Leaderboard

Popular Content

Showing content with the highest reputation on 04/29/22 in Posts

-

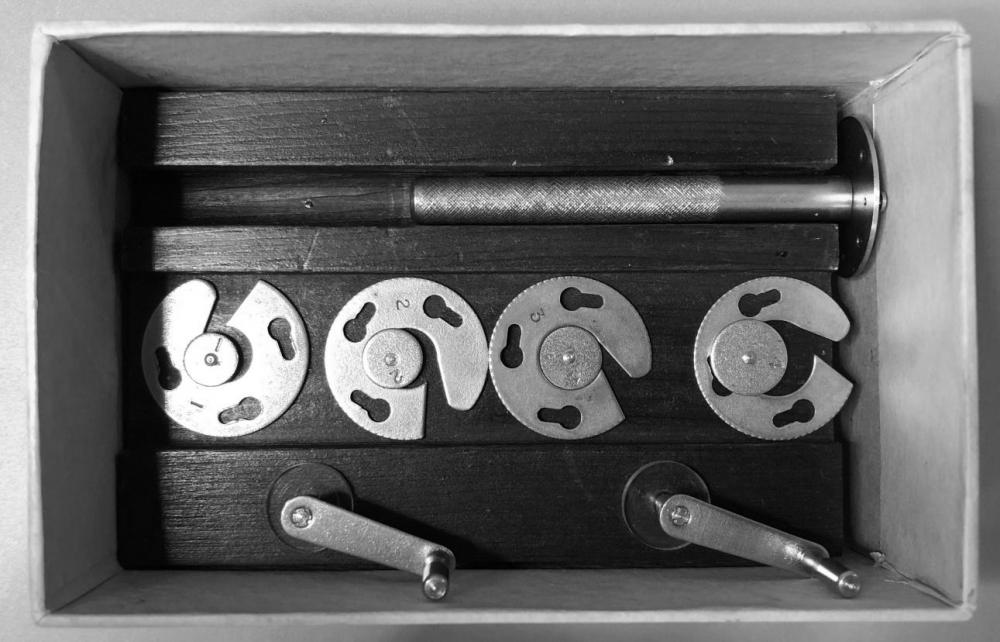

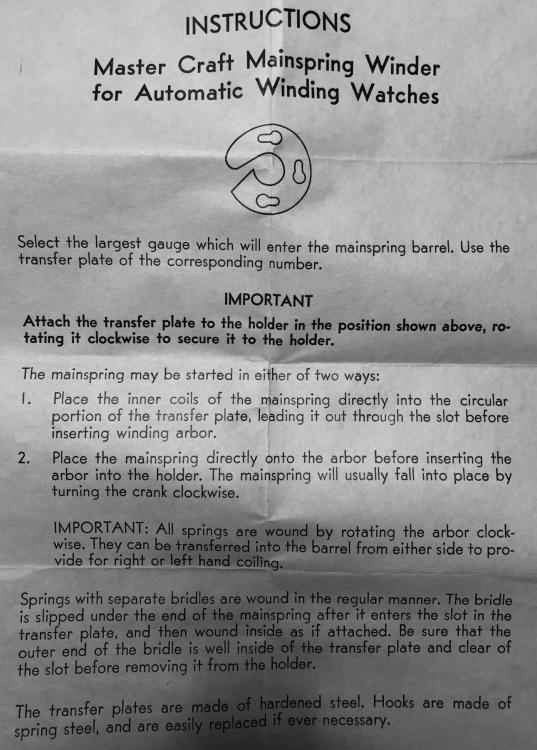

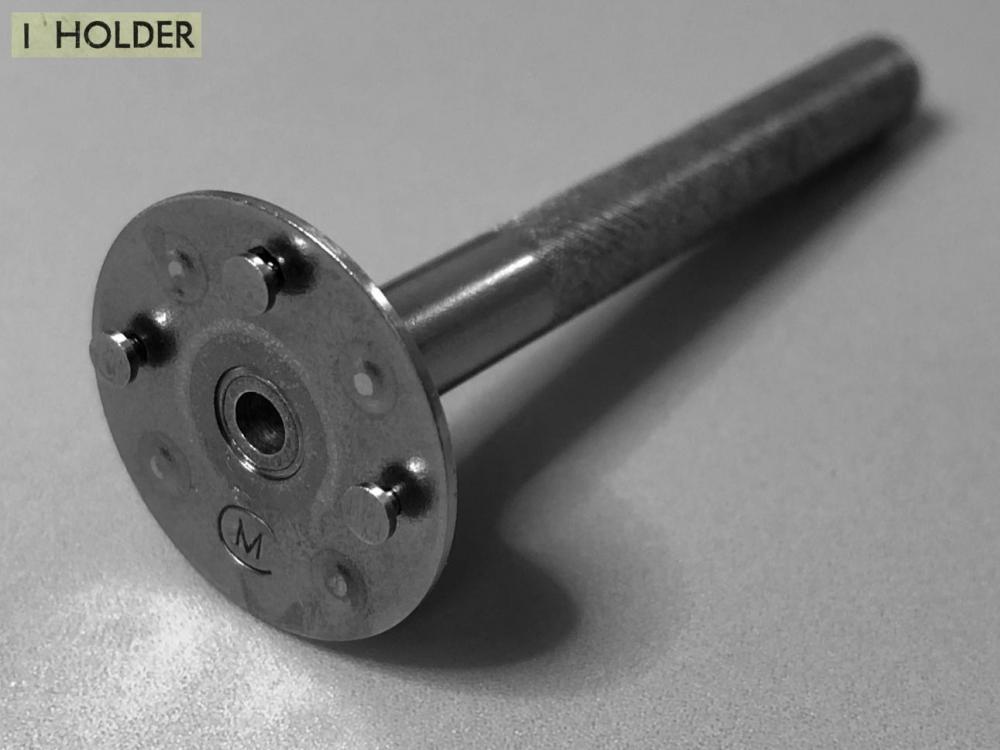

This Master Craft Mainspring Winder has been recommended and praised several times by @clockboy and I’m so happy that I, after several years of trying to acquire one, finally found a copy in very good condition on eBay. The Master Craft mainspring winder is surprisingly easy and convenient to use, and of the mainspring winder variants that I have tried so far, K&D 128, and Bergeon style winders, I must say that the Master Craft winder is the one that I now prefer with a good margin. Maybe a bit exaggerated, but I always dread and feel tense using my other mainspring winders, especially the K&D 128, but with the Master Craft I feel perfectly confident every time. It’s simply a joy to use and handle! There are several things with the Master Craft mainspring winder that I especially appreciate: The transparent discs of the winding arbors that make it so much easier to understand what is going on with the mainspring, both when you crank it in and especially when it’s to be detached from the winding arbor. The gauges that make it superfluous to measure the inside of the mainspring barrel. Instead, you can just try out which gauge best fits in the mainspring barrel and that’s it. That the mainspring can be transferred into the mainspring barrel from either side of the transfer plate to provide for right- or left-hand coiling. A nice feature too is that these transfer plates are coin edged making them easy to attach and detach from the holder. That the mainspring is so easy to crank into the transfer