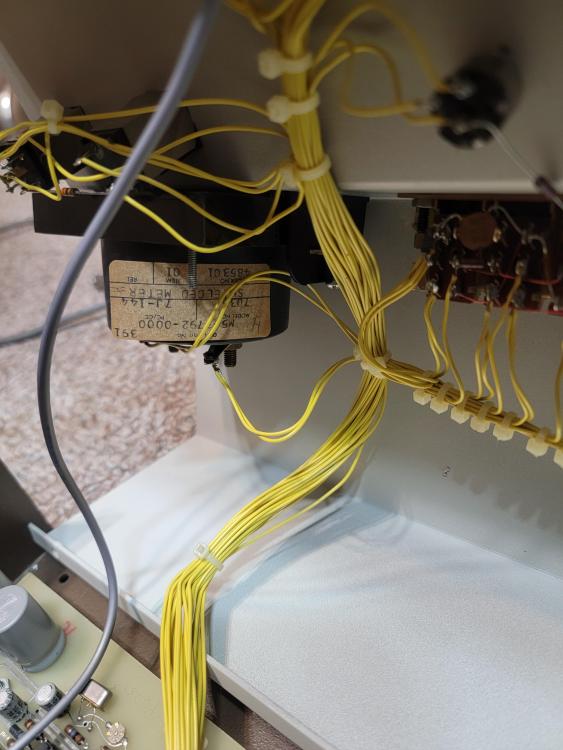

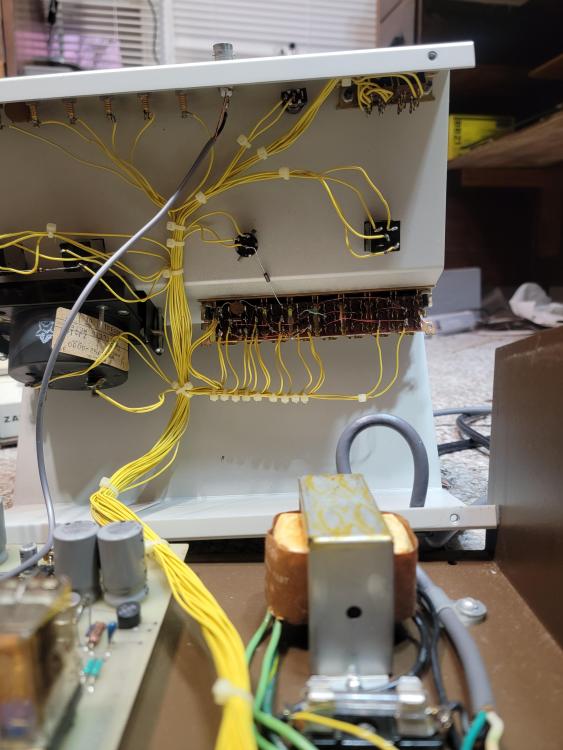

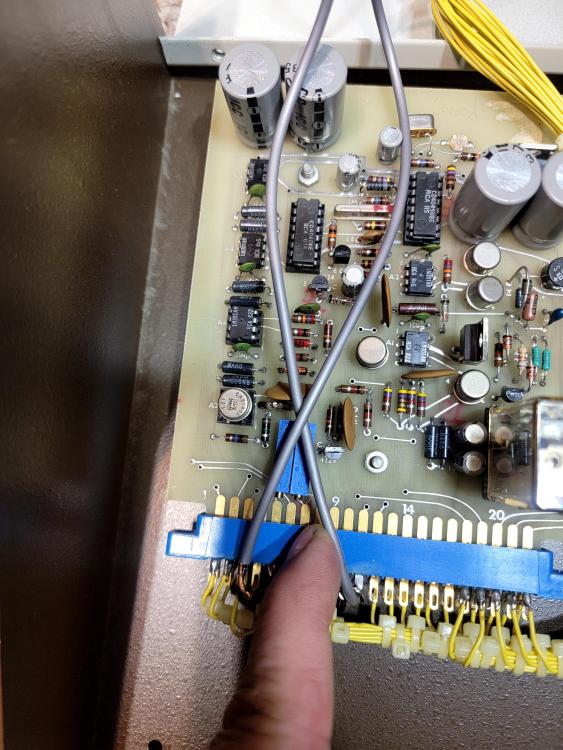

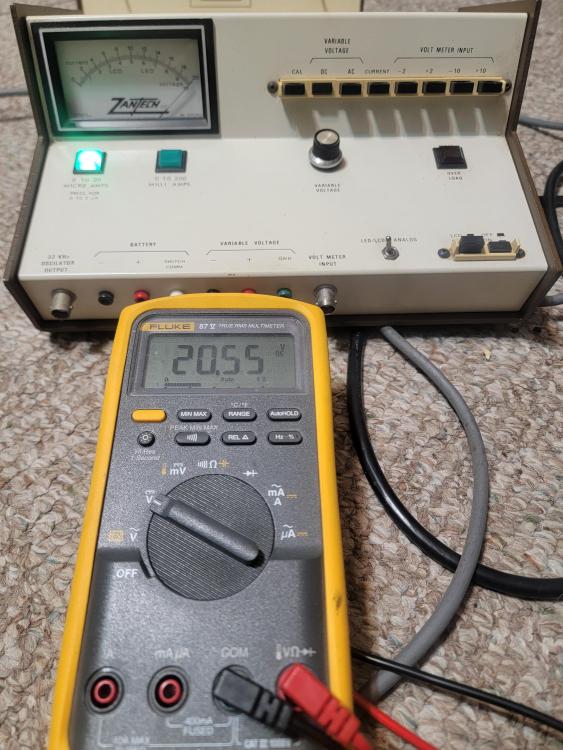

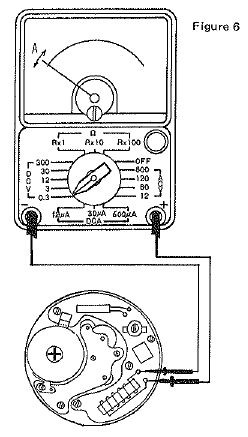

your video shows something very bizarre like what exactly are you trying to do? Are you trying to measure the resistance of an integrated circuit? I think I've seen this video before somebody else might have found it? Well I really can't say anything nice I definitely would not follow the testing procedure as it's a waste of time. a more appropriate test beautiful with the manufacturer recommends as opposed to this. it would help if you have the service guide I've attached. if you had all these quartz test equipment we could check for things like is the quartz crystal oscillating or we could measure current consumption but you lack all of them. We know from the service guy that this watch steps every 20 seconds. We also lack a lot of test points but you can't get to where the coil is in other words to test points in the power going to the coil as shown in the image I found online. if you take your analog meter and set it to the very lowest or most sensitive scale. Typically they'll either be the lowest voltage or the lowest micro amp and sometimes they'll be the same thing. Then with her probes like the image shows you hold the problems where the coil is and you wait. Ill have to wait at least 20 seconds and each time it steps if the circuit is working it will cause the needle to go in one direction than the next step will cause the needle to go in another direction. If that is occurring the circuit is working. 820p ebel cartier 81.pdf2 points

-

It is also worth getting an assortment of click springs from a material house, usually 100 springs for £2 or $4 AUD. if you don’t find the exact one you might be able to modify one that’s close. If all else fails you have springs to practice your tweezer technique that it really doesn’t matter if you ping them off into the watchmaker dimension. Tom2 points

-

2 points

-

