Leaderboard

Popular Content

Showing content with the highest reputation on 09/14/22 in Posts

-

Thanks for your kind words @Neverenoughwatches! Well, I try to stay away from the Internet and spend more time in the real world. After all, the best thing you can do to become good at servicing and repairing watches is to service and repair watches, and time is limited.2 points

-

2 points

-

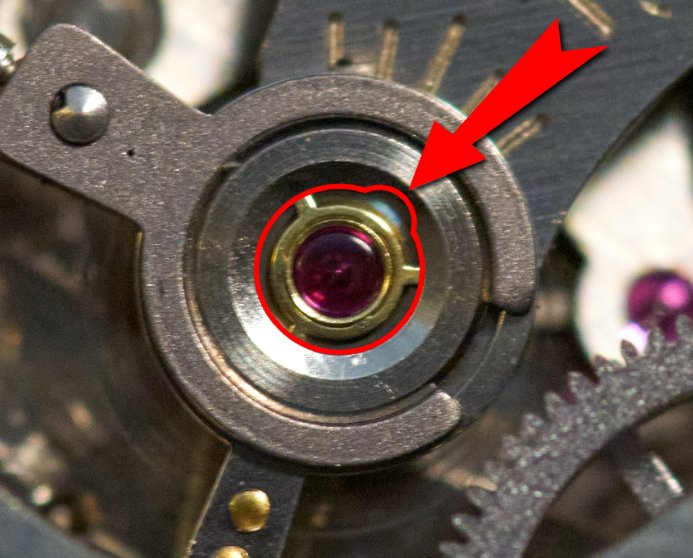

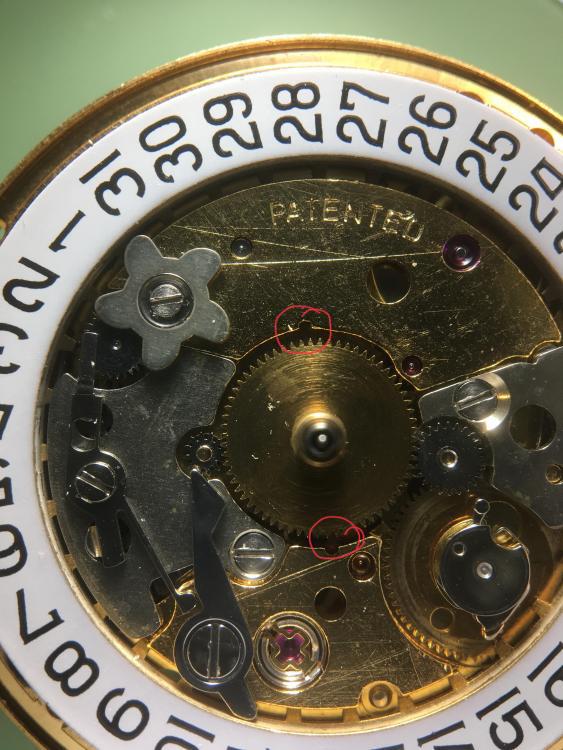

Introduction This service walkthrough is not a tutorial on how to service a watch movement. I made it for myself because I think it's fun and because it will make it easier the next time I service a Vostok 2431. I also think it feels nice to be able to share this walkthrough considering all the valuable information that many very talented members on WRT freely share. Many, many thanks! There is a lot to learn when servicing a watch movement that is not covered in this walkthrough. Therefore, I recommend, for example, watchfix.com, learnwatchmaking.com, or timezonewatchschool.com. I feel like I got the most bang for my buck at watchfix.com (I'm not sponsored in any way) but I've also had a lot of fun and benefited from the other online schools. Links to photos on my OneDrive Vostok calibre 2431 disassembly walkthrough. Please sort the images by name in ascending order. Vostok calibre 2431 assembly walkthrough. Please sort the images by name in ascending order. Curiosities I think it was in 2014 or possibly 2015 that I bought my Sturmanskie Open Space. I had just discovered that there were watches where the hour hand only rotates one revolution per day and at that time I knew absolutely nothing about watch movements, service and repair. The idea that the hour hand of a watch only rotates one revolution per day seemed not only completely logical but also different and fascinating. The earth rotates one revolution around its axis per day, so it should be obvious that the hour hands of our watches do so too. The fact that the letters on the watch were also Cyrillic did not make the whole thing any less exciting. I just couldn’t resist it and I’m happy I didn’t! Vostok claims that their movements only need a service every 10 years, and I think that's true because the tolerances are pretty rough and therefore large amounts of dirt are needed to stop a Russian movement or even cause it to run badly. It has been said that the amount of dirt required to stop a Vostok movement is enough to stop a hundred Patek Philippe movements However, the price for this endurance is a movement that doesn't come close to the precision offered by high-quality Swiss and Japanese movements, but it's still quite easy to get these Russian movements to run accurately as long as they're worn and used consistently. About the movement Russian watch brands such as Vostok, Raketa, and Poljot, to name a few, are known for using their in-house movements, but not this Sturmanskie which is instead powered by a Vostok calibre 2431, which is a 24-hour movement. However, it is not a true 24-hour movement. That is, the movement is not originally designed as a 24-hour movement. Instead, Vostok has modified the movement in its calibre 2416B so that the hour hand only rotates one revolution per day. Calibre 2431 is otherwise identical to Vostok automatic calibres 2416B and 2415. The motion work(/dial train) in Vostok 2431 The way that Vostok modified the movement so that the hour hand only rotates one revolution per day is by modifying a) the minute wheel, b) the bearing for the minute wheel in the main plate, and c), adding an intermediate date indicator wheel. The minute wheel has been modified so that it has two pinions that lie on top of each other. The lower pinion drives what I call the first intermediate date indicator wheel while the upper pinion drives the hour wheel and has been adjusted so that