Leaderboard

Popular Content

Showing content with the highest reputation on 04/12/22 in Posts

-

Hi reading and understanding the results of the timing machine can some times be daunting if you do not understand the functions of the watch especially the escapement because this is the part which generates the noise (tick tock) that the machine interprets in to a display for you to read. With the above in mind I have attached th Witschi training manual for you to read through. Once read you will then understand what the machine is telling you. Timingmachines are a wonderful invention but they can lead you astray if you do not understand the out put and can lead to further complications. Years ago when I started they only existed within the sphere of the watchmakers world, amatuers had to use their ears and eyes or build tic amplifiers but still relied in their hearing. I hope the attached brings you a little enlightenment. all the best. Witschi Training Course.pdf5 points

-

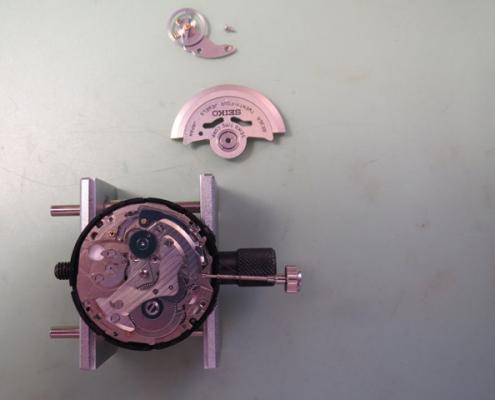

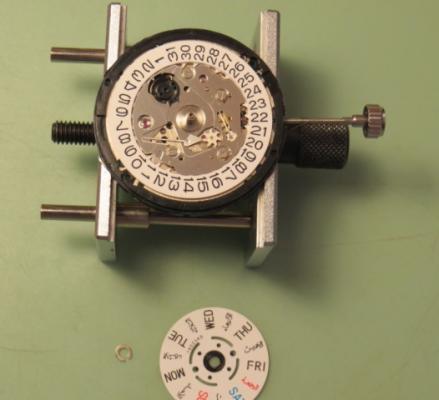

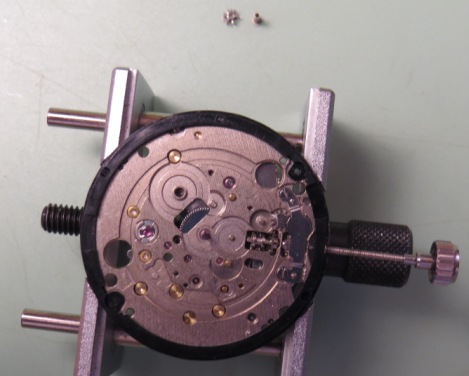

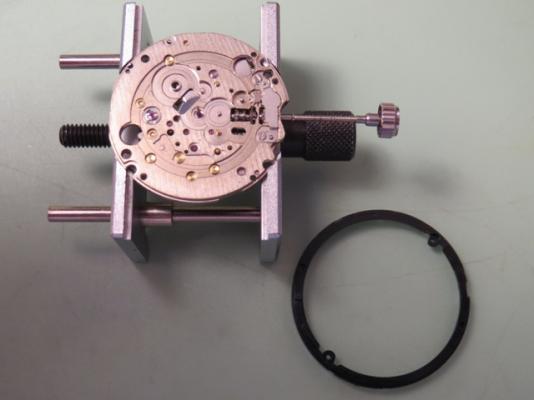

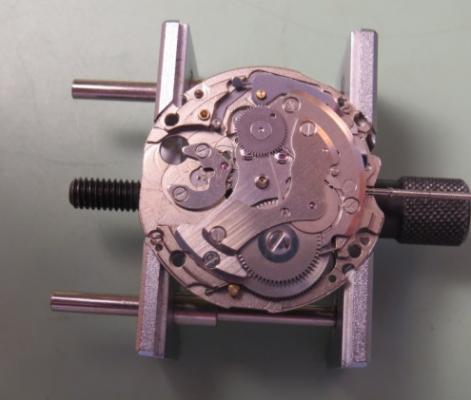

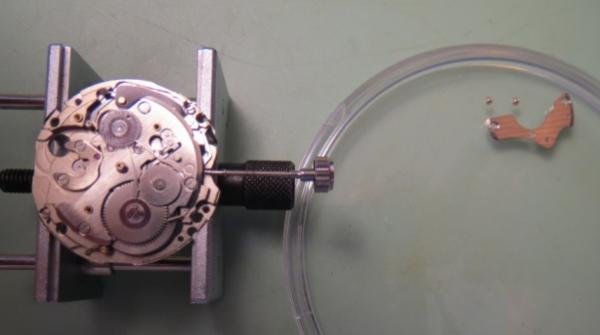

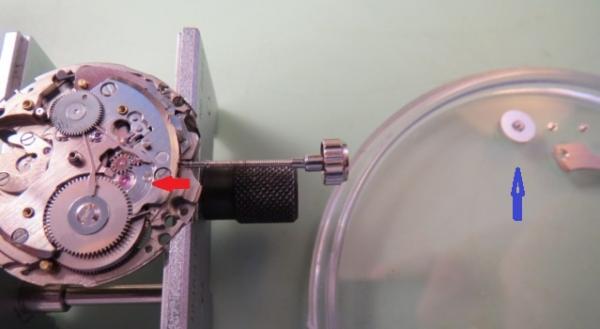

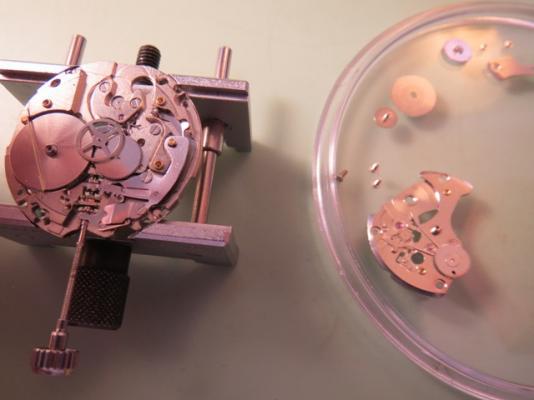

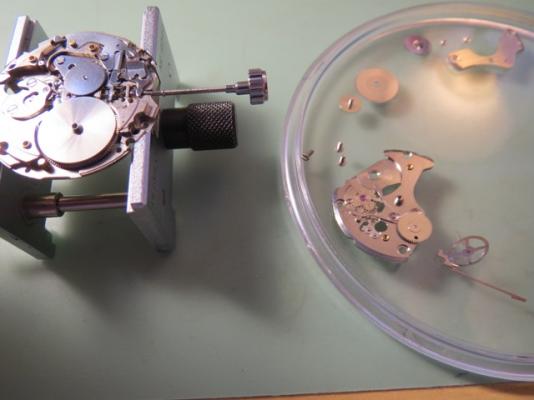

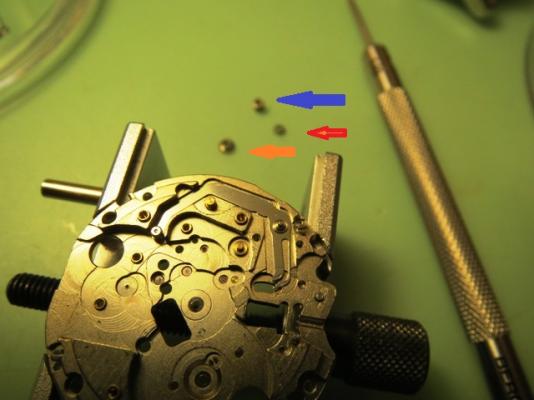

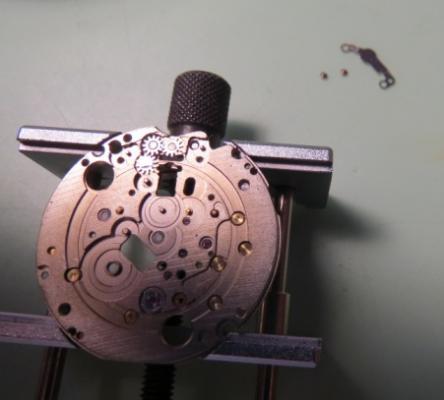

Hello from Canada I am so happy with my latest restoration/repair that I decided to share with you. a bit of history first : this watch was bought from a local jewelry in mai 2020. It was in pieces, crappy, broken stem, but otherwise complete. Cheap as it come, I think the jeweller didn’t realize that it was worth more… I bought it as the first watch to play with it, not knowing that it is a