Leaderboard

Popular Content

Showing content with the highest reputation on 10/30/24 in Posts

-

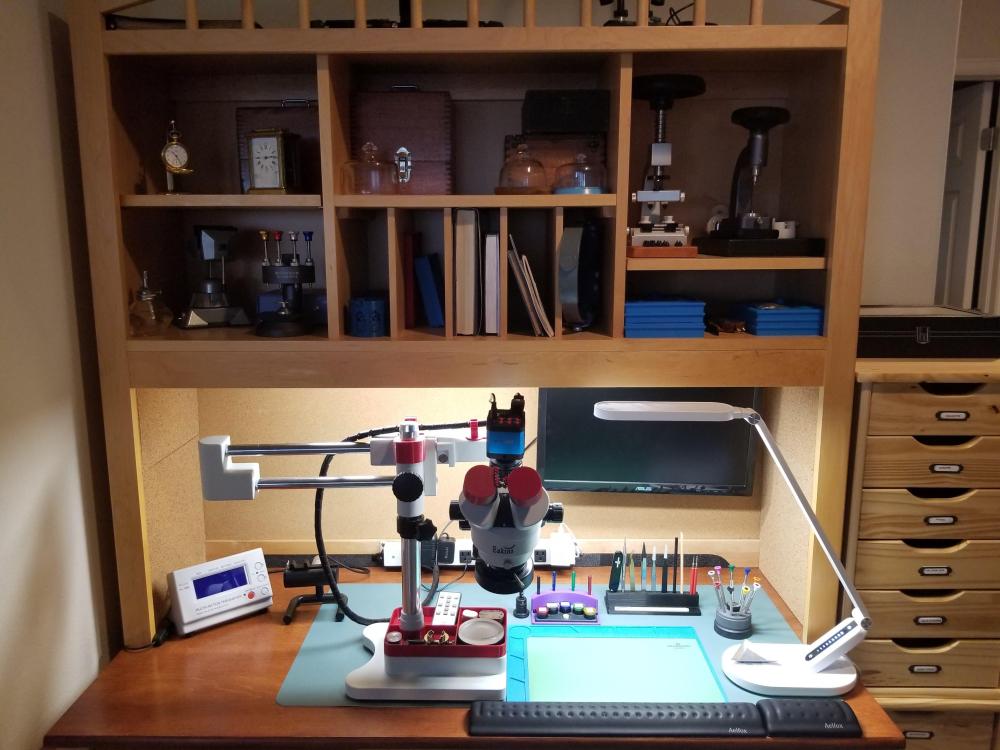

My setup has continued to evolve. Not ideal, I know, but it works well for the tight real estate that I have. Added an optical microscope. Takes up a lot of space, but so much nicer than using a loupe or magnifying visor. Better on my back, for sure. Added two sets of drawers for projects, parts and tools. Keeps me better organized. I now use the desk drawers for tools and supplies that I more commonly need. The hutch and drawer units are handy to store all of the tools that I have been acquiring. The computer wrist rests help corral parts. I plugged up the gap between the hutch and desk with some foam, where some parts liked flying to. I also added some cork board to the sides of the hutch for a bit of parts ping abatement. There's only one part (a screw) that pinged away that I haven't been able to find, even with the big magnet wand that I keep off to the left of the desk. Lighting is still something that I want a better solution for. The microscope gets in the way of a portable desk light. I did buy a unit with two adjustable lights for the times that the microscope ring light provides too much glare for photography, but it's awkward to use and isn't as bright as I'd like. I keep my ultrasonic cleaner and watch cleaning machine down in my basement.4 points

-

4 points

-

A Vostok (1975 inscription on the back) with 2209 inside, a nice gentle dial patina, Cyrillic printing, perfect hands and numerals. I did the restoration about 18 months ago but the 2nd wheel hand setting friction was too low and it would occasionally lose a minute on the wrist. I didn't have the confidence or time between projects to pull the part out and tighten it until yesterday, thinking I didn't have the right tools to separate the friction pinion from the 2nd wheel. Of course I had them. 10min job and now it's perfect. It runs +2/260/0.0 on the original spiral mainspring.3 points

