Leaderboard

Popular Content

Showing content with the highest reputation on 10/04/22 in Posts

-

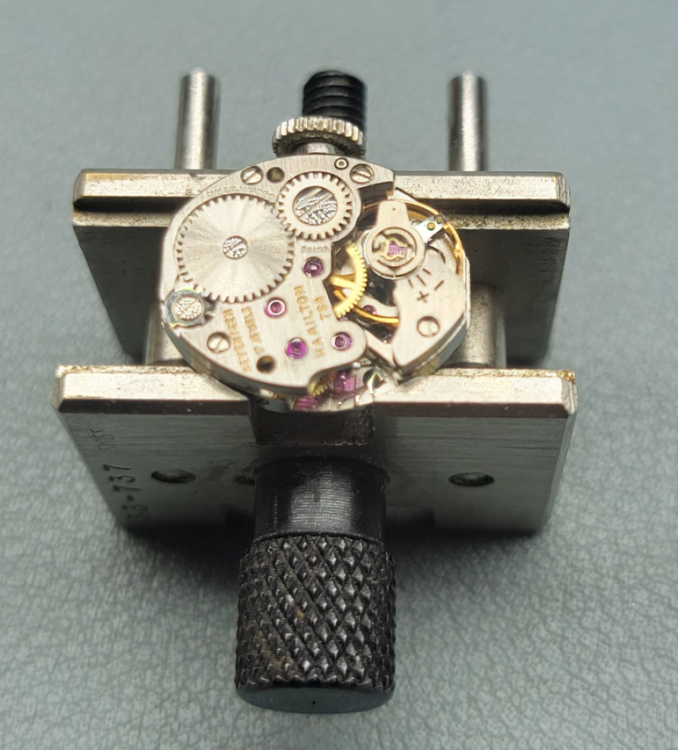

I hate working on ladies watches, but this belonged to my aunt and the family asked me to service it. She was a wonderful lady, so I made an exception. All of the train wheels are covered with one plate. I thought it was going to be a royal pain to assemble, but surprisingly it went together without a hitch. When I dropped in the balance assembly, it ran really goofy and stopped and when running it was at 28,800. What was going on. Geez...the hairspring was sitting on top of the center wheel. Well...everything is so small...so tight. Anyway, I made it right and it is running fine.2 points

-

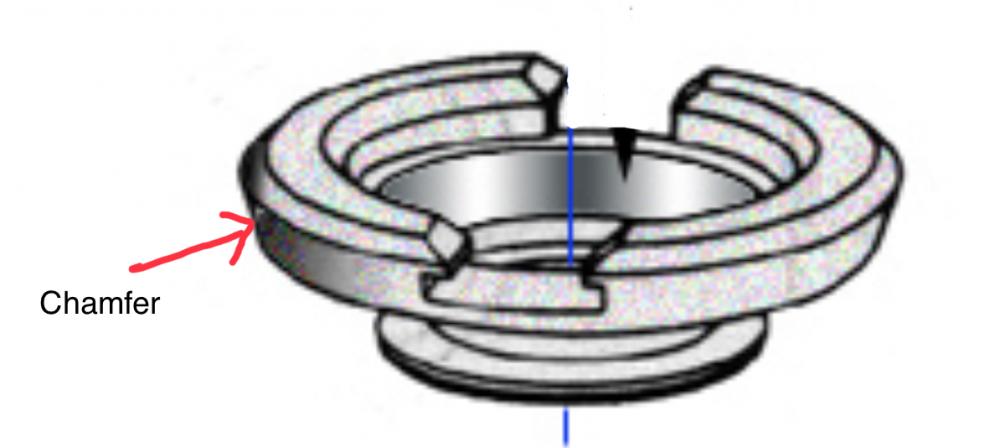

That looks about right I was talking to one of the only guys I consider a genius in watchmaking a few years ago and asked for his advice on these little guys. He said, "take the movement out of the case, hands and dial off, and throw it in the trash". Hahaha. He did have some insight: the proportions are all wrong basically. The hairspring collet is huge for the balance size, bringing the hairspring center far from the balance center. Pivots end up large for a given wheel (especially balance). The whole escapement is often about the right size for a 13"' watch, where the old rule of thumb is the escape wheel diameter is around the radius of the balance wheel. On and on. He's right. But they did run, and people were satisfied with them. For him one of the biggest things is the size of the hairspring collet.2 points

-

Ah, one of the about billion ~5x7?"' movements that were made between the 50s-70s. This is a Buren (they had a thing with Hamilton), but Fontainmelon and AS probably made 75% of them. Amazing that they could mass produce such small pieces! Back in the day when trade shops were churning out watch repairs for jewelry stores these little movements were done at about 75% of the price of a regular "men's" watch, insane. Never figured out the reasoning. There were some pretty high grade ones too, from JLC and Zenith in particular. But these small guys rarely run very well. I remember doing one for Cartier, from their dark period in the 70s (AS 1012 movement dressed up a little). Impossible to get better than a 60s delta in 6 positions. With their approval I literally spent a week (I think I may have mentioned this before): changed fork, escape wheel jewels for domed with olive holes, changed balance jewels same, made 2 staffs, pushed the escapement adjustment to the ultra max, polished the fork slot, etc. Still had a 100 degree amplitude drop from horizontal to vertical, terrible delta. Good job getting this one going! With 25 years experience I have dunked the hairspring on these guys a couple of times, always the "last time the balance is going in or coming out". They got repaired, but it was like a day of work. Glad yours didn't get hurt!2 points

-

I found 2 possible part numbers on the Boley site 8662990 and 8662995 both for the 7s26-03h0 and Cousinsuk has them both in stock https://boley.de/en/case-parts/seiko/37258.7s26-03h0?q=Seiko 7s26-03h0&p=0&s=10 https://boley.de/en/case-parts/seiko/8239.7s26-02w0?q=Seiko 7s26-02w0&p=0&s=10 hope these help in your search Tom2 points

-

it appears you have a stopwatch and you do not want to be doing what you're doing now you will regret it. stopwatches are really interesting for the hands in that there is a heck of a lot of force applied to them so they have to be on super super tight. this means typically you never remove the hands. Fortunately there's a procedure. underneath each hand is a heart-shaped cam that frictions on a post so you remove the dial and gently lift up at the hand and its heart-shaped cam will hopefully slide off the post and that's the way they would normally be. For some reason you absolutely had to take that handoff there is a special tool for that but you're not going to do it with any of the normal tools you have. By the way what does the other side of the movement look like?2 points

-

just as a reminder flat hairsprings were always vibrated to the balance wheel they were on. So have flats hairsprings are never available as a separate component. Watches that have over coil hairsprings sometimes they were available. But they're not just a swappable components they require matching to the balance wheel so you'd have to have the additional timing screws they go with the balance wheel to match otherwise the watch will not keep time. What you really need is a time machine. You need to build all back in time and send your watch to the company and the advertisement below. They would vibrated hairsprings to fit your watch. Unfortunately all these companies are all gone. the problem for vibrating a hairspring is you need raw hairsprings. That is a problem because the Swiss no longer make raw hairsprings for general use. Swiss like to re-consolidate their companies for maximum productivity so now they hairspring companies only make hairsprings specific for the company so the company can vibrating hairspring with that hairspring or they will fiber eight the hairspring for the balance wheel of a company. This means as I said there are no more raw hairsprings available other than which you can find on eBay that presents a problem. The biggest problem is if you've never vibrated hairspring to learn how to do it takes quite a bit of time and you go through a heck of a lot of hairsprings learning how to do it. That's because the used to teach hairspring vibrating in schools typically wostep schools would torture their students and teach them how to vibrated hairsprings. Or the Bulova school of watchmaking that's no longer in existence they would teach their students how to vibrated hairsprings but their school was associated with a factory where they had infinite supply of hairsprings. the problem and watch repair is it's a very precise field. When you're talking about the balance wheel and hairspring they have to be very very exact and precise otherwise the watch does not keep time and very likely will not run at all. So everything has to be sized exactly right. If you are replacing then you'd ideally use the existing collet and stud. Although at one time they did make assortments of the horse just like they hairspring as they once made but don't make any more. simplistic answer to your question is you're going to have to find another watch the steel a balance from but at the link below scroll down to the section titled Joseph School of Watch Making then ideally download the entire book but you need units 67 and eight. This will give you a clue of how to vibrated hairspring. But just having a knowledge doesn't help because it still requires a heck of a lot of skill and hairspring is that you can't get anymore https://www.mybulova.com/vintage-bulova-catalogs2 points