the hour wheel only rotates one revolution per day. The number of teeth on the hour wheel itself may have also been adapted, but this is not something that I have investigated. Normally the minute wheel is mounted on a regular metal post on the main plate, but in this case, Vostok has replaced the post with a beefy, jewelled bearing. I assume that this has been necessary to get the minute wheel, with its two pinions on top of each other, to rotate sufficiently smoothly and stably. The added first intermediate date indicator wheel drives the second intermediate date indicator wheel which is part of Vostok's regular (non-modified) calendar complication. And this is what it looks like with the hour wheel mounted. Cleaning I have found that it is all too easy to underestimate the importance of cleanliness when servicing a movement, perhaps because the parts are microscopic and therefore it takes time to get used to thinking microscopically, even though I have been doing this now for five years. Cleaning of pinions and pivots A type of watch movement part that is particularly important but also difficult to get completely clean is pinions, but @nickelsilver advised me quite recently that in its pre-cleaning you can dip and rub the pinions in pith wood that you have impregnated with an effective degreasing agent, for example, Horosolv. I've done it several times now and it works amazingly well. Speaking of pinions, independent American watchmaker Josh Shapiro mentioned in a podcast that he considered pinions to be the most difficult part of a watch movement to make perfectly. Whether it's true or not I don't know but I think it's likely. To get the pivots clinically clean, I have also started using EVEFLEX, but you have to be careful because the material has an abrasive effect. It is important to choose the right polisher and to be careful. I have summarized my experiences with EVEFLEX in this post and I mention it because EVEFLEX is easy and quick to work with and gives me very good results. End-shake If there's one thing I've learned this time around, it is that a Russian movement cannot be converted to a Swiss movement because the tolerances in Russian movements are generally much coarser. Experimentally, I adjusted the end-shake to 2/100mm on everything from the pallet fork to the centre wheel, with the result that the amplitude and rate became extremely erratic. I created a thread about this: "Can end-shake and or side-shake ever be too small?" As you will see if you follow the thread, once again @nickelsilver, @Shane, and @JohnR725came to my rescue. Many thanks! My recommendation is to let the end-shake be slightly wider on Russian movements. After I increased the end-shake to approx. 4/100 mm, the amplitude and rate returned to typical, i.e., still somewhat irregular but perfectly normal for a Russian movement. Side-shake In this video, Kalle Slaap from Chronoglide shows an amazingly simple and effective way to determine if the side shake is correct. Since there was a crack in the third wheel jewel in the train wheel bridge, I replaced it, and when I then used Kalle Slaap's method, I could clearly see the 3rd wheel pivot jumping back and forth in the jewel hole. So, I replaced the jewel with a hole that was 1/100mm smaller and the visual difference, just changing it by 1/100 mm, was nothing less than dramatic. I am incredibly happy that I got to learn this simple and exceptionally clear method. Many thanks to Kalle Slaap at Chronoglide! Vostok reverser wheels If you Google “Vostok reverser wheels”, there is a lot of whining going on. I don't think there are any major problems with Vostok's reverser wheels, but they are unfortunately easy to damage during service or modification of the movement, and I think that is the real reason for the whining. Next to Seiko watches, Vostok watches are immensely popular to modify in terms of