Leaderboard

Popular Content

Showing content with the highest reputation on 08/23/22 in Posts

-

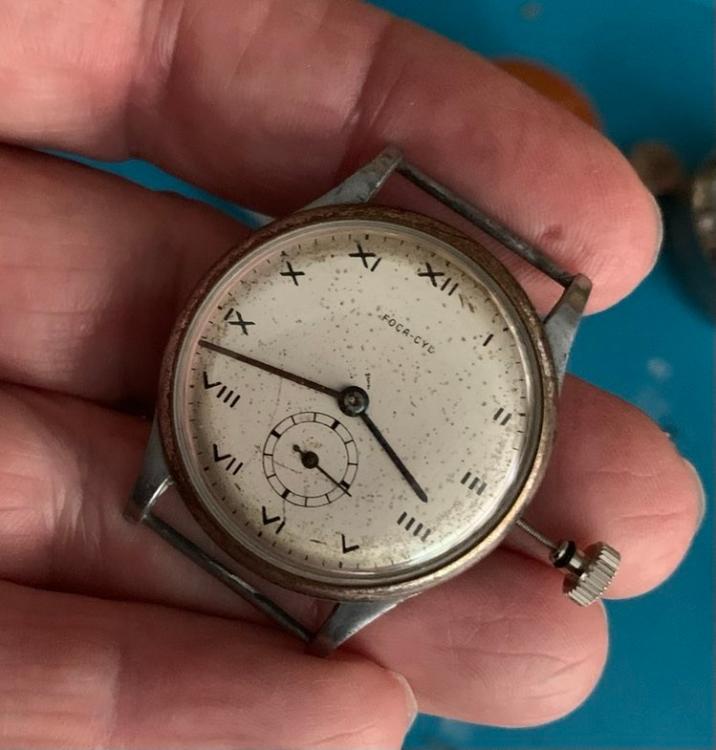

Picked up a job-lot few weeks back that had this interesting fixed lug case watch. Inside I found an AS 960 with missing winding stem. Found one from a seller in Portugal. Part arrived today and now I'm testing the time keeping. Besides the stem, I have replaced the crystal that was very yellow. Next up I think I will attempt a nickel plating.4 points

-

As I've documented briefly on here previously, I've been put through the gauntlet with my first full service/rebuild. I had a great looking purple/blue (depending on the light) Seiko dating to 1974 that I chose as my first candidate. It has a Seiko 7006A movement. The mainspring taught me a lesson when I tried to wind it by hand, the hair spring had a kink in it, which I failed in my attempt to repair, among other things. I purchased a 'balance complete' which I learned afterwards only consisted of the balance wheel and spring assembly. I just assumed 'complete' meant the full bridge, etc. Well I had a heck of a time getting the replacement spring mounted. The balance complete I received had a twist towards the end of the hairspring, causing the stud on the end of the spring to not line up correctly with the arm on the bridge. My feeble attempt to re-align that mounting stud taught me another lesson about the word 'delicate'. While trying to take the twist out of the end of the spring I put the spring out of flat, and did not have the skill to correctly align that spring either. I could not find a donor 7006A movement without buying a full watch, so after some research I ended up purchasing a donor 7009A movement which uses the same balance bridge, wheel, etc. That donor movement came in. I fully disassembled my watch again, swapped the balance from the donor to my 7006A and did a full cleaning once again. Now I finally had all good parts on hand to get this thing going! Assembly was going well until I tried to use some peg wood to clean the jewel on the top of my donor balance assembly. It went flying, never to be found. Thankfully the jewel from my original 7006A balance cock was the same so I cleaned it, and moved forward with the reassembly. I ended up replacing the barrel, arbor, and mainspring with a NOS Seiko unit, the balance assembly was swapped with a 7009A donor movement, and I ended up swapping out the date wheel because my donor movement had one in better condition than the original. I put a full wind in it and It's been running for about 45 minutes. I did a quick adjustment to get the beat error and S/D somewhat close to where it'll end up, and have just been letting the watch run. I will come back tomorrow and see what the numbers look like, but I am so happy that this one is finally up and running. What a humbling and rewarding experience! I will be doing a bit of work on the case in the coming days and hope to have this watch ready to wear soon. The only thing left will be to find an 'XL' length strap, as the factory bracelet is woefully short of fitting on my wrist. Yes I know there are a ton of scratches! After the 2nd disassembly I finally figured out a screwdriver technique that works for me, and afterwards did not add any additional scratches to the watch. It's something I'm going to take special care to avoid moving forward. Here's a couple of photos from my previous post on this watch. I don't have the dial and hands reassembled so I figured re-posting these would help you remember the watch I am referring to. I have a replacement crystal on hand, and replacement bezel on the way. The bezel currently on the watch has well over 50% of the plating gone. Once received I'll be able to finish with the full assembly. I'm really glad I didn't give up on this watch. For a short while I was telling myself that this had too many issues and was above my ability to repair. I'm glad I stuck with it, as I don't think I could've gotten over having to quit on my first project. Lastly, I am so completely enamored with this new hobby. I have been trying to keep my eyes out for some future project watches and I went a little nuts on eBay over the weekend. I purchased 3 watches that should be here soon. I'm looking forward to getting them in and having them ready to work on once this one is fully finished.3 points