complex watch and my experience was, well… zero. Rapidly, I realized that it is over my head as a immediate project and I put it aside, not before playing a bit with the movement and, unfortunately, breaking the upper pivot of the balance. Yes, noobie error, putting pressure on the balance with your finger, I know it (now)! Several other watches were used to garner some experience and many errors and trials went on and on. I slowly disassembled the watch, cleaned the case and bracelet and decided to change the crystal also (Sternkreuz variant to the Seiko original, thanks to cousins). A new stem was found, and also a new balance complete, thanks to the big bay… I tried to learn and change the balance staff, but I miserably failed, I think I am not there yet… Finally, two months ago, I had the courage to delve in and disassemble to movement, clean it and put it together again. All went well, with some trial and error also, as the assembly is not always straightforward, ie the chronograph wheel levers and springs… but I succeeded. I learned a lot in the process and there are several small things that I would do again better, but for now, I think the result is more than satisfactory for me. so there it is: Seiko Jumbo 6139-3002 Chronograph, around 1973, restored somehow at its ancient glory! Only things changed: stem (original NOS), balance complete (Seiko original NOS), crystal (as mentioned). All in all, it is a beautifully preserved watch that I am proud to own. Even the lume is still working, quite faint, but still… Movement 6138B, around 230 degrees amplitude, beat error between 0.0 and 0.3 ms, +4s to -2s per day in all positions… power reserve above 42 hours without the chronograph, more or less 41 hours with the chronograph… It is one of my favorite watches as we speak, and also one of the most accurate!!!3 points