-

That's a great looking watch. Maybe this forum wasn't such a good idea for me, I'm now on the lookout for a Longines and a Caravelle .... I want one, 70s watches that can be used as a bludgeon are right up my street. Got some time to kill here at work, it's got busy, that means quiet for me, so whilst I wait for things to quieten down a bit, and provide some light reading whilst you're killing time reading through the posts, I'll share what I'm sporting on my wrist this morning. Well it should be the Timex, it's time isn't up yet, but I've had to call in a substitute. The watch is doing really well and time keeping spot on, but I just wasn't diggin the strap, it was busy digging into me, so it's sat on the side forming the strap around some pipe lagging. So I thought I'd go back to where it all started for me with mechanical watches. This Orient chronoace with the 21 jewel 42940 movement. Probably not the wisest choice for a first movement, but it was available, came with a lot of digitals. This movement was rusty! If I ever come by a watch as bad as this was again, it won't be getting sorted, I'll be looking for a donor. But as a keen new starter, soldiered on, slowly assembled as replacement components arrived, and eventually ended up with a working watch, I was pleased. I should probably strip and service again now that I've got a lot more experience under my belt, but it's running fine. It did dawn on me though whilst I was getting this up and running again that it's never had a ride on the timegrapher. Amplitude was ok, just ok, running way too fast, throttled down accordingly and the beat error 0.1! I can only assume that was good before the rust set in and miraculously I didn't mess it up. The rust damage had creeped around onto the dial, clearly visible are the areas that I learned that watch dials don't like being cleaned. My first success, I wear with pride.3 points

