Leaderboard

Popular Content

Showing content with the highest reputation on 11/07/24 in all areas

-

4 points

-

3 points

-

That's most probably the glycol ethers. Perhaps I should add "accidentally stripping the paint from the bonnet of your classic car" to the list in the above disclaimer.3 points

-

In the spirit of the general destruction of perfectly good time pieces that this thread embodies, I would like to point out that DOT5 brake fluid is mainly silicone oil with a few herbs and spices for rust inhibition and improved lubrication. Make of that what you will. A note of caution for anybody daft enough to be interested in this observation, DOT3, DOT4 and DOT5.1 brake fluids probably would not be suitable for this game, as they contain glycol ethers, and may well dissolve some plastics. Always check the label before filling your perfectly serviceable watch with bizarre fluids. I take absolutely no responsibility whatsoever for anybody dissolving their watch/arm/cat/beloved family member when conducting said experiments.3 points

-

So for anyone who is remotely interested in how my Slava 2428 power reserve test went, the results are in. It actually performed far better than I was expecting, the stated power reserve for this movement is 47 hours, my watch achieved 40 hours and 20 minutes. I don't think that's too bad considering the mainsprings are very probably the original from manufacturer. As previously stated, I had my doubts to the results being great as winding is very easy all the way to the stop, not like some movements where you dont even try to get to the stop, you feel that much tension you just think no, that's enough. But I do have a few watches with this movement so I compared the winding, and they are all the same, wind easily to the stop. So perhaps that's another benefit of the twin smaller barrels, and if you then consider the automatic version of this movement, would it be easier going on the auto works? Well as it's now run down, it can have a rest. Recently I repaired and serviced this early Accurist quartz which uses the 7 jewel ESA 9632 movement. I replaced the quartz oscillator and with it's new battery has been running well, so this can have the rest of the week getting worn. Time keeping is excellent, I use a radio controlled clock to set watches, and this is still to the second from when it was repaired.3 points

-

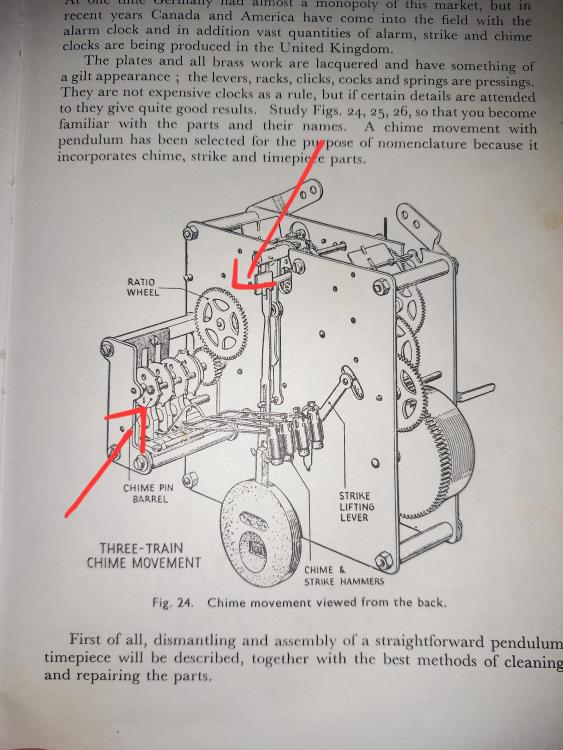

Hi there. If I have misunderstood, please ignore my response. When the second hammer stops, is that on a particular quarter? If that is the hammer next to the lowest note then it should sound last on the half-past and the o'clock (I think - have been humming it in my head). If you nudge the chime pin barrel and it behaves again, it could be that you need to reset the position of the barrel. The reason it stops 'up' and doesn't go again is perhaps because there just isn't enough power to budge it when it tries to move again (it needs to gain momentum to get going and being stuck, it doesn't get the chance). I have attached a diagram that might help. What I would do is loosen the ratio wheel, that will free the chime pin barrel, then move the barrel round in its direction of travel (clockwise) a small way (one tooth). Then retighten the ratio wheel. It should then play and clear the last hammer. I'm sure there will be lots of help with this.2 points

-

2 points

-

Not sure what it brings to the table in this particular case, but the linked thread created by @Jon contains one of the most appreciated posts on WRT:2 points

