Leaderboard

Popular Content

Showing content with the highest reputation on 01/14/22 in Posts

-

I would avoid the Indian screw plates - I own one and they are shite. The thread doesn’t conform exactly to any standard and they are not very nicely made. The associated taps snap very easily and I guess are likely to be hardened carbon steel (nothing wrong with that instead of HSS, but the exact temper is important….. excellent makers like Presto used high carbon steel, so it’s certainly good enough). I mainly use German-made tap/die sets these days but do also have Martin screw plates for odd jobs. I also make my own crown pipe cutting taps from stems where it is a non-standard pitch, eg. for some older JLC and IWC watches. There is a SE Asian-made tap/die set which I think only goes down to 1.0mm and up to 2.2mm but for the money it is excellent.2 points

-

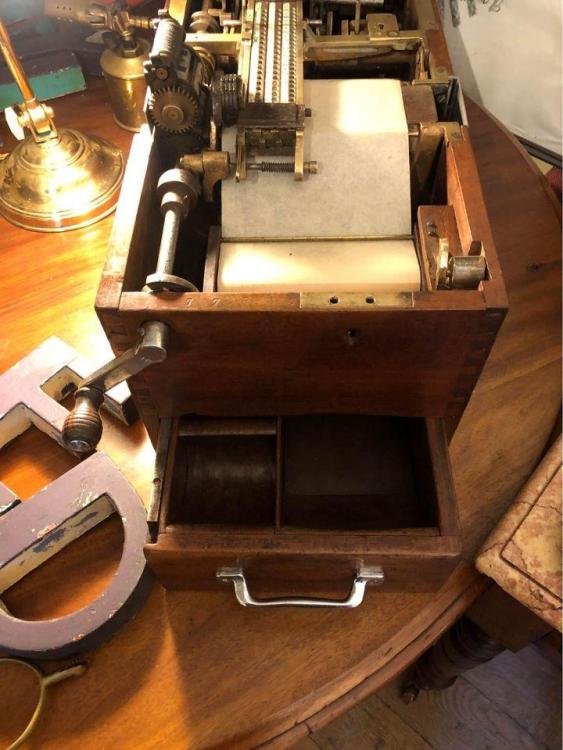

Hi, My father who spent many years collecting pocket watches and repairing them has recently moved into a Care Home suffering from Alzheimer's Dementia and I have got the unenviable task of clearing out his workroom. My husband and I both have engineering backgrounds, having worked at Rolls-Royce Aerospace, and are familiar with or can work out what some tools do but are less familiar with some of the more specialised watchmaking/repairing tools that my father has. We have already used watchrepair talk.com/forum to gain knowledge on some tools, thank you, and would very much appreciate using the knowledge of the members to identify some of the more obscure tools and their manufacturers, if possible. Hopefully, this is within the remit of the website. Julie1 point

-

Hi attached tech sheet for the PUW 255 hope you find it useful cheers 3610_PUW 255 - 2570NEW.pdf1 point

-

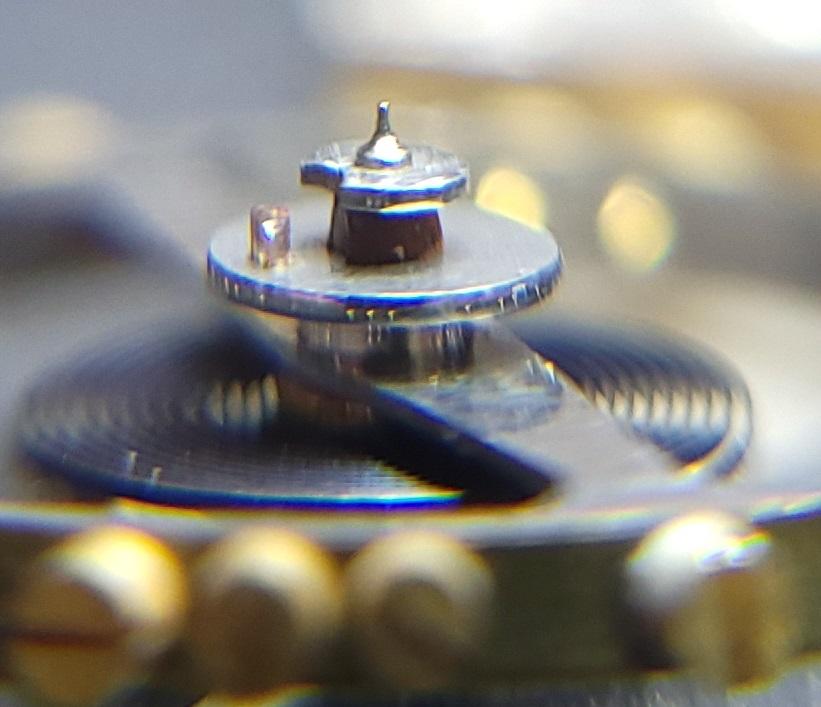

Tape loupe to phone, rest subject and phone on the bench, shim and move around until they are at minimum focal distance. BTW I can't tell for sure but it seems to me the impulse jewel above is chipped.1 point

-

Lathe carriage stop This is my first milling project. I'm fond of it not just because it's a very useful accessory, but because the Chinese sellers, knowing that is not widely available, ask about Euro 50 for it. The included angle for the way is not 90 deg, and requires a bit of attention. I experimented with a radius cutter for chamfering the edges, as one can see I can improve on that. And I haven't fitted yet the screw for fine adjustment.1 point

-

By the way Daveswatchparts.com in the states is a good source of parts .1 point

-

A loose screw graunching around the movement would have repcussions if it got trapped some where, so its more like a repair gone wrong.. be careful of staff s elgin/waltham have a variety if sizes as I found out repairing one, best heasure the staffs with a vernier for size.1 point