-

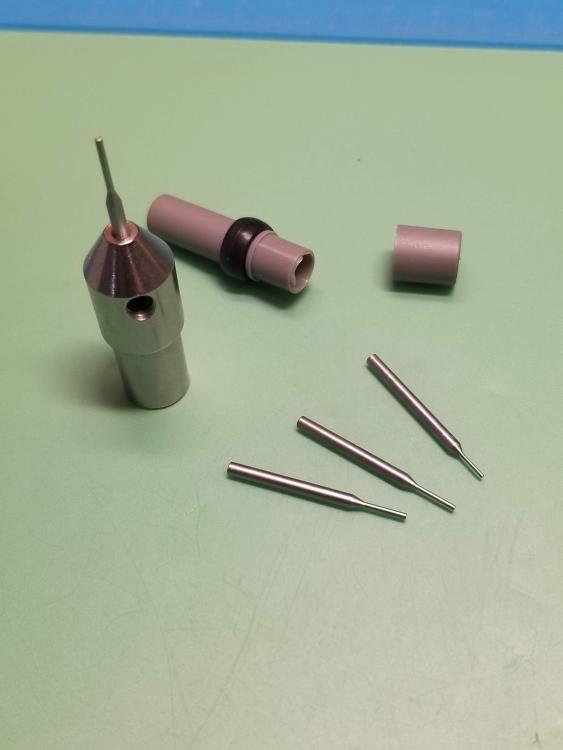

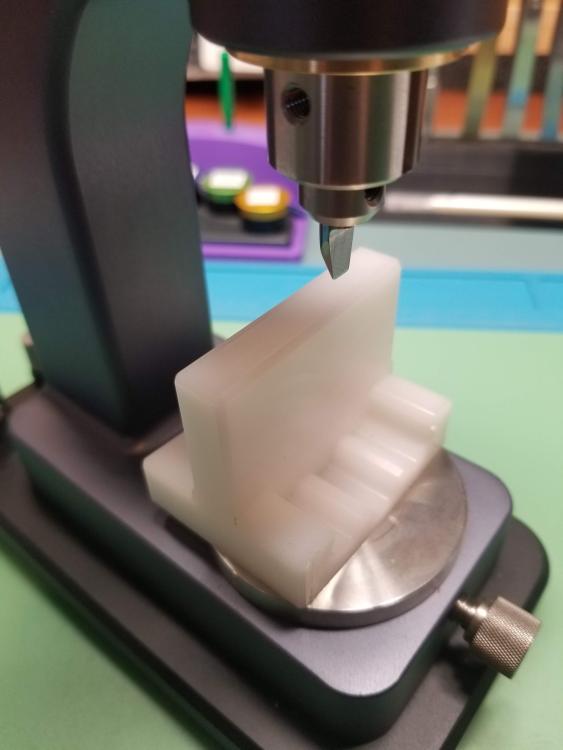

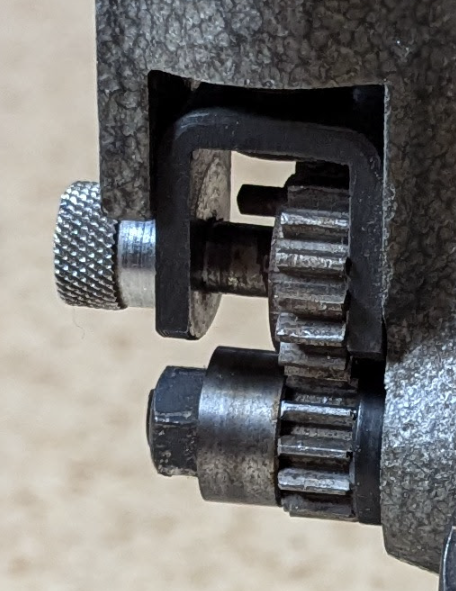

I think my journey for a good crystal press is over. I just got the press shown below and am liking it so far. Far better than the other two cheaper Chinese ones that I have tried. It is solidly built. Can also be used to open snap on casebacks and adjusting metal band links, so it is a 3-in-1 tool. I had the problem opening up a Waltham wristwatch with a caseback knife and this opened it up no problem. What I don't like about it is that you need an Allen wrench to change out the upper bit. Maybe I can change out that grub screw for a knurled head screw. Also, the handle turns opposite of what I expected. Counter-clockwise to lower and clockwise to raise. I'll get used to it. It did not come with the crystal press dies, but those are pretty inexpensive to get a set of nylon or aluminum ones. https://www.aliexpress.us/item/3256806922669039.html Started with one like this. Ended up getting it for free, as I had to repair it. https://www.aliexpress.us/item/3256806885195604.html Then tried this one. Was certainly better than the first, but sold it when I thought that I was getting a vintage Robur press (press only) that ended up getting lost in the mail. https://www.aliexpress.us/item/3256805690261587.html As a crystal press: As a caseback opener: To adjust watch band links: Bit storage:2 points

-

I'll see what I can do with generic first. Cousins don't have them so it looks like it would be buying from eBay in the US. Some corrosion on the battery terminal, and the battery doesn't stay in place. I'm not sure what to do about that. Adjust the positive terminal somehow? The PO had a piece of tape over it to hold it in place.2 points