plate as the contact area between the mainspring and the transfer plate is so small. It almost feels as if the spring has lost 50 % of its tension. It also makes it quite easy to pull out the mainspring a bit from the transfer plate if you happen to crank it too far to get the bridle in. That it’s so easy to get the hook on the winding arbor to attach to the hole/eye in the inner coil of the mainspring. Using the suggested "method 1" in the user manual, I just push the winding arbor down in the inner coil of the mainspring while I crank it and the arbor hook automatically finds its way into the hole/eye in the mainspring. Conclusively, I must say that I’m super happy with this cleverly devised mainspring winder. It exceeded all that I was hoping for and was expecting! So much that I felt an obligation to write this post.6 points

-

Hi just setting up my new location from office to my conservatory I have yet to make a tall table to work from. You will see around the photo's that I had converted it to a Art studio about three years ago for air brushing but I couldn't control the air brush very well I even had lessons but gave up. So apart from my microscope what else is needed to complete the work shop for now. I do have a ultrasonic cleaner and I am using a 3D resin washer as a IPA last rinse cleaner it works quite well but they are in the garage. Lighting is all daylight bulbs and led panels above (two) any advice on improvements are very welcome3 points

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Here are three more that are a must to watch I recommend them. https://www.youtube.com/c/ChronoglideWatchmaking https://www.youtube.com/c/TommyJobson https://www.youtube.com/user/spahlow/videos3 points