Hello everyone! This is my first post here on WatchRepairTalk, and I wanted to share a project I've been working on—a DIY Watch Cleaning Machine that I designed and built myself. Since it's difficult to find a good-quality machine at a reasonable price, I decided to use my engineering skills and create one. Why not, right? Look at a demonstration video on my instagram page. You can follow this page if you are interested in my watchmaking journey! Demonstration video of Akrid the Watch Cleaning Machine I named this machine after my alias from the Dutch watch forum, Akrid (which is also my alias here). It features three stations: one for cleaning and two for rinsing. The final cycle is for drying the watch parts, allowing the movement to be reassembled immediately after the cleaning process. I've been using it for two months now, and it's been working flawlessly! The cleaning results are far superior to what I used to get with my ultrasonic cleaner. See the cleaning results here: Cleaning results of Akrid I'd love to hear your thoughts on the design!1 point

-

I believe I have this or a similar watch. On mine (1957 to your 1956) the tab that is supposed to slot into the cutout in the case is right above the 'O' in 'Bulova'. If it is in the same place on your watch then the tab has rotated out of the slot and is likely deformed and wedged against the caseback. That shouldn't stop the outer ring from rotating but sometimes on the Bulova's with these outer rings the two pieces can stick to one another so that when you turn the outer ring it wants to turn the caseback too which may be difficult with the wedged tab. Try and put pressure with your thumb on the caseback so that it doesn't rotate while you or someone else turns the outer ring CCW. Once you get it off when you go to put it back on keep a thumb on the caseback while you rotate the outer ring CW. If you do use one of the bench tools to do that you have to be careful not to put too much downward pressure on the outer ring or it will turn the caseback with it and crush the tab (ask me how I know). The same applies when taking it off in the future.1 point