-

It might be worth contacting https://vintagetimeaustralia.com/ as they stock specific seiko gaskets that they have manufactured for them2 points

-

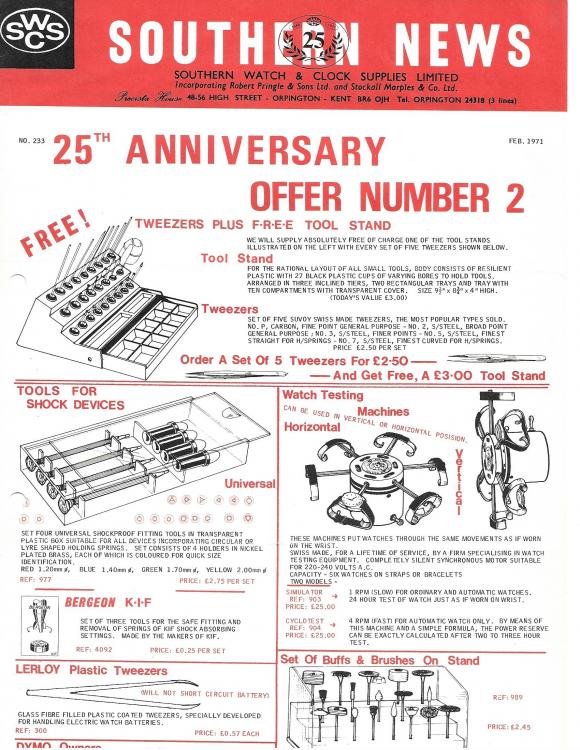

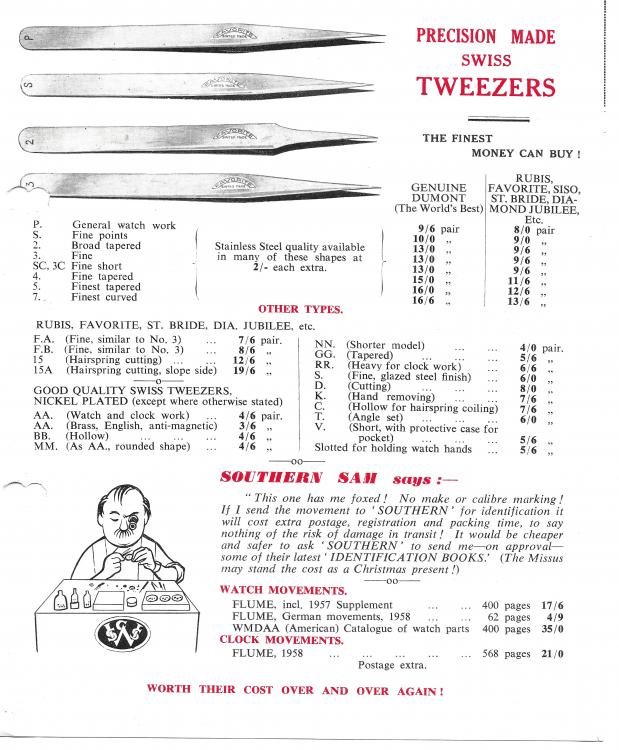

Five Swiss tweezers and a tool stand for two-and-a-half pounds! Back then, in the states, it would come to about $3.50 or $3.75 in US, I believe. As a kid, I was making that much per day just cleaning gutters and doing other odd jobs throughout the summer. All this time, I could have been buying quality tools and entering more seriously into watch repair so much sooner! Ah, if I had known! But thank you for posting these. It was a different time then, and one I am fond of.2 points

-

I thought I'd share this although small I still think it's an achievement, for me anyway. Very skeptical of the superglue and nut technique, thinking the glue bond would give as soon as applied pressure, but I was left with no other option as it wasn't working with my case back tool. Kept slipping. To my astonishment it held, and I started to get movement on the back, not without incident though as I managed to break one of the movement holder posts.1 point

-

Bloody brilliant Lui, my favourite all time maker that kicked Rolex's arse in 1953. I have 3 Astrals and about a dozen Empires, yet to find a Deluxe at a good price though. Love the Sooty alarm clock i just have to have one. Great post that will help me identify my Smith's . Thanks1 point

-

Whether you succeed or not I figure it would be some great practice!1 point

-

1 point

-

Seems like sound logic mc. At least you have the chance of a usable watch at the end of it. What you thinking about the case ? Are you working with just loupes. With a microscope and a sharp caseknife you would be able to determine how easy the bezel can be removed. Any tight bezels i remove under a scope , you can easily see them start to give way and can work around the perimeter with much less chance of damage.1 point

-

yeah they don't list a size, they don't even have a description most of the time. Just says "Seiko gasket list" I was able to do some googling and find that one of them goes to a watch with a similar dimension case to this one, just different style so i'd wager it fits. Well iv'e decided to upgrade them to sapphire, luckily the diameters of both's crystals is a standard size so i guess i can just get the OEM gaskets and the new sapphire from cousins. THe sapphire will have a different height but it might actually be beneficial to one of the watches where the crystal popped out higher than the bezel and was really easy to chip by hitting it on things. I damaged one fo the crystal gaskets taking it out (Because i thought you were supposed to replace all the gaskets every service.) but the other is fine even though i did remove it. I"ll order a replacement just in case. it's so bizarre to me though how crystals come in increments of .5mms but none of the generic crystal gaskets come in divisible thicknesses. They're almost all .4mm thick.1 point

-

@Bearman "Very skeptical of the superglue and nut technique..." Ha. I actually once had a bigger problem removing the glue and the bold off the lid.1 point

-

Heh, welcome to the wonderful world of watchmaking my man. Most of the swiss watches do seem to use standard sized gaskets (busy with a Longines now and it's no issue finding the correct generic gasket on Cousins), but with Seiko things are a pain. For the hard crystal gaskets, I do re-use them as many times you just don't have a choice. For caseback gaskets I make a point of keeping stock of assortments so close enough will do. Then you get this issue with the crown gaskets that also appears to be non standard for Seiko. It really is a pain. The VTA link above is one source of gaskets, so is SpeedTimerKollektion. But those are mostly limited to caseback and crown gaskets. They also have crystal gaskets for popular watches, but for obscure ones you're SOL - I did have luck getting crystal gaskets from our local Seiko importer though. So in your case, it may make sense to try and contact Seiko USA themselves?1 point