-

I’m finding by fiddling with the crown while front is open, I can get the movement to drop down enough to see the battery. I haven’t committed yet to actually pulling. I haven’t run across another so don’t want to break the movement. If this model was the cheap throw away, then I am assuming the stem and crown are original to the watch. I just can’t bring myself to start yanking. I can’t believe this exact model sold in 69’ for $110.00 Alright. Took the plunge and put some real force on the stem. As you can see, it IS a split stem. I am impressed by how clean it looks. Thank you again for all the suggestions and input. I will post my progress in it as I go.3 points

-

Hello all, Embarking on a new adventure! Starting with an inspection and disassembly of an Omega 351 bumper automatic. Feels like a privilege, what a blast! Seeing as this is a new movement to me and I'm a little outside of my novice comfort zone. This one looks like it's been sitting on the shelf awhile. Inscriptions on the case seem to be servicing from the 70's. I have a few questions to ask and pictures to share along my journey. The inspection turned up a few key items: 1. Large intermediate wheel has two broken teeth 2. The movement is held by a single case clamp and metal bracket that is rusted and bent. Pulling/pushing the crown moves the entire movement within the case. 3. The barrel has excessive side shake due to wear damage on the barrel bridge. 4. There was a concerning clicking noise about once per full rotation of the crown. 5. Leaning towards replacing the crystal although it's probably salvageable 6. The mainspring is an unknown because I don't have mainspring winders in the budget just yet and thus I haven't opened it. Question: Any tips on securing the movement in the case? Should I try to bend the bracket? I'm afraid it may break. Any thoughts on the rough click and noise while rotating the crown? If anyone has a spare intermediate wheel, or bridge to sell please contact me I'm interested. Enjoy the pictures from the disassembly! It's about time for the ultrasonic ! I think this is gonna clean up nicely!2 points

-

For a few dollars more, you can get a swiss-lever watch that will be 100 times easier to work on and everything you learn on it will be fungible knowledge going forward.2 points

-

Hi I can vouch for the superglue and nut method, it sounds brutal but works evert time. remove with acetone.2 points

-

Best option in my opinion. Hand winding springs in always leaves doubt about what damage could have been done. Have you ever taken a spring out and seen that its coiled upwards? Usually that's because its been wound in by hand - and so the spring can potentially be rubbing on the barrel lid. Not judging - I've done it myself in the past, even automatic (slipping) springs, but you never know if damage has occurred unless, of course, if you remove it again to inspect - a new spring is pre-lubricated and ready to fit into your cleaned barrel, and they're relatively cheap to purchase. Using Mainspring winders, like many aspects of watch repair, takes practice and patience to use them without damage - but I personally feel that the potential for damage is greater with hand winding in.2 points