dials and hands, and in addition, many people want to fix the seconds hand that sometimes stutters on these movements. The latter is done by bending the second-hand pinion spring illustrated in this thread. To make these modifications, the oscillating weight/rotor must be removed and when it is to be screwed back on, it is easy for the rotor pinion to end up on top of the teeth of the reverser wheels. If you tighten the rotor screw in that position, even just a little, the reverser wheels will inevitably be damaged. The result is that the automatic winding stops working or only works intermittently. An easy way to check if the reverser wheels are working as they should is to manually rotate the oscillating weight alternately about 20 degrees in both directions with a piece of peg wood while looking at the 1st reduction wheel which is large and easy to see. If the 1st reduction wheel continuously rotates in the same direction (counterclockwise, if I remember correctly), no matter which way you rotate the oscillating weight, you can be sure that the reverser wheels are working as they should. If, on the other hand, the 1st reduction wheel rotates alternately in both directions when you rotate the oscillating weight alternately, then you can be sure that the reverser wheels are damaged and need to be replaced. Servicing the automatic mainspring I find it difficult to service the mainspring on automatic movements. It is, in my opinion, a construction that leaves room for improvement and that is why I generally prefer manually wound movements. If the mainspring in an automatic movement slips too soon, it reduces the amplitude and the power reserve, and if the mainspring slips too late, there is the risk of re-banking and that the movement runs much too fast when you are physically active, especially when you take a brisk walk swinging your arms, and the oscillating weight rotates constantly. The effect is like continuously turning the crown of a manual movement with high pressure when the mainspring is already fully wound. Not good! What I learned this time anyway, long story short is that you can be quite generous with braking grease on the rim on the inside of the mainspring barrel. Even if some of the braking grease ends up where it really shouldn't be, I don't think it will destroy or affect anything negatively. Also, and again from Kalle Slaap at Chronoglide, I learned that you should press at the end of the spring at the bridle when it is mounted in a spacer, and you are about to push it into the mainspring barrel. In this way, the rest of the spring automatically follows down into the mainspring barrel. You can see it in this clip. Very smooth, especially in combination with my highly rated Master Craft mainspring winder which I wrote about in this post. Lubrication of cap jewels For a long time, I have had trouble getting the oil to stay in the centre of the cap jewels and not flow out after I oiled them and installed them, despite treating them with epilame (Fixodrop). I think it's because (and now I'm going by gut feeling) that I previously always installed the shock assembly in the main plate before installing the balance and that I didn't treat the jewel housing (chaton) with epilame. After several failures in servicing this movement, I decided to treat both the cap jewels and jewel housings with epilame and mount the shock assembly after having replaced the balance. It did the trick and also made fitting the three-legged anti-shock spring much easier. My theory is that the balance staff pivots stabilize the oil in the centre of the cap jewels when the jewel housing (chaton) is dropped into place, and better hold the jewel housing in place, which will otherwise slide around while installing the three-legged anti-shock springs. Have I just written the longest post in the history of WRT? Anyway, hope you enjoyed it!1 point

