Leaderboard

Popular Content

Showing content with the highest reputation on 02/13/23 in all areas

-

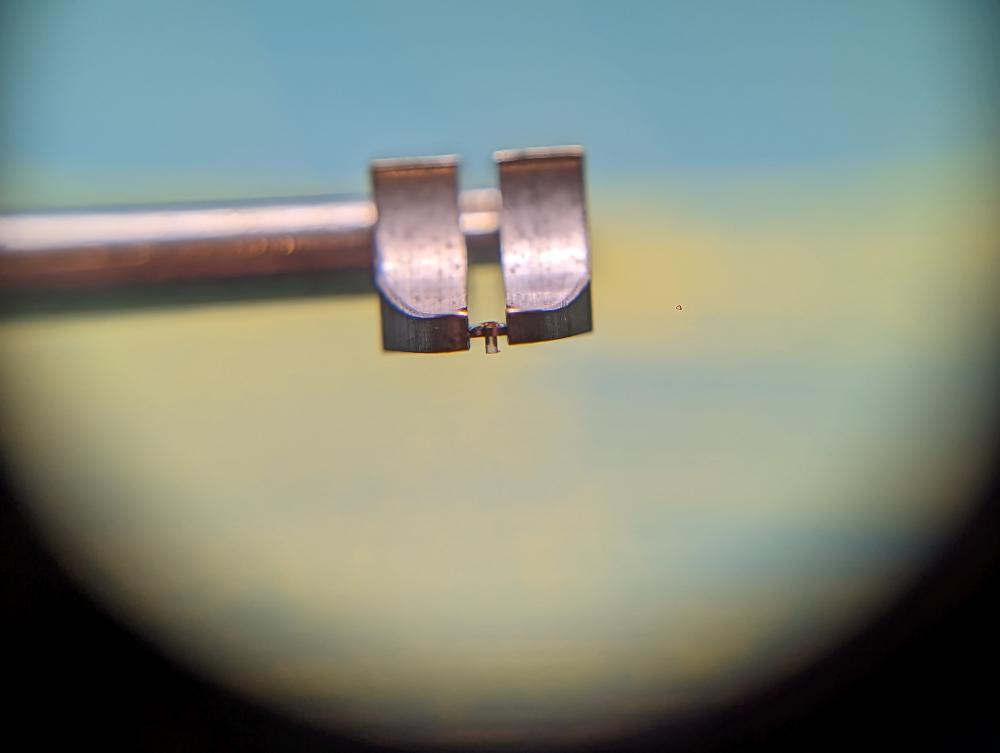

I am beaming with pride that as a novice who still can't help constantly shooting cap jewels or diafix springs out of tweezers into oblivion, I just succeeded in installing a new roller jewel for an Elgin 6s pocket watch. I don't yet have my staking set to finish reinstalling the roller table, but one thing at a time.3 points

-

2 points

-

As I was just casually browsing "Swedish eBay" (tradera.com) I found this machine with 3 minutes remaining on the auction and the following description from the seller: "A powerful demagnetizer from Swiss Greiner. Works when checked, demagnetizes and the light flashes. Crack in the cover lower right. New price today at Cousinsuk is £885." Indeed, when checked, the price of Cousins was £885, and as my Elma Antimag doesn't seem to work all that well with larger magnetized objects such as screwdrivers and hand levers I placed a bid and won it for £115! Not bad if it works as intended. Now my question is if there's some easy and convenient way to test that it really works. I'm sure I could figure out something for myself (and I have an Indian hand lever that I've been unable to demagnetize with my Elma), but any tips/ideas would be welcome!1 point

-

I'm sure everyone knows what a rolling ball clock is but just in case somebody new it's nice to give a picture of it because they're rather interesting devices.1 point

-

1 point

-

The one on my wrist right now came from Ali express, it was a dial, hands, case, bracelet combo for about $40aud. It's actually okay but the bracelet is a bit cheap, bending at the end links. Otherwise you might be able to get a nice original case from speedtimerkollektion.com I'd be happy to hear of anyone else has a line on some good 7009a cases. So you're saying watchmaking... takes time?1 point