-

Thanks. I did some googling and found this. At least that helps me understand the shape I need to make or the part I need to find: eBay has some options so at least I can get a replacement if I can source some wire. Shipping kills me to Australia. I measured the existing wire and it’s 0.32mm on the other springs. Luckily I can get 0.3mm music wire and it’s about 1/4 the price of the replacement part. So I’ll aim for that as a primary solution.1 point

-

Hello Micheal, bet you can't guess my name. Hehe.1 point

-

Absolutely! I'm planning to post a full walk-through when I service it in January (hopefully). I already know/assume that it has a loose cannon pinion (shout out to @SiZi) and running at pretty low amplitude (220°, dial up, fully wound). PS: If anyone has any service manuals or oiling chart, please share1 point

-

1 point

-

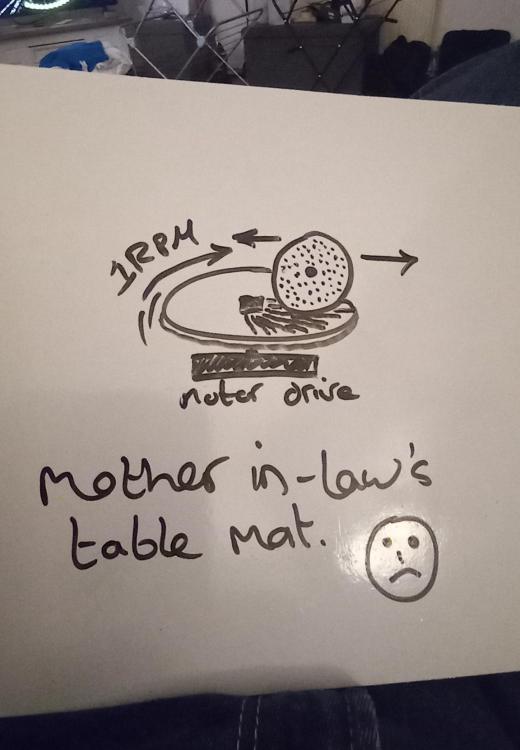

Lol anything that can quickly revolve a small grinding wheel or wire wheel to form the engraving or graining ie. Dremel. The ratchet wheel could be set into any kind of jig that you can turn by hand if necessary...1RPM is an approximate speed slow enough to keep the graining in a straight line radiating out from the center ie. sunray/sunburst...apparently there is a difference between those two graining effects. Just to clarify !....there are two rotations taking place...the ratchet wheel and the device forming the graining effect. The ratchet wheel's rotation must remain constant to maintain even graining across it. Bit more clarification as to whats going on....including my shitty evening1 point

-

Lol hitting with a hammer is the final emotion when nothing else works...even that isn't acceptable,because...well everything in watchmaking is useful...eventually . The most difficult job first which is the escapewheel jewel. If that cant be accomplished then all the other work is just an exercise.1 point

-

1 point

-

1 point

-

Found it and as it's got the wrong o-ring. I wouldn't be convinced it's original and think that's what the AF stands for but looks a decent aftermarket if it would accept the correct o-ring.1 point

-

Where in the world are you? Is there anyone close that maybe able to help.1 point

-

1 point

-

If you can't get it with a spring bar tool then you should be able to push it from the outside with a pin removal tool.1 point

-

you can see the springbar under the band end-piece, it is frozen, both sides should have the same hole, try the other side and or soak/tap....it looks to be a brass plated springier1 point

-

1 point

-

Hi. The regulator will pise off . I would remove the balance from the cock before attempting any work and if you decide to. Prise it off ,do it in a plastic bag to minimise the flyers. Attached some info on platform escapement repair David la bounty on platforms.pdf1 point

-

I couldn't care less about replacing a rubbed in jewel with a friction fit one but I know others may disagree.1 point