-

You want to try make a hairspring yourself ? . Murks bless you, your enthusiasm is out of this world. I always try to think that nothing is impossible, being positive in life is super important. But mate i have to say that making a hairspring without the machinery , knowledge and skill it is impossible. Possible you could buy one but again the skill to match it up to a balance wheel is not a task for a beginner. Coincidentally i reading about doing just that at the moment. As far as know uncolleted and non vibrated hairsprings are not available as new anymore, to us mere mortals anyways. But to answer your final question yes the hairspring has to be matched in size and strength to a balance wheel, not so much the collet and stud as long as these fit the balance staff and balance cock. The diameter has to be correct to fit within the parameters of the stud and regulating pins also retaining a particular number of coils that allow the hairspring to breathe without fouling each other or anything else and enough coils to allow a smooth non violent oscillation . And the hairspring must be strong enough to oscillate a balance wheel's particular weight and torque . Your best and maybe only option at this stage is to buy a balance complete. Ie the whole assembly, possible as new old stock but more likely inside a donor movement. Good luck matey.1 point

-

Birbdad, if you ask this vendor on eBay, perhaps you will get an answer? It appears that he sources genuine Seiko parts? If you don't want to ask, you could check the return policy and spend $13 to see if it's the correct one.1 point

-

Hi Murks, Obviously watchmakers have made hairsprings from scratch for many, many years. I doubt that you have the tools or skill to make one yourself. Depending on the watch of interest you may be able to find an entire balance complete to fit the watch. It is also possible that (depending on the specific watch movement) you may be able to source the needed hairspring. Yes, the hairspring needs to meet the needs of the power passing through the train and facilitate the balance oscillation managing the pallet fork. I recently had a situation where the balance staff was damaged in a 110 year old Elgin. I was able to find an identical movement which had a good staff and during my attempt at replacing the balance after lubricating the top jewel I managed to completely destroy the hairspring. In the photo below, the balance staff on the left balance has a broken top pivot while the one on the right has a destroyed spring. I don't feel comfortable attempting to remove that hairspring and installing it on the good balance staff with the matching balance wheel. There are things that I'm just not ready to do.1 point

-

Here is a video of the ABS rotor running from start, a bit of bubbles at 2-3 minutes, and a photo of when it finished. Feel like the video makes it seem like there was a bit more bubbles then there actually was. I think if I increased the level of the fluid a bit it might help resolve it. But nothing that seemed to be concerned about.1 point

-

This shouldn't be that difficult. I just did something similar a couple of days ago. It was a Russian Slava 2414. And that had an extra beat error corrector. I remove the balance completely and simple aligned everything and press it in with my bare hands. After all, the balance cock hasn't been cleaned yet. Slip in the regulator at the base of the fork, then using your thumbnails to press on boths sides of the fork, working your way up to the open ends. It should click into place quite easily.1 point

-

Well, I can tell you this much: being that the case is most likely plated brass, it probably goes without saying that you wouldn't want to try bending it cold. I think it should work to remove the works and the crystal - basically strip it down to just the case frame - and then use maybe a butane torch to heat it before bending. Something tells me if you try to bend it cold, it will either crack or break off.1 point

