Leaderboard

Popular Content

Showing content with the highest reputation on 09/12/22 in Posts

-

4 points

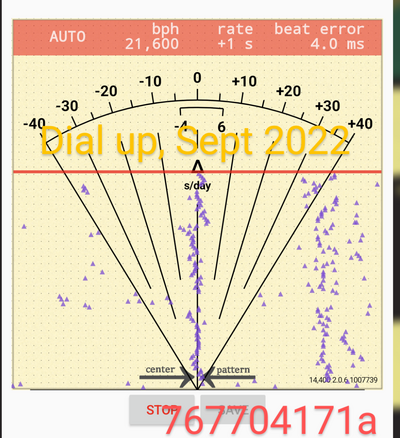

-

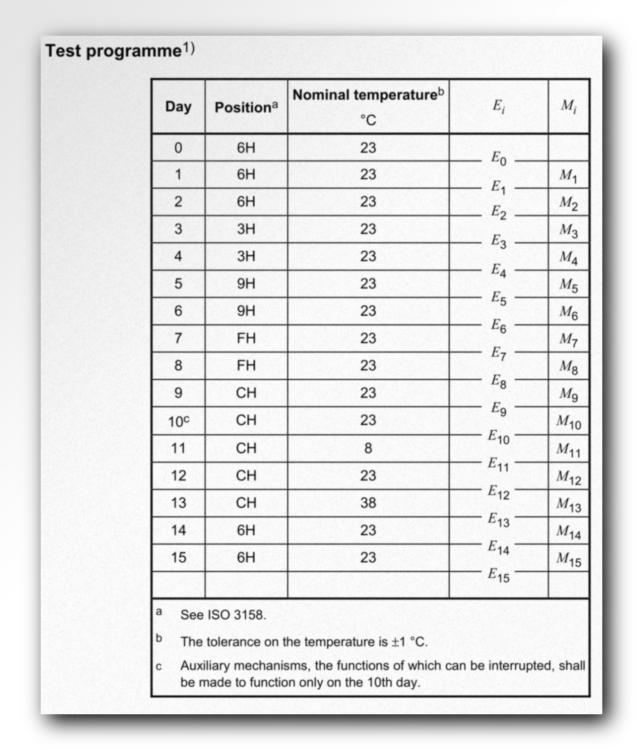

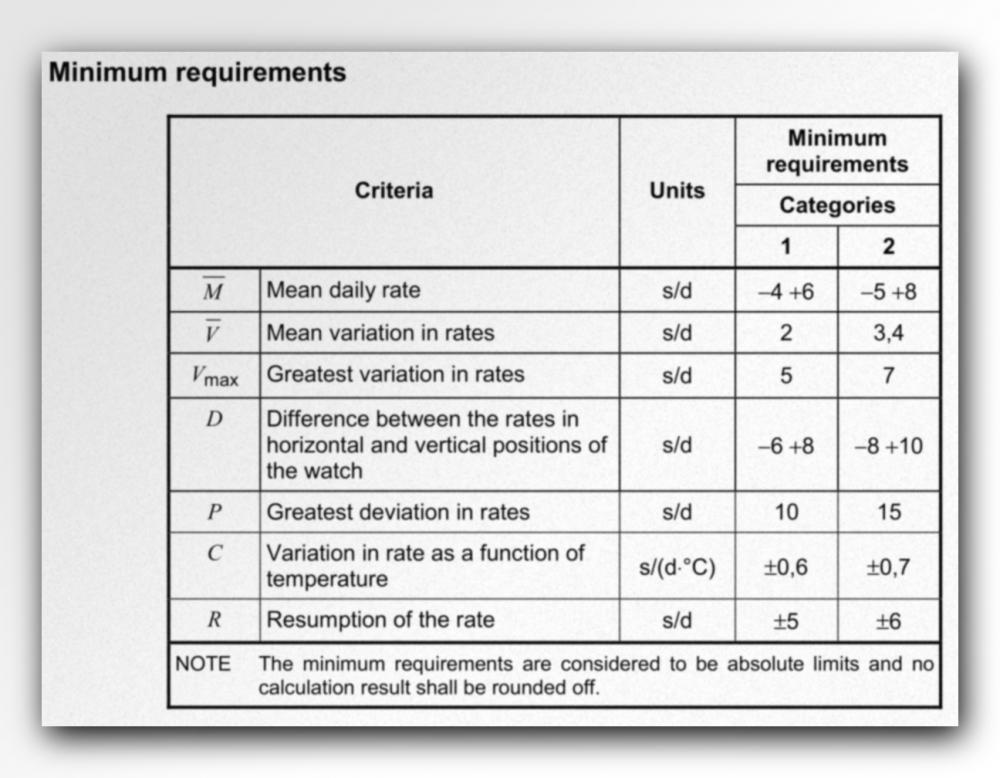

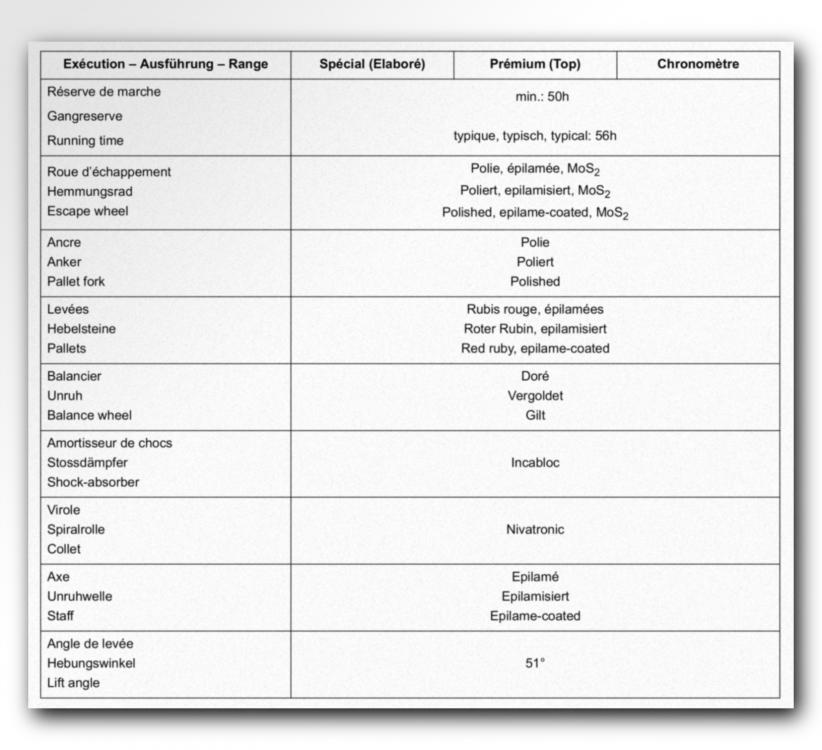

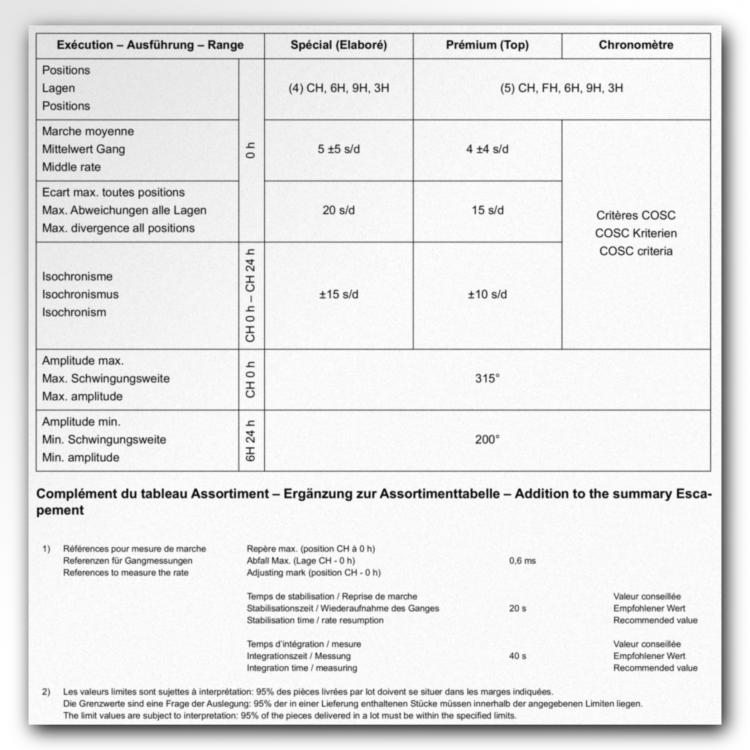

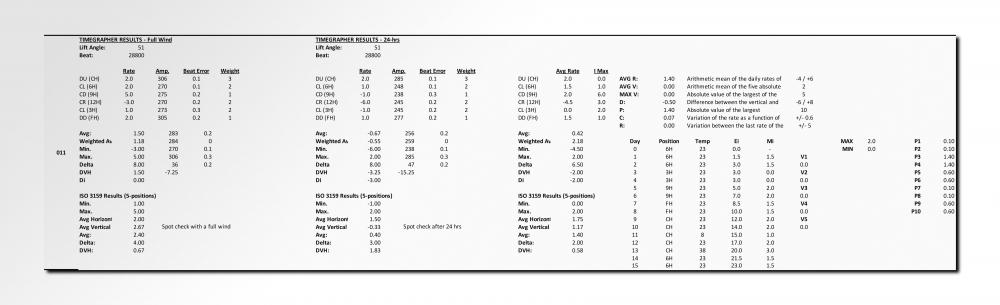

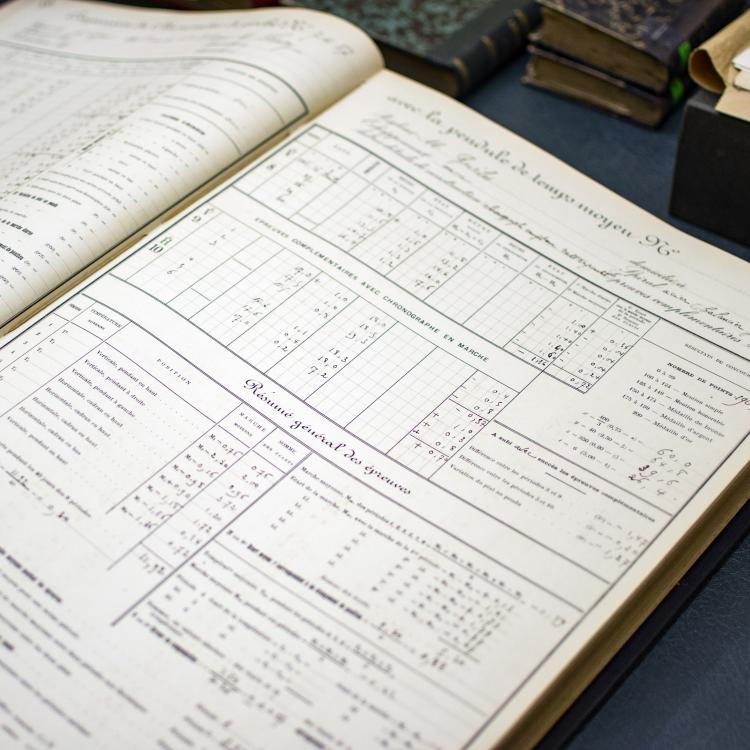

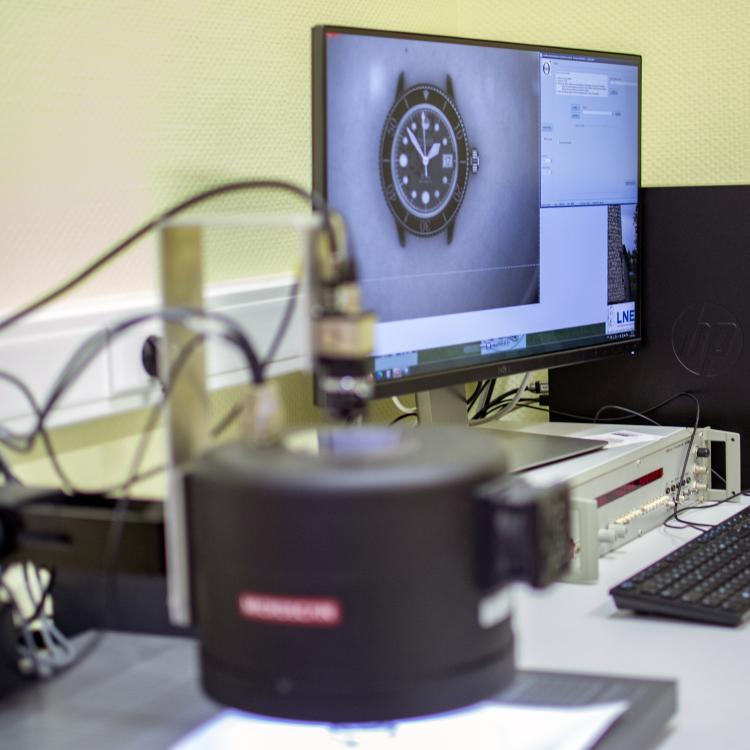

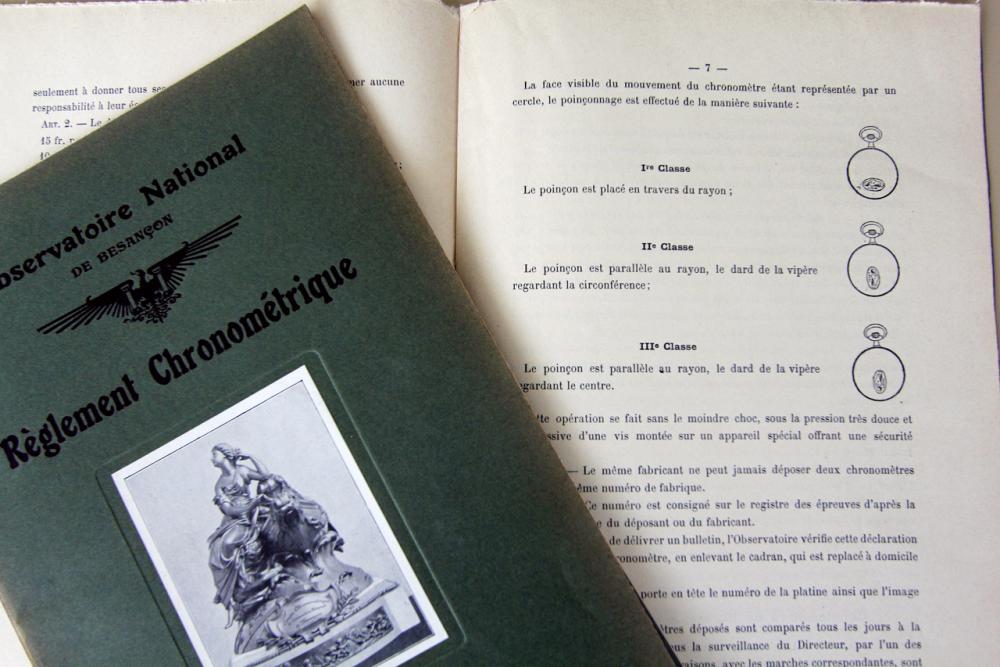

Introduction Before I jump in to sharing my story I will introduce myself. I’m Matt. I’m the founder, designer, and watchmaker of Typsim Watches. Typsim is a small, independent watch company based out of Seattle, WA, USA. This is my experience with chronometer certification of the Typsim 200M-C. I chose to have some of the Typsim watches chronometer certified out of my desire to produce the high-quality, accurate watches. For me, chronometers represent watches that use the highest quality materials, are put together with great care, and are rigorously adjusted and tested. But further, they connect a timepiece to the history and pursuit of precision timekeeping Typsim is a USA-based company, registered in the United States. The watch components come from Hong Kong, China, Canada, USA, and Switzerland. The watches are designed, assembled, and regulated in the United States. Because of this, Typsim watches or movements cannot be tested by COSC, Contrôle Officiel Suisse des Chronométres. The Typsim 200M-C is designed with a Sellita SW300-1 movement. This is Sellita’s comparative movement to an ETA 2892-A2 or Omega 1120: Diameter: 11.5”’ (25.6mm) Height: 3.6mm Frequency: 28,800vph (4hz) Jewels: 25 Power Reserve: 56hrs Features: Center Second Hand, Quickset Date Sellita offers their movements in several grades, Special (Elabore), Premium (Top), and Chronometre. The primary difference between Premium and Chronometre is the precision in which the movement is regulated for the average rate, max positional rate difference, and isochronism tolerance. The Typsim movements were ordered as rhodium-plated, diamond-snailing decoration, blued screws, custom logo engraved oscillating weight, custom date disc, with Premium regulation and Chronometre grade components (balance, pallet fork, escape wheel). What’s required of chronometer certification? The chronometer test program is defined by ISO (the International Organization for Standardization). ISO also accredits the testing laboratories that perform the tests. For reference, COSC follows ISO standards and is accredited as a testing agency by Swiss Accreditation Service. There are several other testing agencies around the world that can test and certify chronometers which include Besançon Observatory in France, Glashütte Observatory in Germany, and very recently the Horological Society of New York in the United States. A certification is provided to a wristwatch that successfully meets the requirements of the testing program defined by ISO 3159:2009. Test testing protocol lasts 15 days, tests 5-positions and 3-temperatures. The minimum requirements are: I selected to have the Typsim watches tested and certified by Observatoire de Besançon in Besançon, France Besançon, the historical watchmaking capital of France, is located in the eastern part of the country near to the Swiss border. It’s history as a watchmaking place began shortly after the French Revolution and culminated in the mid-twentieth century. Unfortunately, the 1970’s rise of quartz-based watches create a sharp downturn in mechanical watchmaking and shuttered much of this city’s watchmaking companies. The city’s expertise in precision work pivoted toward micro technologies. Since the 90’s the watchmaking industry has slowly recovered with a focus on high-end and custom watches. In 2002 the Observatoire de Besançon reopened for chronometer testing. Since then, they test several hundred watches a year, mostly from independent companies like Laurant Ferrier and Voutilainen. The typical success rate hovers around 70% with even the best companies averaging 80% success rate. Testing at the Observatoire de Besançon differs from COSC in that the Observatoire de Besançon only accepts fully assembled, complete watches with all components engaged for testing. COSC on the other hand tests bare movements with the automatic device (if a part of the movement) disengaged. This means testing with the Observatoire de Besançon accounts for more complexities faced by assembling and having an