-

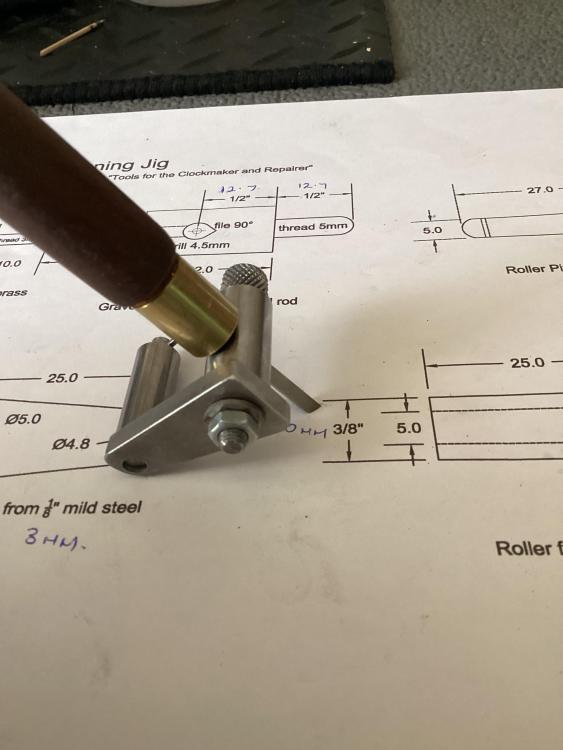

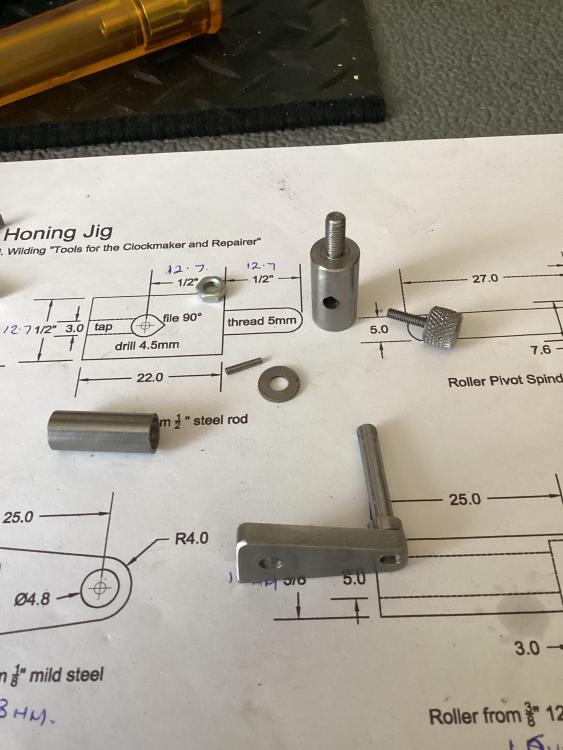

@tomh207 Thank you - the diagram adds crucial context to what was shown in the NOMOS finishing video. With the right tools this feels pretty achievable. (and yes you guys all got me lathe shopping now)1 point

-

@SiZi, it's pretty clear. Cannon pinion is too loose. A clear sign is: if you can turn the crown (in time setting position) without noticeable resistance (e.g. turning easily with one finger running along the crown), it's too loose. Find a replacement or tighten it (not too difficult).1 point

-

the problem is the back is held on with a threaded ring. The back itself is not meant to rotate typically it has a tab which drops into the slot to hold it in an exact location. If you attempt to rotate the center part you'll break that off with the bonus that it's not coming off because you have to unscrew the ring. with just a reminder the ring is not actually attached to the back it's just a locking ring. then a tool like this is always outstanding for stock case backs and/or rings that won't rotate. But just a reminder as they usually have adjustable jaws you only want to rotate the ring. In other words you only want to have your jaws pushing on the ring this would also include your hand wrenches just get something into the ring notches do not push on the back.1 point

-

1 point

-

For calibration you need guage blocks, which I believe can be more expensive than the micrometer.1 point