-

Thank you so much, Gramham. That's so generous of you but I have already bought a NOS one from my regular Russian watch parts supplier. He's from Ukraine and I hope everything is well with him.2 points

-

Well done and some good numbers there! I just love Seiko’s in general because there’s so much interchangeability with them. You can have an expensive classic, but many times the key components are based on cheaper movements that make great donors. In Swiss watches everything is relatively more expensive so it’s more painful when something goes missing or is broken.2 points

-

2 points

-

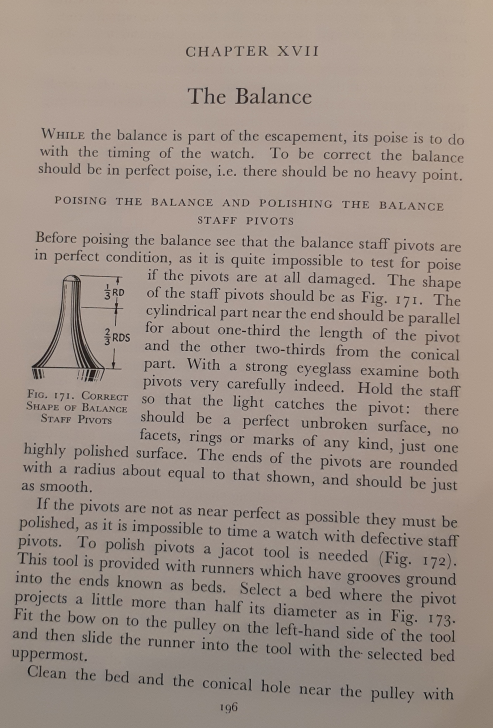

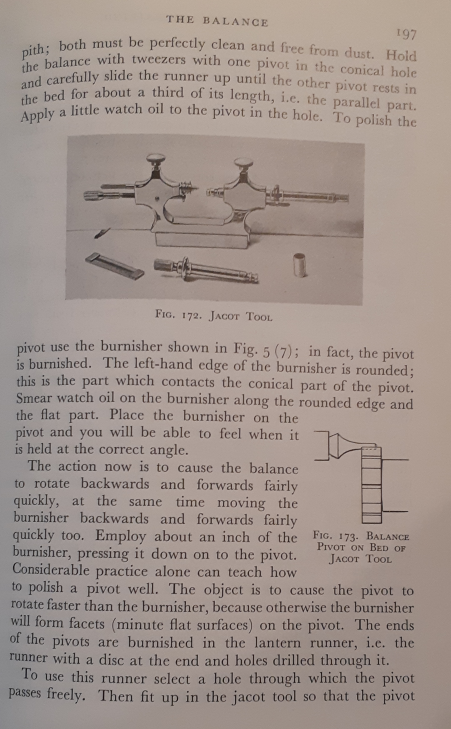

Hello @mikepilk, I may have some helpful information, though from a purely theoretical perspective. I just watched a video over at ChronoGlide where the stated difference in friction between pivots in line with the center of the Earth (i.e. Dial Up, Dial Down) and when at right angles to the center of the earth (Pendulum Up, Pendulum Down, Pendulum Left, Pendulum Right) was in the order of 800%. This makes sense when you consider the amount of surface area of the pivot coming into contact with the amount of bearing surface area that it has been set in (brass or jewel). In de Carle (1981, pp. 196-197) there appears a discussion of the proper shape of the end of a pivot, as well as a couple methods of polishing the end of a pivot, one manual and one machine-based that relies on the use of something called a Jacot Tool. Could it be simply that your pivot ends are rough from corrosion, which is affecting effective transmission of impulse energy through the train of gears? Have you inspected the pivots and bearings for rough surfacing under a microscope? Are they sufficiently polished? I include screen shots of the above-mentioned sections of the book for your convenience: Forgive me if you know all of this stuff already, I am just trying to be helpful. g. ---- REFERENCES de Carle, D (1981) CLOCK AND WATCH REPAIRING (2nd Edition), London: Robert Hale (ISBN: 0-7091-9436-6). https://www.gettextbooks.com/isbn/9780719803802/2 points