assembled watch. Preparations Understanding the testing requirements and average failure rates, I felt immense pressure to submit the very best performing watches I could. The first step was identifying the best movements out of the batch of movements provided by Sellita. Sellita provided movements conforming to their Premium regulation standards: Adjusted in 5-positions Average rate of +/- 4 s/d Maximum difference between positions of 15 s/d Isochronism of +/- 10 s/d Per terms with Sellita, up to 5% of the movements are allowed to be delivered outside of Premium regulation specifications. I created a preliminary, bare movement testing protocol to identify the best movements out of the box. I tested each movement in 6-positions with 20-seconds of stabilization and 40-seconds of measurement per position at both full wind and -24hrs wind. I was able to discover the number of winds to achieve the full wind and -24hr wind thru crown rotations, not waiting 24hrs. I measured the number of winds it took to wind up a watch to full wind after 24hrs. That number was subtracted from the number of winds it took to fully wind a movement to determine how many winds to wind to -24hrs. The instantaneous values from the timegrapher were inputted into a spreadsheet which calculated: Average Rate Weight Average Rate Minimum Rate Maximum Rate Delta DVH Di Isochronism Hypothetical Chronometer Testing Results based on the average between 0hr and 24hr rates From this information, the best performing movements were selected for assembly. Movements were selected for the amplitude, min/max rate delta, isochronism, and their apparent aptitude for passing the hypothetical chronometer test. These values gave me an idea of how well the movement was fabricated, lubricated, assembled, and regulated from the factory. Serial numbers were engraved on to these movements. One anomaly that bothered me at first, but I eventually let go, was the rate in the 12H (crown right) position. This is a position not tested under ISO 3159:2009 nor as a part of the Sellita specifications. Frequently, this position presented beat rates 5 – 7 s/d slower than the minimum beat rate in the other 5-positions. The selected movements were selected in part because they did not demonstrate