-

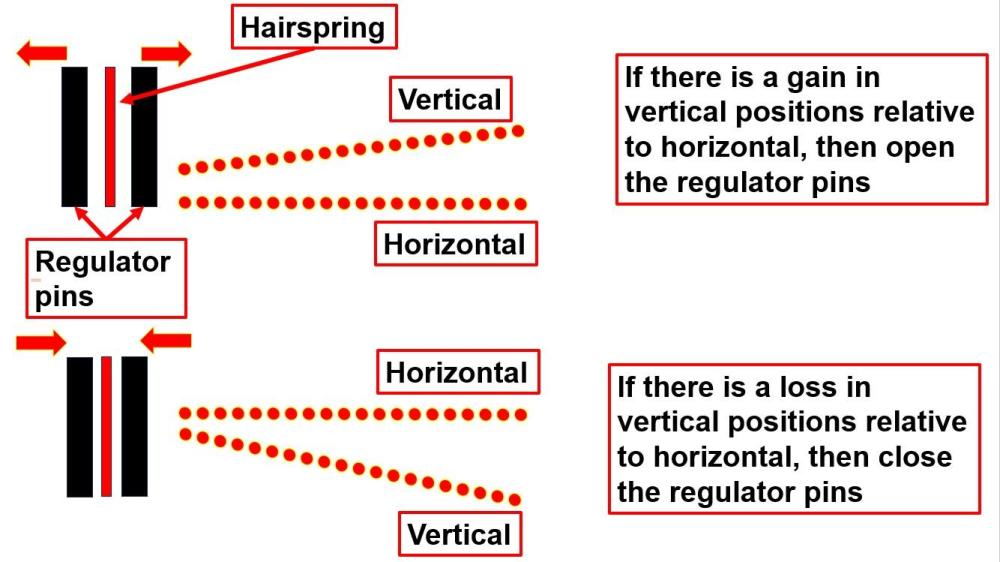

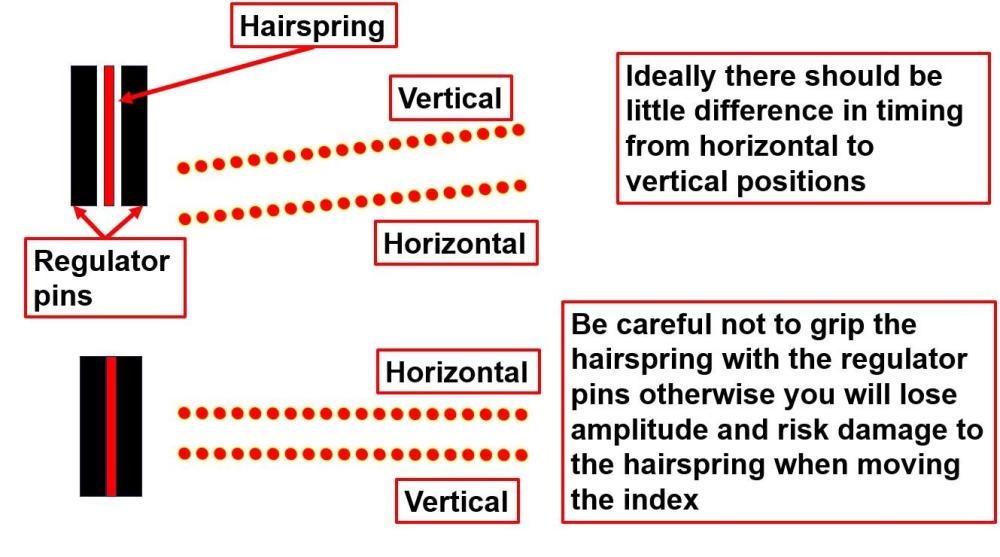

Turning the boot will not help. You need to bend the pin towards the boot. This doesn't mean that the pin will not be parallel to the boot any more - You can bend the pin more where it gets out of the regulator and bend it back little bit further, so it will be closer and the same time parallel. But being 'parallel' or not doesn't matter any more if there will be no free play of the hairspring. Closing the gap will make slight change in rate - the movement will start working a little faster. It will affect the vertical positions more than horizontal positions, so this is the effect needed.2 points

-

2 points

-

So the house we live in has a dedicated spa room. (as in the water filled one) Liz and I hardly use used it and it has been empty for a while now as the circulation pump shaft seal died and all the water that was meant to be inside the spa decided it would be better off being adventurous on the outside of the spa. So out with a bit of garden hose and siphoned it all out. We have also bought ourselves a very nice free standing induction stove and oven. The catch with it is that it needs a 40A supply. The spa was 32A so the sparkle is going to disconnect the spa completely, upgrade the circuit breaker in the board inside the house. I am not sure if this will also involve upgrading the external board as well. New wiring has to be run to the stove. Not the easiest of jobs in a 2 storey house. We have some things in our favour so we will see how we go. The upside is that we have a friend who wants a spa so I'll be getting a new pump, fitting that and then selling the spa on. So now I will have an empty room with a very handy door to the house which has a much higher than usual door handle. Pool rules. So that will keep out nosy grandchildren unless Poppy is with them. It will be turned into a watch and clock workshop and I will be moving all of my gear from a dusty garage into a lockable, closed part of the house. Wife's idea. Go figure. I'm quite chuffed about it, to be honest.1 point