-

Hi Never enough By all means, down load a copy. . Its placed here for all to share . the information I post is from the public domain and freely available if you are prepared to trawl the net which I do, At 78 I gave up running races. So please make as much use of any data which I put up on the forum, and that means everybody. Its placed on the forum for all to share as thats what the forum is all about sharing young , old experienced professionals ( of which we have quite a few) and the Amatuers ( some as good as the pros) whos information I read. I can understand that some data cannot be shared by reason of copyright but there are kind souls who post the relavant parts if not the whole who deserve our thanks. all th best.3 points

-

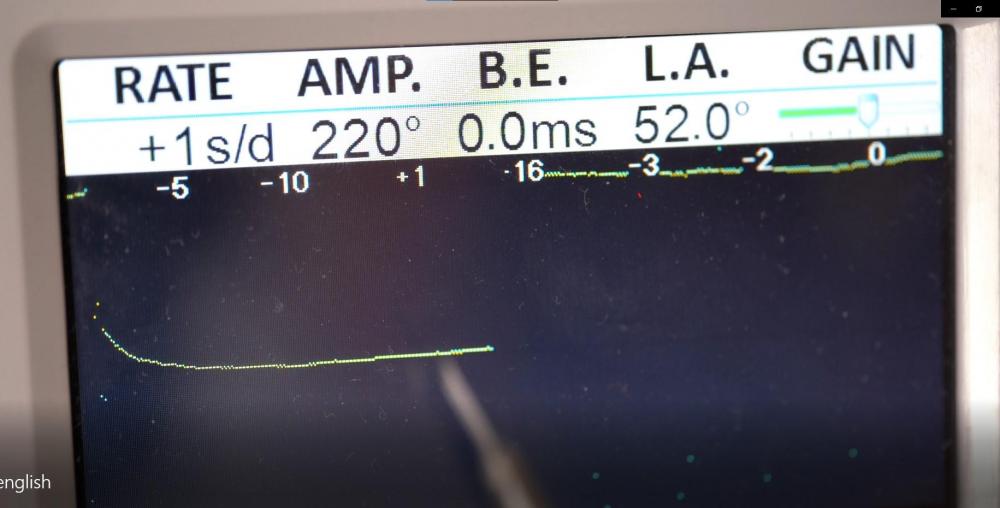

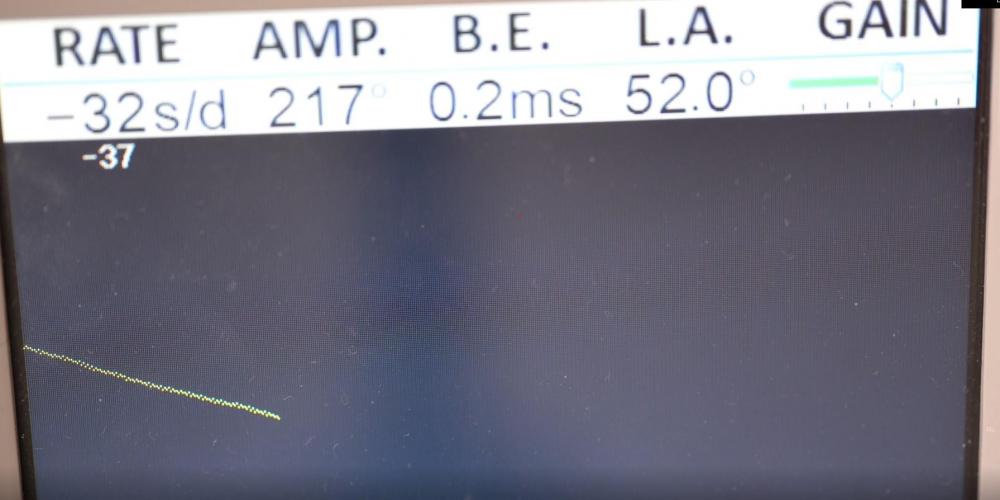

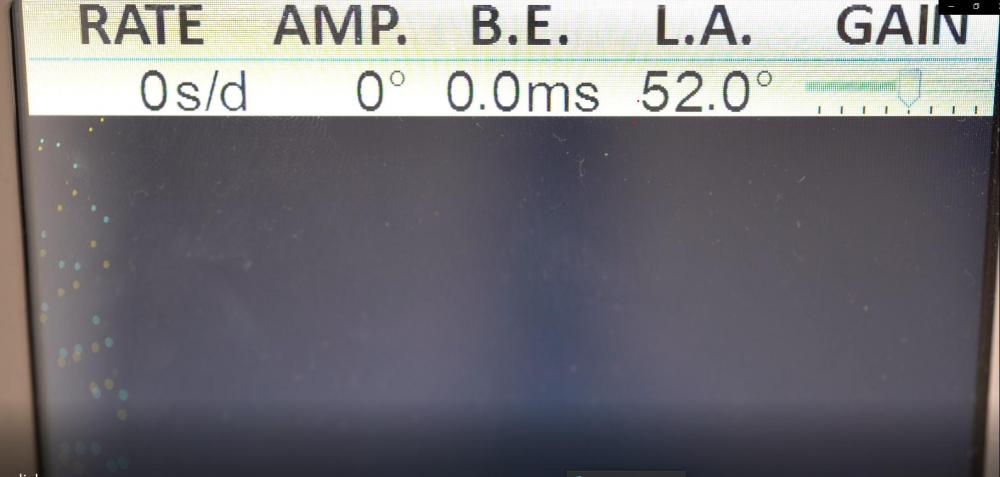

Timing machines are interesting devices? They listen to the ticking sound of the watch and display things based on whatever they receive. Usually for the results to be valid three things have to be right. Visually the watch has to agree with whatever the timing machine is showing. The numbers and the graphical displays have to agree. This is a perfect example of super low amplitude on the timing machine. The timing machine interprets the waveform which is made up of five sounds overlapping as the amplitude decreases the width of the waveform gets longer. At some point in time the timing machine does not have the intelligence to grasp what it's looking at and will sense the signals in the middle of the waveform and give you a very happy amplitude numbers. Usually you'll have a suspicion because the other numbers may not look right and visually the balance wheel will tell you looks like crap. Another thing that happens with low amplitudes is everything gets magnified it looks much much worse. So basically when you look at a timing machine and your dropping below 180° than all the rest the numbers should be viewed with a certain degree of suspicion of not being correct. So basically the timing machine has done its job it's told you that all your watches are in desperate need of servicing.3 points

-

Thank you and I envy your locale. We love the PNW, such a beautiful area. Cheers!2 points

-

..... I found my Click .... perseverance is everything !!!!!! ...... and I have no idea how it got to where it got.2 points

