Leaderboard

Popular Content

Showing content with the highest reputation on 08/29/22 in Posts

-

3 points

-

By short I mean the distance from pivot to pivot- on watches with center wheel under the barrel this can be very short, and sideshake at the pivots will be amplified at the end of the cannon pinion. In that case I would really look for 0.01mm clearance/shake. If your center wheel is "normal", i.e. above the barrel, the pivot to pivot (shoulder to shoulder) distance should be long enough that the extra 0.01mm shouldn't matter- in either case it should run fine. In the "short" case you might wonder why the minute hand is twice as far from the dial on one side compared to the other!2 points

-

For a balance wheel like that, my test is (not based on anything but experience) : give it a good blast from the puffer, and there should be good movement ( >180°) after 30 seconds.2 points

-

It's great software - but it's not been updated in years and its terrible for touch screen laptops because you cannot change the size of the buttons and this means you need a mouse or laptop with trackpad. So it takes a lot of space up. No but graham used to sell converted mics from vintage machines or he will convert yours. I supplied an old one from a Greiner machine I had and he converted it and did a bit of referb. Incidentally, I now use the OneOf Accuracy Pro now and the software is excellent and touch screen friendly. https://www.cousinsuk.com/product/oneof-accuracy-pro One side bonus is the OneOf microphone works well with Graham Baxters eTimer software too so best of both worlds.2 points

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

1 point

-

You will need to make sure you have the correct depth, other wise they will do fine.1 point

-

I would always replace the rubbed in jewels for friction fit, unless it was about restoration or preservation of the timepiece. As you said, sourcing the jewels will be relatively easy. anything that is of questionable integrity, replace. That's a pretty big job, as it looks like a lot of replacement jewels are needed. The pivots/arbors will burnish and polish up nicely, as there only slight wear on them.1 point

-

Oops! First newbie mistake...need to divide the numbers by two.....I looked up the definition of amplitude and my face turned red as I realized mine is varying between about 210 and 140 depending on orientation.1 point

-

Moving to correct sub-forum. ---- Why is this happening? Please don't be offended - from time to time, in an attempt to keep WRT organized, we need to move threads to another area more suited to the subject of that thread. Members can help the forum staff by checking for a suitable sub-forum before posting as this will help to reduce their admin workload.1 point

-

Funny- there is a procedure in the design phase of watch development where the "Q factor" is determined. There is a lot of math involved, but very basically, taking into account the inertia of the balance, its hairspring specs, frequency and some other stuff, they start it vibrating at a given amplitude (300 seems to be the base) and then measure how long it takes to come to rest. I have the formula in one of my books somewhere. The Q of a really good wristwatch might be 200, 600 for a pocket chronometer, higher still for a box chronometer, etc. When vibrating a new spring on the Luthy tool, where the balance is suspended by the spring with one pivot resting on the glass, it's pretty easy to get 60 seconds of run with a start amplitude of 180. What Mike observes with the balance in the watch sounds pretty spot on.1 point

-

0.01mm would be great, 0.02mm on pivots of this size is still good unless it's a really short arbor (like certain calibers with the center wheel under the barrel), 0.03mm is a bit much.1 point

-

You know if you mix and match balances and hairsprings, you then have to vibrate the hairspring and balance by finding the pinning up point, so the hairspring is able to regulate the movement at whatever beats per hour required. You may already have done this1 point

-

I picked up a 5Kg tub of oxalic acid earlier this year after watching some YT videos on how wonderful it is. But after some experimenting, I don't find it very effective. I tried removing rust stains from cloth, removing rust from screws, yoke springs, lime scale around the taps, etc. And I wasn't impressed. Previously, I used hydrocloric acid, phosphoric acid and citric acid for rust removal. All of these work better than oxalic acid but are more prone to creating pitting of the surface. I also tried a 50/50 mix of citric/oxalic acid. This seems to work best. Let us know your experience when your oxalic acid arrives1 point

-

Thank you Mark. I am such a new bee that I did not search for IPA as an abbreviation for isopropyl alcohol. (The search for IPA brought many hits) I only knew IPA as India Pale Ale. I will try to not be such a headache in the future. By the way I am truley enjoying your lessons. I need to do fault finding over, at least a few times to get it down. Thank you for all the work you do for us. Larry (Midazolam)1 point

-

Thanks to everyone who replied I’ll take your guys’ advice and buy some 8217 when I can Thanks !1 point

