Leaderboard

Popular Content

Showing content with the highest reputation on 08/04/22 in Posts

-

I already knew that I didn't have a whole Eyerna movement so I spent some relaxing time going through all the orphaned main plates, that I have collected through the years, on the off chance that I had the setting lever spring that you needed. Sorry to say that I don't have it but at least I identified about a dozen or so plates that I filled away with similar matching whole movements. My miscellaneous piles are now smaller so I feel it was time well spent. Good luck. Shane2 points

-

This is a great video. It shows using the jewelers saw with a bench pin (home made), and all of the steps involved. I like his little vise, that's one of the things that I need for doing this kind of work and I'm going to make one for myself. His layout and freehand sketching of the arm is awesome I had planned on leaving the template on the material during sawing, but I think I'll scribe it out like he did and see how it goes. I actually have a broken setting lever spring from a Bulova that I had saved to use as a template to try this. This thread and this video has motivated me to move this closer to the top of the ToDo list. Thanks!2 points

-

Do you have access to something like the series from the Chicago School of Watchmaking? It has very good sections on pocket watches from the major American pocket watch makers. The pdf should be available somewhere for little or no cost. Here's a snippet from the part on going barrels. Is the click between the plates present and with spring? Good luck.1 point

-

Lol. I'm not particularly a cricket fan myself more rugby league. When i was younger i found i was much more adept with a baseball bat than a cricket bat. Now I'm older and a lot more tame thats now in the loft, and I've grown fond of the tennis racket. Here there are two points of contact, the softer netted side is the warning side the hard edge side is the you're starting to pee me off side1 point

-

As a semi-pro musician and luthier, I did much worse in apartments in my youth... Put some good pads under the feet of the bench to prevent sound from traveling mechanically through the floor, keep it off the wall, and that aspect at least shouldn't be an issue.1 point

-

Haha. Funny. What and make my baseball bat redundant? I dont think the warning " oh shit Rich is getting his antique watchmaker's tool out " has the same effect as "Oh shit Rich is getting his baseball bat out "1 point

-

1 point

-

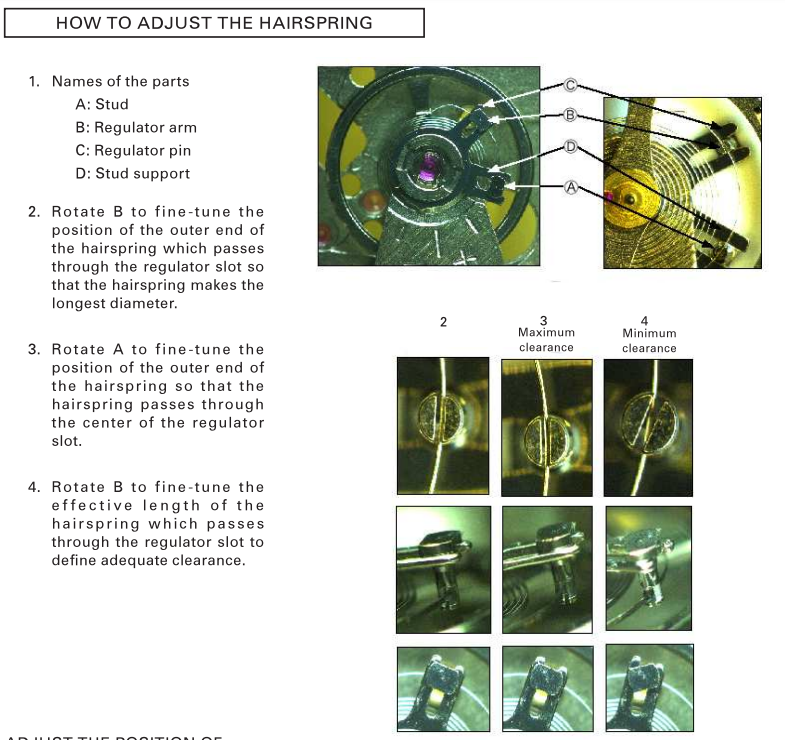

1- You would want the coil centered. 2-Adjust the hairspring to pass through the mid-point of the gap in this " the etachron regulator stud", when the oscilator is at rest. You may need to turn the reg-stud a bit for such adjustment for isochronism which is best done with special tool. See DIY tools made by members, it basically a slot filed on a screwdriver blande to fit the stud head. Good luck. https://cdn.watchrepairtalk.com/monthly_2020_07/20200712_093708.jpg.d48b96ede20ea50904daaf1b682afbee.jpg It can be used to turn the reg-stud with as well as pushing it out of the reg- arm.1 point

-

Mmh…the hair spring is definitely out of center. Easy fix for a trained person. Risky fix for a beginner.1 point

-

Hi all, an update to how I'm getting on here. New jewels came in the post, so I've fitted a pair and they seems fine. Kalanag you were absolutely right that I had one of the stones in upside down, it no longer stops when I put the shock springs in. So that's at least one small thing solved. I've dug out an old macro lens that I can use as a magnifier, and I've also bought a timegrapher. As was discussed above, I was able to get decent timing and amplitude face up, amplitude and timing dropped substantially face down. I've examined both pivots on the balance under magnification and I'm pretty sure they're both intact. However i've now lost any ability to regulate the watch on the timegrapher, maybe I damaged the spring? Or maybe I magnetised it. I took this photo below, it doesn't look as concentric as before, the coils on the left seem too close? On the time grapher it just looks like a snowstorm of dots all over the place. I figured I'd try and solve this issue first before delving further into the face down problem.1 point

-

1 point

-

1 point

-

Is it gold? if so a jewelers shop that does repairs should be able to help. Many jewelers shops send there repairs away. If it is plate then I'm not sure what can be done.1 point