-

Pretty new to watchmaking and am keen to learn. I live in Northern Essex in the UK. I used to do woodworking and leatherwork as hobbies but for various reasons no longer do so. I'm looking to get up to speed as a hobby with a view to perhaps earning an income from it in the future.1 point

-

That became evident on the day i joined Richard1 point

-

I've been working on getting myself a workbench put together. The kitchen island was not going to cut it for the long term. Seeing as I wanted to save as much money for tools as I could, I wanted to do save some bucks on the watch bench. I took a 2nd hand desk that I got for cheap, refinished the desk top, installed a LED light bar, added a power strip, and created some storage in the otherwise useless keyboard tray pullout. The hutch is good to store some tools and accessories. I've got a couple of drawers to store parts, supplies, and project watches. I put a chair pad down over the carpet, to hopefully keep some flying parts out of the carpet. Hadn't used this much yet, but so far it seems like it will work. Eventually, I would like to add a binocular microscope to the mix.1 point

-

Hello , good evening and welcome. What bit have you only just figured out ?1 point

-

1 point

-

1 point

-

1 point

-

Lesson 33. ETA 955.422 Assembly.pdf You might find this lesson I wrote helpful. Unfortunately, I converted it into a PDF to post so it won't show the video of fitting the keyless work. Here's a link to my cloud storage where you'll find the PowerPoint presentation https://docs.google.com/presentation/d/1_OPys8CnqdprxOvnHL2QTTFR802jjFW1/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true It won't be there for long, so download it to refer back to1 point

-

I agree with Nev. Make sure that the regulator pins aren't touching the hairspring when it is at rest. Move it through the entire range of adjustment to check it.1 point

-

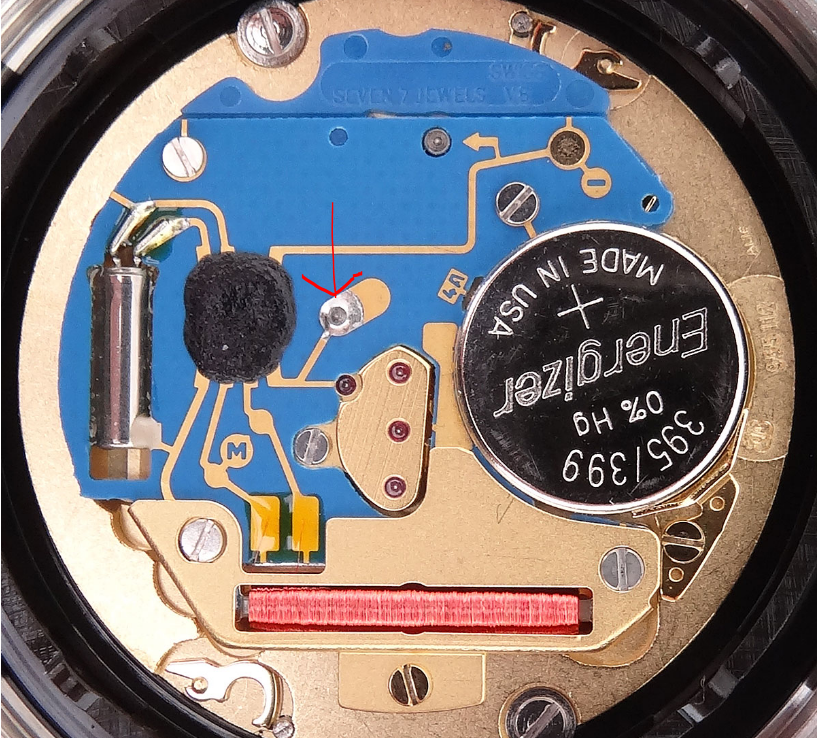

I just serviced a few of these movements. I honestly would remove all of the keyless works and start again. In my experience, trying to finagle and move spring loaded parts usually takes more time than just starting over. you can use rodico on the on the movement side to hold the setting lever pin in, but it usually isn't necessary. A side note on this movement, one I recently serviced would not pulse or run, but when removing the circuit and coil from the plate, those would generate a pulse. This pin on the underside was grounding out on the plate below, so I had to file a bit away to stop that. Something I hadn't come across before.1 point