-

My name is Ernie. I work as a building inspector in Seattle. I have a background it many, many, many skills. Blacksmith, welding, knifemaker, gunsmith, machinist, jeweler, glassblower, potter, foundry, carpenter, leather work, metal spinning....... Lots and lots of skills. Started watching Marshal's videos on youtube as Wristwatch Revival. I remembered I had a pocket watch that had been broken for years, and would love to make it live again Started acquiring tools and stuff, then bought a bunch of broken movements off eBay and began tearing things apart. The broken watch I have had all this time is a Hamilton 975 I got for my High School graduation back it '83. Chose it because of the lovely movement. It got broken because I carried it in college and had a bad habit of catching the chain on things like lathe crossfeed handles. I began this adventure winter of '22 and have dubbed it my winter hobby. I think I have around 30 Hamilton movements now, and a smattering of others. Definitely staying with pocket watches. I did manage to fix my Hamilton 975, and also a larger 18s Hamilton. Eventually I need to start casing the ones that work and kicking them back to eBay. I have a long standing habit of not waiting for tools to become available and I just make them. So far for watchmaking I have made a size 12 mainspring winder, a staking tool, and an oiler caddy. You can check out my Flickr gallery to see all the silly things I build. https://www.flickr.com/photos/129065511@N02/albums I truly love fixing and building tools.1 point

-

1 point

-

Fortunately I bought a load of restore/repair movements, because I've already lost 2 diashock springs. One literally disappeared from the safe spot I had it sitting, and the other disappeared through a wormhole when it launched itself off the movemement. Otherwise I've successfully removed/reset these (diashock) springs easily a dozen times now with the tweezer method. I'm still waiting on a new MS for this project. Considering how much I paid for the thing I would hope it's here pretty soon. I'd like to be wearing this watch by the weekend. I'm also waiting on GS Hypo so I can fit some glass and complete a couple other rebuilds too, but I don't think I'll see that for another month. Honestly, waiting for parts/materials is the absolute worst part of this hobby, next to paying for parts/materials.1 point

-

This one doesn't appear to have one. Then not all watches want to be in setting when you remove the stem some do some don't if you do it wrong the clutch wheel sometimes will twist themselves and then you have to disassemble the watch. I've also attached the parts list in case you need it 645_as2060,1,2,6,4,6.pdf1 point

-

This dimension makes it around 18 to 19 line movement. Here's one that's close not exactly the same though. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Zenith_19_5 Similar designs still not right and diameter is much bigger. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Zenith_20_5_NVI One of the problems with identifying watches on this discussion group is we didn't get a diameter. Now that we have a diameter you'll notice that this watch is about one half the diameter size ruling it out as they watch. Pictures of watches can be so misleading which is why we need sizes http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Zenith_10_5_NSI1 point

-

Thanks, @Endeavor I'll report back as soon as I've tested it. For the time being I'm practising HS-manipulation whatever little time I have left over after work and family. Ay caramba, it is challenging! Especially when the spring is neither flat nor round.1 point

-

I snipped out some images. They hairspring isn't centered but it's not enough to be a crisis's. But in one of the images it's obvious they hairspring is not flat and where I put the little mark notice how low they hairspring goes down. If the hairspring touches the balance arm that would be why your balance wheel doesn't seem to oscillate. One of the hardest things for anybody to see is whether they hairspring is touching the balance wheel. I've attached a fourth image where I put an arrow notice they hairspring as it crosses over the balance arm does it cross over the arm or is it touching the arm? Even sometimes tell by the lighting shadow if it's actually up a little bit. Or if you're really careful you just gently push down on the outer coil and see if it actually moves or whether it's touching the arm. But very gently kiss we don't want to distort the hairspring anymore than it already is. As far as the watch being in beat it looks really really close in Bill adjusts that so that's not the issue. The most likely issue with any of us starting out is the hairspring is touching the balance arms and then the balance definitely will not run. Then not enough resolution look in sideways look at the bottom of the balance wheel is the pivot in the hole or is it next to the hole? Look at the picture I snipped out of the hairspring not being flat it almost looks like the pivot is not in the hole?1 point

-

It's an Adolf Shild (AS) movement, possibly any one of 1816, 1906, 1916, 2066, 2076, 2166, 2176 depending on beat rate and other complications. If you look under the balance wheel you will see the AS mark and the caliber number.1 point

-

Let me know how you get on! I have (I think) the same movement in a Timor WWW that's next in line on my bench. I think as Marc says, hopefully pretty straighforward. Have you folloed Mark's courses on watchfix.com? I think with the knowledge there, you should be good to go.1 point

-

AS984 / 1002 is a nice basic sub-seconds time only manual wind movement so about as uncomplicated as it gets. You're highly unlikely to find a service manual for it but all you need to do is to follow a logical system of work, work slowly, don't force anything, and take pictures of every step of the strip down as reference for when you put it back together. Also make sure you let down the power before you start, and it's good practice to remove the balance cock and balance and put it somewhere safe at the start of the works, that way it's less likely to be damaged. One thing to note (and I have just checked this on a 984 in my parts stash) is that both the crown wheel screw and the ratchet wheel screw are reverse (left hand) threaded, so turn clockwise to undo. Otherwise there should be no real surprises. I have attached a copy of the BHI guide to lubrication which should be more than adequate for your movement and is a good starting point for most clocks and watches in the absence of anything more specific. If you get stuck on anything just ask on here. BTI-The_Practical_Lubrication_of_Clocks_and_Watches.pdf1 point