-

1 point

-

You'll learn quite a lot watching some videos: https://www.youtube.com/c/WatchRepairChannel or It's about time or take some courses: https://www.watchfix.com/ Welcome to the forum! There are 6 or 7 guys here that will be helpful along with quite a few somewhere further along in their journey than you are. Ask specific questions, post photos to illustrate your question and try to get your question in the right area.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

if you look at the parts catalog you will notice a lot of variations in those Waltham watches. There is no guarantee if you get a lower plate that you have a Jewel that you can push out. Fortunately it look like the parts list there is only one Arbor which means typically only one pivot size. then there is another option which is replaced with a modern jewel. That can be done in a variety of ways. Some of it depends upon how big the original setting was and how much modification do want to do to the plate? So for instance providing get a jewel taken off and it has be slightly bigger than the original hole size because ideally digital has to friction in and it's unlikely that the setting size would correspond to the diameter of a modern jewel. Then you'd use the reamer in the jeweling set the open up the whole the correspond to your modern jewel size. Just in case you haven't use the reamers despite what it says about the precisely made in the make the whole the precise size you what it be really careful not to go all the way to the end because sometimes the Hollands up to big and that's a definite issue C want to go almost to the end and try the jewel and try not to break the jewel in the process. Also it's hinted at the book there is a picture of it they also make brass bushings that you could conceivably fit into the hole and then you open that up with the reamer and put the jewel into that and it would have to modify the main plate providing bushings the right size. Then of course and maybe one of the videos or something up above you can do is make an entire new setting and I was a piece of brass the right diameter with a hole corresponds to the modern jewel and use friction your modern jewel in and push the whole thing into the main plate. But a course that assumes you have a watchmaker's lathe if you start making the setting. Otherwise a time machine would be good to go back in time the buyer jewel but if you are a time machine I think there's a lot of other more productive things you to do even if you restricted it to horology only just think about all those cheap pocket watches back then1 point

-

I can't imagine a reason that these need to come out, is it just to be "complete" about the disassembly? If they really do have to come out, I would grip them in a lathe in a collet and twist the mainplate to coax them out. In the case they were scarred up like yours I would again use a lathe to resurface them.1 point

-

1 point

-

Hi The coil looks a bit suspect, parts can be had from Jules Borel USA. I have checked and the coil is available at $11.70 on their site. But first check the battery is ok as I have known some not work and If Jeweler's change battery's and if the watch does not start they give up as they have no means of testing the watch, Check out Borel's Attached the tech sheet for you. 766_Seiko 8123.pdf1 point

-

1 point

-

when you're looking at the Waltham parts catalog even the one that's 100 years old you should come to recognize that the likelihood of finding any of those parts in stock in a material house today is limited to nonexistent. even look at eBay you might find something but typically the things you find a common things like balance staff mainspring. Not saying the jewel won't show up I once saw an assortment of Waltham jewels unset for burnishing in on eBay but that sort of stuff is extremely rare. do you have the manual for the tool?1 point

-

1 point

-

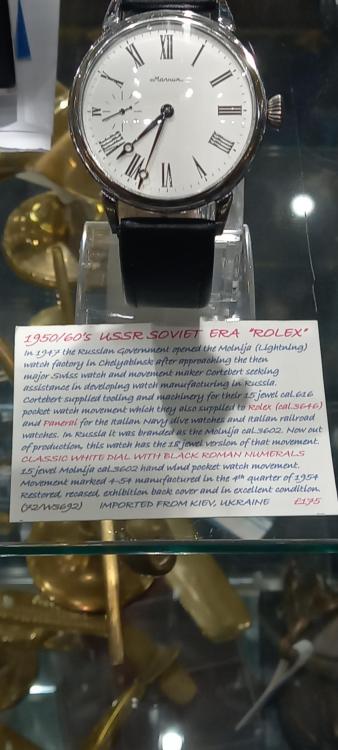

Appreciate this post Watchie, your information is always spot on my friend and worthy of commiting to memory. Particularly interesting regarding lubrication with the balance staff in place. I am in historic York in the UK this week, lots of antique shops. Spotted some early big post war Russian watches you may be interested in possibly having a Rolex connection . I will get some photos tomorrow. Look forward to your next post, where have you been ?1 point

-

For those who ask about which winder sizes they should use, I have included a guide in the wiki on how to select the correct winder sizes based on your mainspring diameter: https://github.com/vishnu350/rs-mainspring-winder/wiki/Selecting-the-correct-winder-size-for-your-mainspring1 point

-

Hi willow with it being a deadbeat(Graham) escapement (no recoil) it has to be right, The diagnostic path as laid down by Old Hippy has to be followed and all points checked. A recoil escapement gets a bit of help from the recoil and can overcome little problems like slightly out of beat or locking. Its a question of patience and dilligence. all rhe best1 point