-

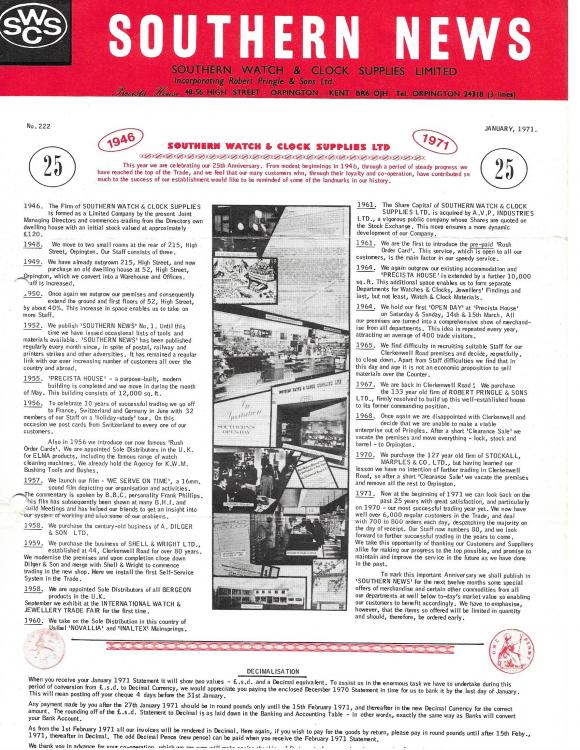

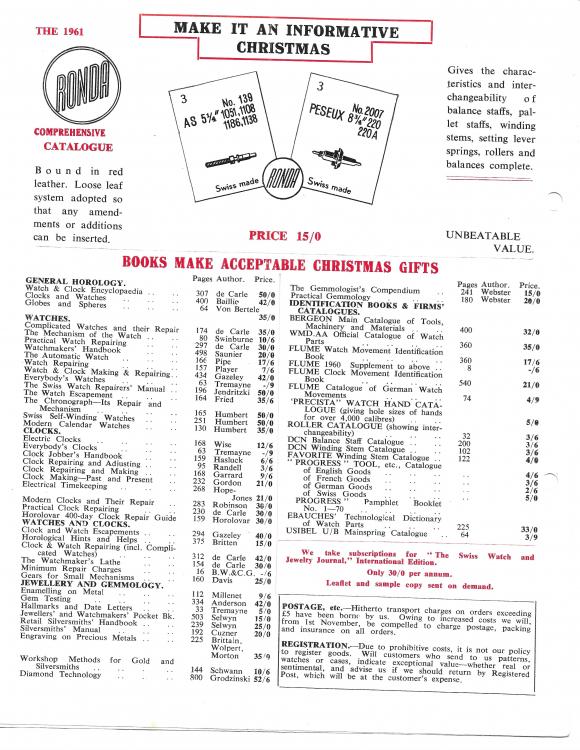

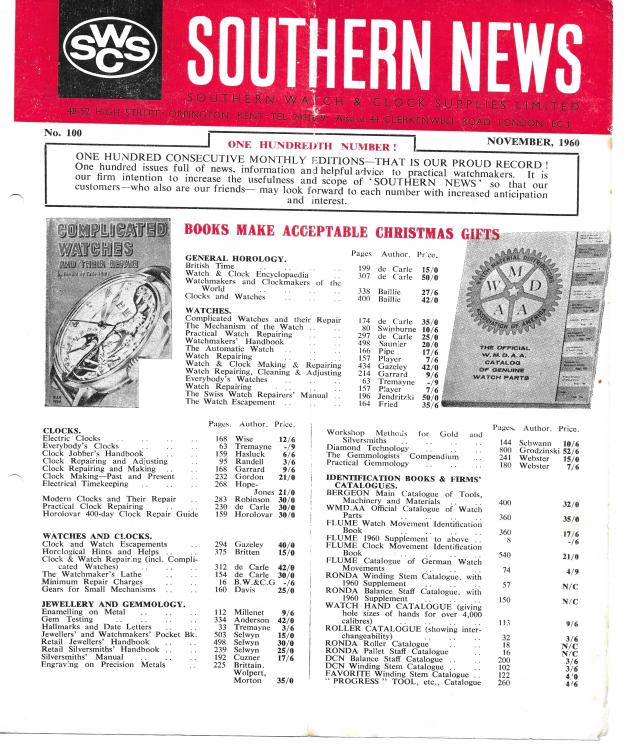

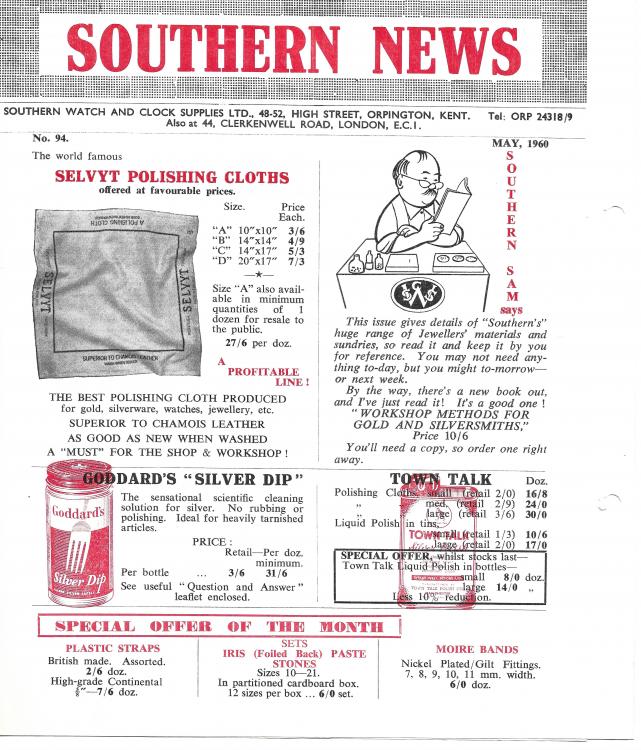

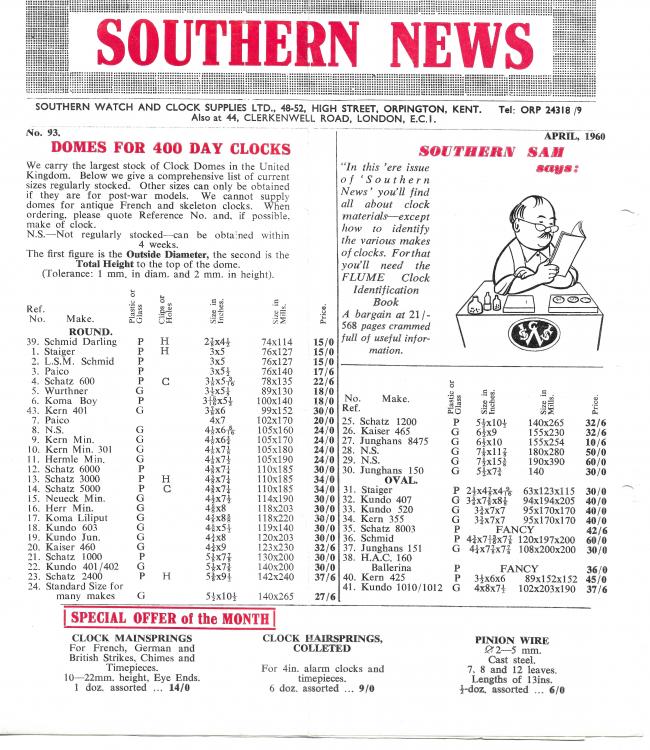

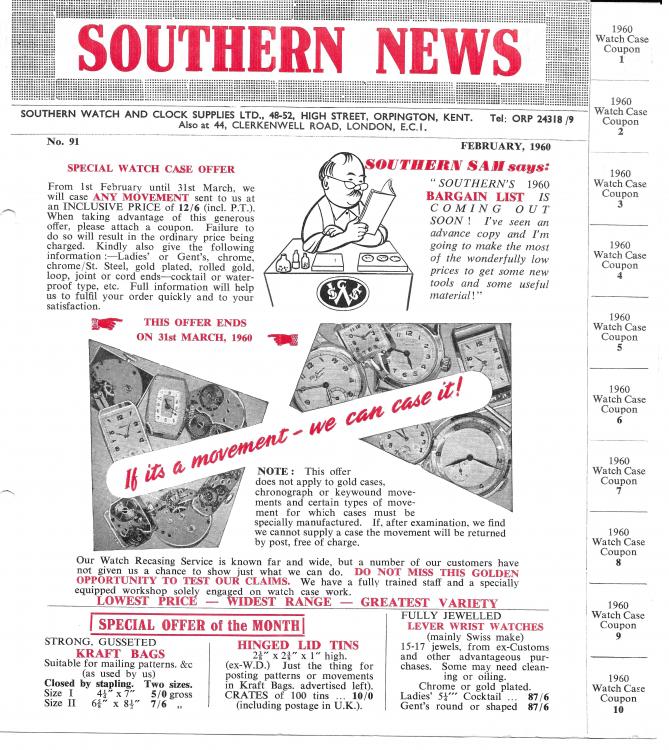

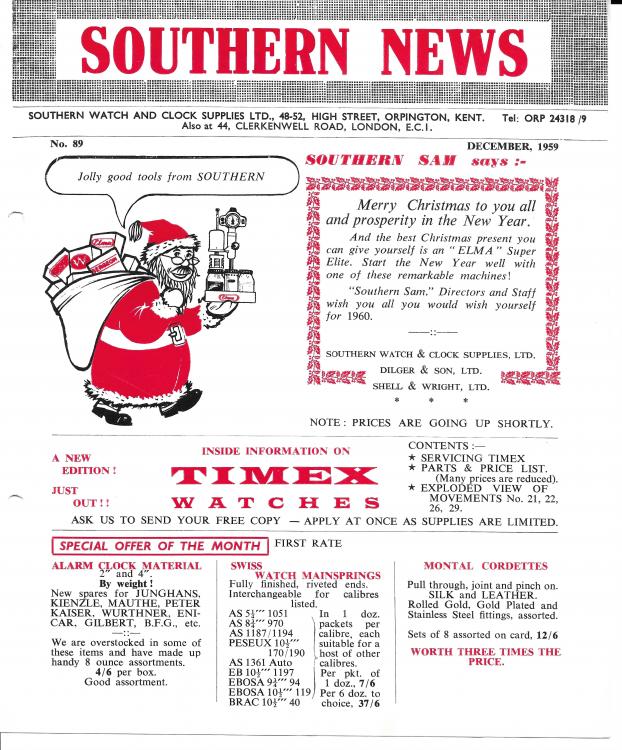

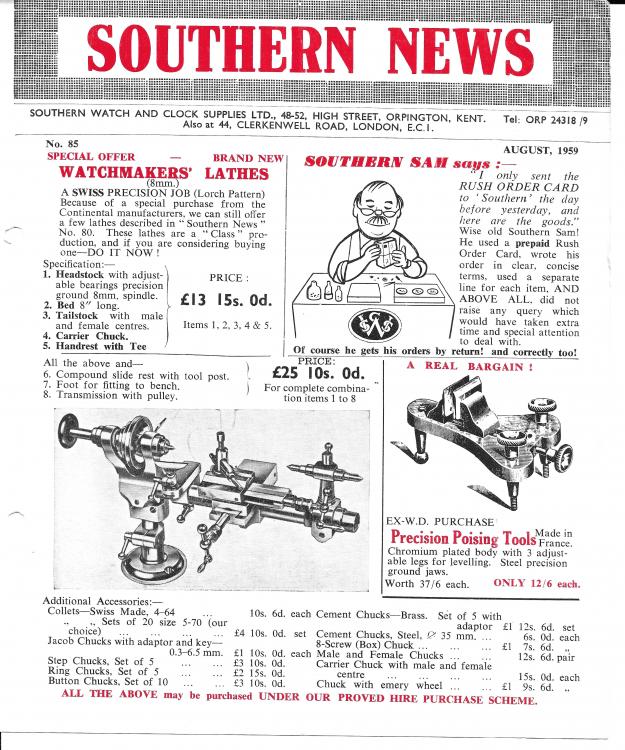

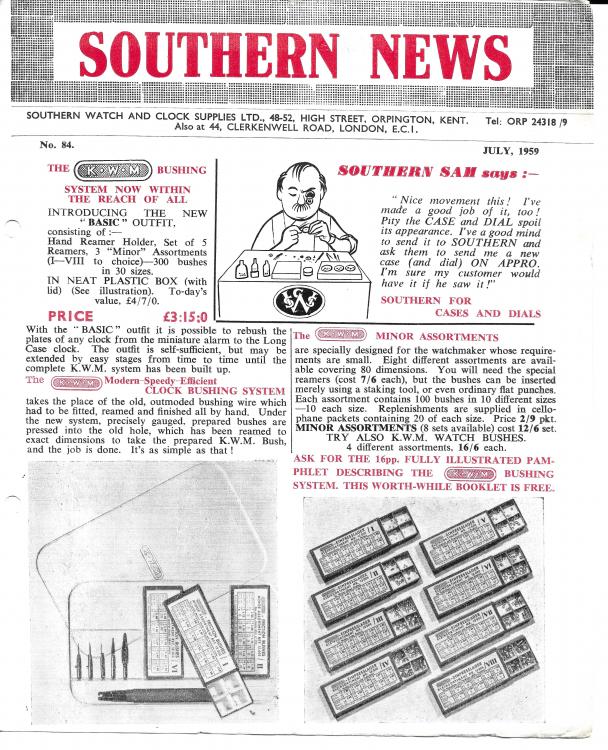

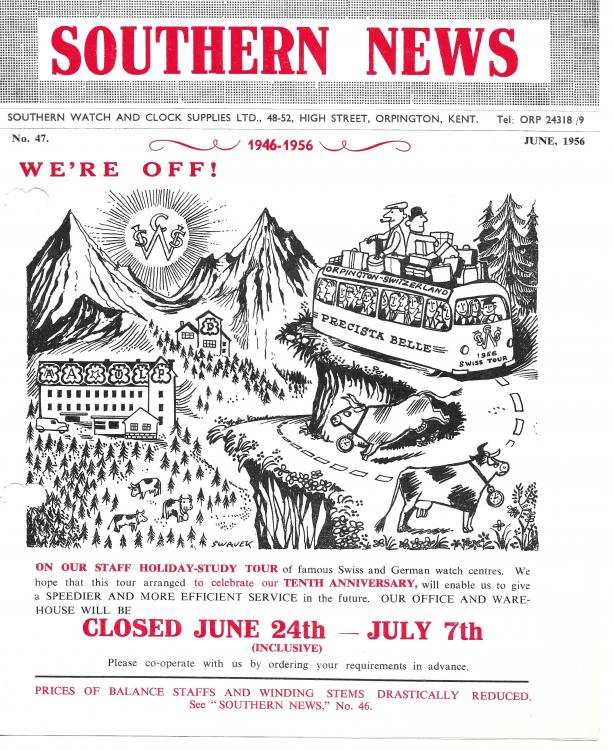

SWCS 1946-1971 25th Anniversary issue No 222 and 233? "This year we are celebrating our 25th Anniversary. From modest beginnings in 1946, through a period of steady progress we have reached the top of the Trade, and we feel that our many customers who, through their loyalty and co-operation, have contributed so much to the success of our establishment would like to be reminded of some of the landmarks in our history " A bunch of leaflets including SWCS and A.G. Thomas were generously donated to me by Niall, somebody where my first bunch of SWCS leaflets came from. I take the opportunity to publicly thank him for this. Unfortunately I have not got a lot of time to spend with watchmaking lately and the little I got I spent with old Greiner timing machines and with their resurrection, however tonight I decided to scan two of the SWCS leaflets. These two are about the 25th anniversary. Issue No 222 and No 233? at the beginning of 1971 (it seems they made a typo here and the issue number became 233 not 223?). This was the time I still did not exist. Issue No 222 lists those landmarks mentioned above indeed, some of them are here: - The first Southern News were published in 1952. - When they went on that tour to France, Switzerland and Germany in 1956 celebrating the 10th anniversary they sent a postcard to their customers from there. 32 people participated. They also introduced the 'Rush Order Cards' in 1956. - 'WE SERVE ON TIME' a 16mm sound film was made in 1957. (now it is going to be our mission to get our hands on it and watch it) - 1970 the most successful trading year yet. It's worth to read their full history and even though they were successful at this point of time it was not an easy ride. Another interesting fact is the decimalisation which was introduced in this very year and some instructions were provided at the bottom of the front page of issue No 222. I also scanned the front page of issue No 233 or shall we say 223? If time allows I scan the rest of the issues I got including A.G. Thomas and some other leaflets.1 point

-

I am glad to see that my post on Reddit inspired Charette's version of the watch cleaner! I have since added a 3D printed L&R type holder for the baskets. I use a 200rpm DC gearmotor and I think the speed is just right. I did introduce myself back in March, I think. I have not posted very much because I am able to find most of what I need by searching.1 point