-

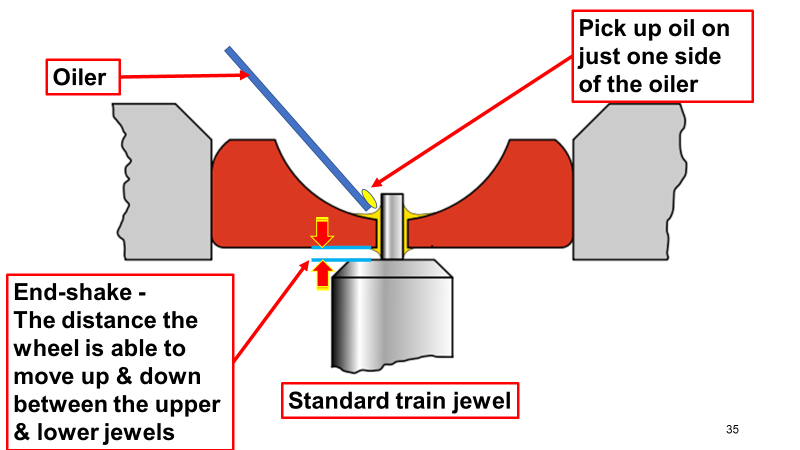

It's a pity we can't post a video. I've got a great one I show my students how to check end-shake, filmed under a microscope So, if when the screws are screwed tightly, you may have the jewel Shown in red in the pic) which the pivot passes through bind tightly against the shoulder of the pivot (which passes through the centre of the jewel shown in red) which doesn't allow for any up and down movement of the wheel, therefore the power can't flow properly, stopping the watch. Sometimes the jewel has moved and needs pushing out to regain that end-shake, which really requires a special tool. It could be either the jewel in the mainplate or the bridge, so either top or bottom jewels, so with tweezers you would hold the spoke of each wheel and see if it can move up and down slightly. you should feel it more than see it. more end-shake on the bigger wheels and less on the escape wheel and balance. I must say, I like your enthusiasm starting with a 7750, regardless of being a clone or not! He who dares, wins! BTW, that was a slide from a lesson regarding oiling, just in case you thought what oil had to do with anything... lol3 points

-

2 points

-

Hello everyone, happy to see this forum and looking forward to exploring and gleaning some advise on my watch/clock servicing journey. I’m in my early 50’s and from one of the Maritime provinces in Canada. I have always been interested in horology but never thought I would want to tear down a clock or watch movement. I’m not rushing things. Currently I’m voraciously reading and putting a megaton of hours viewing servicing videos. Favourite Youtube channels currently are Nekkid Watchmaker, Wristwatch Revival, Vintage Watch Services and of course Watch Repair Channel. Also currently procuring basic tools and lubricants. I look forward to any type of advise you are willing to unload. Cheers1 point

-

100 % yes! The Horia type without a lever is very easy and precise to use. The only potential problem is you might overshoot and press out the jewel, so you need to go easy on the screw. Little by little and a bit back and forth does it.1 point

-

1 point

-

I received the replacement movement ring and it's exactly like the first. I cut out some material from the ring to give the movement screws some clearance around the screwhead so they would line up straight, and then installed it. The movement screws pull the movement up and make it line up with the stem tube, so that's good. I went ahead and cut a small amount of plastic from the ring feet and now the case back closes better, but still makes contact with the ring, thus holding everything in place. I've come to the conclusion that most people just crank down on the case back and distort the ring without even knowing it. The people at Otto-Frei say they sell many many of these and never get a complaint. I guess I'm just picky about how things fit. There is a small gap between the dial face and the inside of the case, not sure that really matters, I can only see it with magnification, so unless there's some other reason the dial needs to be in contact with the case I think I'll just live with it. I'll post a photo of the watch when I finish it. Thanks, Bill.1 point

-

Hi Daniel 123, I still have the hairspring taking a bath in naptha. It's been close to 48 hours. I already have all the parts numbers and I have them located at different places like cas-ker, ebay, etc, but I haven't bought anything yet waiting to see if I can get the hairspring clean. If so, I will just buy the staff and the hole jewel (which is a cheaper option). If the hairspring breaks or is too deteriorated, I'll have to buy a balance complete which I also have located(more expensive option jjj). Thanks for asking. I'll keep you all posted here.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Is there a cal number on the movement? Some good photos would help. If there is no cal on the movement we need photos of the keyless work side and a photo of the incabloc. Give us as much info as you can.1 point

-

email this person. http://www.lathes.co.uk/watchmaker/ Here is the phone number 01298 8716331 point

-

If you drag across and highlight a portion of somebody's reply you will then get the option to include that bit in your reply. As above. If you just start typing in the space below the message you'll simply see what you replied. As @oldhippymentions, you'll get everything from the person's answer and you can then cut out whatever you don't want.1 point

-

Could be the Automatic winding weight is from another watch?1 point

-

Ok so Nerf. Personally I don't like anything that has water as a base, I had a bad experience this way, and I will probably never use anything water based again. Saying that the pros use water based products and apparently have good results with them. But they also have the correct equipment and knowhow of how to use them . But it's not for me. I personally use naptha to degrease parts and then high grade ipa (isopropyl) to rinse with (but not the pallet fork or the balance as the ipa can have the potential to soften the shellac in these areas ). And that seems to work OK for me. It's fairly cheap and does an acceptable job, I'm not a pro and barely an amateur. It's a good place to start in other words.1 point

-

1 point

-

Simply just reply to topic. If you click on quote it will copy all of the text you are replying to.1 point

