Leaderboard

Popular Content

Showing content with the highest reputation on 04/25/23 in all areas

-

as this is an automatic the spring's bridle is designed to slide around the barrel wall with the help of a special grease before the springs tension becomes too tight. Without this the autoworks would be constantly trying to wind the spring most likely resulting in a breakage.4 points

-

Nothing today but i made a stupid mistake on my last service that i shouldn't be making after servicing 5 7s26 seiko movements and not even needing instructions to assemble and disassemble them, but here i am telling you about it. I had it all put together and went to double check the date function and when i turned the crown to check that the date rolled over correctly i felt a snap and the date did not roll over. I had put the damn thing together without one of the arms from the date jumper wheel on top of the date jumper plate and snapped it off breaking the wheel. Thank god i got a drawer full of parts for these things so I swapped it out and reassembled it correctly and smacked myself upside the head.3 points

-

Only cost £5. I'll do a full service. Do a practice on a one jewelled watch. Yes, that's right One. Remove the spring barrel lid. 'Ping'. Spring is attached to lid. Oh heck. I'll put it back in. Great, all done. What! the centre is now too big to fit on the spigot. Take it out. I know, I'll tighten the centre the way I was told. Use fork pliers and apply gently pressure to the centre. That's almost to the right size.. Ouch. Kink in the spring just before the spigot hole. Bummer! Gently move it back. 'Snap'. Didn't want to fix it anyway!!2 points

-

Hello everyone and hope you all doing well. I've always been a tinkerer and love exploring how things work. I'm hoping to dip my toes in the waters of watch service and repair. I have a small mechanical watch collection and my goal is to get to a point where I'm comfortable being able to service them. This is a hobby I've thought about often and was finally motivated to pursue after being laid up with a cold last week and binge watching some Wristwatch Revival on youtube. Motivated! I'm currently in the process of collecting some tools to get started and have picked up two ebay specials to attempt/pratice disassembly and reassembly. The first is an Elgin Shockmaster that I actually quite like the style of and would love to get up and running again. The second is a Windsor with a badly cracked crystal, missing seconds hand, and case in overall rough shape. This one already has me stumped on how to remove the movement from the case back. It seams like the movement should drop out the front but I'm not certain what is retaining the movement at this point. Looking forward to the journey, thanks in advance for you patience and assistance!1 point

-

I won what looked like a fair condition Zodiac Sea Wolf on the bay. It arrived quickly and at first glance looked half decent. The lume had gone from the hands but it was ticking, which was a plus point compared to some other recent eBay purchases. Then I opened it up. The watch could have applied for membership of OPEC there was that much oil in the movement. It was everywhere, apart from some areas it should have been. Second observation was that the previous person who worked on this used a variety of small chisels and other assorted sharp implements to "service" the movement. Turning to the dial side, there were a couple of screws missing and some obviously put back in the wrong place, plus the hands must have been removed by Edward Scissorhands, going by the marks on the dial. It was also running like a dog; +280 seconds a day, 150 amplitude and a beat error above 9. So, two weeks of stripping, cleaning, ordering missing bits, installing the correct crystal, re-luming the hands, sympathetically restoring the bezel and it's back in operation. I also had to recreate a new seconds hand as the old one resembled a hockey stick that had been left out in a hailstorm. Whilst the amplitude is now up to 280 and the rate is +- 5 seconds, I'm still not happy with the beat error which is sitting around 2.5 - 3 so more work to do. A word of warning for anyone looking to buy a beater of this movement, Zodiac 70-72, to fix up. The parts are rarer than rocking horse droppings and quite pricey when available. The mainspring barrel is sealed, and I mean sealed. A replacement is around $140. Same for the balance. However, this movement was a collaboration with Zodiac, Favre-Leuba, Girard Perregaux, Doxa and Eberhard. I managed to find a Favre Leuba movement that was a lot cheaper than the Zodiac and the parts were fully interchangeable. On the plus side, this is my wife's favourite watch so I'm sure she won't mind me finding another few to fix up.1 point

-

Welcome - good to see you jumping in at the deep end!1 point

-

As long as you have the special grease, breaking grease, orange goop, black goop, any colour goop that is designed for that specific purpose. Did we mention the grease ?1 point

-

Already on the way. Well done. Welcome. Good people here.1 point

-

1 point

-

Just need to remember to use breaking grease on the wall of the barrel to ensure that it can slip freely when it needs to. The correct grease which is different from the regular grease you grease the mainspring with. Breaking grease holds the spring so you can wind the watch (if it slipped early you could never get a full wind) but then lets it slip so that the automatic works can still spin even when the watch is fully wound - amazing stuff that orange goop!1 point

-

That's an Olympus SZ series scope, an excellent microscope! It is trinocular, but you have to pull a rod out to engage the 3rd eyepiece (where you might want to fit a camera), which blocks the left eyepiece. That one is fitted with 20x eyepieces which are really too strong for watch work, 10x is standard and gives a good range of magnification. Eyepieces are found easily and reasonably on Ebay. Working distance is about 75mm, not the longest, but similar to other high end scopes; I have this one, and a Nikon SMZ-1B and AO 570, those are maybe 1cm longer- but optically they are all on the same level. Definitely worth getting. http://www.alanwood.net/downloads/olympus-sz-iii-sz-tr-brochure.pdf1 point