-

usually a car clock or perhaps of it went in some kind of like eggs. Like a travel clock but usually the crown is on the other side. But usually when I think Waltham car clock I'm thinking of eight day movements and that is not what I would call a pocket watch size movement? so for instance the pictures the pocket watches up above give a misleading impression of what were looking for. I am attaching an image unfortunately we don't get a size perspective. But if you go to your favorite search engine online and search for Waltham car clock you'll see lots of pictures. also what you're looking at the pictures of notice in some creative individuals have mounted their car clocks in such a way that they now become a desk clock.1 point

-

usually best if you can determine what the problem is before cleaning as cleaning usually doesn't fix problems. sometimes cleaning will fix the problem if it's because the watch basically is it running because it desperately needs to be cleaned but usually if there's a problem it's best to figure out what the problem is and try to fix the problem before you do a cleaning. hairsprings are tricky things to look at. One of the key things is they have to be flat they can't be touching the balance that would cause issues Be touching the balance bridge more issues basically can't be touching anything and not supposed to touch. Often times that is really hard to see. it be nice to see a picture of your tangled hairspring and why is it not tangled all the time?1 point

-

I have never considered Moly to be a braking grease, nor can I remember ever having seen it being recommended for this application on any sheet including Rolex - or at least I have most of the Rolex service sheets and can't remember seeing it. Kluber 125 is my go-to now but sparingly applied, I've seen it really being piled on in certain Instagram posts in the past . To the OP - my two cents: I recommend grabbing some Kluber or 8217 if you're going to be working on any number of automatic movements - it will definitely improve performance and give you peace of mind that you have done a good job.1 point

-

1 point

-

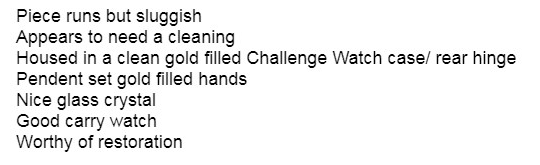

Hello Everyone. Just won this one. Elgin Antique American Gentleman's Pocket Watch Grade 303 Circa 1927 (#29296413). The practice movement I bought is from the same Grade and a reasonably close serial number (#23687805) so I hope to be able to make a working piece out of the two. Practice Movement: https://pocketwatchdatabase.com/search/result/elgin/23687805 Semi-Working Pocket Watch: https://pocketwatchdatabase.com/search/result/elgin/29296413 Here's the description: Wish me luck in this restoration! Does anyone have any tips for me? g. ----1 point

-

If what is pictured is the part that came adrift, between the movement and dial, it is the cannon pinion assembly and it goes back onto the tall staff right in the center of the movement (which drives your seconds hand from the center wheel)1 point

-

I use a large head pin, stuck into a short length of wood cut from a bamboo chopstick. The pin head picks up a lot of oil. For thick oils like D5 or HP1500, usually a single dip is enough. Thin oils like 9910 would require a few more. I'm OCD, so I use a separate dipstick for each type of oil. I even use a different oilers for each type of oil. My mentor taught me to stick the oiler in a piece of pithwood to clean it. But unless the piece of pithwood is disposed of very frequently, the different oils will mix in the pithwood and cause cross contamination. So, what do you think? Do I need psychiatric help?1 point

-

Only counts toward initial acquisition cost. Just about every watch needs at least a crystal or mainspring or something, and if that went toward the cost of entry I'm not sure you'd be able to get anything under the 404 bar unless someone paid you to take it! Parts that go into making it good are not tracked at all on my ledger. Only reason to do that is if you're trying to sell it later and make a small profit. I wouldn't even worry about discounting the other 11 that came in the box. If you bought a box with 12 watches for $12 and 11 were crap, but the 12th was a Rolex, I'd personally count that as a $1 Rolex for 404 entry purposes.1 point

-

A probably Swiss, maybe not, possibly in need of little more than a service, maybe not, possibly quite early judging by the jewels, (but maybe not), keyless wound pocket watch movement. Seller claims the balance is OK, so there is a chance this may be salvageable. I might even have a suitable case, crown and stem for it (perhaps). I guess you could argue that if I add the case, it pushes things out of the 404 club price bracket, but then gain if both items come to less than £4.04 each, then according to my completely arbitrary and illogical interpretation of the rules, that is just fine. It may of course be little more than a paperweight.1 point

-

Here is a live footage of the process. To remove the crystal, you will need special tool, either a crystal lift or wrench.1 point

-

Aye you right I blew up the picture and there it is. I have attached a coulpe od documents that might come in handy if you have never worked on one before cheers 577514301_03.CasingGuide.pdf 1034_Seiko5606A (2).pdf1 point

-l1600.thumb.jpg.cb4fce767586b1fa52d1d6444912ff70.jpg)

WB-l1600.thumb.jpg.66de1bd57456e9213460266bcbab5cf2.jpg)