-

If it is stopping because of the escapement check all the pivot holes for the escapement, pivots and burr on the escape wheel and the angle of escapement the pallets also need to be smooth with no marks or signs of wear. I can't tell by the photos but many clocks with this type of escapement the crutch is friction tight, so it has to be tight enough for it to work, too lose and it will stop, to tight and it won't set its self in beat.1 point

-

The watch is now running perfectly! Like I was told, I rotated the finger slightly which did the trick. I also had to tighten the chrono seconds hand since it was sitting a little loose after having been taken off and put back on. Once again, this forum delivers. I am just as amazed at the help everyone here can provide every time. Truly amazing. I thank all of you who helped me with this project(; Thanks!1 point

-

Thank you everyone for the great answers and advice!! This did the trick for me, lacking a better tool. I think I haven’t broken anything… but I will know more when assembling Thank you!!1 point

-

Totally agree! I am just like you so these sheets are incredibly helpful. When I get some more spare time I will sit down and go at it at the watch. I will keep you updated!1 point

-

it would be nice to have a picture of the watch because we like pictures of watches. yes it's amazing the Elgin knowledge he has like for instance. Pocketwatch databases filled with thousands of errors especially related to Elgin watches. That's because it's based on the Elgin parts catalogs especially the later Logs. The purpose the parts catalog is to help you to identify the correct replacement part. The parts catalog was never meant to be used to identify your watch. Diveboy can you give you the exact year but basically and thinking about I can't remember the year before your watch though but Elgin changed how they did their catalogs so a lot of earlier watches all get lumped under one category when they're not actually one category. And even for your watch the difference the jewel account does it change the parts used in the watch. So basically the pocket watch database points you in a direction but it may or not be 100% correct because it's based on faulty information. But for the most part nobody seems to care as they totally unaware of the problem. As I said it's a much greater problem if you have watches made at the very beginning where it might actually be incredibly rare but against lumped under the same categories a bunch of other watches because it use the same parts. In a case it be nice to see pictures of your watch1 point

-

@Jon, I can't thank you enough for posting those slides. I have serviced chronographs before, including one of my own, but I still feel like a beginner at it. Since I hardly ever work on them, I've picked up some non-running chronograph movements to practice upon. Those slides made my understanding quite a bit clearer, as well as helping with some of the part names that I didn't know. So again, thanks for that. Much appreciated.1 point

-

Bingo .... and thanks everyone. Soaking overnight plus a little very gentle heating with a fine soldering iron and it came loose .... it was a reverse thread as you all thought.1 point

-

1 point

-

I put small parts in a little zip lock bag and demagnetize them. Otherwise, it's just more grief when they stick to other parts.1 point

-

1 point

-

Harbor freight has a fantastic magnetic broom for $14, It saved me many more than that,1 point

-

Good day to everyone. I just wanted to first introduce myself here. I am a new member from Oklahoma. I am slowing piecing together tools and just dipping my feet into learning watch repair. I've always been a pretty handy person, and enjoy the process of fixing things. Mechanical watches have always intrigued me. The genius of their design to track time through a completely mechanical process is fascinating. On top of that, the precision of the parts and skill of a good watchmaker have always impressed me. I began collecting watches, and as the collection grew from the more affordable quartz watches, to in the past few years (as my budget has allowed) more automatics and a few 'luxury' timepieces the reality of needing to service those watches has given me the 'excuse' to invest time and money into learning this new skill. I obviously am not planning on servicing any of my more complicated movements, such as my Omega Co-Axial watches, but I figure that the watches in the collection with Seiko, ETA, etc. movements are definitely on the table for me to service myself when the time comes. I have been trying to learn as much as I can, and am buying the basic watchmaking tools, lubricants, etc. to get started. I'm also now looking for a few watches on eBay, Facebook, etc. that I can use as movements to begin my learning journey. Lastly, I am signing up for Mark Lovick's online courses on WatchFix.com. I've been referred to him I think that it will be money well spent to have that amount of learning material available to view and reference back to as my journey begins.1 point

-

1 point