this beat rate delta. With movements selected, the Typsim 200M-C watches were fully assembled and retested all over again using my pretest protocol. This was done to verify the assembly process was executed without causing issue. The watches were all adjusted based on the pretesting protocol. The beat error was reduced to 0.0 or 0.1 in CH (dial up) position. The rate was adjusted based on the average beat rate between 0hr and 24hr instantaneous rates. The Etachron pins were adjusted to narrow the isochronism down as close to 0 as possible. I would soon find out this was not the best route to make adjustments for this test. With the watches adjusted I set about testing them in accordance with the ISO 3159:2009 testing protocol. I planned to take measurements every 24hrs and adjust as required. The watches were set against www.time.gov and measured against the same online atomic clock after 24hrs to determine their actual, daily positional rate. I quickly discovered the movements were not demonstrating a rate that averaged between 0hrs and 24hrs rates but instead represented the instantaneous rate taken at full wind. Said differently, in real world timing condition, the rate was what a timegrapher said it would be at full wind. If the full wind timegrapher results for CH (dial up) indicated +1 s/d, the 24hrs wind timegrapher result indicated -4 s/d, the watch would demonstrate +1 s/d when measured against the online atomic clock after 24hrs. This was true of all positions. From the point of this discovery onwards, my adjustments were made only considering full wind timegrapher results and actual timing results. Each movement was tested for actual timing results for two weeks in CH (dial up) and 6H (crown left) positions. These two positions were prioritized for two reasons. First, ISO 3159:2009 emphasizes the rates and differences between these positions in the minimum requirement calculations and number of days tested in these positions compared with the other positions. This meant these positions needed to be as close as possible in their rate. Second, when CH and 6H rates are adjusted to be equal the other 3-positions were reined in to be within +/- 2 s/d, having a 5-position rate delta of around 4 s/d. Confirmation of 