-

1 point

-

This one would be a challenge for a highly skilled watchmaker with lots of hairspring experience, and very well could be impossible to get "perfect" for even the best hairspring person. But as others have said, it's well worth some time to see how much better you can make it. Just a couple of tips- Check what kind of correction you want to make, it will basically fall into two categories: correction in the round, and correction in the flat. Generally the correction is made at one place for a given error- though that can be a bit fluid with a spring so mangled. -for a correction in the round, find the point of maximum error, go back (follow the spring toward the center) 90 degrees and make the correction. -for a correction in the flat, find the point of maximum error, go back 180 degrees and make the correction.1 point

-

Ok, another attempt at 3D printing in ABS plastic. Did more work and design to keep it from warping off the build plate. There was still a tiny bit of warping, but overall ended up much flatter. Also used a brass threaded insert melted in the side for the setscrew. Overall, the results seem very good. I'll have to run it thru a few cycles to see how the ABS holds up in my solutions. I'm using the Non-ammoniated Zenith solution followed by distilled water then 99% IPA. The basket still works best in 1 of the 3 orientations. I was thinking of designing a 3D printed basket to remove that variable as well.1 point

-

It might be interesting to hear that Dr. Roland Ranfft as a watch enthusiast and creator of the worlds greatest watch caliber datebase claims to successfully use just three lubricants for watch services: a thick oil, a thin oil and a PTFE grease. All are synthetics! He uses the PTFE grease for barrel walls of automatics also.1 point

-

Please, whatever you do, don’t let lack of funds stop you from getting into this hobby. As long as these pieces are for your own use, you pretty much have Carte Blanche to use whatever you can afford. In fact, yours is the best approach; as you learn you get what you need. We’ve all fallen in the trap of putting together an impressive list of “essentials” and that list becomes expensive quick - with the risk that half the stuff ends up not being used. So no hanging here, you do what you can justify and grow from there!1 point

-

I would never criticize anyone for working within his or her means. If you are getting any results or encouragement using what you have or can afford at this time, more power to you. From each according to his ability, to each according to his needs. Karl Marx I do hope Santa comes through for you. Good luck and keep plugging away. PS: that's a handsome looking watch. Shane1 point