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. The Eta 980 you can download from here https://watchguy.co.uk/cgi-bin/files?subdir=ETA&dir=Technical Manuals&action=documents Bulova 5BA from here https://www.cousinsuk.com/document/search?SearchString=bulova+5ba2 points

-

Thanks for the introduction and welcome to WRT @RCAnderson74 ! I'm also pretty new to all of this. At 68 and following a stroke that clobbered my left eye a year ago, I was also worried that my eyesight wouldn't be good enough. It seems that it's fine - as others here have pointed out, you're usually looking through a loupe one-eyed anyway. I'm stalled partially through my first watch movement restore due to waiting on oils and tools (all of which should be on their way). We're getting snow here in Portland this morning - crazy!!2 points

-

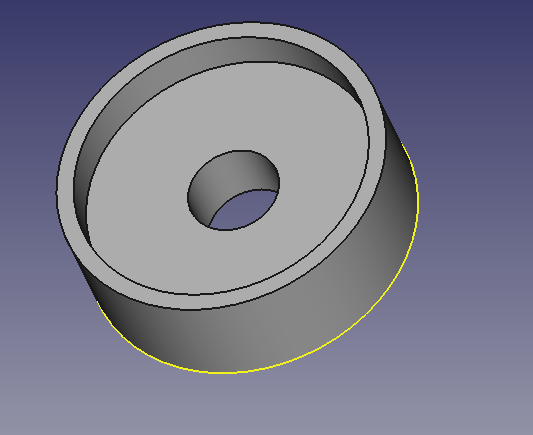

I bought this Mido wrench to address one watch in the LWS. Got it from Ofrei for a very good price. But, I want to use it on other watches--particularly ones that are front-loaders and/or armored crystals. So, I decided to 3D print some inserts with different dimensions to address this. I tested it on a Stellaris watch I had that is an armored front-loader. It worked! I show the wrench, a metal insert that came with the wrench, and the black inserts I printed.1 point

-

Hi everyone, I would like to introduce myself; my name is Fabz and I have recently started watchmaking as a hobby. I am excited to join this group and learn this art from the more experienced members. I would like to service 2 women manual watches I have just bought; the first one is a Bulova (movement 5 BA) and the second one is a Nobellux (movement ETA 980), but I am struggling to find the service manuals. I wonder if anyone from this group can point me to the right documents. Thanks in advance. Fabz1 point

-

Hello, I just wanted to politely introduce myself. I'm a 43 year old American who has been living in England for 20 years or so. I've recently been bitten by the watch bug and started collecting and tinkering - both in very modest ways. Various family members have passed me old(ish) watches which I've been learning from and I even managed to buy all the requisite parts to assemble a Seiko-based timepiece for my wife. Now I'm trying to build up the courage and knowledge to start making some more serious adjustments and repairs to other watches. M1 point