5-postiion average rate and rate delta was performed every 4-5 days during this process using the pretest protocol. Achieving a 4 s/d tolerance provided for a daily average rate that was well within ISO 3159:2009 requirements. My methodology for equalizing the rates between CH (dial up) and 6H (crown left) was to measure the instantaneous rate at full wind for each position. Depending on the results, the Etachron regulator pins were rotated further opened or closed. If vertical position had a faster rate than the horizontal position, the pins were opened. If the vertical position had a slower rate the pins were closed. I adjusted the pins with the movement running at full wind, testing for the results after each adjustment. I found, minor rotation of the pins would increase or decrease the beat rate in CH (dial up) position. The smallest rotation I could make would affect the CH (dial up) beat rate by +/- 10 s/d. I discovered that amount of rotation would bring the rates between CH and 6H together by about 1 s/d. If my CH (dial up) rate was +1 s/d and my 6H (crown left) rate was +4 s/d I would need to open the regulator pins just enough to reduce the vertical rate by 3 s/d. I would rotate the regulator pins until the CH (dial up) rate was approximately +31 s/d. I would then adjust the regulator arm to +1 s/d and measure the resulting rate for 6H (crown left). The resulting rate would typically measure +1 s/d. I would not call this scientific, but the results were consistent enough that I could rely on the action and corresponding results. I have a suspicion the instances that didn’t work out this way were due to my inadvertently moving the regulator arm, hence changing the rate more than the pin rotation alone. At the end of the 14 days the watches were performing at +0 s/d to +1 s/d in both positions – both as shown on the instantaneous timegrapher results and with 24hr timing. The Test Historically, the Observatoire de Besaçon used a Lunette Meridienne instrument to measure elapsed time through precise observation of solar bodies passing through the meridian. This one axis instrument sits on a dedicated, three-story, solid foundation – as do the reference piers outside the building – to maintain instrument stability. Comparing