-

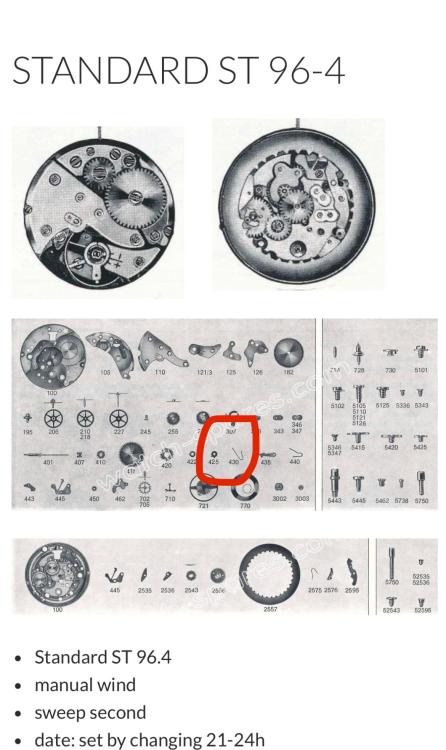

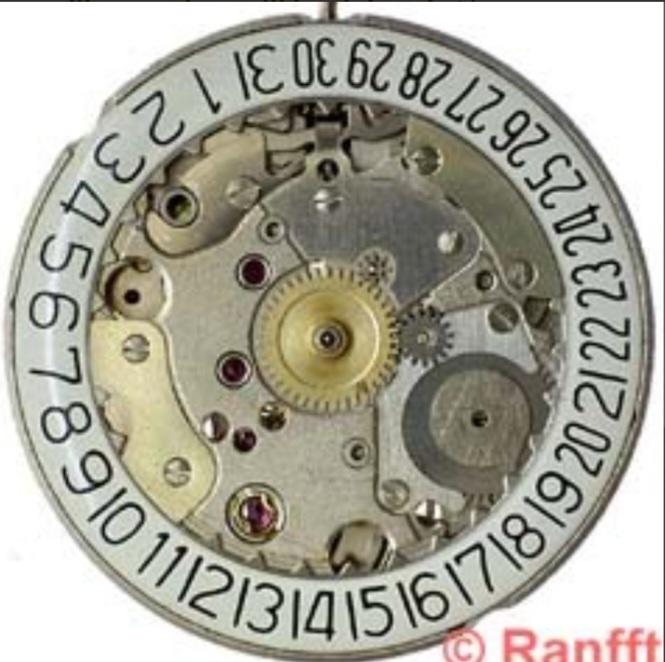

An open ended cannon pinion will nearly always indicate that the movement was designed for a sweep second hand, we are talking mostly wristwatch here and from a point in time when this design became the norm.Exception would be an incorrect cannon pinion fitted. The sweep hand can move independently of the minute and hour hand. Lets have a nice picture of the movement's dial side that provides a platform for folk to help from. What do we know about what the cannon pinion's function is ? To my mind it provides a way to tranfer what the center wheel is doing and convey that to us in an easy visual way, by movement of the minute hand.1 point

-

1 point

-

1 point

-

Running for a hour is good, can't be anything major wrong with the movement but just replacing the mainspring is a mistake. It almost certainly needs a service, replacing the mainspring alone will cause excessive wear on numerous pivots.1 point

-

I went on to buy some conductive tape which was said to be conductive on the adhesive side too. I cut as thin a sliver as could but when I first applied it I couldn't get connectivity. I put the pcb to one side while I researched a smaller soldering iron than the one I had thinking I'd try the technique you mention using perhaps a piece of coil wire. However, when I dug the pcb out recently I found that the break was mended - maybe the adhesive had solidified &/or I'd applied enough pressure with my Multimeter probe to complete the circuit. I half expected that the fix would fail as I re-assembled the watch but to my surprise it began ticking as soon as I inserted the battery keeping good time. The person whose watch it is was delighted when I phoned with the good news as it had some sentimental value. She sent a gratifying message in a thank you card plus a (unsolicited) contribution to my 'Tool Fund'!1 point

-

Not generally, but if the bone mass is so weak that a screw won't bite on occasion we do augment the fix with bone cement.1 point

-

1 point

-

Rather often I find a crack in the tube (on vintage). Those cannot be tightened, hand or tube must be changed then. Frank1 point

-

Just bought another Longines (a 1958 30LS). I'm a big fan of older Longines, especially of the '30' series with the big balance. (There's a thread on here where someone wanted an accurate movement and @nickelsilver mentioned the 30 series Longines). A few months ago I got a 30L (sub second). Spent a while on dynamic timing and got it running nicely. I wound it each morning and wore it for a week (including two round of golf, which is challenging for any watch). Checked it three times a day and it was never more than 4s out, and after a week it was within 2s. This is a 30LS, same as 30L but with a sweep second (the only other in the family is the 302, which is a 30L with adjustable stud carrier, and the mythical 30Z, a movement specifically designed for the Swiss observatory chronometer competitions. If only I could find one). A bit of a polish and new crystal, and it should look nice.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)