-

As Dadisic said that's a good place to start. If you still get stuck, i'm sure someone here will have your back. Shane1 point

-

You can find the Timex service manuals that I am sharing here - https://drive.google.com/drive/folders/0B-IKHN7WFKiwY3JMMDJnMld2SE0?resourcekey=0-7myGNNAUiShb5ihA-o6PnA&usp=sharin Should get you started. Cheers!1 point

-

Ok everyone, the lathe arrived, the cross slide fits, my 3 jaw adjustable chuck arrived along with the foot (lathe arrived with a wheel that mounts on table so you rotate it by hand. I will probably just take the headstock apart to clean it and re-lubricate. The lathe uses bushings so it should be fairly ok to reassemble, but I want to make sure it is lubricated as it was sitting in a garage for a while while the previous owner decided to retire. So here are a few things I need to get next - a lathe motor (I've seen some watchmakers use this one, but I would ideally like one that supports variable speed via pedal control), recommendations welcome. - find a wooden base (maybe I'll just get a 1 1/2 inch cutting board, any recommendations welcome). - Audit all the collets that arrived with the lathe and slowly buy the missing ones. - get some gravers and sharpening tool so I can start producing chips1 point

-

Lol. I used to do this with cars, " have i put that part in without damaging it i did seem to be a bit heavy handed, lets take it out and check it. Yes its fine " then break it on its second fitting.1 point

-

Check out the superglued nut method G. It works a bloody treat good sir People say the same about me Kalanag although i'm more of a jeans and got your ticket to the gun show white t shirt kind of guy.1 point

-

I rewind the spring in a ring and rinse then it can be inserted in as you would brand new ones. Keeping the rings to have a collection. Poor man's mainspring winder.1 point

-

Hello Everyone, This arrived in the mail today. It's a runner. Paid HKD100 for it (About USD12.75). - Crystal just a little scratched, throwing a shadow a 7 O'clock. - Baton (is that right) hands in reasonable shape, it seems - Sweep/second hand with little red end (nice touch!) - Baton indicators - RED Date in framed window - No calendar quickset - No hacking - Seconds index around perimeter of dial Did I get the above right? Did I miss anything? Does anyone have anything to say about Shanghai watches? Has anyone worked on something similar? Any advice? I cannot get the back off - yet - because I am still waiting on my sticky ball.... g. ----1 point

-

1 point

-

Well done matey. You really did run the gauntlet with your first repair. You should feel rather proud of yourself1 point

-

1 point

-

1 point

-

I couldn't get on with watch mainspring winders. If you know how to take the spring out then do so and clean the parts then use finger cots and put the spring back in then oil the spring, some will oil the shoulders of the barrel first before putting the spring in.1 point

-

Very casually the balance looks like for cylinder but look carefully there is a lever and a weird escape wheel? I've seen the weird insert before I guess is there to keep people from over winding the watch..1 point

-

They are two separate PDFs.. One of them is an ancient Omega document that I scanned to a PDF which covers really quite a bit of what you need to know to lubricate the watch Then the other comes from a document by Seitz Just can't quite remember which one I got it from so I'm attaching something that has the equivalent.. 667675573_OilingOmegawatches1957.PDF Seitz book.pdf1 point

-

Thanks for revealing this mystery!!! Put in a new battery and let us know if it runs.1 point

-

So to update (I always hate threads with no ending) -- I had to reach out to Deep Blue a number of times and stay on top of them for updates, but they did allow me to exchange the broken watch for a new one. I paid the shipping to get it back to them, and they paid to send the replacement to me. New watch keeps time, but seems to be running at +25spd dial up if I track it over 12-24hrs. On wrist closer to 0, but I do hate watches that are all over the place when it comes to positional accuracy (my other 4R and NH3x watches are all pretty stable). Hoping it smooths out a bit with a few weeks of run time. But in the end, I did end up with a working watch. I also do want to learn how to do movement swaps though, so might pick up a cheap Pagani Designs watch at some point just to open and play with. But that's for another time.1 point