-

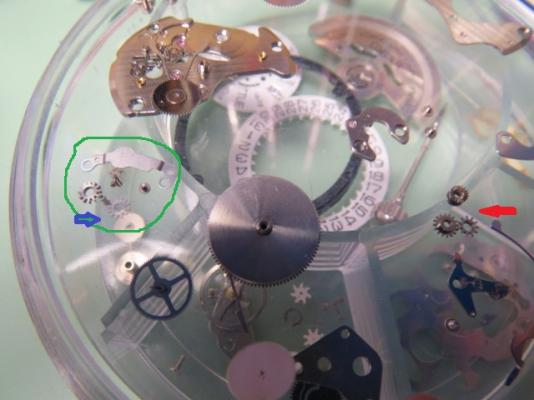

Hello fellow watch enthusiasts! After alot of logistical drama with DHL, I finally got a few parts and calibers which I ordered off of Ebay last year. Coincidentally, a friend of mine gifted me an old book about watchmaking for my birthday, so I thought what better way to show him my gratitute for his thoughtfull present, than to show him that cramming the books contents had payed off! This little documentation hopefully can help people work on their Luchs in the future! I did post a wlak through on a different forum and was informed that while the dial was original ( yay!) the hands, case and crown are from historically different models so this watch has had quite an interesting life! At least all parts are original luch components haha Here to the initial state of the Watch: - Missing crystal - Wear on case - Missing movement holder claps and screws - Winds but no ticking. Hands move erratically after the watch gets some kind of shock ( dropping it onto the table) - Loose Second hand: - Missing jewel on mainplate : Here is the complete disassembly: 1. Remove the bezel so that the watch movement can be taken out. In my case the dial was loose so that popped out aswell. 2. Remove stem by pressing down on the stem releasing button and isolate the watch movement. 3. Remove minute wheel and canon pinion. 4. Remove the setting system cover. 5. Remove the three translation (two small and one big one) wheels. 6. Remove the setting system compontent : The setting lever, the setting spring, the two clutches. The left over lever will be removed later on. 7. Flip the movement and remove the balance wheel and pallet fork + bridge. ( Love the older designs with the pertruding wheights on the oscilating wheel,so pretty!) 8. Remove mainbridge. 9. Remove visible gear train 10. Remove the secondary bridge and the two small gears which it holds and the hidden canon pinion. ( forgot to take a picture sorry!) 11. Remove winding system. Beware, there where small metal rings between the wheel and the metal pins! 12. Remove barrel bridge, mainspring barrel and unhook the lever in the front. That concludes the strip down! Mainspring service: Now the mainspring looked pretty decent and I didnt have one spare on hand really so I took it apart. Washed it in lighter fluid, alcohol and lubricated with Moebius 8200 before winding it in by hand, Since it is manual winding, there was a hook on the bridle which you could hook onto the floor and the lid of the barrel, interesting since ive only known manual watched which hook onto the side of the barrel! I winded it in the wrong direction and broke it haha I did end up finding a replacement though! Here are some steps of the way: Cleaning: Good old Soak in lighter fluid followed by a rinse in isopropanol alcohol. Of course the palletfork aswell as the removable jewels for the balance where not included here. The dial was treated to a good session of rodico aswell as some rough Q-tip rubbing with luke warm soap water. Lubrication: - Moebius 9010 for all jewels except for the pallet fork jewel bearing - Moebius 89415 for the pallet fork jewels tips - Hp 1300 for the gear teeth contacts - Molycote DX for Setting system and Winding friction points -Moebius 8200 for Mainspring ... And for a the reassembly just reverse the dissasembly and dont forget to oil and clean the balance jewels! Oh and intersting the acryl crystal, that was done by hand, not with a crystal lift. Finally I put it onto the timegrapher after demagnatizing : 1. As you can see, the result is horrible haha. But I did replace it with a different balance wheel from a donor. 2.Much better! 3. After regulation Final pictures with the strap, me and my friends bought, for my friends timepiece present: Over all a great and fun project I must say! Ive shipped the watch to him now so lets hope he will like it! I know that there are see through backs for the Luch 2209 however I have not gotten around to getting my hands on any of them. Would love to show off the pretty golden movement! Any questions, comments or improvements please feel free to write me! Oh and here is a full narrated video of the process: So long watch bangers!1 point

-

1 point

-

With a lathe, you can fix the ones you got second hand. Generally the only issue is the nib has worn.1 point

-

Somewhere on this forum, I posted a picture of what I did...I think...but cannot find it yet. I used what is called 01 steel I think. It may also be referred to as "silver steel." I learned about it from @nickelsilverabout a year ago. It is soft enough to turn easily but is still plenty strong. After turning the arbor portion, I drilled an orthogonal hole and drove in a piece of pivot steel that I had turned with a nib on it. I felt like pivot steel was necessary because it deals with the stress.1 point

-

One question that was asked several times: Have the watches been serviced? I read through the thread and do not see an answer. The answer to that is the sine qua-non of going forward. In reading this thread, I had a chuckle or two. When I first joined, I locked horns with @JohnR725over some issue that was peripheral to horology as I recall. After being on this forum now for about 16 months, I can say that @JohnR725is indeed one of the horological gods here. He has enlightened me on a number of occasions as has @nickelsilverand @watchweasol. The ability to tap these guy's brains is of immeasurable value to me...thus my regular attendance to this forum. Many others have helped me too... Anyway...back to watches. Let us know about the service of these watches. Also, do you have a watch that you know is functioning properly, i.e., keeping time on your arm? Might be useful to put it on the Weishi and make sure it is running properly. In spite of the fact that I was one of the designers of the microcontroller used in the Weishi, it can make errors...OH NO...unlikely MY CHIP causing the problem, however...could be circuitry designed by someone else!!1 point

-

1 point

-

No, they can be had for well under $1000. I only use my Mido tool to remove the crystal. I use my BB Crystal press to put the crystal back on. AND!!! I printed a special base for my crystal press that is specially fitted to the back of the Stellaris. The back is not planar because of the battery compartment. I have two of these watches. They are a bit of a pain to regulate because, you cannot regulate while in the case, thus you have to remove the crystal, remove the stem, remove the movement. Then put it on the timer and regulate.1 point