the elapsed time on the watch with the movement of solar bodies allowed the observatory to calculate the rate to the tenth of a second. Today, Observatoire de Besaçon uses three interrelated atomic clocks located in a thermally and seismically isolated room to synchronize the various clocks throughout the laboratory. These clocks are a part of the French national and international atomic clock organizations, setting the most precise time around the world. The watches are provided a QR code, and the hands are digitally synchronized to their timing software with a high resolution, macro camera. Each watch is held in position by holders and placed in a temperature and humidity-controlled vault each day after measurements and winding. I decided to fly the watches from Seattle to Besançon myself, hand delivering them to the Observatoire de Besançon. Due to the sheer value of the watches being shipped from the United States to France and back again, the shipment needed to be processed through customs with a Carnet. This is a special, temporary export/import procedure allowing for products to be shipped between countries without duty. The caveat to this procedure is the shipment needs to be hand carried or couriered (basically not shipped with FedEx, DHL, etc). I also had concerns that the vibrations of a cargo plane or handling of a courier could displace the precision adjustments in the watches. Finally, I personally wanted to see the historical observatory, meet the staff, and understand every part of the process. The watches safely made it to France with me in mid-August 2022 and I was notified of their success rate in early September. The 95% of the watches successfully passed the test and were certified chronometers. 70% of the movements had an average daily rate of -0.5 s/d to +2.0 s/d, aligning with what the preparations and pretesting indicated. The remaining successful results were just barely outside that range at -2.0 s/d or +3.0 s/d. The failing results were not far off at around +6.5 s/d, just outside of minimum requirements. Each movement will now receive a Tete de Vipere, symbol of the viper, the historic marking used by the Observatoire de Besançon that the movements were certified chronometers in Besançon.4 points