-

1 point

-

Sometimes a part becomes loose because of wear on both the male and female parts. So sometimes just replacing one half is enough. I had a Komandirskie with a loose screw down crown. I thought I needed to replace both the tube and crown but after I replace the tube, the crown could screw down just fine, so I left it alone. Sometimes a trick that mechanics use is to wrap the male thread with aluminium foil. The extra thickness will fill up the gap and allow the screw to grip.1 point

-

Here you can mount another cutter (upside down) to part off the part. Really useful with a quick-action headstock and a lever operated tailstock. I have a 2nd Andrae-Zwingenberger with that eqipment. Use it rarely, as a serial task comes rarely and there is much to adjust and try in advance. Frank1 point

-

I haven't measured them but they seem to work with most wrist watch barrel sizes. If I have the time I'll measure them later today and will get back to you.1 point

-

Thanks for sharing this interesting concept! Which barrel diameters is this winder made for?1 point

-

1 point

-

1 point

-

Before you do any irreversible damage to your case, have you considered getting a new pendant tube? Sometimes a new pendant tube is able to grip the remaining threads. Have a look at Cousins range of generic pendant tubes and crowns. https://www.cousinsuk.com/category/generic-rolex-case-bracelet-parts-by-list1 point

-

Two dial refinished I have used in the states. Kirk Rich, and International Dial. Expect to pay $100 to $200. Many years ago, Southern Dial in Dallas, but they are no longer in business.1 point

-

1 point

-

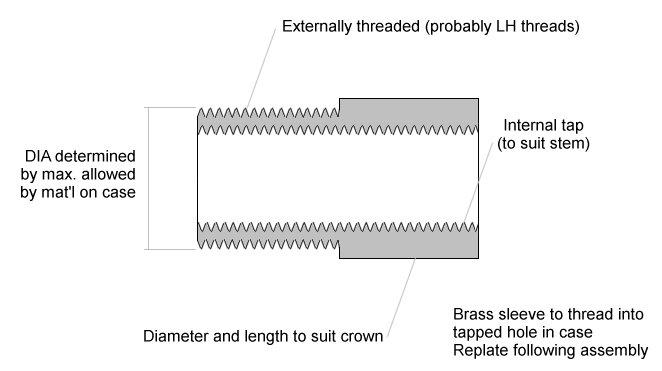

Hi In a case such as this I would think a brass sleeve and soldered not glued. This can be achieved by tinning the sleeve and fluxing the drilled hole, pressing the bush into the hole and using a rod in the tube heating the rod close to but not touching the case. As the rod heats up the solder melts and the flux will transfer the solder to the case. Best to use solder paste for such and application. Once done the real work begins in re drilling and cutting the threads.1 point

-

Cannon pinion as already said is the likely culprit.. When adjusting the hands there should be a slight resistance.1 point

-

If you're doing this make sure you place a slightly undersized rod inside to prevent the canon pinion collapsing. Anilv1 point

-

1 point

-

Hi I suppose one could ream/drill it out and solder in a brass bush and then re cut the thread might be less destructive than welding.1 point

-

1 point

-

I don't know the answer to the original question, but I do know that Tag Heuer for example are in a similar situation as the average Joe trying to buy parts- they are having a hard time themselves. Many original vintage parts are simply non-existant now, and the explosion of watch repair as a hobby probably hasn't helped, as the demand from outside for parts has certainly gone up. Yes, a company like TH can have parts re-made as needed. For that matter, I make a lot of parts for vintage chronos that probably are available if I spent the time to search them down but I spend the same making them, so. Not defending TH or especially many other makers who restrict parts that they certainly have plenty of, even to professionals with proper papers and all. But for older stuff there's the simple fact that parts are quickly drying up. A company I do work for (as an outsider), has me reuse mainsprings if at all possible; many are not available from GR anymore, and they have no stock. I needed a balance complete for a watch, they sent me a balance with broken staff and a hairspring from another balance. A staff made and about 16 tiny holes drilled in the balance rim later and I had a working balance complete for this watch from the 70s. No. Parts. If they don't have them to supply to themselves, they aren't going to supply whatever little else they have to Joe Blow who, if they read some of the forums, gets irritated because their parts aren't coming out clean in a 15 dollar jewelery ultrasonic and some Ronsonol. I'm not harping on hobby watchmakers, just to be clear. I know many hobbiests strive toward and attain a level that many pros would be happy to have. The writing started getting written on the wall in the 70s with the quartz crisis and, I think especially in the massive U.S. market, with watchmakers going from doing the best work possible, as they were taught in school, to finding any and every shortcut to get watches in and out, while cutting prices, dropping quality, and besmerching watch repair from any source that wasn't "factory". So no help on your question, but if it's any consolation Tag has a hard time too with their vintage stuff.1 point