-

Not "all" their other movements since all of the 5606's that I have worked on in front loading cases release the stem by pushing the set lever towards the back of the movement causing it to rock back on its pivot, lifting the opposite end of the set lever off the stem. Incidentally lifting the back of the setting lever up towards the dial may even have the opposite effect to what is required as it could cause the setting lever to rock forwards at the pivot resulting in even deeper engagement between the front of the setting lever and the stem. Another possible detrimental effect could well be that you could actually lift the setting lever off its pivot altogether, requiring a strip down of the keyless works to put it back in place. Perhaps it might be pertinent to point out that (on the 5606 at least) the set lever is not held in place with a screw but sits on a simple post (Seiko call it the setting lever axle) and is held in place by a sprung tab on the setting lever spring. Lifting the setting lever towards the dial could potentially lift it off its axle. As I said...... This set up can be deployed in pretty much any movement where the set lever sits on a pin rather than being held in place by a screw as the pin greatly facilitates the rocking of the set lever. The only modification needed is to extend the side of the setting lever that is opposite the stem to provide somewhere to push, and we know that Seiko did this for the 2706A as the tech document that I uploaded earlier clearly states that this is the case. As I already stated I haven't worked on a 2706A so can only draw my conclusions from the marked similarities with 5606's (I have attached the tech doc for the 5606, if you compare the setting mechanism with that shown in the previously uploaded sheet for the 2706 you'll see what I mean) that I do have experience with which also seems to concur with the information that @mikepilkprovided from Seiko's own casing guide for this specific case/movement combination. It would also seem reasonable that if Seiko developed this set up for the 5606's they would also deploy it across any other suitable movements when they are destined to go into monocoque cases since it requires only a very minor modification to only one part, the setting lever. The tech sheet for the 5606 actually states that there are 3 different setting levers available for that movement, and the wording suggests that they are case specific. 5606A.pdf1 point

-

Thanks @Grazianothe video is inspiring. I still need to source the raw material economically (I'm new to this more involved aspect of watchmaking.) I'll try annealing the steel from a feeler gauge to start with.1 point

-

1 point

-

No is the answer.....the 105 and 25 share very few interchangeable parts. BTW: adding pictures greatly helps others to lend assistance.1 point

-

Hi there if you want to try and make one here's a video for guidance , enjoy Graziano1 point

-

You definitely want a hardenable steel, high (mid to high) carbon, like O1 or 1075 or similar. It cuts with a saw and files fine in the annealed state. McMaster Carr sells both the above alloys in various thicknesses (very big choice in 1075) in small quantity. These are easily hardened with a common propane torch and oil quench. If using feeler gage or hardened steel shim stock it really needs to be annealed otherwise you're stuck using carbide drills and grinding the profile. Sticking the old part to the raw material is a tried and true technique. Super glue, shellac, or soft solder all work fine. A particularly good soft solder for this is Tix, with its accompanying flux. Silver solder (braze) requires too much heat, all temper would be lost if trying to repair it, and doubtful it would really hold up. It would be way overkill for holding the parts together for cutting out a new one.1 point

-

Hi, noise from a small lathe is minimal. The lathe itself is near silent unless you are working something well ouf of balance (which would be unusual) in which case it may cause the bench to resonate or thrum and could transmit through the floor. Occasionally the graver chatters but it is not noisy, probably quieter than speech. Motor noise is the loudesf part but still low. I use an electronic controlled servo motor and its quieter than a conversional voice. Old fashioned sewing machine motors are even quieter. You wiĺl need to protect the adjacent wall from flying chips and possibly oil drops for sure.1 point

-

Thanks @mbwatchand @Nucejoe. It's just over 15mm so 6 3/4 ligne, and 18,000bph so the AS969 looks like the best match of that family. The keyless works is a perfect match to the photos on Ranfft. Apologies for the blurry picture but it's getting dark: I'm now confident I can find spares and it's a simple movement so I'll crack on I think. Many many thanks!1 point

-

1 point

-

I didn't know this! To be honest I was just glad my eyes were good enough to see thing thing at all Once I have both stones back in place, I'll try and make sure this is sorted so we can cross that off the list of potential issues. Thanks! I'll check this issue out as well. As below, I'm pretty sure the stones have gone to live with someone else because they're not here! I may be ressurecting this thread in a few days Lol "I'll fix my own watch, how hard could it be?" The stone may turn up in due course, but for the sake of my sanity crawling around on the floor I'm going to order a set too. I'll keep looking. The ones I can't find are both one end stone, but also the holed jewel with the metal setting it is attached to. On cousins the part lists includes Inca 122.11 - Endstone which seems pretty self explanatory. Another option is Inca 111.09 - Jewel Hole, is this the holed jewel in a metal setting? These seem to come in packs of 5. There are also upper and lower blocks which presumably come with jewels but seems over the top to pay for all the metal surround and springs which I haven't managed to lose yet. Thanks everyone for the support so far it's hugely appreciated.1 point

-

If you happen to have a UV flashlight, they can help, too. The little buggers will glow when they are hit with UV. Helped me several times.1 point

-

OMG! (I‘ve been there) This tiny particle can jump into your hair or even nostril and disappear forever. Good luck finding it!1 point

-

I understand that at the beginning the watch ran but did it badly. After disassembling and reassembling the end stones it doesn‘t run at all anymore. Did you know that the endstones have a flat and a domed side? The flat side is inwards. If the domed side happens to point to the pivot the balance has not enough end play and binds.1 point

-

Space is precious in an apartment. Consider selling it to someone who will use it more often. You can always pick one up again later in life when the situation is more favorable. Or technology advances allow for mini sized Chinese 3D printers to shoot radioactive lasers in order to reshape objects. Doesn't look too far away to be honest.0 points