-

I suppose you could try replacing it? the positive terminal does appear to be listed as a replaceable components if you can find one anywhere in the universe will it does seem to cross reference to quite a few things. Then we are searching for parts it does appear to be your missing a plate screw. Otherwise you could try gently bending it hopefully it won't break.1 point

-

1 point

-

too much honor, Nev! On those good photos even a watchmaking mole would have seen the issue Frank1 point

-

Hi, pictures would always give a more helpful response. Assuming that as a 'big tick' there is no second hand, so it may be possible the minute hand is not seated correctly and making contact with the inside side of the crystal for the first half hour.1 point

-

Certainly not. If it's running you will be able to keep it ticking. Problems to watch for are degraded or no shellac on the pallet stones, same with the roller jewel or broken roller jewel. If it already ticks, a clean and reassemble will make it run a little better. But these movements are really capable of running very well even if they had few factory adjustments and you can acquire a lot of interesting tools in pursuit of top performance. If it was your first ever attempt I would say put it aside but you sound like you have enough experience.1 point

-

Here’s a video of it all put back together. It’s been running like this for the past 15min, fully wound up. I’ll check in every few hours. But hopefully this is it… I am receiving a weishi 1000 in a few weeks and I’ll do a check on it at that time. But for now, I’m just glad it’s working. Being my first repair, this watch taught me many things: 1. How to tighten a canon pinion, and then loosen an overly tightened one! 2. How to find spare parts for a discontinued movement 3. how to adjust the position of the stud on the balance so it lines up with the pallet and escape wheel pivots 4. How important it is to use correct vocabulary and I now have a great glossary bookmarked for reference 5. how to test different works while reassembling step by step 6. it helped me build up significant fine motor skills because the movement is minuscule and I had to take it apart and put it back atleast 15 times! Thank you to everyone from the community here, for your help across multiple boards on this forum. This repair has given me so much learning and confidence that I repaired another watch - Omega Deville from the ‘70s - while I was working on this one! I am well on my way to adding watch servicing and repair to my list of hobbies/interests now. thank you! I just might be back with more questions if the watch stops or the Timegrapher tells me I’m waaaay off1 point

-

1 point

-

1 point

-

1 point

-

I expect you'll need something thinner than a case knife, possibly a stanley knife, but you need to be careful not to damage it or yourself. Photos of the bezel would help confirm this as there may even be a gap to start the process. This is a Rotary I'm currently working on that has a chamfer opposite the crown.1 point

-

Yes the later you go the more machines came in to do the work. They were all checked and finished by hand a sort of quality control and they took pride in there work. Unlike today most couldn't give a hoot as long as they get paid.1 point

-

I was more meaning the pinions OH, surely would they have been cut from standard stock...starting from circa ? I also thought that Rob and pinion profiles must have been standardised at some point in time. Its the pinion thats broken Cyclops1 point

-

Part number 28172 found me a set of wheels on ebay! Now I wait for delivery and will update the forum once I plug in the new wheel. I will try to buy this one if my wheel purchase does not work out. Escapement parts look good and it is indeed th same model - 1910.1 point

-

Looks worth the gamble. Looking forward to seeing what you got. Here's my latest gamble. A Lonville pocket watch in a gunmetal case. I too have absolutely no idea what lies inside. Possibly a Langendorf. Possibly a 7 jewel cylinder movement. Possibly a small lump of coal inside and a note to Santa Clause. Time will tell. Lonville watches seem to still be around (or perhaps they have been brought back to life). https://lonville.com/1 point