-

Thanks to everyone who's been assisting me here the last couple of months, I have two Timex projects I finally completed tonight and are ready to go to new homes. The first is a 1969 Mercury whose numerals I found really striking. It was a non-runner and looked much worse than it actually was on its original expansion band (which is now clean and usable again). But it really only needed service, a new crystal, and some patient cleaning, and now I think it looks amazing. This is the kind of watch my grandfather would have worn for special occasions and treated like a treasure. And next is the 1971 sort of rally diver Timex Electric I had a bunch of questions on in this thread. I received it as a non-runner, badly gummed up inside with a crown that just barely turn. Thorough cleaning and service didn't quite get it running because it had a bad copper coil. A donor balance finished it up and with a new crystal & mint dial & case, it looks sweet. Only the worn plastic bezel shows its age. It's only in want of a better strap now. To my surprise, it was pretty much bang on for a Timex, and I didn't have to touch the regulator. The noise on the right is I think because the seconds hand only advances on one direction of the balance swing. (But these early 70's Electric movements are are kind of frustrating to work on and with super slow hand setting gearing and no date quickset, I can't see myself jumping to do another unless it is really unique looking) Thanks to everyone who helped on these!4 points

-

one of the reasons you are finding a hard time finding information is the various watch companies renumbered the watch and you need to know what it is you're looking for. So in other words you could use the service manual from any of the companies because they would all be identical just have to find one or perhaps a website like the site below where he goes through servicing one. https://electric-watches.co.uk/movement-types/tuning-fork/esa-9210/3 points

-

I think the question is , unless you try you wont know. And if nothing else you will have gained a bit of knowledge. It all depends on the degree of corrosion and how far its penetrated. Heed the advice given by Nicklesilver Attached the general service manual for your information. cheers Bulova_SMQ Service Manual (2).pdf3 points

-

It will really need to come apart and have a full service to be sure there's no debris in the works, plus is certainly has dried oil everywhere (these movements will continue to run even with gummed up oil). These are particularly delicate, not for novices. Parts are becoming very scarce so a mistake can be very costly. Just to take the movement out of the case you must remove the tuning fork module first as any bump to the hands with that in place can cause major damage. But these are super movements and well worth saving!3 points

-

2 points

-

I would say it depends on the detail on the center shaft. Best to make that determination on a case by case basis. Shane2 points

-

The depth adjuster will get moved if some silly bugger has been messing about with the pallet stones. watchweasol is right on the button with this one.2 points

-

Hectors design is the modded one and is a deal safer than a raw cutter, a piece of brass/Copper wire (Tapered) inside the Cp is best as its soft enough to allow a decent indent without cutting the CP. It should be noted that the adjustment is done by degrees and test fitted after every try. I mounted my clipper on a wooden block to provide a stable base and makes the one handed operation easier. You will probably find the square jawed clippers better instead of the curved jaw ones. I believe they are for Toe nails and the curved are for finger nails. Available from any chemist/Apothacarys shop.2 points

-

2 points

-

Hello to you all. Last week I visited a local thrift store and found some watches I think are interesting as learning projects, as I'm still at the start of my watch making roadmap. First watch is an Oris with a 7 jewel 292 movement. Second watch is a Bucherer automatic. Third watch is a Universal Geneve with a microrotor movement. Oris and Bucherer are complete, first assessment is that need complete service but show no apparent defects (at this stage). Universal has the wrong case, but recovering that movement is a challenge in itself. I'd appreciate links to service sheets etc or links to service jobs on similar watches. Thanks in advance!1 point

-

yes in the old days of timepieces that Time good enough that you'd be concerned if there were off by a few seconds a day dropping them hard enough to move the regulator would break the balance staff. Then timekeeping would not be good at all is the watch with no longer run. you still really need a timing machine to assess this. Then damage is a misleading word. We get watches into the shop from time to time that are going out of specs might be a way to word it. I remember one Seiko that came in I didn't even open up by just put on the demagnetizer and that's all it took. It's really easy on the modern watches to knock the hairsprings out of place.damage just put them where they're not supposed to be. It also seems to be possible and knock the regulators out of place it makes me wonder how hard somebody dropped the watch. this is where are you really need a timegrapher anything involving regulation of watch it's silly to do it any other way it's almost well ask it is impossible. Ideally when you look at the watch on the timing machine usually look at it and dial-up and dial down and at least one crown position just to see how it's doing. Then yes soon as you go from a dial position up or down to the crown position it always loses amplitude just what they do.. But if you're amplitude is pathetic for some reason and any go to a crown position and it drops 30 or so degrees worst-case it's going to look really really bad. oh and minor other little thing depends on where you bought the watch from as to how fast they turn over their inventory. Just because you purchased a brand-new doesn't mean it wasn't sitting in a warehouse for some time. \1 point

-

Hi Not had any through my hands but I have attached the tech sheets for the Omega1255/ESA9210. There is further information on Ranfft's website. 486_Omega1250,1255,1260_New0713 (1).pdf1 point

-

silver oxide batteries typically have sodium or potassium hydroxide in them. If you're not familiar with the compound sodium hydroxide is typically drain cleaner. So you don't necessarily need a full hazmat suit or breathing apparatus but try not to ingest it or get it in your eyes. https://en.wikipedia.org/wiki/Silver-oxide_battery1 point

-

Hi You have done ok there, The Bucherer is an ETS 2824, nice movement. The universal looks interesting with the offset rotor. and the Oris a good movement too so all in all anice handful.1 point

-

There is a fairly new YT channel currently called "Its about time" (previously called It's about f*****g time). The poster of the videos is named Alex Hamilton, and is a watchmaker in North Carolina. He has quite a few videos directed mostly to the new watchmaker and hobbyist. Some of them are very insightful. His current video goes into great detail on how to source parts. Parts for every era of movement. I wanted to share this with the community in case folks like me have a hard time looking for parts. Several of the web pages he highlights were known to me, but there were several that I was unaware of. I am still in the early stages of learning this awesome trade/hobby. I have been known from time to time to lose parts.... lots of parts. I then spend days looking for those parts and it does get tedious... I know... Stop losing those parts. Im working on it LOL! Here is the link to the video and I hope others find it as useful as I did. Good Luck "IT'S ABOUT TIME"1 point