-

1 point

-

Facing a similar dilemma, I'm going to try something based on a tip from Jerry Keiffer. Pin gages, as in something like this - https://www.mscdirect.com/product/details/40427296 I'm going to try and use them as a reference when machining.1 point

-

To finalize this thread I like to report that I successfully serviced the movement. I used the old pushers in the newly gold plated case. The plating was done by a goldsmith after I had removed the crystals, the crown tube and the pushers. The crown and the front crystal are new. My friend is happy wearing a good looking watch again1 point

-

1 point

-

Filming this process is not easy with a bloody big macro lens in front of you - if its not in the video it doesn't mean it's not been done though - there are quite a few things that don't make it in my YouTube videos which are not step-by-step instructionals But to be clear - they absolutely must be clinically cleaned and lubricated, as painful as the process might be.1 point

-

Try different methods 12 to see what you are happy with. As you can see there are many different views. Old school watchmakers didnt have the extra luxury of forums to gain knowledge from. Much of their experience came from a trial and error approach .1 point

-

Cleaned up this thread out of respect for the OP1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

I notice that the shield seems to align perfectly with the lugs. This leads me to believe that it is not a screw back (never seen a screw back that seated perfectly to align a logo--but it could happen). Are you sure that it is not a front-loader? I would first remove the crystal to see if it is a front-loader (please post a picture of the dial side). It would be obvious if it were because you would see at least some forward movement of the dial side outward from the case. EDIT--on second thought, since it is electronic, I seriously doubt it is a front-loader. If it is clear that it cannot be a front-loader, I would use a safety razor to slip between the (what appears to be) back...working around the circumference. Exercise caution and don't cut yourself.1 point

-

yes that's one of the amusements with this group an obsession with amplitude. obviously nobody from Seiko factories ever on this group they would be so unhappy their watches totally suck for amplitude at least according to group specifications. Notice how normally and never find a Seiko referenced amplitude except the 4006 a manual specifies fully wound up you should have a minimum of what? typically for the watch companies if they have specifications are concerned if they have too much amplitude like over 300+ degrees otherwise they could care less until 24 hours later. Then it's supposed to have a minimum but the big thing they want is time keeping. So while Omega specifications are almost everything they have a section on vintage watches not found in the normal specifications and I snipped out that image. Notice the minimum amplitudes I'm not sure I want to say what those minimums are because somebody's go find some tar and feather and track me down for daring to suggest a watch could even run at those amplitudes. On the other hand these are Omega watches which are usually really really nice other watches probably would keep horrible time of those amplitudes but still it tells us that they don't care about amplitude wound up the only care about timekeeping amplitude at 24 hours then taking a quick look at the rest the Omega timing sheets looks like the highest of the low amplitude is 200° and the low as 160 and then it just depends on the watch it could be as I said 160, 170, 180, 190 and then 200 But there's no specification that says you've done a good job if you watch is doing 271.9° I'm just joking about that particular number but that's not in the specifications. Realistically it seems to me that if the watch was running before you cleaned that if you ran a timing profile and if afterwords it was doing better amplitude and preferably better timekeeping you did good enough at the end of 24 hours it still running and keeping reasonable time than you did outstanding.1 point

-

way too many variables here to even make a guess. size the watch will make a difference ladies watch pocket watch for instance. Condition of the watch has it ever been serviced what is its current amplitude so in other words adapted really sucks need to serviced then it would be much greater. Quality the watch modern versus vintage. A whole bunch of things can make it a challenge to have an absolute this is good versus bad situation. than usually if you're looking at technical specs from watch companies they are more concerned about timekeeping in various positions. they're usually not obsessed with amplitude other than at 24 hours and if the watch still keeps time. I snipped out something from the witschi technical PDF which I attached there is what they think should happen. But they sometimes tend to have a more idealized world of things average modern watches in good condition not vintage watches for instance. Witschi Training Course.pdf1 point

-

Attach it by carefully bending the spring end to the barrel arbor. I say careful because it might snap and break off. I always used a pair of round nose pliers.1 point