-

Why. That is a nice watch, give it a chance in the hands of someone else. Like 5 Euro on Ebay, or gift. Maybe it's just me, but I can't throw away a watch, or anything the like.1 point

-

And this Floridian loves Texas. Just recently sold my house located near Lampasas. We do miss it. Thank you and cheers!1 point

-

The lower caseback is like a tin can with a slot cut out for the winding stem. Usually it is loose enough for the movement to be pulled apart by holding the caseback in one hand and the dial in the other. Sometimes if it is really tight, some prying around the dial with a case knife is necessary.1 point

-

neither am I ... I am working from family history. The watch is my mother's and she inherited it from her grandmother who died when she was 8 in 1944. I understood that my great grandmother had the watch from her 20s and she was in her 60s when she died. I also understood that pre WWI gents wore pocket watches and ladies smaller movements work on the wrist? It was WWI which popularised the wristwatch amongst men, where as before they were regarded as 'not very manly' ? The case has some hallmarks ... if anyone is any good at reading I will post and we can see if I am way off or not!1 point

-

Theoretically you are actually correct. Oftentimes you'll see the regulator and watches pushed to the extreme to make up for a problem or perceived problem of timekeeping. Use of the problem is the watch desperately needs to be serviced. Conceivably a heavily magnetized watch could cause the same thing to happen. On discussions like this where things aren't going in the direction they should be now is the time where additional questions are needed. Like the running watch what was it doing how well was keeping time. Then the usual one was the last time the watch was serviced and it would be nice to know what watch it is. Also timing machine pictures it be nice to see a picture of the timing machine. Often times we may see or understand something that's not obvious to someone new to the use of the timing machine.1 point

-

One doesn't need to own a timegrapher to know on the subject. As discussed many times before, the reduction in amplitude reading is about 1.5 deg for each less grade set as lift angle. There is a formula for this which I will omit to report here. So again, what I'm trying to convey here is that when a mov.t has a terribly low amplitude, as in 126 deg, having an inaccurate lift angle in the timegrapher, even 10 or 15 plus or minus, will not change the fact that amplictude is insufficient by one half at least. In these cases the repairer needs to focus on the watch, not on the instrument.1 point

-

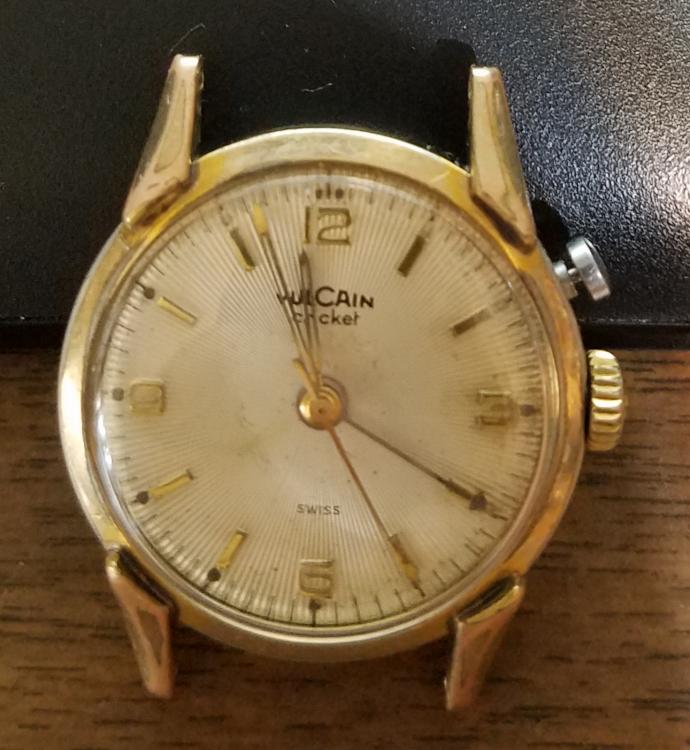

Here is another Vulcain I got off of Ebay. It had some foreign ingress via the stem hole. It was a black nasty stuff that fudged up the keyless works. The stem could not be removed. Fortunately, this particular watch has an odd case system. You can remove the movement without removing the stem. Yay for that...otherwise I would have been SOL. I posted about the rusted stem elsewhere in the forum today and @Nucejoenudged me over the finish line. This watch represents a milestone for me. It is the first watch I have cleaned using a bona fide L&R vintage watch cleaner and "really and truly" watch cleaning solution (L&R of course). My donor Vulcain actually became the movement I used and I took several parts that had been scavenged already from the movement that came with this case. Notice that the alarm pusher is stainless steel--that came from the donor because this Vulcain came without a pusher. I am investigating electroplating it. Maybe electroplate the whole case which is already 10KGF and wearing in several places. I am going to leave the dial as is for now. The discoloration is not what I would call "patina" since it probably resulted from the "accident" with this watch. Sometime back, I bought a box of round watch crystals off ebay for 60 bucks or so. Most of them are smallish, but I got lucky and found a crystal for this watch. So far I think I have found three crystals from this purchase. Not the best ROI, but hey...1 point