-

@HectorLooiYes, that looks very serviceable and as @watchweasolhas said, approach your setting cautiously. Just one extra thought, this is spring steel, for the most consistent results, the setting screw should be as close to directly under the lever's fulcrum as possible. Thank you for the photo. Shane1 point

-

Hi Willow as you look at the screw there is a slot in the back plate align the screw slot with this and then try again. normally these screws are factory set and do not need adjusting as the depth is set up. If some one has turned it it begs the question ,why, the "Brocot" escapement is usually very good unless its been worked on by some one. You have basically to reset the depth on the lockings on the pallet, check the pallet surfaces are not worn or chipped and highly polished (mirror finish). Fit the pallet anchor assembly and wit a couple of turns on the spring check the action and adjust untill it locks and unlocks then try the clock for running. Might take a bit of time going bit by bit. all the best1 point

-

Wow, agreed, that was enlightening! Well done with the success rate.1 point

-

Fantastic description of the process. Thank you so much for posting this!1 point

-

AS 984 is definitely a Left Handed ratchet wheel screw. I made that mistake on the first one I disassembled and wound up with a snapped screw head as a prize! I just tested a couple other AS 984 movements I have and they were also both LH ratchet screw.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Hi JRod, welcome to the forum! we are happy to have you here. Looking forward to seeing what you are working on. -Drew1 point

-

I never bought a full set of winders until I got the vintage K&D set for pocket watches. I've bought the Bergeon left and right handles, but you can actually do without them if you want. I buy the right hand winders with the arbor in the size that I need, and then if I want left in that size I just get the left handed arbor to use with the winder. Still expensive, but not eye wateringly so like buying a set would be. I get the numbered sizes that are not caliber specific. If I found myself working on a lot of ETA's, for instance, I might get a caliber specific winder, but so far no need.1 point

-

I would expect so Ross. If i were to buy a set of winders i would choose a generic set that had incremental sizes of .5mm or maybe a little less at the smaller end of the winder sizes and then a slight increment increase as the sizes got bigger. Just so i covered my bases. I'm guessing this manufacturer is attempting to appeal to fresh amateurs, i suppose a little like buying spanners that would fit Porches and Lamborghinis. A bit gimmicky imo as a pro that works on high end movements would never touch a set like this. Hey matey check out the watch on the right of picture 4 at this link. https://www.ebay.co.uk/itm/234591030160?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=VYphkhamTOi&sssrc=2349624&ssuid=tBiLZaCfRb2&var=&widget_ver=artemis&media=COPY1 point

-

The final parts for these watches arrived on Thursday and today. I documented the adventure I had with the Lord Matic crystal yesterday in another thread. After 4 weeks of shipping time, the bezel for the 1974 Seiko arrived today. I so happy to see these running. I'll order some straps for these this weekend, and by the time I return from my work trip next week, hopefully they'll have arrived. The 1972 Seiko Lord Matic: The 1974 Seiko 7006-8190R There was some surface spots on the bezel, which I was able to remove by using some glass cleaner and a microfiber cloth. It took quite a bit of scrubbing, but I was able to clean it up pretty well without damaging any of the plating. There is only a hint of a spot visible around the 10 o'clock position on the bezel. Aside from the few marks on the dial that I could not remove with Rodico, this thing is in great shape now. Now that I'm looking at the photo I realized that I never pushed the crown back in after setting the time when I took the photo. It's bugging me now, but I don't want to go and take another picture!1 point

-

Bingo .... and thanks everyone. Soaking overnight plus a little very gentle heating with a fine soldering iron and it came loose .... it was a reverse thread as you all thought.1 point

-

If that amplitude is correct, then it is very low. I wouldn't rely on working out the amplitude by filming it with slo-mo. But you have given us nothing about the watch, how old it is, when the last time it was serviced. A 1917 trench watch might be good to go with low amplitudes, but not a modern ETA 2824-2. Unless you have some sort of timegrapher, I wouldn't rely on visual guesswork regarding the amplitude. Amplitude isn't measured as the full swing of the balance to full swing of the balance. It's measured as the balance at rest (as the impulse jewel is between the banking pins with no power on the mainspring) to the full swing of the balance. So, you might be thinking the amplitude is something other than it is1 point