-

What is the amplitude, and beat error of the movement, If the movement , is still fast with the regulator in full retard, check the balance coils for fouling the cock or balance arms andthat they are not sticking together during oscillation. also bear in mind the fact that it may be magnetised so a demagnitisation would be in order.1 point

-

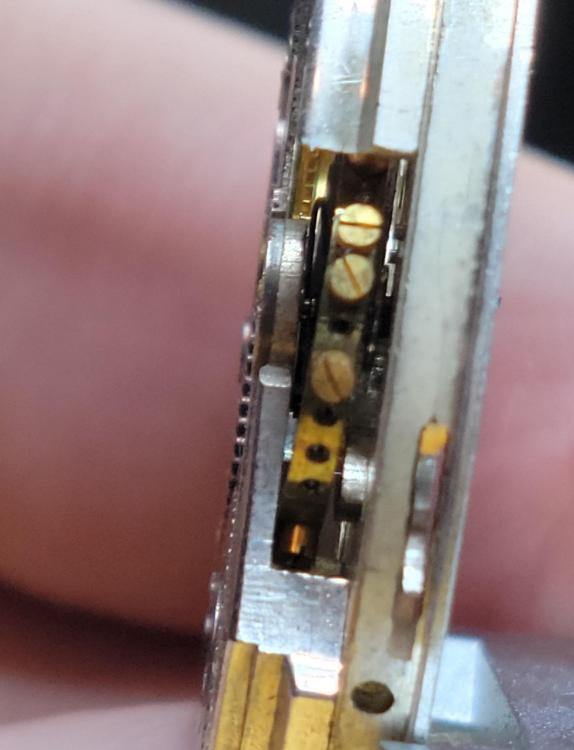

Ah, good point. I didn't think to, since this balance came out of a movement that (I think) worked in all positions, but it never hurts to check. This looks good to me, yes? Yeah, that's kind of where I'm at. I always hate to see something this beautiful relegated to a drawer or spare parts, but sometimes there's no reasonable choice. At this point I'm also trying to fix everything because it's good practice. Cheers, thanks for all the input!1 point

-

Did you lubricate the reversing wheels correctly? Have a look at this video from 8:28 onwards:1 point

-

You can try annealing it of course but in the end is made to make pivots not screws. It is much easier to turn hard steel rather than threading or drilling it. If one opens a metallurgy box head drops on the 2nd page, but not much metallurgy knowledge is needed for watchmaking, as it reduced to recognizing like two heating colors, and the tempering process is almost always skipper altogether. One thing is enjoying masochism, another nice is being able to resolve small problems quickly. As mentioned the cheap Chinese M1 - M2.5 taps and dies (white tray clear cover) set works well on soft material, and lets you make and repair tools and stuff beside watches. OP has a quality WIRU plate. I mentioned Indian pivot steel not plate, although I also bought the latter because it has a nice wooden box, like most Indians sets for that matter.1 point

-

1 point

-

1 point

-

1 point

-

Got it in one, the cracked/chipped jewel is most likley the culprit. Judging by the state of the jewel the trace is not that bad under the circumstances.1 point

-

Don't just use a screwdriver on one side to remove it though as you will damage things, you need 2 leavers on opposite side of the wheel to lever it up evenly.1 point

-

The first thing you do is to take the tension off the mainspring to avoid accidents, then remove the platform escapement and set it aside to avoid damage and also keep it covered... Then with a set of levers (easily made ) lift the gear, . protecting the plate with a piece of plastic or cover the gear with a piece of plasic bag and then remove, doing this will avoid the gear taking of into the ether The platdorm escapement can be dealt with later.1 point

-

I made a comment on here at the outset of this debate, some 7 years ago and the same thing is being discussed, now, as was then. My particular take on the whole aspect of US, is that if it works for you, then great. If, in the other hand, you are the wary sort, then use a full blown cleaning machine at some vast cost. I have made my own cleaning implement, giving me total control via a digital timer, it works perfectly, and has never let me down over the last 5 years. I must admit I have the Elma US, which does give 37 & 80 mhz, also Drying machine. The quality is superb. All the component parts are in an Elma Basket and trays, attached to motor in Elma RM90 jars, then 15 mins @ 37mhz, 3secs agitation at 1600rpm, every 30 secs, remember the agitation is dampened by L&R cleaner. Then span off for 30secs at 1600rpm, then into 2 separate rinses at 80mhz................ then into dryer for 30 mins. Never had anything disappear or loose shape. I have just done 2 separate services on the thinnest movement 1.6mm, an AP 2003 & VC 1003, all as above. The hairspring is minute, not a problem............ If it works for you, great.....................1 point

-

1 point

-

OK this is a realy old posting and hopefully no one will read this I am obviously a hippocrite as I have an iwatch 6 provided courtesy of my son. It does provide certain health benefit advice that assist with the various medical conditions I currently host. However, I will not get used to my watch picking up all my calls and texts and immediately drawing my attention to them as well as the numerous deliveries from Amazon etc. My activities have been somewhat curtailed recently due to sight problems and other stuff but I have not quite given up on the hobby it just takes much longer to do anything. Happy new year to all, Vic1 point

-

1 point

-

Hi all Just received the 2 versions from Cousins Both have the same internal and external circumference measurements. The plastic one is 1.5mm thick and the metal one is 0.5mm thick. Not sure is the 1mm difference matters, I suppose it might bring the hands closer to the back of the crystal. Might also be possible to fit 2 metal ones but then the price would be getting close to the plastic one by then. I have working on a movement now, if I get it going I will try the metal one and report back. Paul1 point