-

yes I agree this is not a long term solution and I have written a letter to santa telling him to bring me expensive greases and oils for christmas...(my how ones desires change with age) and this was more of an exercise in getting an old cheapo banger stripping it, and putting it back together using my 150 euro microscope...(yes I am investing in tools for this) which has been a great help to my eyesight as squinting down a loupe is just not for me. I would rather got the THX 1138 route and remotely manipulate things whilst looking into its rather largeish screen. Rather than looking directly at them via a loup, it works for me, as I have high visual and spatial awareness so grabbing things with tweezers sight unseen but on screen has been pretty easy for me. But it's crap for filming as the microscope is so low you can't get your hand in under it with a screwy so your having to drag it out of vision all the time to nail somehting down. but I do not intend to start youtubing either on my van fixes or my watch repair as no one wants to hear a Yorkshireman chuntering throwing tools about and swearing all the time about stuff... But It would probably go viral as the kids would have field day mashing it up probably. but I do not want to be a tv star, I leave that to those good at that... But I see you have been following and replying to my posts and I thank you for your interest...But of course i am going to buy the oils mark recommended as if you want to seriously service a watch you need both them and an ultrasonic cleaning machine... But as it stands I have spent more on tools and equipment than on watches...but I will be ready for the gem of a seamaster or rolex when i find it in a thrift store... But my scores so far are 7009A achieved, although the intermediate date wheel was totally banjaxxed in both the movement I bought and the donor movement (i am now the man to see for 7009a parts) and i am begging anyone and everyone for their contribution of one of those. Although I have to tell the truth and I did destroy the first original balance in the 7009A with my hamfistedness but all in the learning curve. but the problem there is that the hour wheel spins loose probably because the intermediate date wheel is not there to hold it...but the second hand ticks along like a champion and the magic lever is working as it should so when I get the wheel it should be wearable... and The Unitas 176 Achieved in the Cauny 17 rubis Antimagnetic which now works and keeps pretty good time with just 3 in 1 and car grease, but like you so rightly said probably not for very long... But I worked it out that if I greased the CV joints with braking grease and the rest of the grease points on my Renault master van, then the whole vehicle would be worth more than a Ferrarri...1 point

-

Red locktigh wich I believe is still cyanoacrylate based. Things, in certain circumstances, can only be loosened without damage after applying heat. The above makes sense but I'm sure it can make your wife a bit miffed if she finds that in her oven.1 point