-

Is the balance oscillating freely? To test, you can simply rotate the movement holder a few degrees back and forth to get the balance started.1 point

-

1 point

-

$30 gets you the whole movement. Then you'll have all the spares. You could even turn around and sell the parts you don't need to recoup costs if you don't want the spares.1 point

-

Referring to the article I wrote last week, regarding suspected magnetism of my movement-holder, I since learned a few interesting things. As described in the article, I used a compass to detect magnetism. According to the compass, the movement-holder guide-rails, the circlip and the adjustment-screw were magnetized. And so, according to the compass, were all my Dumont 95% anti-magentic tweezers. I tried to demagnetize all the movement-holder parts and my tweezers with my own made shaded-pole-motor demagnetizer, but the compass needle kept stubbornly showing magnetism. Doubting my shaded-pole demagnetizer, I set out and build myself another demagnetizer based upon the same principle as the ($$$) Elma demagnetizer; a play between a coil and a capacitor causing a deteriorating magnetic field. The new demagnetizer worked but, according to the compass, the parts stayed stubbornly magnetized. However, all by the compass determined "magnetized"-parts could not lift or did not attract even the smallest iron screw I could find ! ? So with how much magnetism were my tools actually "magnetized"? According to the compass they were magnetized but in practice the magnetism was not noticeable/detectable. Discussing this with another forum member, the point was brought forward that the tip of a compass needle is in itself magnetized and therefor the tip of the needle would, when another iron object is held close enough, attract itself to any iron object ....... Testing this I found that indeed any iron object could move the compass needle when held close enough. Unless all the objects I could find were already magnetized, but if not it would make the compass as a magnetism-detection-tool pretty unreliable. Is it a magnetized object attracting the compass needle or is the compass needle attracting itself to the iron object ?? And at which distance and with which magnetic-field strength does the "change-over" occur? By no way of knowing whether it is the one or the other and the when, the whole idea of using a compass to detect magnetism becomes a very doubtful / confusing / unreliable method. Perhaps my movement-holder and the tweezers were not magnetized at all or if so, with how much ?? And how to find out without using a compass and with no physical signs of magnetism detectable ? Lepsi makes a "watch-magnetism-detection" App for IOS devices (iPhone or iPad). After locating the iPhone or the iPad sensor, it tells you whether a watch or parts thereof, by moving the objects closely over the sensor, are magnetized or not. It gives two indications; "no magnetism" or "magnetism detected", but is doesn't say by how much magnetism if magnetism is detected. There are just the two options; Yes or No. Funny enough the Lepsi "magnetism-detection" App is to be found in between the "metal-detection" Apps. Do these both Apps work with the same sensor? To find out I downloaded a "metal-detector" App as well. I've been paying with both Apps and it seems that they both make use of the same sensor. The Lepsi App being more sensitive. The Lepsi App detected at close range magnetism by my movement-holder and tweezers. It also detected at close range magnetism by 9 out of my 10 good running watches ! All my watches are running healthy, with straight lines and do not show any abnormalities on the timegrapher. Of course, nearly all my watches could be magnetized without showing any signs of magnetism !? How does the Lepsi-App work? If it is based upon the same principle as the metal-detector Apps, at which point or at which sensitivity/threshold does it indicates "magnetism detected"? By no way of knowing the level of magnetism, I've no idea how "bad" things are? Neither of the two; nor the Lepsi-App nor the iPhone(model?)- or iPad(model?)-sensors are calibrated or have the option to do so. Perhaps the Lepsi-App yields different results depending on the iPhone / iPad sensors-sensitivity. Perhaps my iPhone sensor is one of the sensitive sensors and I gives me "falls Alarm" ?? With the compass being a doubtful magnetism-detection method it seems that with the un-calibrated iPhone & iPad Apps low levels of magnetism detecting becomes close to pure guess work. Perhaps I was wrong or received the wrong information? Perhaps my tools were/are good enough and do have (if any) such low levels of magnetism that the risk of magnetizing the movement on hand is negligible? There are no physical signs that any of my tools are magnetized nor that there is any strange behavior of any of my watches. With no physical signs of magnetism, assuming this means low levels of magnetism, it becomes very risky to put a watch on a demagnetizer because a compass or an App say so .... at low levels of magnetism there are too many unknowns and both methods above don't seem to be of any reliable help ......1 point