-

Hi guys, I wrote this lesson for my second students to understand the theoretical aspects of the Swiss lever escapement in conjunction with the practical application of end-shake and setting jewels using a jewelling tool. Both Seitz and Horia-type jewelling tools were used. Although I talk about measurements using the settings on the side of the jewelling tools, it is more about what 'feels' right, especailly when gauging the end-shake of a particular component, such as the balance, pallet and escape wheel. Ideally, you wouldn't start by adjusting the end shake of the balance to suit your needs, but if the IncaBloc setting has been replaced or the Inca setting has been moved to replace the shockproof spring, then it is important to set the end-shake correctly. This presentation also looks at how to set the correct end-shake of the pallet in relation to the balance safety roller as well as other critical measurements, including the height of the escape wheel teeth hitting the impulse face of the pallet fork in both dial-up and dial down positions. The escape wheel and pallet have to have the exact same end-shake as each other for this reason. Unfortunately, the slides that contain videos can't be played as I converted the PowerPoint into PDF. I have used some diagrams from a WOSTEP handout on this subject, to show the vital measurement of the escapement in relation to the balance safety roller, so all credit goes to the author of that hand-out, which has been posted several times on this forum. All the students that set all the jewels after removing them and the balance end-shake to its optimum got a watch movement working with much improved amplitude than when they started. All ten jewels in the wheel train were removed as well as both IncaBloc settings. Another lesson was created just about the balance setting and disassembly and assembly of the EtaChron balance system which included removing a replacing that Inca setting. I haven't included that lesson. Not every aspect of this work is within the presentation, as it would be very long otherwise. I talk a lot and explain more as the lesson proceeds. This lesson was held over six to seven hours. If anyone is interested in learning more on this subject, please message me. Lesson 16. Balance endshake & Incabloc adjustment.pdf Lesson 16. Balance endshake & Incabloc adjustment.pdf2 points

-

1 point

-

A mainspring is determined by 3 sizes only: width, thickness, length. If you need to push it directly into the barrel and lack a winder: diameter If your watch needs a special end other than the usual bridle: type of bridle. I wonder why people still use such rubbish like Dennison sizes today . Frank1 point

-

1 point

-

1 point

-

Managed to pick the number out from the dial and yes it's a 6139-8002 Dial and the Speed-Timer has faded. Case isn't from a 6139-8050 either so don't be surprised if the movement isn't even a 6139. I don't know where in the world you are or where you bought it from but it's what I'd call an Indian Special1 point

-

It can be caused by many things, but don't assume how you found the settings is how it is meant to be. If there is too much end-shake of the balance, look at the safety roller and see if the guard pin is in direct line with that safety roller in both DU and DD and that the impulse jewel isn't too deep or shallow into the notch in DU and DD. The end-shake of the balance should be about the same as the pallet fork for the reason I just said and the escape wheel should be the same end-shake of the pallet fork so the escape wheel will hit the same point (Middle to top 3/4) the impulse face of the pallet stone in either DU or DD. Once you understand these basic parameters you have to adhere to it will be a lot easier to alleviate the problem. By what you have said and let's presume the balance staff is the correct size, I would first ensure the IncBloc setting on the balance is seated properly and that there isn't any 'birds feet' under the balance cock or that it has been bent to increase the end-shake of the balance. Once you know that is right, I would move the IncaBloc setting in the mainplate towards the balance to decrease the end-shake of the balance, but be very careful when fitting the cock after doing this just in case the shake is now too little and you crack a cap jewel doing up the cock. Once the end-shake feels better check the guard pin is in line with the safety roller in DU and DD. You may then want to adjust the shake of the pallet to suit the balance now and then the escape wheel in turn Don't assume that any of the end-shakes of the escape wheel, pallet fork or balance is correct to begin with1 point

-

I just want to add to this topic, in case anyone else searches this, that making a burnisher is incredibly easy. You can take a cheaper file or a HSS lathe tool blank, and flatten it with a stone, then as Dell mentions, you draw file it with emery, or in my case a ruby stone at 3K grit. I was against spending the ridiculous money that they ask for burnishers and just made my own. They are very cheap to make and very effective. Make sure you harden them after, or you will score the burnisher with a hardened balance staff.1 point

-

Ah sorry I assumed this was already known. It can be the last 5 too, for the later manual movements 104,105,106 that show up in the later 1970's.1 point

-

I don't know where to find a UK 1972 catalog; the dial does not match any of the 1972 Marlins in this US catalog but Timex sprinkled their dial designs over a lot of years https://heritage1854.com/1972-catalog-reference.1 point

-

1 point

-

1 point

-

It strips car body paint beautifully, so if you have a particularly awkward vehical driver that insists on causing obstructions down your street ie.parking in front of or extremely close to driveways making exits and entrances difficult and the said driver pays no attention to polite requests to ease that situation then test its alternate use ( under the cover of darkness ). Just a suggestion not a practice ahem. At least they use silicone oil not mineral oil1 point

-

It's these kinds of jokes that make me wake up with a scream in the middle of the night Seriously, oiling a watch is an art form. Filling it with oil is nothing but an abomination. OK, I will never buy a Bell & Ross. I would never take the risk of degrading my brand name for a few extra bucks.1 point