-

1 point

-

1 point

-

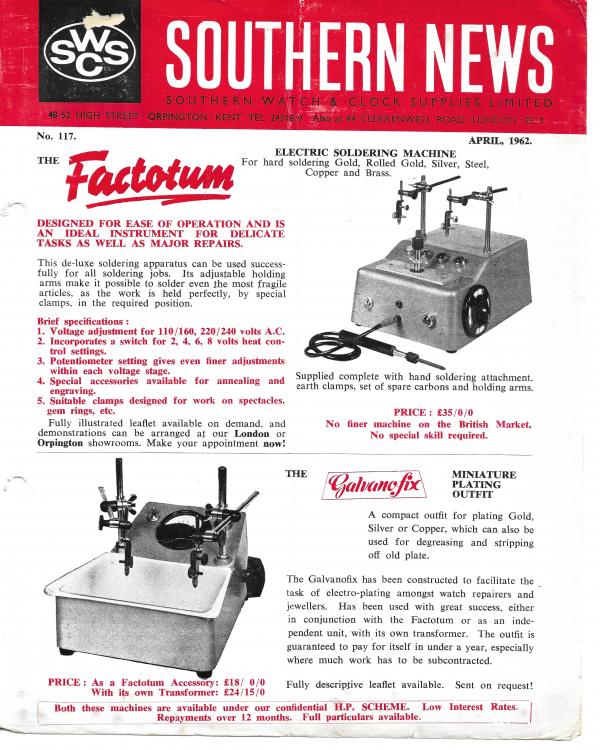

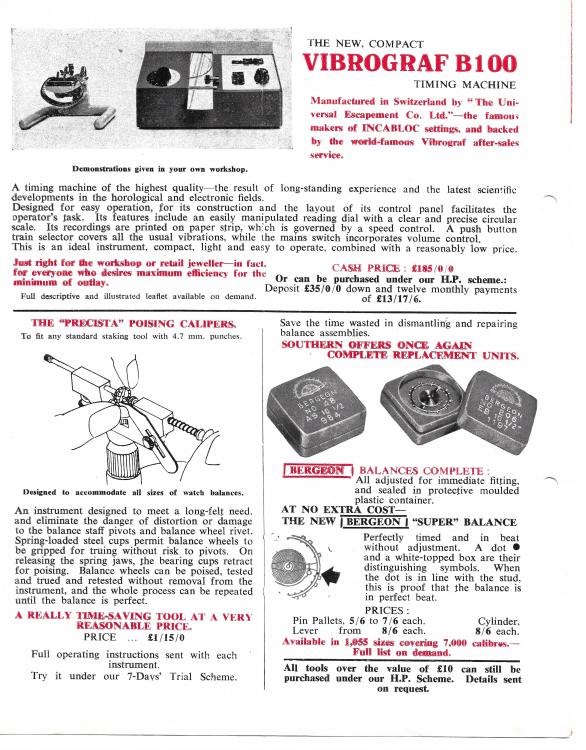

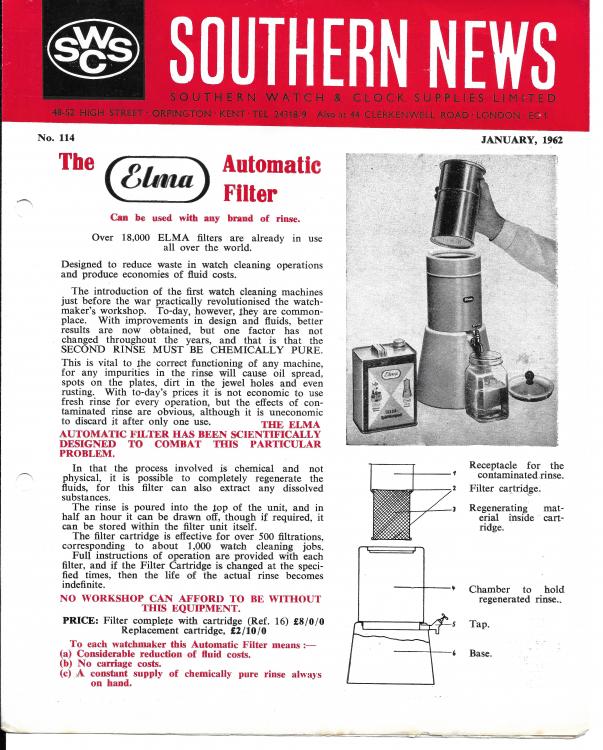

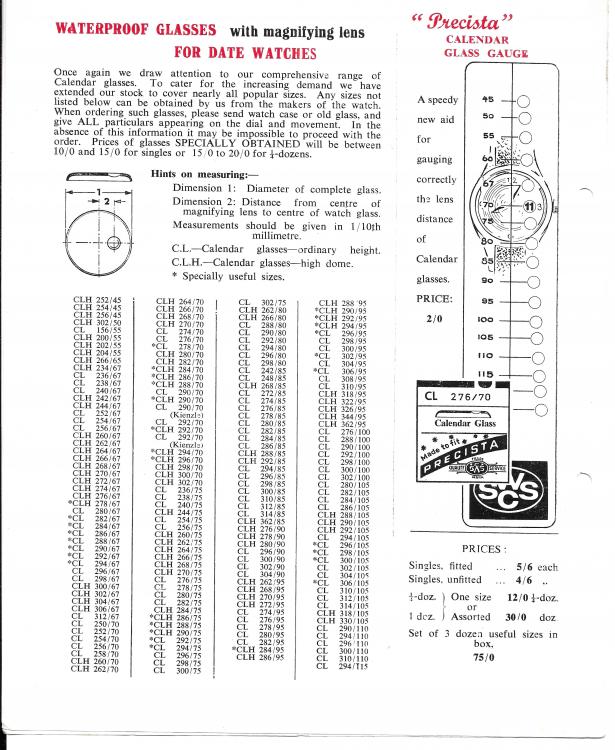

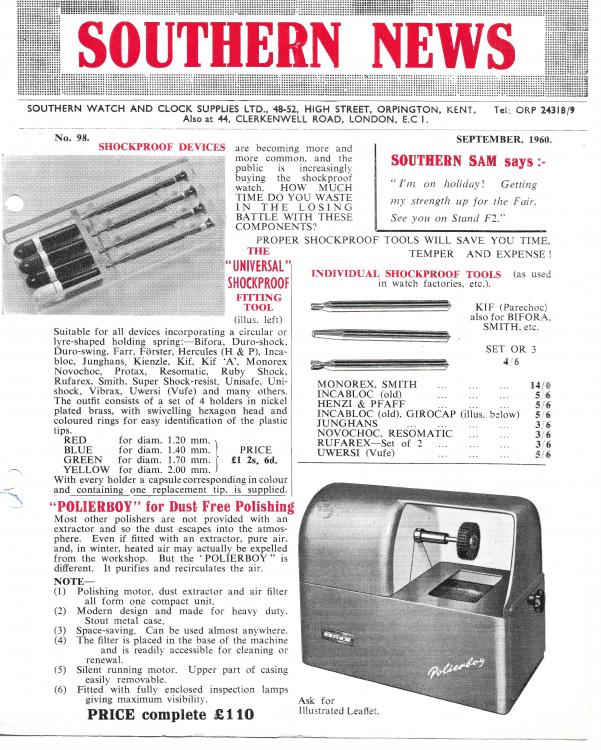

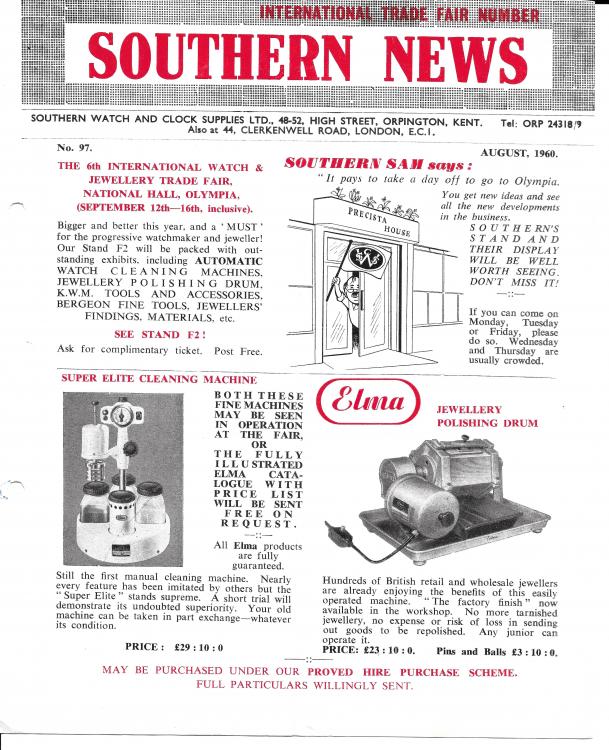

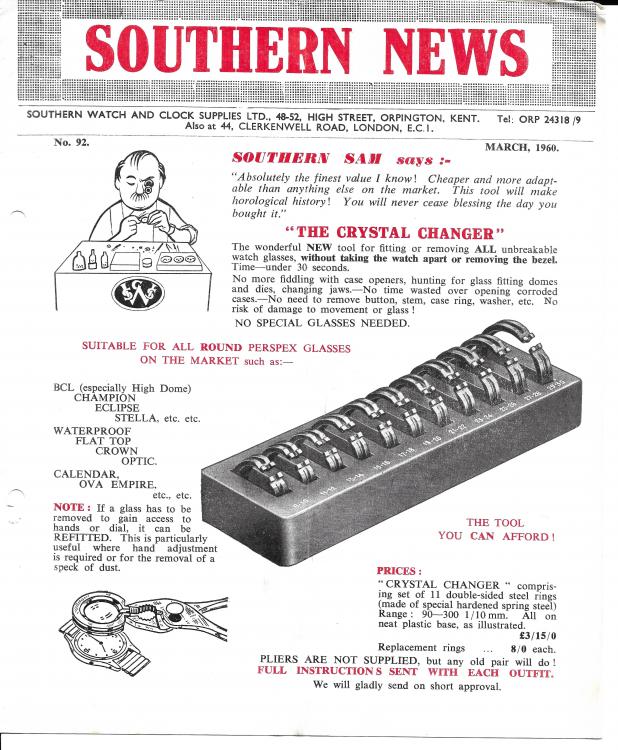

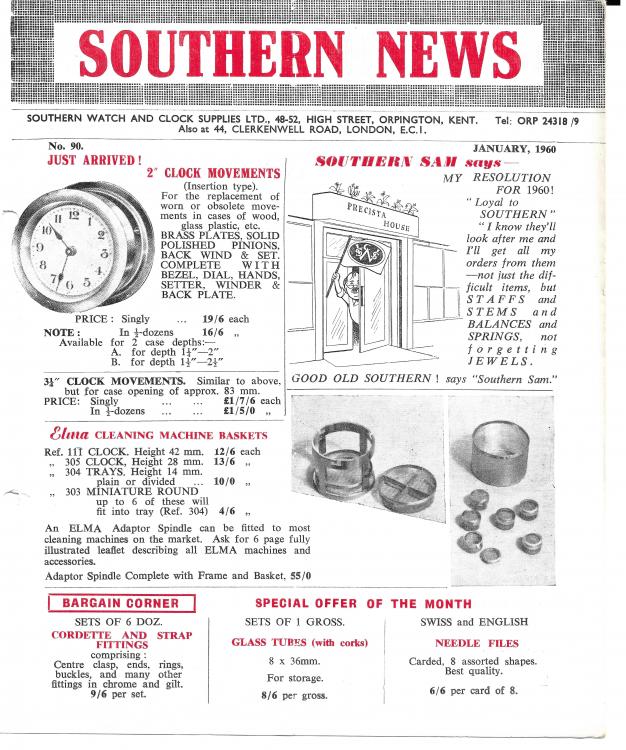

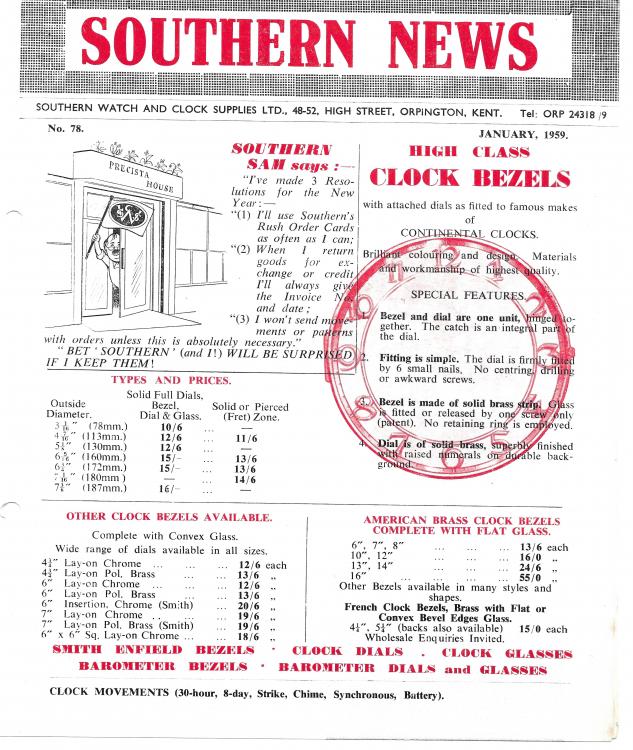

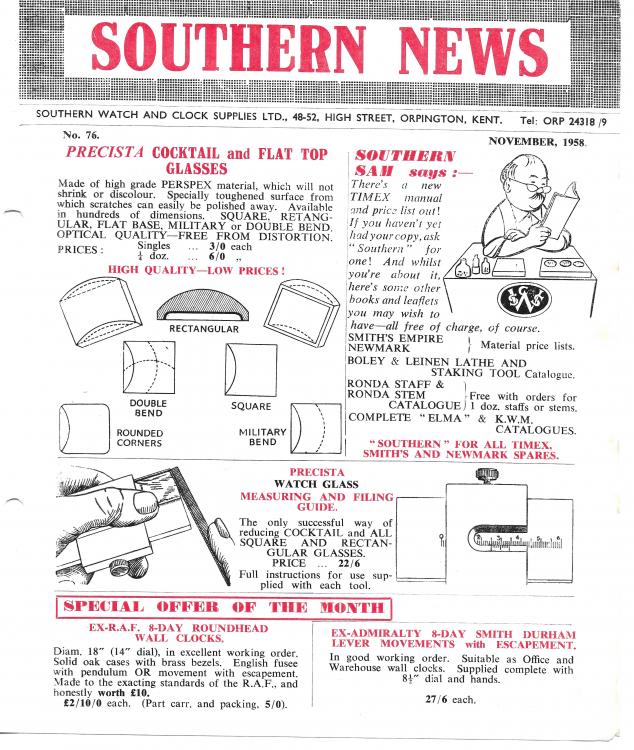

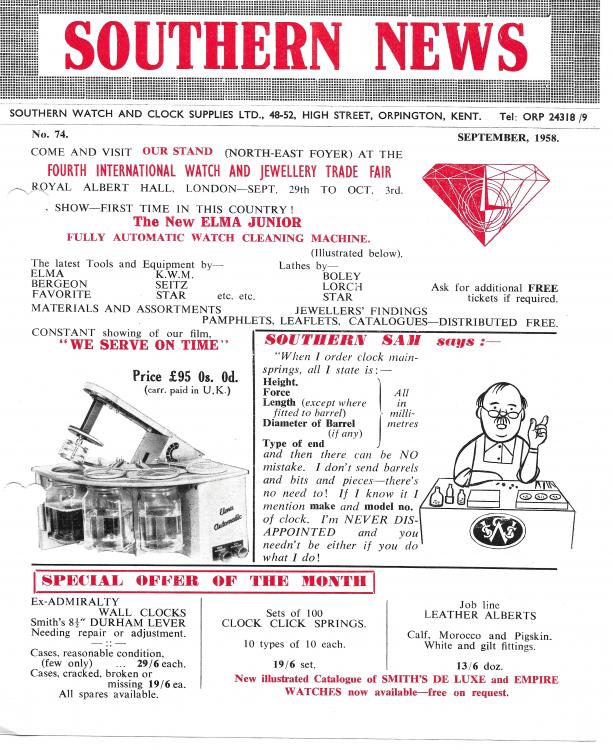

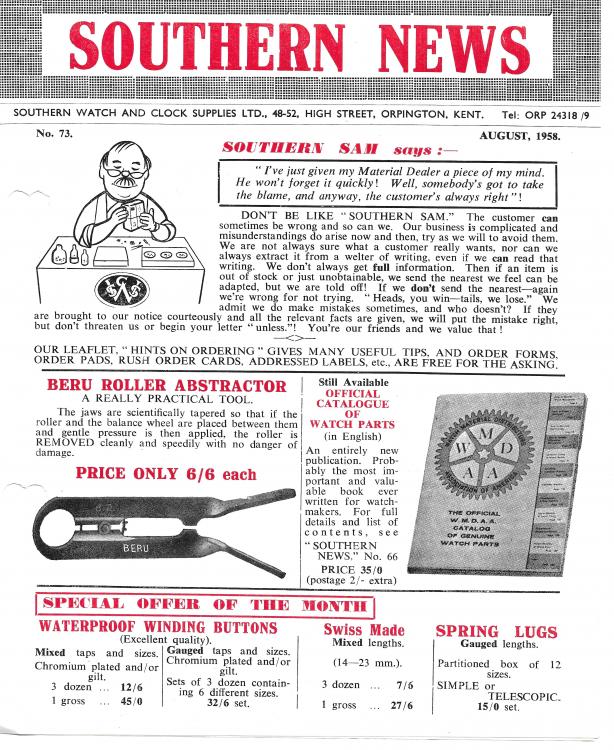

Even though these are "just" leaflets it is an extraordinary reading. As I mentioned i have the issues between May 1956 issue nr. 46 and April 1962 issue nr. 117, but I don't have them all I have gaps here and there, however these leaflets give you a chance to have a glimpse into a watch and clock parts supplier life in the 50s and 60s and trough them into a watchmaker life that time. They give you an endless source of information/observations and for those who lived it trough it is probably not so interesting, but for us who were born later and new to the watchmaking industry it describes a fascinating and probably in certain ways troublesome world prior to the internet and online ordering. First of all these are the times before the decimal days introduced in 1971 when 1 pound was 20 shillings and 1 shilling was 12 pence, or 240 pence was 1 pound. The Southern Watch and Clock Supplies Ltd. started to operate just one year after WW2 because issue nr. 47 tells us that the team went for a holiday-study tour to Germany and Switzerland to celebrate the 10th anniversary a few months before the short lived Hungarian revolution: 2nd International Watch and Jewellery Trade Fair: Rush order cards to ease the ordering in 1958: The first time I can see "Southern Sam" appear: Aceton vs Perspex and SWCS