-

1 point

-

Are you saying I'm a dodgy antique dealer You could age it with tea but on card I don't think I would want to, on the other hand I have found this. https://www.google.com/search?q=how+do+you+age+whit+card+to+look+old&rlz=1C1GCEA_enGB908GB908&oq=how+do+you+age+whit+card+to+look+old+&aqs=chrome..69i57j33i10i160l5.23968j0j15&sourceid=chrome&ie=UTF-8#fpstate=ive&vld=cid:1092a78e,vid:YP_VQ4xVQyc,st:211 point

-

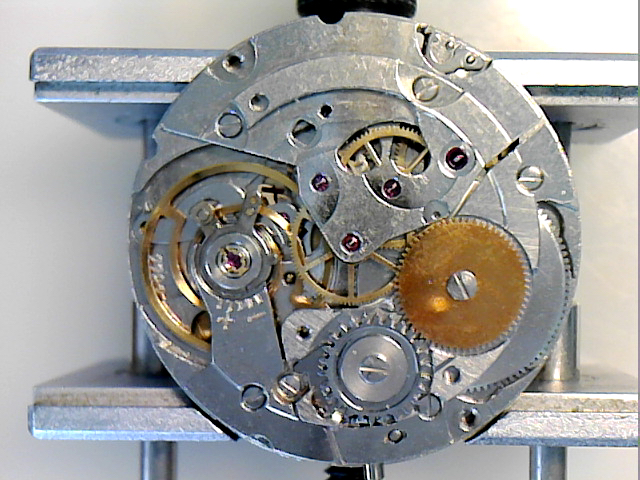

in a watch repair discussion group we really like to see pictures of the movement. Even pictures of the movement filled with oil are really nice to see. I found the picture of the 72 looks like floating stud which means adjusting the beat shouldn't be an issue? http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Zodiac_721 point

-

it probably depends upon who is making up the assortment and where did it come from. At work when we were purchasing parts from somewhere the boss purchased an assortment of crowns and when they came there basically all the exact same thing. The definition of assortment seem to be lacking. On the other hand some watchmaker once gave us a bunch of stuff in one of the containers is an assortment of brand new American pocket watch staffs. I really would've liked of known where that came from and get a lot more of them. Because basically every single staff was new and they're all usable. Yes you had to physically look and see what you're looking for some of them were easy to spot like some of the Waltham's because their friction staff's. Or I think I used up all the Hamilton 992B staffs they were very easy to spot. So extremely interesting use will assortment from some place in the past. So conceivably there are other useful assortments out there but often times they end up being not useful as they just don't have the right sizes or whatever it is you're trying to find.1 point

-

1 point

-

The trouble is a new dial will stick out like a sore thumb. As the old saying goes the customer is always right. Here is a link for Waterbury clock dials. https://www.ronellclock.com/product/waterbury-trademark-paper-clock-dial-4-1-2-to-11/1 point

-

The only problem with bulk sets is the accumulation of bits that will never used as they are generic as a rule, I have one or two I poke about in but never seem to have what I want, gaskets , crowns, stems, click springs. Etc.1 point

-

My luck on sourcing crystals so far is not great on my first try. While I got one that fit a watch, it isn't of the same profile. I could live with it, but likely I'll just order another crystal. For another watch, I managed to order an armored crystal instead of a regular one. Besides, the ring is the wrong color for the watch. I have that same press. Mine had a binding issue and minor alignment issue. I had to tear it down to fix these. With these cheap options, you may need to do some work on them to get them to work as expected. It's worked fine for the couple of times that I needed it so far.1 point

-

Update no.2 and last on this topic Cousins has refunded my empty order, as the claim was accepted by Royal Mail. I had to chase the claim with Cousins, but otherwise all was smooth. I will continue to order from them, for sure.1 point

-

1 point

-

I had a Vulcain 120 running nicely again and I was finishing up the alarm side, down to the last screw- that one with the big head that holds the pusher thingie down. You know, I’m told I’m supposed to make the screws in the Cricket tight so the alarm vibration doesn’t loosen them…well, snapping the off the last screw in the movement isn’t a good idea, either. I’ve since improved my efficiency by striving to get to my foul ups sooner in assembly… One other fun one- I pinged off a click spring a few months ago. I have video showing my stick laying over it but it still managed to fly away. I searched and searched- magnet, flood light, but never found it… This week I did some cleanup and had to move my power strip. Funny thing- it somehow developed a faint little rattle, like a tiny metal part is floating around…could the spring have somehow managed to fly inside? I go fetch a Phillips head to take the power strip apart only to discover it has some kind of odd, Bat-signal shaped screw head slots. Now I have to either find that kind screwdriver or break the thing open…1 point

-

Most memorable, as in sick to the stomach painful, forgetting to let down a mainspring. Just judging by frequency of the spinning wheels, it sounded about the same frequency as a turbocharger spun up. It was a scrap movement, now in the recycle bin, but part of the process is doing everything like it's the real deal. Scrap or not.1 point

-

1 point

-

Similar principle to the tool that kalle uses. Like an auto punch, you push the blade against the case back or bezel as it reaches its tension point it releases and fires the blade forward. I wouldnt trust myself with it. I prefer the slowly slowly catch your monkey approach. I also have the same devise that mike uses, in fact it was mike that inspired me to try it. I dont often use it, not that it doesn't work , i just rarely need anything besides a knife.1 point