-

The amplitude is still much too low, but the relatively clean traces are encouraging. Set your lift angle to 42 degrees, and measure again with and without the chronograph wheels. Test and record in all six positions.1 point

-

1 point

-

@nickelsilver said 42° not 48° - you may want to adjust your Timegrapher @gkmaia1 point

-

Thank you Klassiker for your reply and for your middle ground on this. I'm at the far bottom end of the scale and understand how we at this end feel when subjected to condescending behaviour, that isn't fun. I can't speak for all of us, but yes there are lazy people in all walks of life that want things handed to them on a plate. But also some of us really just want to talk to someone and have things explained to us first hand in way we can understand and learn from and maybe connect and aspire to that member. I catch myself thinking while watching various skilled youtubers "wow I wish could turn a balance staff". We really do appreciate the time that is given up to help us and that goes double for the staff that run the forum. Without places like this to spend our time this amazing hobby and profession wouldn't be as enjoyable as it is. I think your last words pretty much sum up what should be expected from everyone here. Thank you1 point

-

Some do, some just take it for granted. Others are too lazy to use the search function and read what is already available. This from someone somewhere in the middle, able to offer advice, but still asking questions, so maybe in a good position to see both sides. Yes, sometimes there is a response on here which I consider a bit harsh when replying to a beginner, I've been guilty of it myself, but just remember, it might be the umpteenth time that particular god has addressed a similar question, with the same paucity of information to enable a diagnosis. The basic requirements have been spelled out many times. Those gods also post on here voluntarily, in their spare time, because they want to help. They are also free to leave this forum, if it stops being fun. Maybe a little more tolerance and reflection on both sides is the answer?1 point

-

Other than the movements that I'm picking up to practice on, here are the rest of mine (minus the IWC because of how the strap & clasp make it higher than the rest). All but three of the quartz need (at least) a battery. I used to wear a watch every day when I was working. Now that I'm retired, not so much and I rarely wear the mechanicals although they do get a wind every day). I figured out somewhere along the way that if I wind the IWC 3x more than what it takes the Zenith (based on the RDM) things are good. Maybe I should give the quartz ones some love? I have a 1945 Buren 10.5 Grand Prix on the way. Not sure what condition it's in and it's coming from "your" side of the pond. It actually has a case (so far none of the others I've purchased have been cased). I'm also planning to stop by some antique stores later in the week when my wife and I head over to the coast. It's crazy - we got snow this morning. First time in 80 years for the area.1 point

-

Ok I wasn't keen on broaching this and I did have a little rant about it yesterday. Maybe you haven't grasped what I was saying regarding the watchrepair gods comment. No I don't have a better way because I'm a beginner, like the chap that asked a simple question. Now I'm not naming names because that's childish, who I'm referring to know who they are. Or maybe not, in which case they don't know they are doing it. Sarcasm when directed at an individual's knowledge, know how, comprehension, way of explaining things when asking a question really isn't nice. There is a lot of very inexperienced folk on here, that try their best to convey their watch problems, and are often met with sarcasm, and sometimes quite patronising comments by other members with much more experience that think they are the dogs bs. If not that then a flood of incomprehensible answers in all manner of differing contexts that they haven't got a clue what to do with. And please don't say it doesn't happen because it does, I've seen it I've read it. I've only just joined here, after having visited many times over the last nine months that same seemingly superior attitude cropped up over and over and tbh held me back from becoming a member, but I thought hey let's give it a go, I can leave if I don't like it or get banned if I open my gob. I'm sorry but I'm standing up for the ones that have felt belittled or just don't want to make a fuss about it. It hasn't happened to me YET, but I certainly won't put up with it if it does. All I'm asking for is a little respect for those of us that don't know a great deal or struggle to grasp even simple explanations. What might be simple and obvious to higher ranking members might be hellish complicated to a beginner. We do appreciate any help that's been given we really do but I for one don't appreciate the manner in which I've seen it can sometimes be delivered. If I've offended anyone then I'm sorry, I'm not an argumentative sort of bloke or a push over either. Hopefully we can let this go. If I receive a sensible answer then I will discuss it further, but I'm sure I've covered it. Thanks1 point

-

It's not that is 'went' as that was a naturl occurence. Stop for a moment and consider what was the mistake that made that happen, e.g. work not at armpit height, or not supporting the mov.t holder, or screwdriver not dressed properly. Check their Chinese mov.t page: Chinese manufacturers do not make spare parts available for their movements, apart from stems. Also unavailabke are drawings, that not a big deal if one knows how a watch works and take pictures. That being said you may get a working screw buying an assortment or a lot of scrap watches.1 point

-

1 point

-

Hello and welcome to the forum. I’m from South Georgia so we’re neighbors.1 point

-

That is a front loader case and your is the most frequently asked question by beginners, enter "front loader" with double quotes in the search box top right. In short, it is opened removing the bezel and lifting the dial while rotating the crown to free up the two piece stem. I recommend against owners trying that without proper tools to avoid damage.1 point

-

1 point

-

At least we had a decent enough picture to see the image so I snipped out the offending hairspring. One of the things you always want to do with all of your watches is to make sure they hairspring is centered and level. It's always quite amazing all the clever things in hairsprings can do to touch things that they're not supposed to.1 point