aquired DILGER and Son Ltd in London: Customer complaints, DON'T BE LIKE "SOUTHERN SAM.": 4th International Watch and Jewellery Trade Fair and some advise as how to order mainspring: IDENTIFICATION BOOKS (The Missus may stand the cost as Christmas present!) ? Timex manual and price list out: Southern SAMTA (note the M crossed) ? , London Showroom is opening: To ease the ordering and return process: The best are the cheapest in the long run: Nivaflex unbreakable mainsprings and Clerkenwell road, London is in the header: Customers still dont understand how to order properly: ? Cases and dials: They still don't get it: ? Gift ideas for missus: ? Jolly good tools from SOUTHERN: Kienzle: 1960 bargain list: Clock materials Flume Clock identification book: Silly customers still struggling: ? Jewellers' materials: Loyal customers: "THE CRYSTAL CHANGER": Silly Oscar: 6th International Watch and Jewellery Trade Fair: Southern Sam says "I am on holiday!" and it seems he stayed there forever as I cannot see Southern Sam returning from this point on in the issues ? The ONE HUNDREDTH NUMBER, new header: 7th International Watch and Jewellery Trade Fair: Waterproof glasses with magnifying lens: Books: Elma filter: Elma "RECORD": VIBROGRAF B100: And the last issue I have nr 117 with a Galvanofix miniature plating outfit. It might be a long post, i just picked these pages for now as I found them interesting. I would love to have all of the issues, but it is probably a mission impossible. I zipped and attached the pics I scanned because the original copies are a bit more readable. Enjoy. ? Issues I have: 46, 47, 48, 49, 50, 54, 65, 66, 69, 71, 72, 73, 74, 75, 76, 77, 78, 80, 2x81, 2x82, 83, 84, 85, 88, 89, 90, 91, 92, 93, 94, 95, 97, 98, 99, 100, 101, 103, 105, 106, 107, 108, 109, 110, 111, 112, 114, 115, 116, 117 SWCS.zip1 point