-

Your presumptions are both correct, but to both are non classical solutions . Epilame the lubed end stone, so oil stays on dome top. Flipping end stones Usually leaves it loose inside the setting housing, you can streighten the shock spring , even bend it , usually minimal bending would suffice, way before reaching the springs fatigue threshold. This trick is an alternative approach for repairers who don't have a staking set, yet unskilled to restaff a balance wheel or build and poise balance completes or can not find or make a balance staff. Mostly for beginners/ hobbyist. I doubt if its thaught in any class or mentioned in any watchrepair book, however, worth knowing when it works & you get ten more years out of the old balance staff. Rgds1 point

-

1 point

-

People that have lathes make all sorts of things with projects we all do it and I expect this is one. What has been said I agree.1 point

-

Most tailstock tools are used for support or drilling applications . Certainly looks to me like its for supporting a workpiece. Looks watchmaker made rather than factory made. Is it a tapered fit ? You know I'm gonna ask to see your new lathe caseback1 point

-

I haven't followed the discussion in detail, but I'm thinking that you must try to locate the source(s) of the problem. If the problem is that the barrels aren't clean enough that's what you need to do, but I would say that is the least likely source of your problem. Analyse the watch in function groups as show by Kalle Slaap.1 point

-

1 point

-

Remove the fork, put balance & cock assembly back on mainplate, if the balance oscilates freely in both DU & DD position, pivot is not short, adjust balance settings. In case balance doesn't oscilate freely in DU position, pivot on cock side is short, in which case good repair is to replace the balance staff. If its incabloc you can flip the end stone in the setting upside down, so its dome side faces the short pivot. Which is not good watch repair, but works. This test should be done before re-asembly. When you have only balance&cock assembly on mainplate, you have clear all around access to balance complete. Rgds1 point

-

The balance staff is 2.75mm long. Where can I see what is should be? Ranfft has a couple of staffs listed on this page. This is one of them and it is the same length as the one I have1 point

-

Measure the length of the balance staff, it looks suspicious. And not like a Incabloc staff.1 point

-

I was working on a Seiko Kinetic the other day. It hadn't been oil-filled, but it wasn't far off! There was oil everywhere, on the dial, even under the rotating bezel. The movement was junk, replaced with a new one.1 point

-

Unless silicone oil has a very different composition to silicone grease then your first comment is incorrect . And mineral oil (petroleum based) absolutely will react with a rubber gasket. Hopefully the gaskets are from vulcanised rubber....but maybe not. I use silicone grease with all rubber seals in plumbing applications. Mineral oil will degrade some rubbers and some plastics over time. Might take a few years but it will happen. I have visions now of everyone that has mineral oil filled a water resistant battery watch....quickly emptying out the fluid Pretty sure you were never in H . Sounds like a cool idea... I'll try it on my past father's first digital watch , its about 50 years old, then I'll chuck it in the bin when half the insides turn into black goo Which creates more idiots that watch em OH1 point

-

1 point

-

Back to basics Glen......function groups.....if you suspect the balance has the problem....then just install the balance, inspect and work that area.1 point

-

Yes check the jewels can the caps. I agree the staff looks good. It is good practise to remove the balance complete first and put it in a safe place and under cover, before you start on the rest1 point

-

As already mentioned. The minute hand is either loose a or catching the crystal , you will have to remove the movement to check and tightened if loose1 point

-

Hi, pictures would always give a more helpful response. Assuming that as a 'big tick' there is no second hand, so it may be possible the minute hand is not seated correctly and making contact with the inside side of the crystal for the first half hour.1 point

-

Actually, as the wheel is big, it is possible to repivot it without special tools. Just good hand drill needed and proper drill bit of the correct size, close to the pivot size. If needed, I will explain how and show some pictures. Well, this statement brought all of us to delusion. It appears now that the train was blocked by the wheel with broken pivot1 point

-

There is a 1940 parts catalog viewable via this page, though it's not downloadable and a real pain to read.. https://pocketwatchdatabase.com/reference/catalogs I found an alternate link with direct access to each section, this is the Automobile & 8 day link: https://pocketwatchdatabase.com/guide/company/waltham/catalogs/waltham-watch-co-material-catalog-1940/40 So, looking up the part number of the third wheel in that online link - it is listed in the 1911 catalog that only shows movements up to 1907... If you search through it, there are dozens of entries for the 8 day 37s! See the "Wheels" section on page 19 onward of the PDF - the first entry for each type.1 point

-

I take the ideas and 3D print a box to put everything together. The tricky part is the probe with spring loaded tip and articulated arm. It turns out to be quite versatile. The unit is powered by three 18650 battery to get at least 10 volts for the LED volt meter. There are still some minor things to optimize, but I am happy with the initial result.1 point

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)