-

Hi John, Actually, if the stud stays firmly in the stud carrier, there is no mater that it is not perfectly upright. The important thing here is to align the hairspring to be centered and parallel to the balance. This is done by bending and twisting the spring right where it comes out of the stud. If You expect that making the spring parallel will improve significantly any 'fluctuations', then You probably will be disappointed. If the spring now doesn't touch anything in all positions of the balance wheel when it turns, then no reason to expect improvement from the un-skewing itself. It will just make 'touching' less probable, and the spring will look more hansom.1 point

-

Make an ultrasonic lid to hold your solution containers....it gets them out of the mesh basket and floating in the bath.....the cavitations dont need to wriggle their way through it. This little set up is great if you just want to quick clean half a dozen or so parts . Beans tins with cousins plastic and mesh basket for full movement cleans the over motor slowly rotates anything from one revolution to around 20 per minute. Yaa I've considered the marine ply will probably deteriorate in time with condensation over the water tank, i thought about yacht varnishing it......I mean boats last for a long...... long time in water . But then i realised that I really could not be arsed, when the ply is dead I'll make another lid from pvc.1 point

-

Tempting, but based on prior experience I would avoid it. When I was starting out, I bought the red aluminum crystal screw press for $35 less than the typical price. It arrived incorrectly assembled and was generally a QA disaster. Now I assume any alix seller with a too good to be true price on a tool probably has a batch of faulty ones or factory rejects they want to unload. With some research and perseverance, and replacement hardware, I eventually got my crystal press to work correctly.1 point

-

Yes, it is a detecting issue. Cause: the machine misses the 1st (too) small impulse of the tic noise. It uses the next pulse in the noise as start. Because amplitude is calculated from the time interval 1st to last pulse of the noise, this is too short and so amplitude too high (as explained several times before ) Frank1 point

-

1 point

-

1 point

-

Well. Like me, you've begun. Information from a beginner What ever you do, don't begin on a watch you or your bride own and treasure. Go to a boot fair and get some old watches for a few pound. They might or might not work. Doesn't matter. Exactly as Mark says. Look and practice, then practice, practice and then, practice some more. Do each stage systematically. Open then close, do it again a few times. Next stage, depending on the watch. Take it out of the case. Put it back in, take it out, put it back. Show your bride what you can do. Get encouragement. What ever you do, don't take a watch fully apart. You will not remember where anything goes, you will be heavy handed and break a pivot. Oh yes you will. Been there, worn that T shirt. I still have 3 watches that I need parts for, and cannot be obtained. If only I knew what I knew now, or be a gentle as I am now. 2 were heirlooms so to speak. So upset with myself. Could I do them now? Oh yes. Hope this helps.1 point

-

I can’t recall where I saw or the precise turn of phrase, something about the watchmaker must decide if they are the type to break their pivots efficiently and economically with tweezers or if they prefer the expense and precision of breaking them slowly with the Seitz tool…1 point

-

Most were bought already labelled. The stems and staffs i have that are unknown i measure them with a bench micrometer and check them with staff and stem lists. Balancestaff.com have a huge database of staffs and stems. After much practice it now takes around a minute to measure them and can take up to 5 minutes to find a calibre match on the data base. The stems require taking 6 dimensions and the staffs 5. The unknowns are like treasure hunting, interesting when i find something high end. Have recently pulled out VC, Blancpain, omega, Patek. My reason for aquiring large amounts of staff stock as most watches i was buying needed a replacement. I didnt want to be in a position of searching buying and waitng separately.1 point

-

My mentor just seals the part with a slip of paper with the description in a plastic bag. He has a sealer that seals and cuts at the same time. Then puts the little bag in small plastic boxes. Everything is labelled and organized. While me, I keep turning the house upside down looking for things that I know I have, and end up finding things that I don't remember having. Then I get distracted and forget what I was looking for. Anyone else like me, raise your hand.1 point

-

I think all of us start with a nice and neat bench. Then things have a tendency to creep out of the drawers and scatter themselves all over the table. Perhaps it's the gnomes and elves hiding under the table that are responsible. So, having more legroom means more room for elves and gnomes to hide.1 point