-

Check for train freedom with fork out Check the pallet fork snaps back and forth cleanly with balance out Check that balance oscillates freely with fork out Check that balance endshake is correct (as well as fork and other endshakes) Check that hairspring is level and centered If you do that last check you will see that your hairspring is sitting on top of the center wheel. Once you correct that, note that the lift angle for this piece is 42 degrees, not 52.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

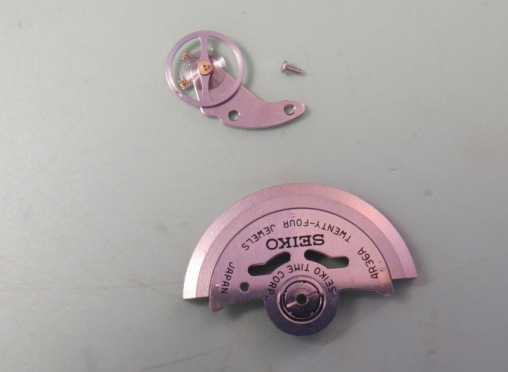

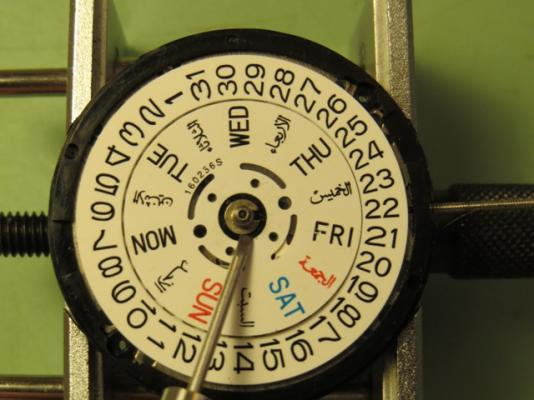

Seiko NH36 Walkthrough This walkthrough complements the 7S26/7S36 excellent walkthrough on this site by Lawson (http://www.watchrepairtalk.com/topic/682-seiko-7s26a-complete-service-walkthrough/). I strongly recommend to check out Lawson's walkthrough first). This is a more recent movement based on the said 7S26. It is a 24 jewels day/date, center seconds, movement with hacking capabilities and manual wind. The ligne is like its predecessors ~12. It is popular in the new Seiko models and Invicta watches among others. In brief, former movements didn't have hack or manual wind. Still, several parts are interchangeable with the older 7Sxx series. Here is the service data: 6810_Seiko NH3 Series Part Sheet.pdf My first step here will be to remove the "oscillating weight" and balance and place in a safe place. Those parts could be easily damaged so we put them out of harm's way. Starting on the bottom side, normal removal of "snap for day star with dial ring" Note that the reverse of the snap has indentations to fit a small screwdriver and lift it clear of the day disc (yellow arrow). This is standard for this movement family and snaps, day disc and date rings are interchangeable. The other picture shows the snap right side up. Under the day disc: Showing the "intermediate wheel for date corrector": Moving on, "date indicator maintaining plate" and related screws. No philips proprietary 4th screw here, all four are the same... Date jumper and date dial: also "Day Date corrector wheel", "hour wheel", "minute wheel and pinion", "date indicator driving wheel" and "intermediate date driving wheel and pinion": "Canon pinion" and the new addition for this movement "Day Date corrector setting transmission wheel E": Removing the "Dial holding spacer" (this one is from a 7S26 not the original one which is thicker): Turn over Baby! Ehem, just the other side view... :) More changes are introduced: We remove the "automatic train bridge" and screws: Notice the added 24th jewel (red arrow) to accommodate the newly designed "second reduction wheel and pinion" (blue arrow) which is much thinner than in previous movements. Removing "ratchet wheel" and its screw (nothing new here): Removing the familiar "Barrel and train wheel bridge with hole jewel frame", notice the familiar "long screws" inherited from previous designs: This bridge has been modified also to add the manual winding mechanism. More on that later. Removing the click and the "fourth wheel and pinion": At this point we remove the rest of the loose bits ("Third wheel and pinion", "scape wheel and pinion" and "barrel complete with mainspring": Then we remove the "Yoke spring" and characteristic "long" screws (different from the ones used in the balance cock and "barrel and train...bridge": Removing the "yoke" and the "setting lever", note how the lever shape has changed from the previous models: The story so far after removing the "center wheel bridge" and its short screws, the "center wheel and pinion", "pallet bridge" and "pallet fork": On the main plate, showing the added "balance stop lever": And the "day-date corrector setting transmission wheel A" (red arrow), "winding pinion" (orange arrow) and "clutch wheel" (blue arrow): Close up of what is left on this end: Removing the "guard for day-date corrector setting transmission wheel" and short screws. Underneath the "day-date corrector setting transmission wheel C" and the "Day-date corrector setting transmission Wheel B": After removing the transmission wheels B and C we are left with the built in wheel on the frame: Notice that transmission wheel "B" (blue arrow) is thinner than its counterpart "C": Next: "Barrel and train wheel bridge with hole jewel frame" disassembly:1 point

-

That's because Bergeon uses cheapo Chinese measuring gauges. :)1 point

-

0 points